Construction method of relief well

A construction method and a technology of relief wells, which are applied in infrastructure engineering, coastline protection, construction, etc., can solve problems such as poor product quality, low construction efficiency, and restrictions on relief wells, so as to achieve less time-consuming hole formation and higher manufacturing efficiency. Hole quality, effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

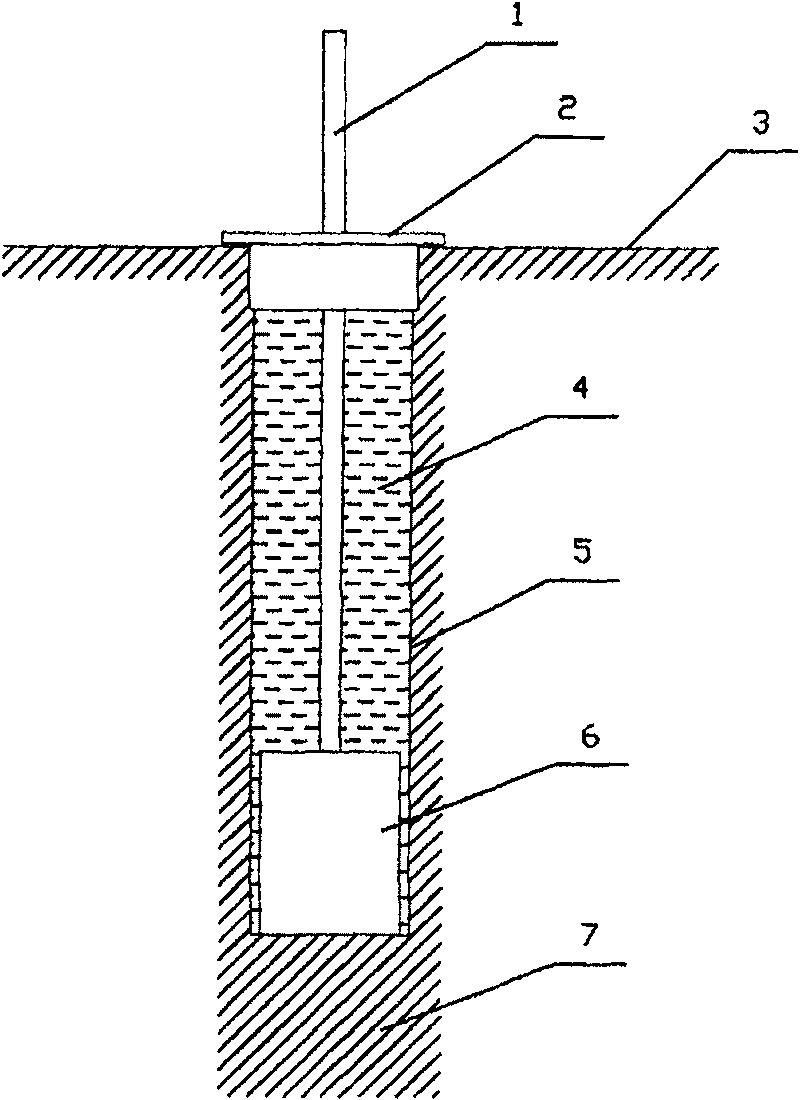

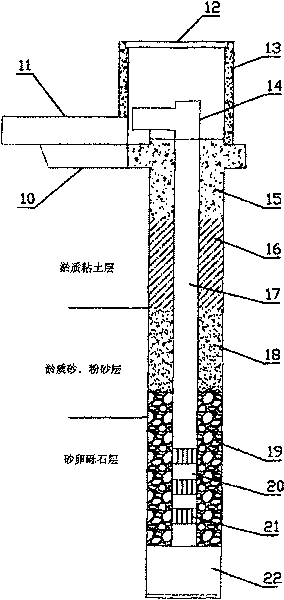

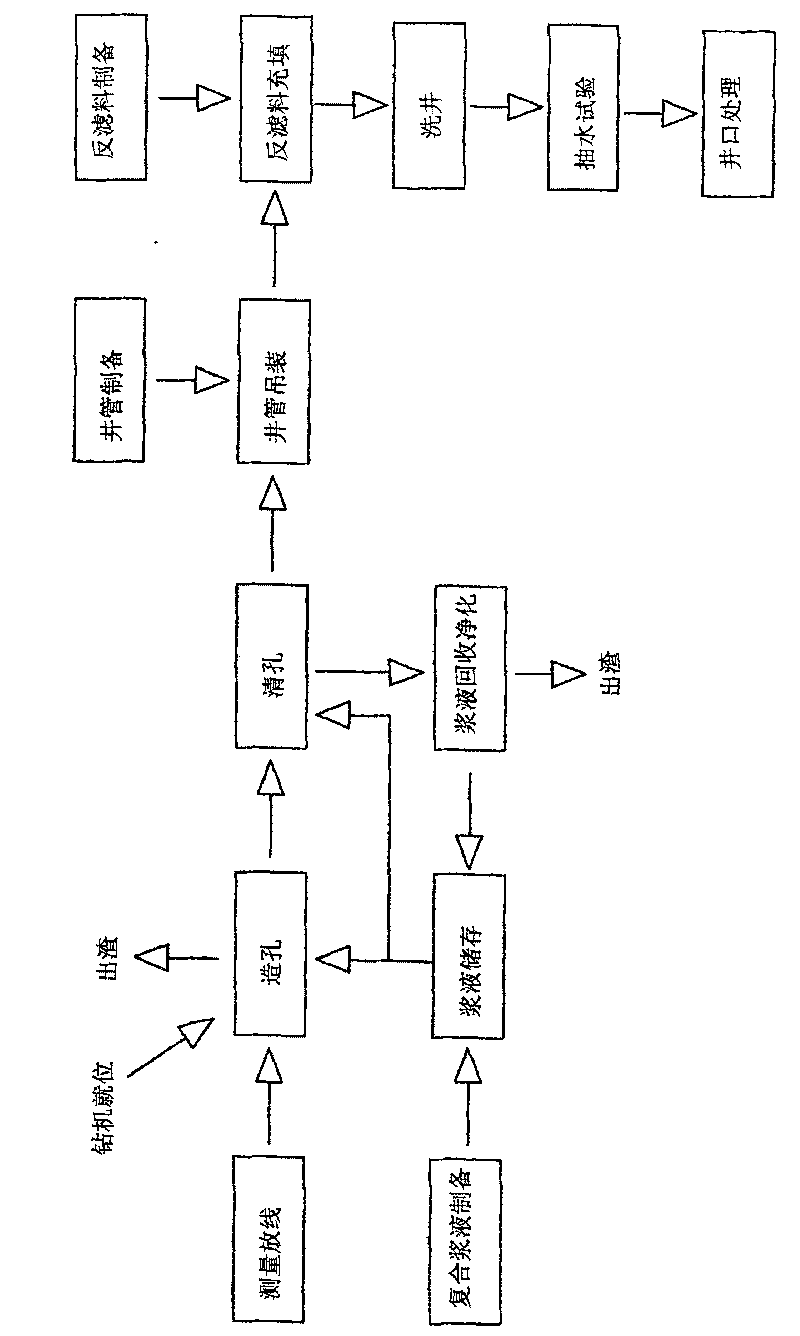

[0045] refer to figure 1 , figure 2 and image 3 , figure 1 It is a schematic diagram of the pore-making principle of the relief well of the present invention, figure 2 Schematic diagram of the relief well structure of the present invention; image 3 It is a flow chart of the relief well construction method of the present invention. The invention proposes a construction method for a relief well, which includes steps such as measuring and setting out, hole making, hole cleaning, well pipe hoisting, reverse filter material filling, well cleaning, pumping test, wellhead treatment, and superstructure construction. in:

[0046] In the hole-making process, the direct earth-borrowing drilling rig is used to make the hole and the high polymer composite slurry is used to protect the hole. In the hole cleaning process, the high polymer composite slurry is used to clean the hole.

[0047] The pore-making process includes the preparation and storage of polymer composite slurry. Du...

Embodiment 2

[0060] The method of operation is the same as in Example 1, except that the high polymer composite slurry used in the present example has a composition weight ratio of:

[0061] water 1000;

[0062] Bentonite 100;

