Patents

Literature

64results about How to "Improve coiling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printed circuit board coil

ActiveUS20090085706A1Reduce skin effectReduce lossTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

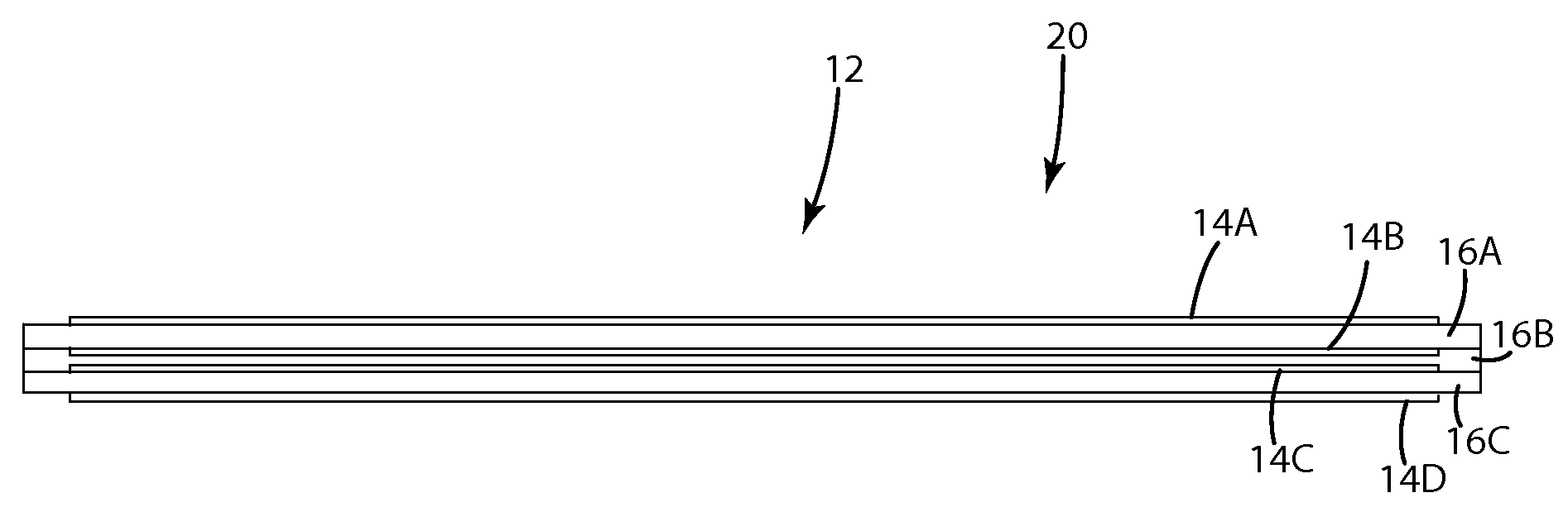

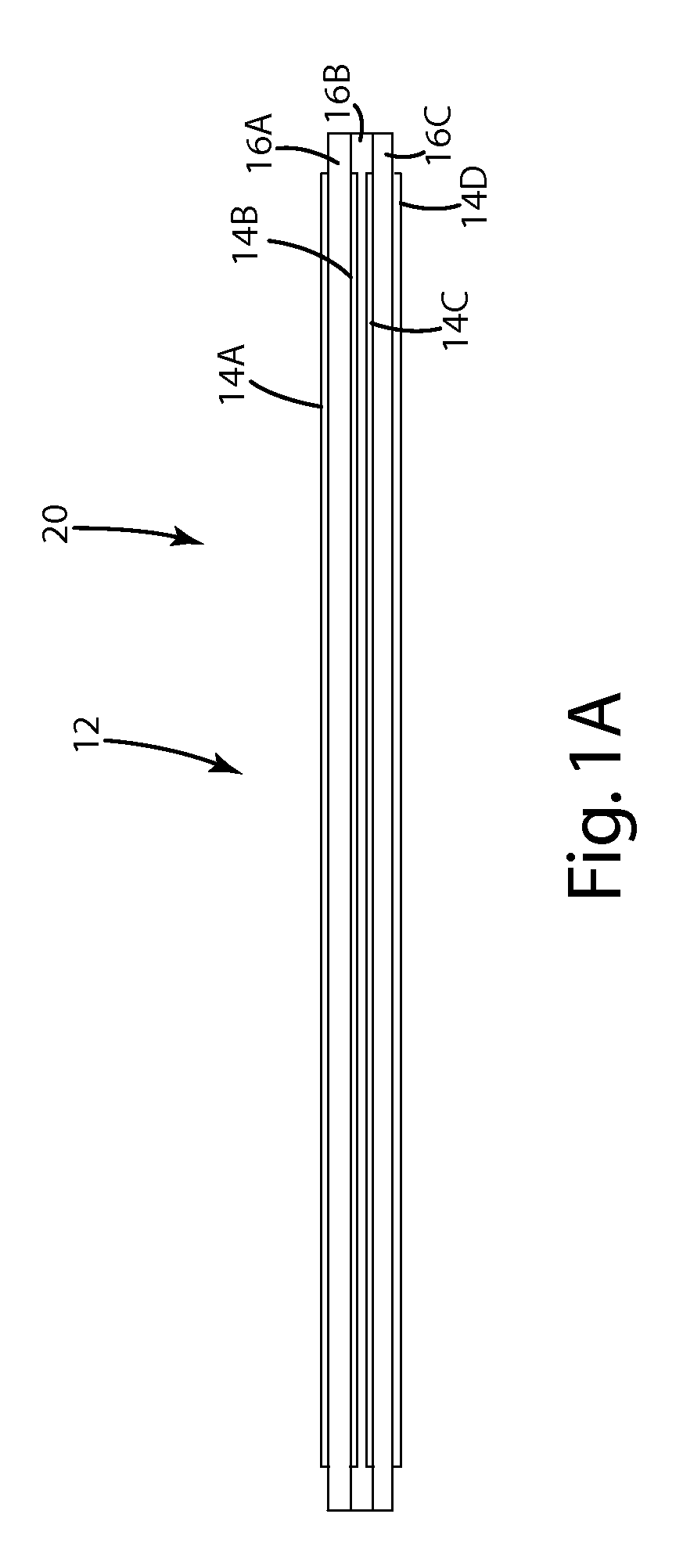

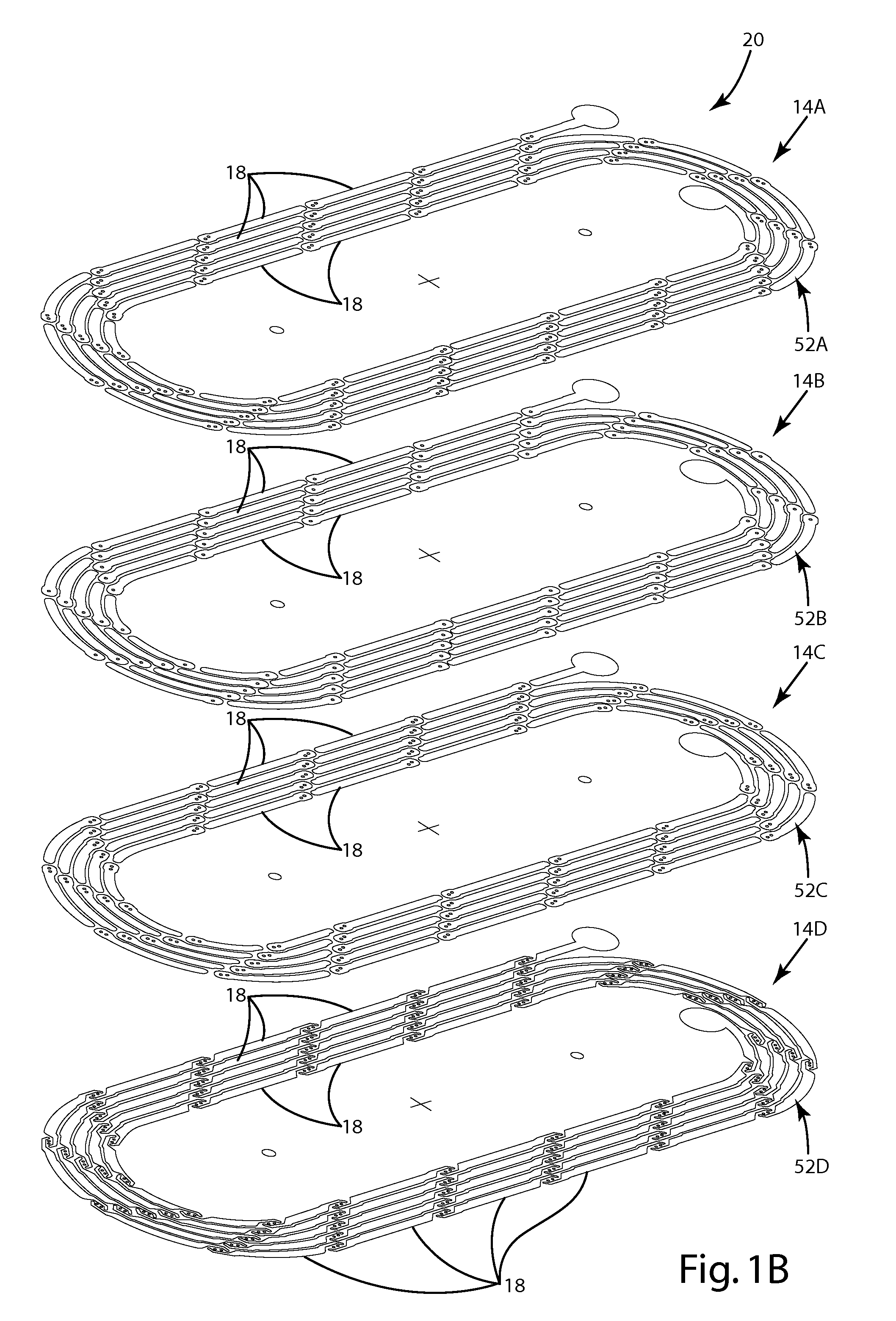

