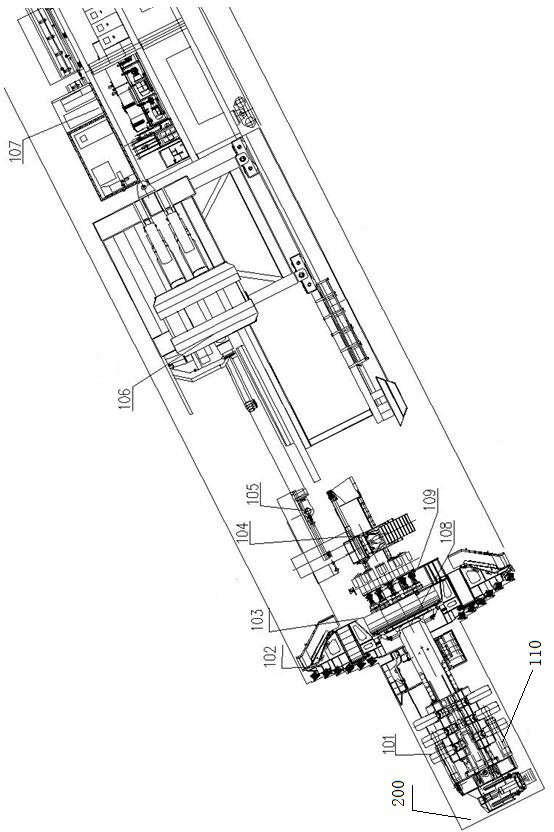

A kind of pilot hole reaming suspension cutting TBM for inclined shaft and its construction method

A construction method and technology for inclined shafts, applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of low expansion and excavation efficiency of inclined shaft pilot tunnels, improve rock breaking efficiency and rock breaking specific energy, and increase excavation expansion Efficiency and the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

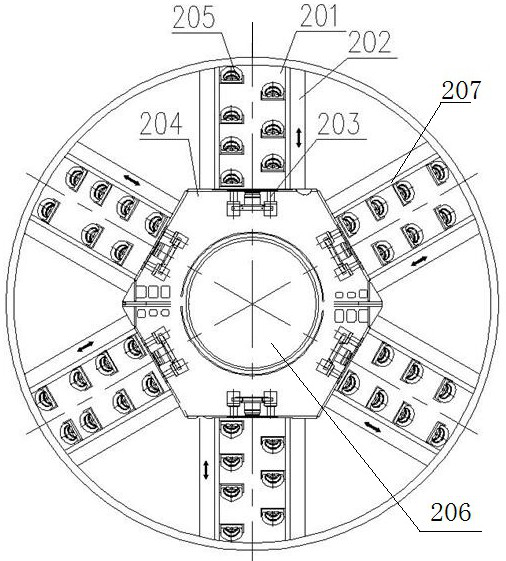

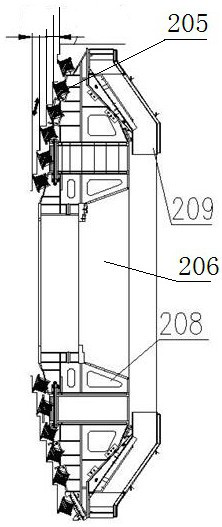

[0032] Embodiment 3: A construction method for a pilot hole reaming suspension cut TBM for an inclined shaft as described in Embodiment 2, the steps are as follows: S1: Align the pilot hole support shoe 101 with the pilot hole 200 and tighten it in the pilot hole On the inner wall, when the TBM excavates through rock, the cutter head 102 for hanging cutting and expanding excavation rotates, and the hanging cutter on the cutter head 102 for cutting and expanding cuts the face of the tunnel face. Before TBM rock-breaking excavation, according to the tunnel diameter that needs to be expanded, adjust the position of cutter beam 201 on the spoke structure 202 through radial cylinder 203 to form an excavation profile that meets the requirements; The face of the tunnel is cut layer by layer to form a hanging cutting excavation; the dregs generated during the excavation process enter the pilot tunnel under the action of the hanging cutting hob 205 inclined on the hanging cutting expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com