[0063] PAM 10;

[0064] CMC+PAC10;

[0065] Industrial alkali 1.5

[0066] weighting agent 3;

[0067] fluid loss reducer 1;

[0068] The above components are prepared in proportion, and put into the swirl type pulping machine successively to make a slurry. The proportion of the prepared new slurry is controlled at 1.14-1.15, and the viscosity is controlled at about 23s. The high polymer composite slurry of this embodiment It is used for the construction of relief wells whose geological characteristics are mainly silt layer, plastic silt layer, and thin pebble layer. The results are:

[0069] Mud skin thickness test (stand still for 12h) 1.8mm. It took 3.1 hours to make a hole at a depth of 24m, 1 hour to clean the hole, and 7.5 hours to wash the well. The ...

Embodiment 3

[0071] The method of operation is the same as in Example 1, except that the high polymer composite slurry used in the present example has a composition weight ratio of:

[0072] water 1000;

[0073] Bentonite 80;

[0074] PAM 22;

[0075] CMC 13;

[0076] Industrial alkali 0;

[0077] weighting agent 8;

[0078] fluid loss reducer 0;

[0079] The above components are prepared in proportion, and put into the swirl type pulping machine successively to make a slurry. The density of the prepared new slurry is controlled at 1.13-1.14, and the viscosity is controlled at about 25s. The polymer composite slurry of this embodiment It is used for the construction of relief wells whose geological characteristics are thick pebble layer, silt layer, and the rest are plastic silt soil layers. The results are:

[0080] Mud skin thickness test (stand for 12h) 1.9mm. It took 4.5 hours to build a hole at a depth of 24m, 1.5 hours to clean the hole, and 9 hours to wash the well. The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com