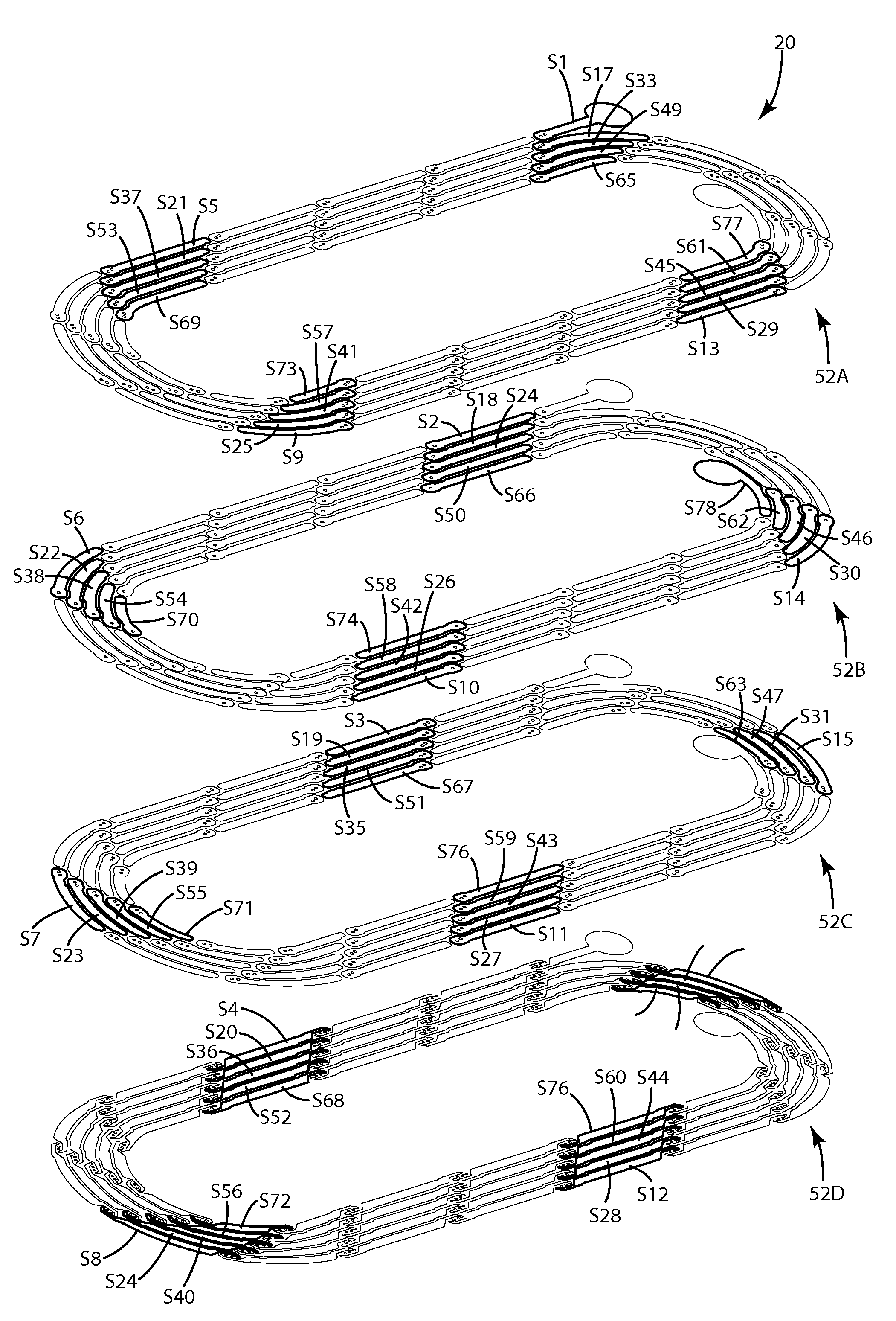

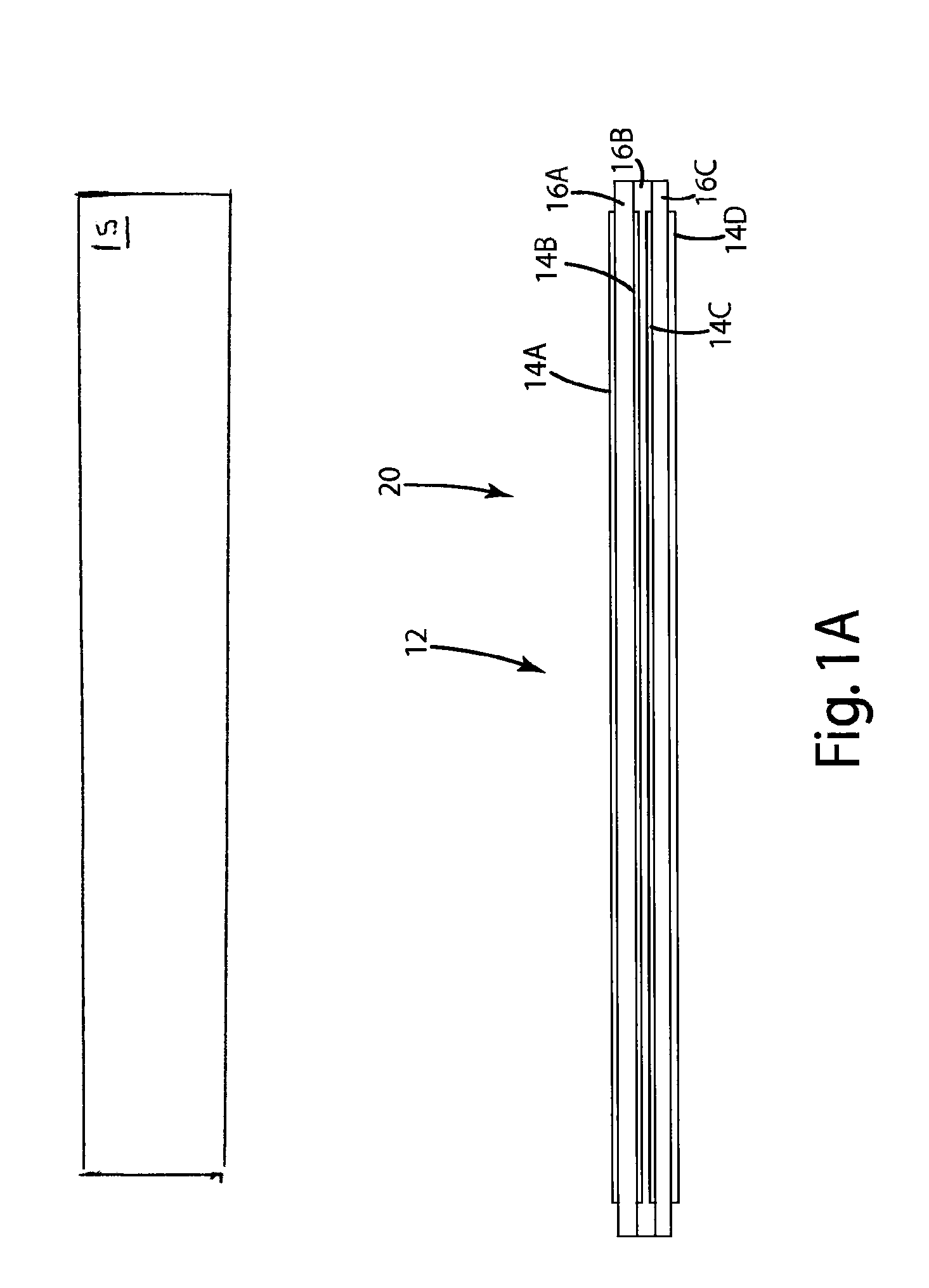

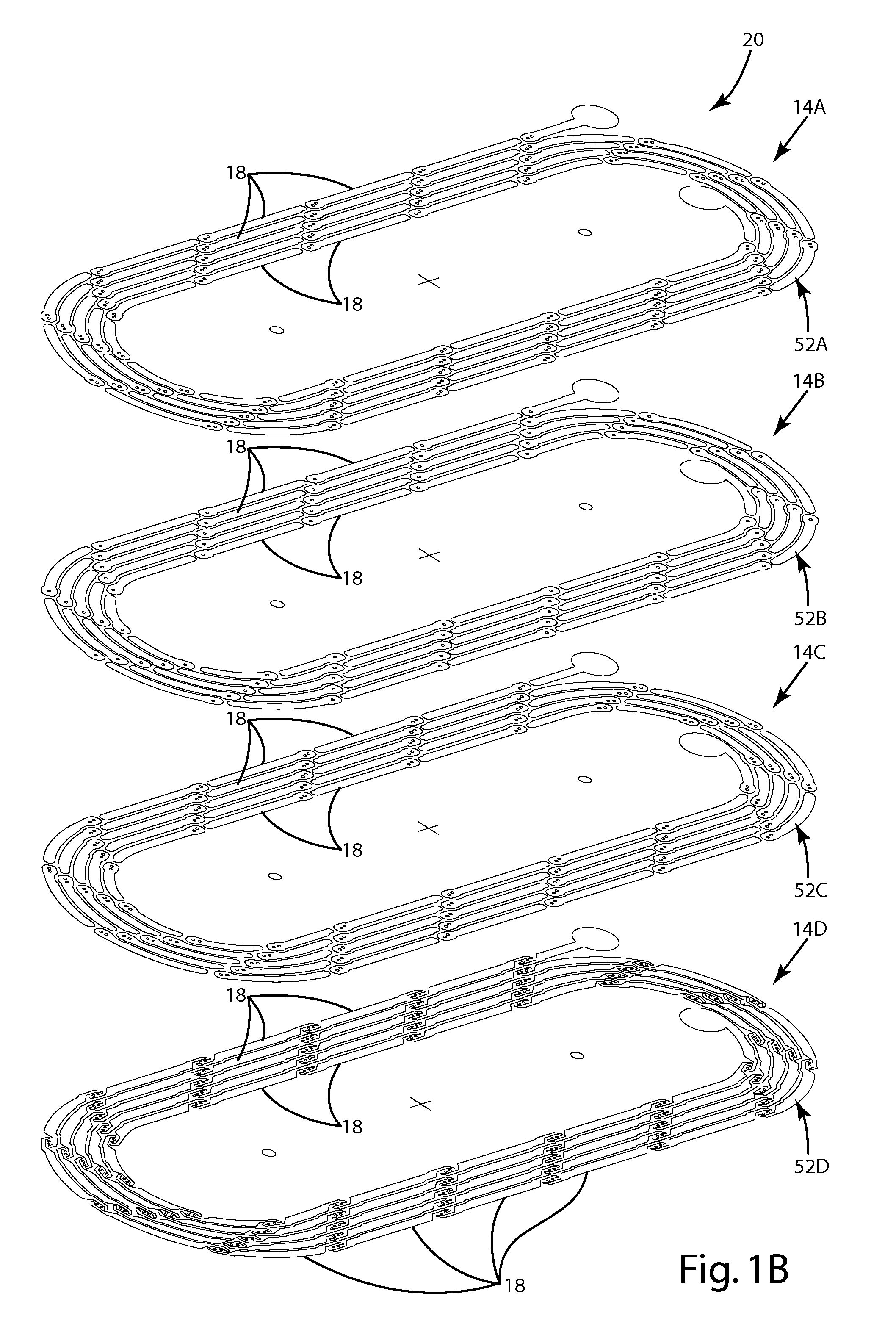

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

