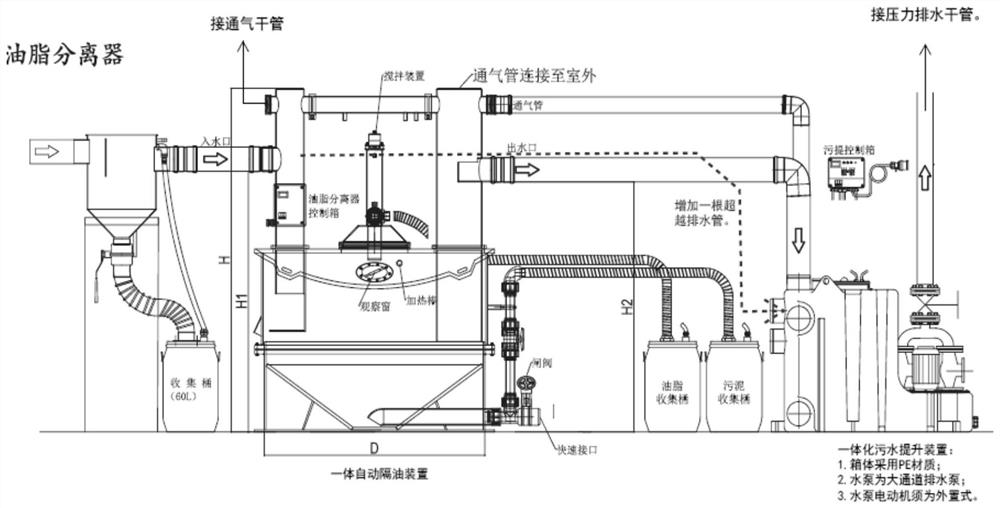

Multifunctional efficient oil separator

A grease separator and multi-functional technology, applied in chemical instruments and methods, grease/oily substance/suspended matter removal devices, water/sludge/sewage treatment, etc., can solve unsatisfactory operation effects, many faults, and peculiar smell Heavy and other problems, to achieve the effect of maintaining low noise, reducing pollution, and ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

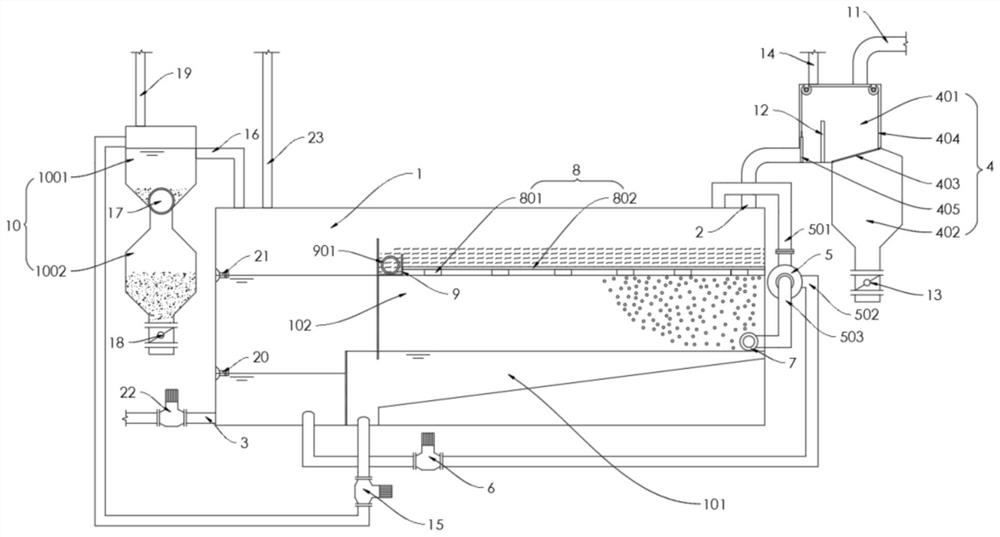

[0039]In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

[0040] refer to figure 2 , a multifunctional high-efficiency oil separator, including

[0041] An oil-separating container 1, the upper part of one end of the oil-separating container 1 is provided with a corresponding oil-separating water inlet 2, and the lower part of the other end of the oil-separating container 1 is provided with a corresponding oil-separating water outlet 3, and the bottom side of the oil-separating container 1 A settling area 101 is provided, and the upper part of the settling area 101 is connected with an oil separation area 102;

[0042] The slag removal mechanism 4 is arranged at the oil separation water inlet 2 of the oil separation container 1, and is used for water intake and slag removal;

[0043] The ejector 5 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com