Tunneling machine slag removing device and tunneling machine

A technology for roadheaders and slag cleaning, which is applied in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of high labor cost, low degree of automation, and slow slag cleaning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

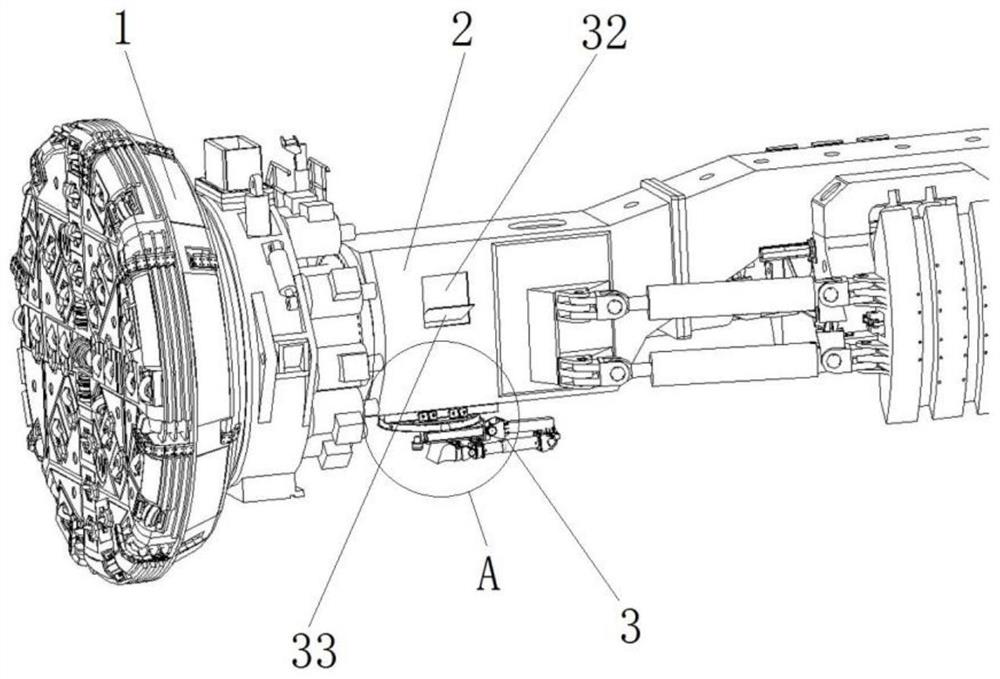

[0083] The specific embodiment 1 of the boring machine provided by the present invention, in the present embodiment, the boring machine is a TBM (full-section hard rock tunnel boring machine), and its specific structure is as follows:

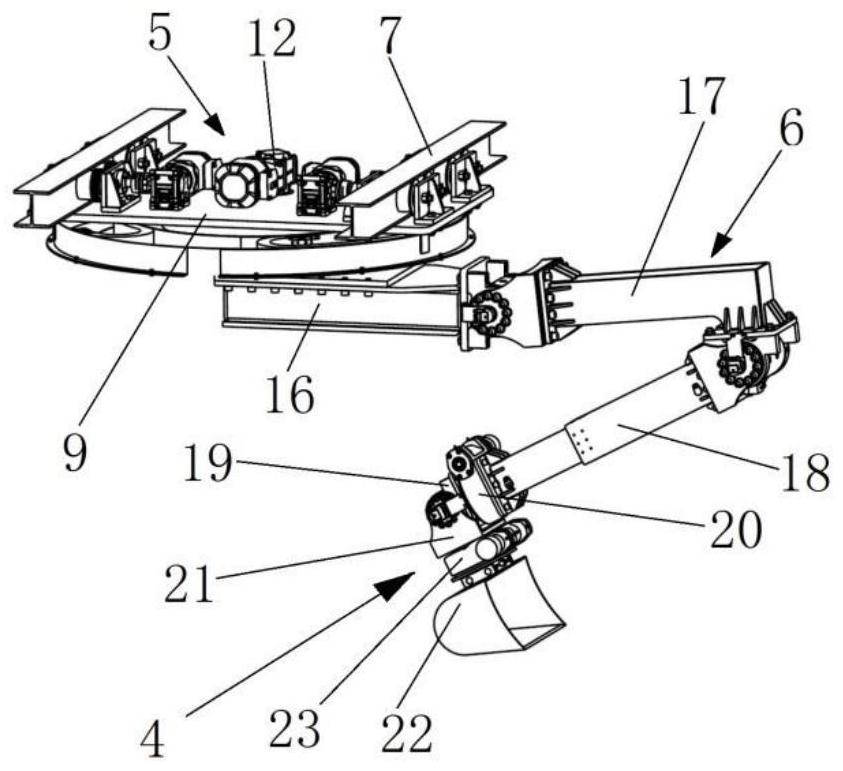

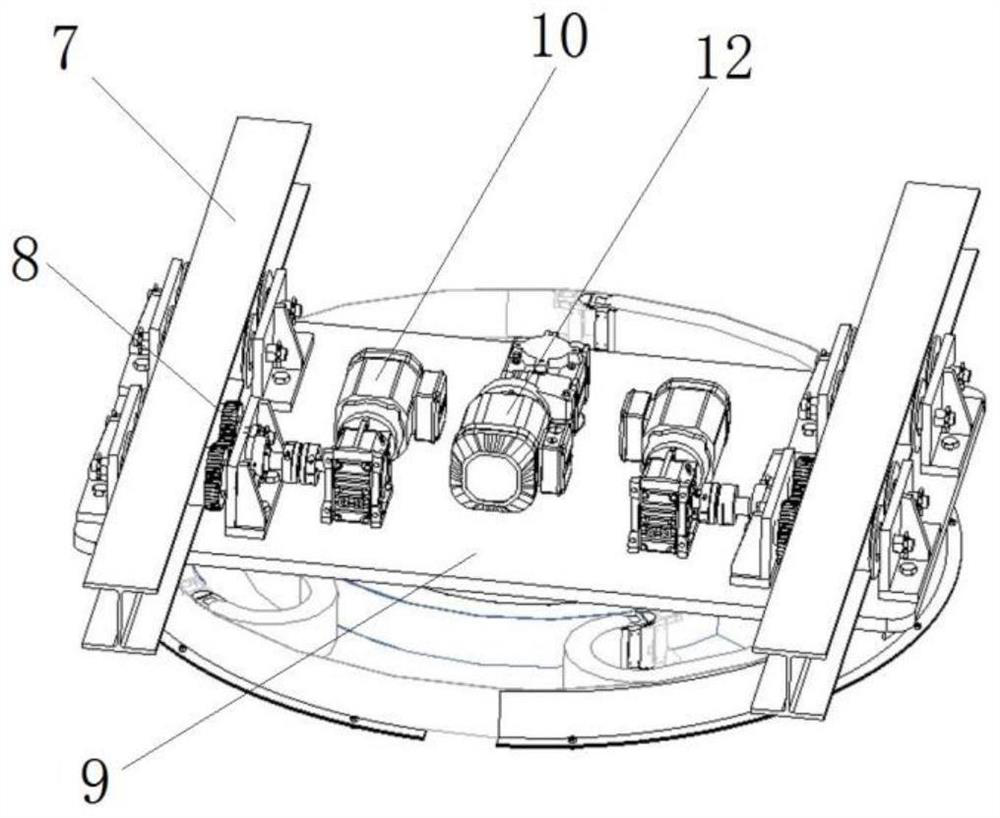

[0084] The partial structure of the boring machine provided by this embodiment is as follows: figure 1 As shown, it includes a cutter head 1 and a main beam 2 arranged on the rear side of the cutter head 1. The main beam 2 is provided with a slag for transporting the earth and rock excavated by the cutter head backward (defining the direction of the excavation of the roadheader as the front). For the soil conveyor, in order to clear and transport the accumulated earth and rocks at the bottom of the tunnel to the muck conveyor, the roadheader also includes a slag removal device 3 arranged on the main beam 2 . In this embodiment, the muck conveyor is a belt conveyor, and in other embodiments, the muck conveyor may also be a bucket conveyor. In a...

specific Embodiment 2

[0103] The specific embodiment 2 of the roadheader provided by the present invention differs from the embodiment 1 mainly in that in the embodiment 1, the slag cleaning bucket pours out the slag material at the slag discharge position. In this embodiment, a discharge door is provided at the bottom of the slag cleaning hopper, and a driving device for driving the opening and closing of the discharge door is provided. When the slag cleaning hopper reaches the discharge position, the control system controls the driving device to drive the discharge door to open , realize unloading.

specific Embodiment 3

[0104] The specific embodiment 3 of the roadheader provided by the present invention mainly differs from embodiment 1 in that in embodiment 1, the connection seat is a rotating seat that can rotate relative to the fixed part of the main beam, so that it can be cleared. The position adjustment of the slag hopper is more flexible and convenient. In this embodiment, on the premise that the slag cleaning hopper of the slag cleaning device can be accurately moved to the position of the slag material by moving along with the excavation, the connecting seat may not be a rotating seat, that is, it may be a fixed structure as a whole.

[0105] The specific embodiment 4 of the boring machine provided by the present invention differs from the embodiment 1 mainly in that in the embodiment 1, the movable arm is composed of two boom segments. In this embodiment, the movable arm is composed of three boom sections. Certainly, in other embodiments, the movable arm may have more than three sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com