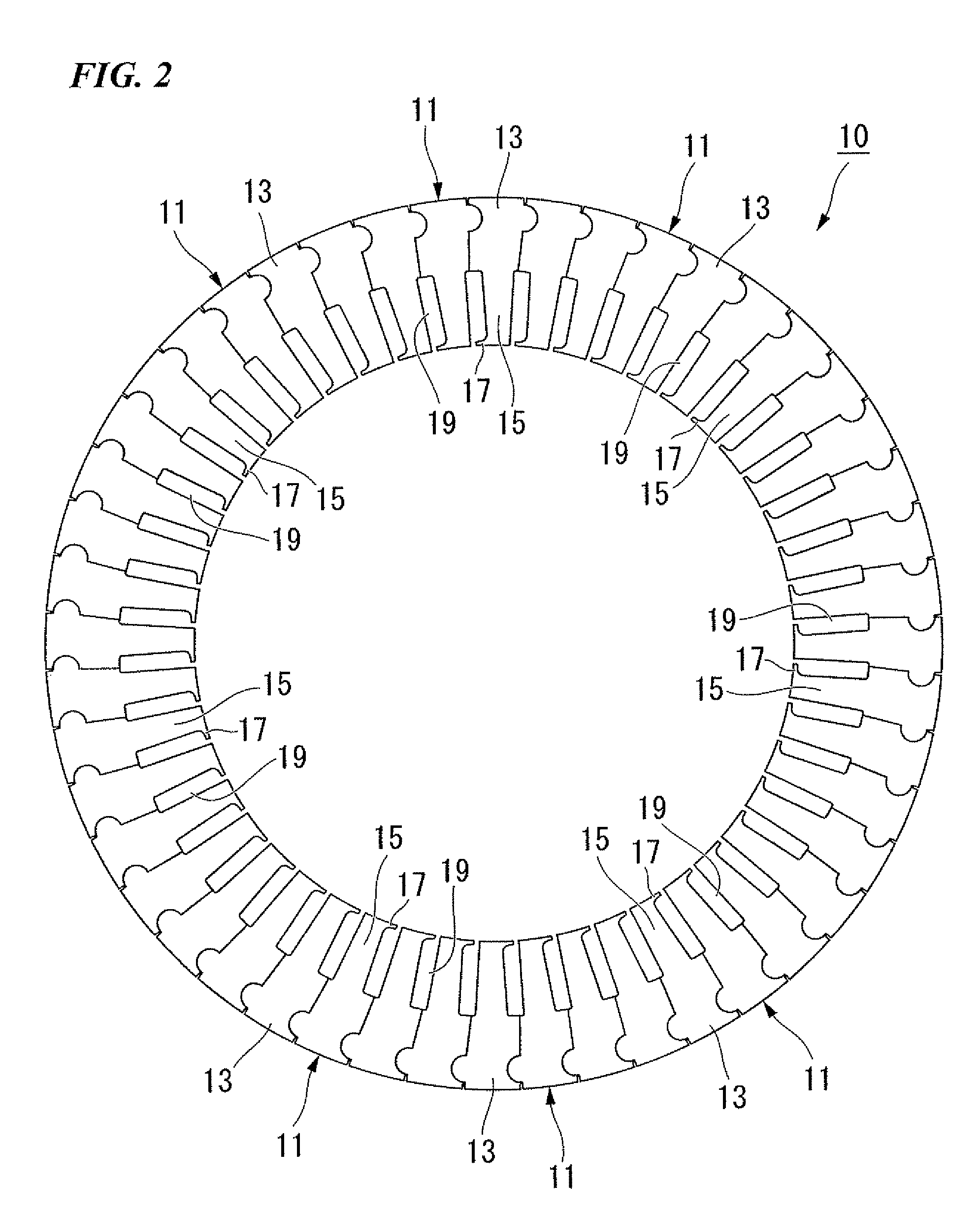

Printed circuit board coil

ActiveUS7973635B2Reliable and easily implementedImprove coiling efficiencyTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

