Reinforcement process method for pile bottom sediment removal of pouring pile

A process method and technology of cast-in-place piles, which are applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as potential safety hazards, sediment failure to meet regulations, and influence on the strength of piles, so as to meet safety indicators and thoroughly Effects of clearing and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

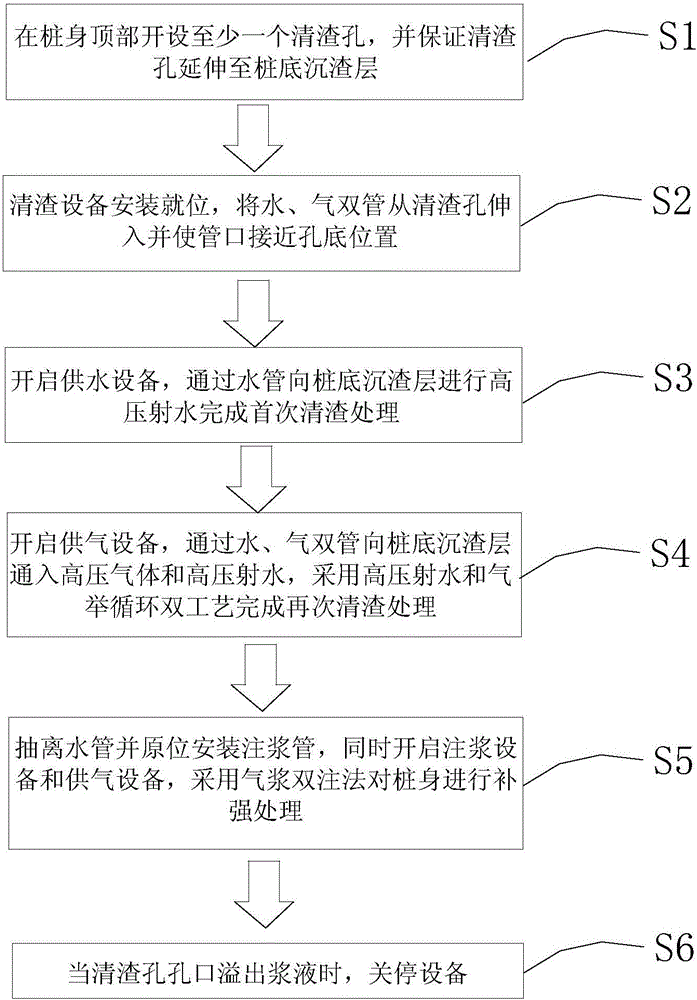

[0028] like figure 1 As shown, a process method for slag removal and reinforcement at the bottom of a cast-in-place pile, comprising the following steps:

[0029] S1: Open at least one slag cleaning hole at the top of the pile body, and ensure that the slag cleaning hole extends to the sediment layer at the bottom of the pile;

[0030] S2: The slag cleaning equipment is installed in place, and the water and gas pipes are extended from the slag cleaning hole and the nozzle is close to the bottom of the hole;

[0031] S3: Turn on the water supply equipment, and perform high-pressure water jetting to the sediment layer at the bottom of the pile through the water pipe to complete the first slag removal treatment;

[0032] S4: Turn on the gas supply equipment, pass high-pressure gas and high-pressure water jet to the sediment layer at the bottom of the pile through the water and gas double pipes, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com