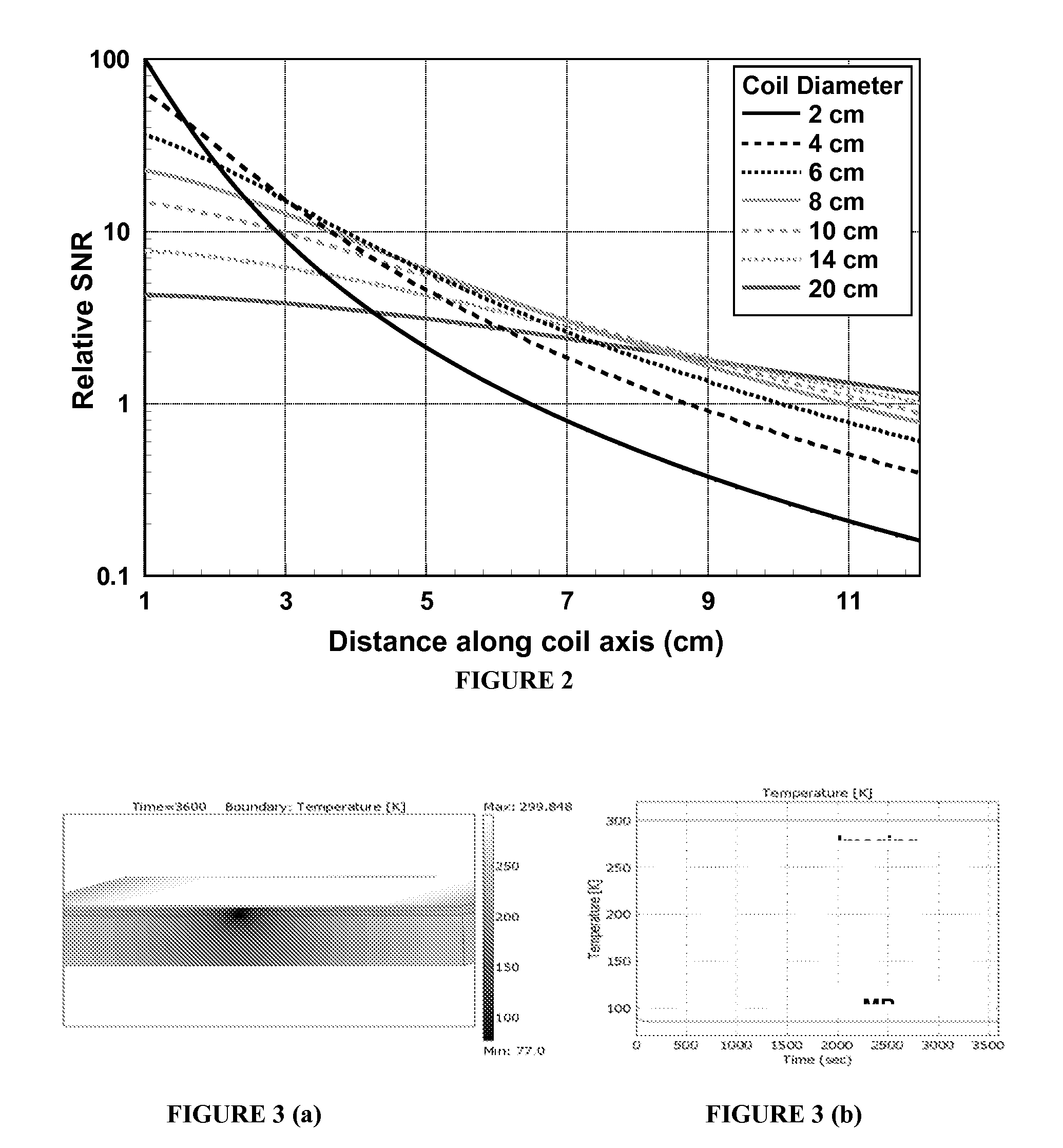

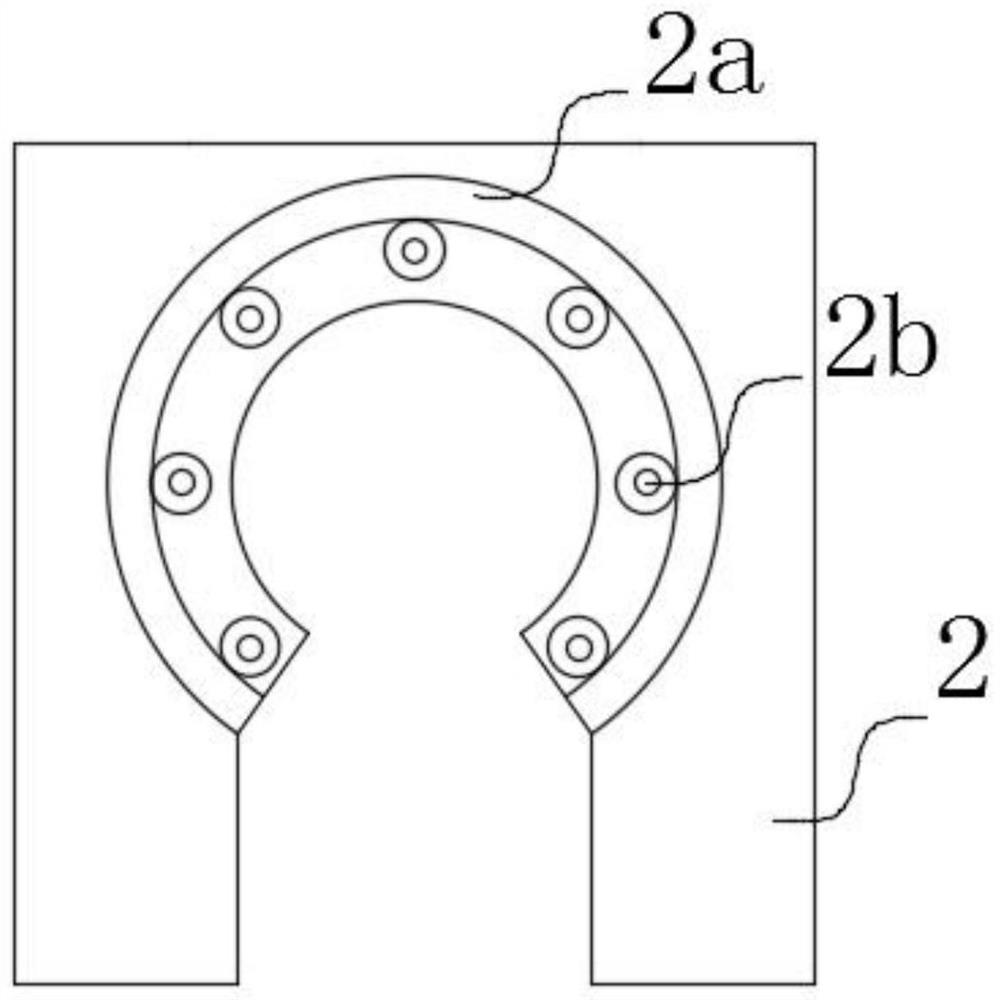

Cryogenic cooling of mri/nmr coils using integrated microfluidic channels

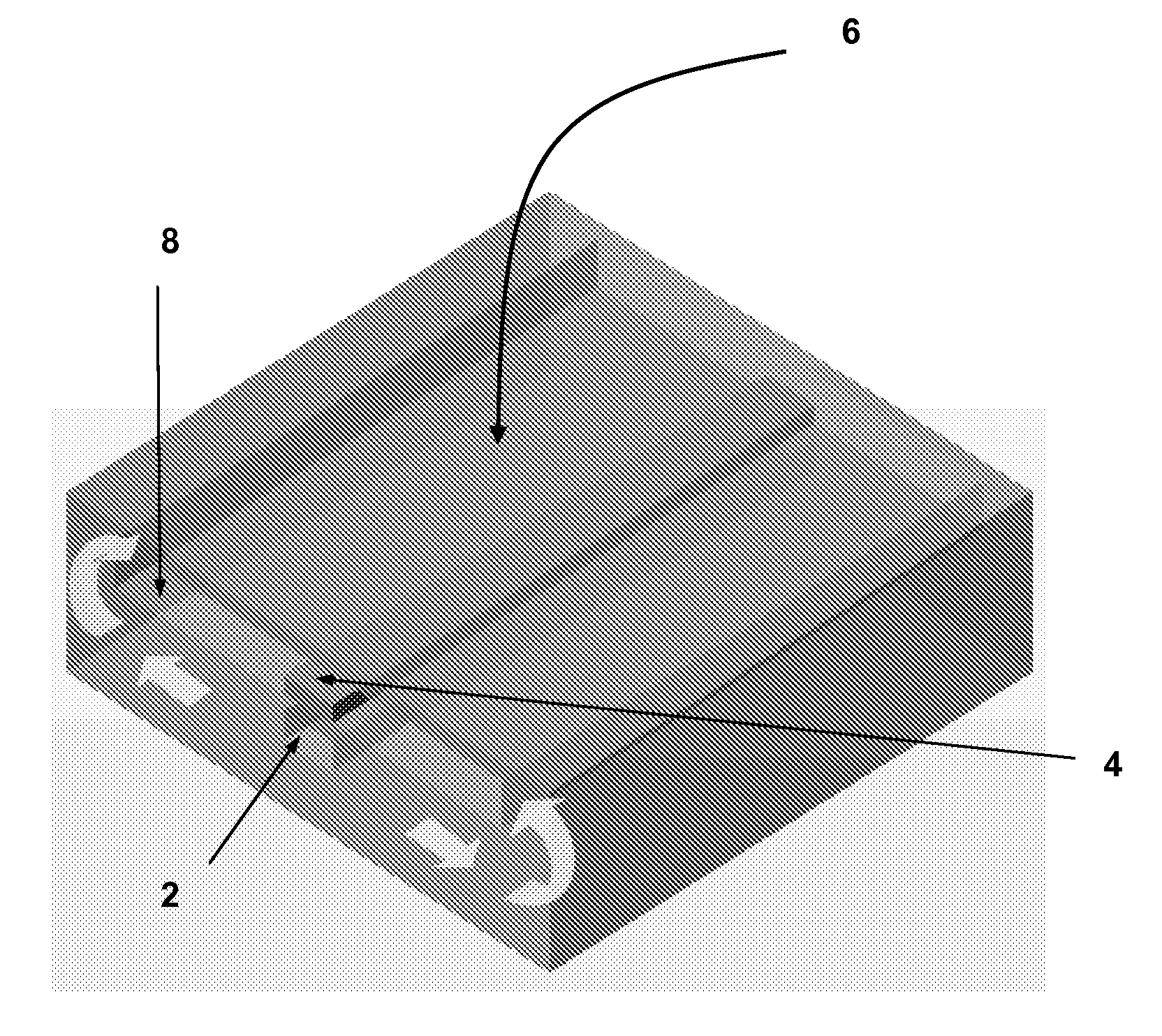

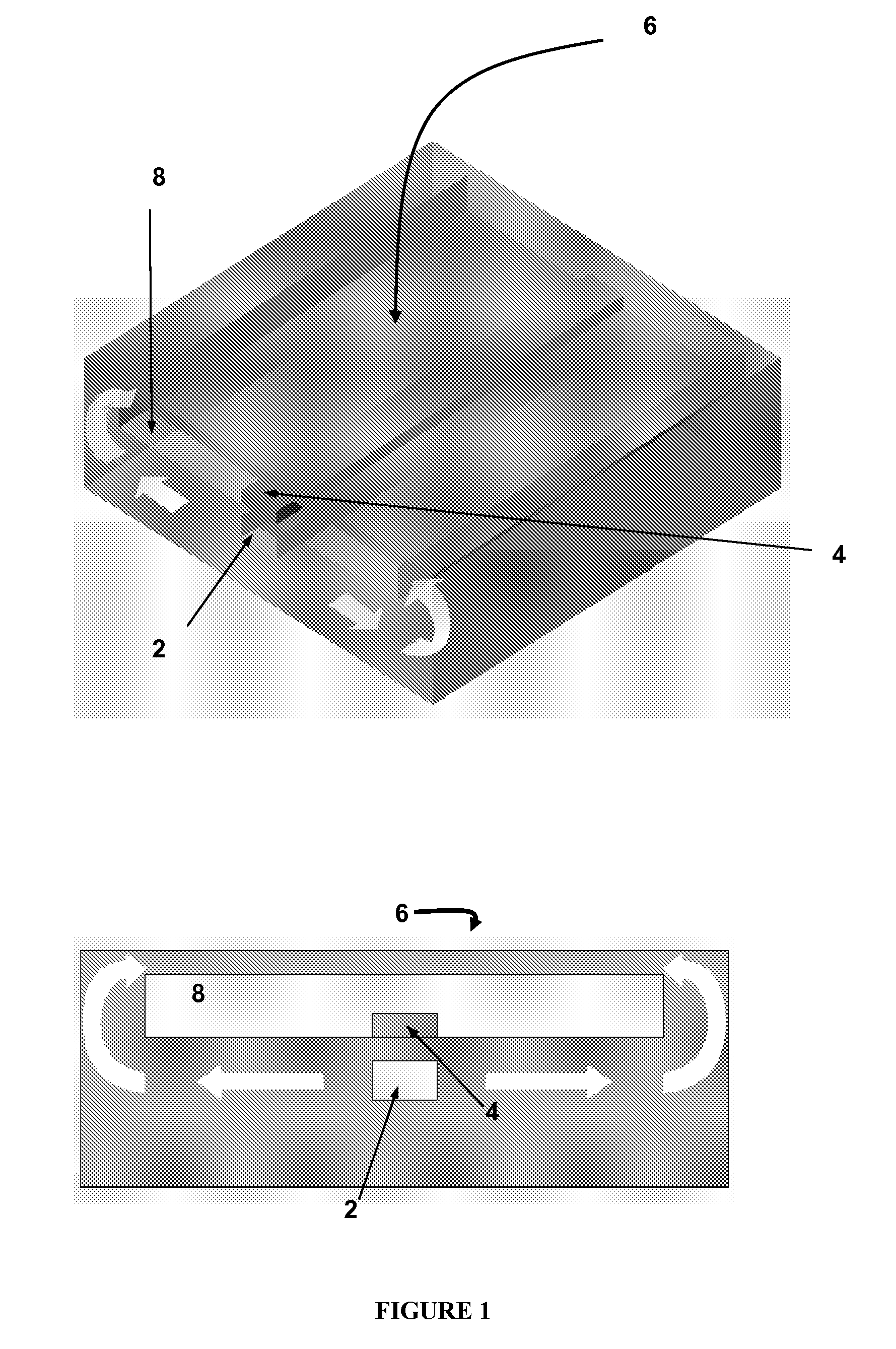

InactiveUS20090174407A1Improve coiling efficiencyMaintaining subject comfortMagnetic measurementsMagnetsNMR - Nuclear magnetic resonanceResonance

The present invention includes an assembly with a magnet for magnetic resonance having a substrate with an imaging surface and an opening within the substrate adjacent the imaging surface. The present invention enhances the sensitivity and reduces the acquisition time of magnetic resonance imaging (MRI) and nuclear magnetic resonance (NMR) spectroscopy by cooling the coil using microfluidic channels through which a cryogenic fluid is pumped. Various embodiments have been detailed for clinical imaging or detection in which the integrated coil / microfluidic cryo-cooling system is outside the patient body or in vivo imaging or detection in which the integrated coil / microfluidic cryo-cooling system is inside the patient.

Owner:TEXAS A&M UNIVERSITY

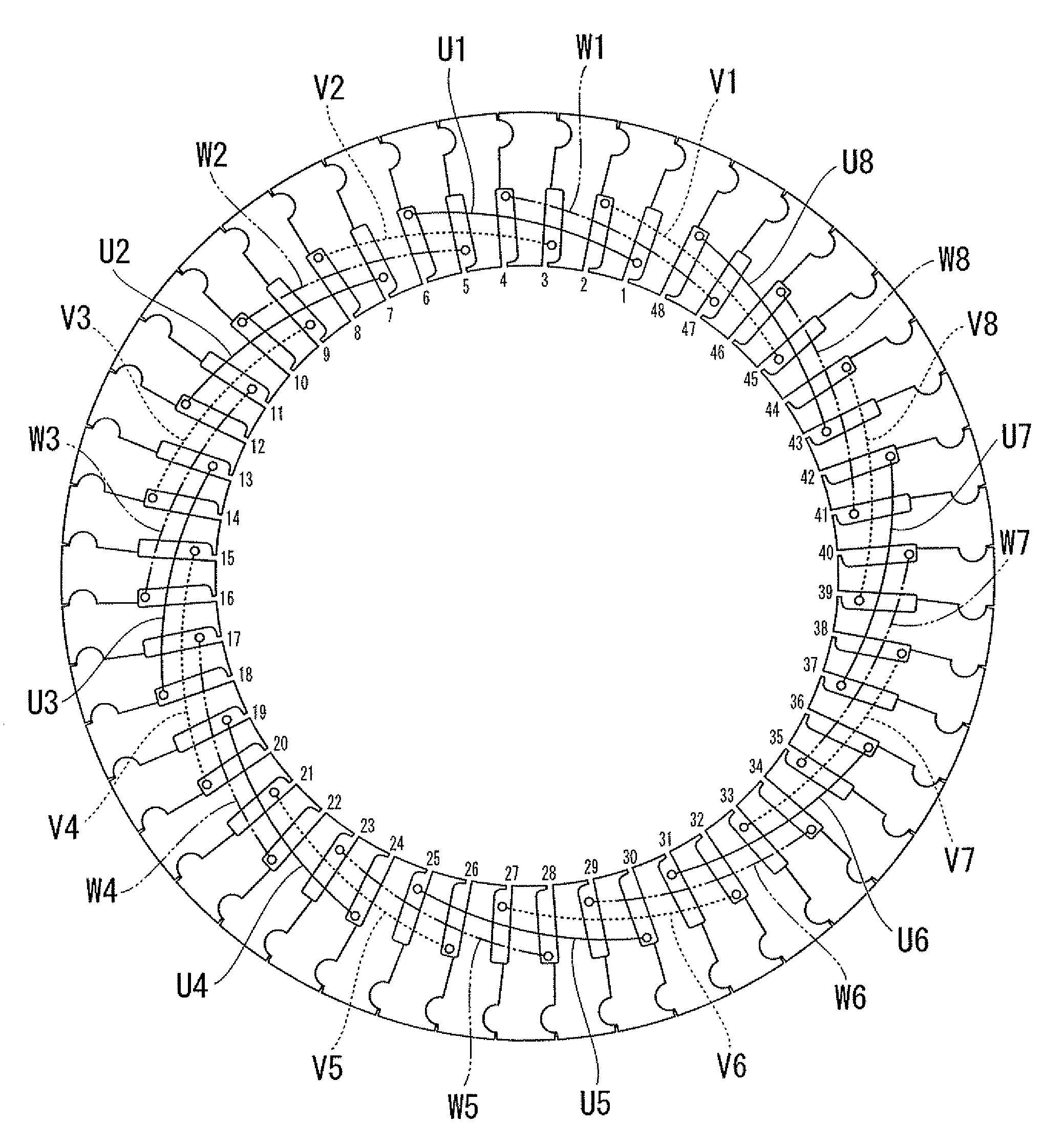

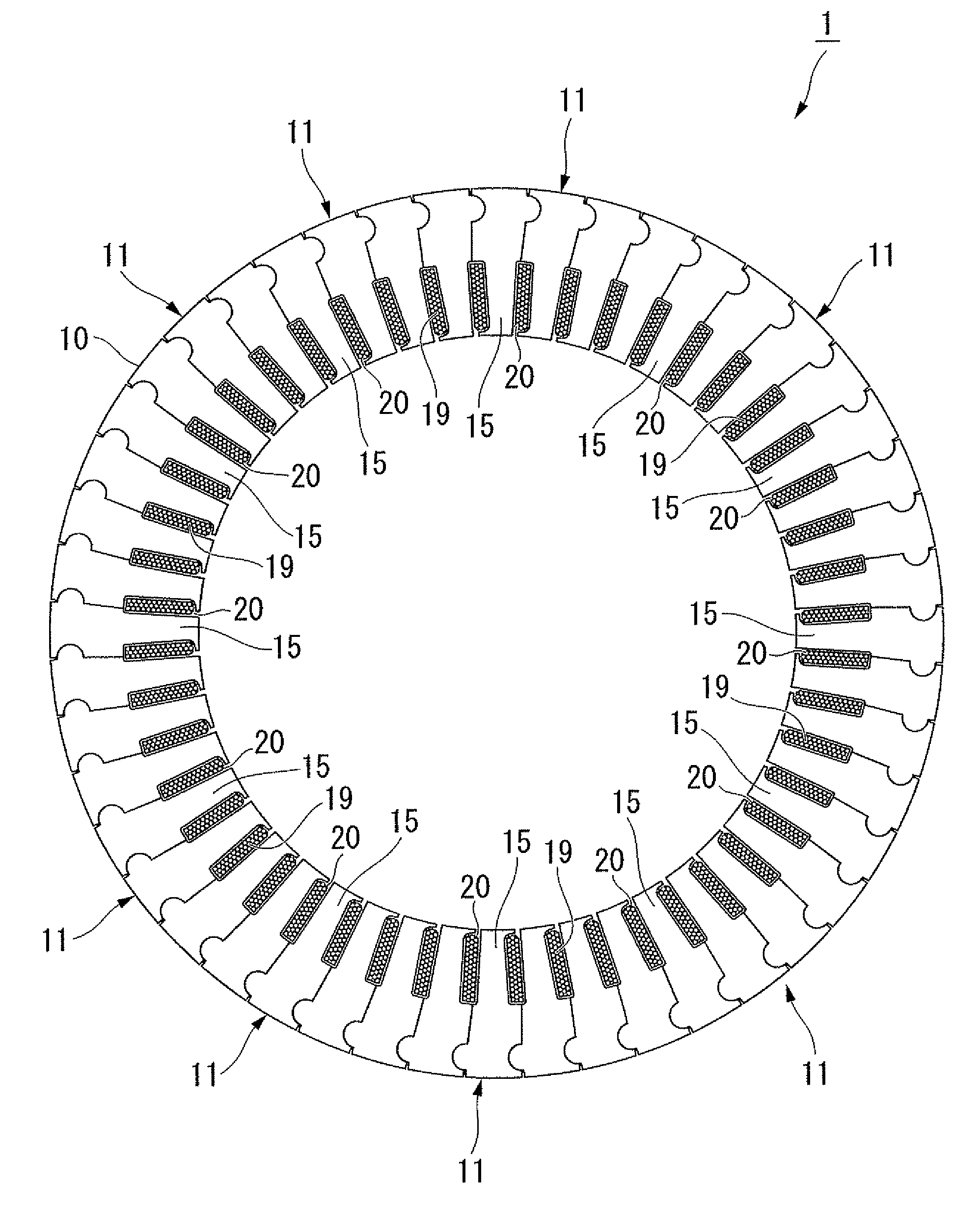

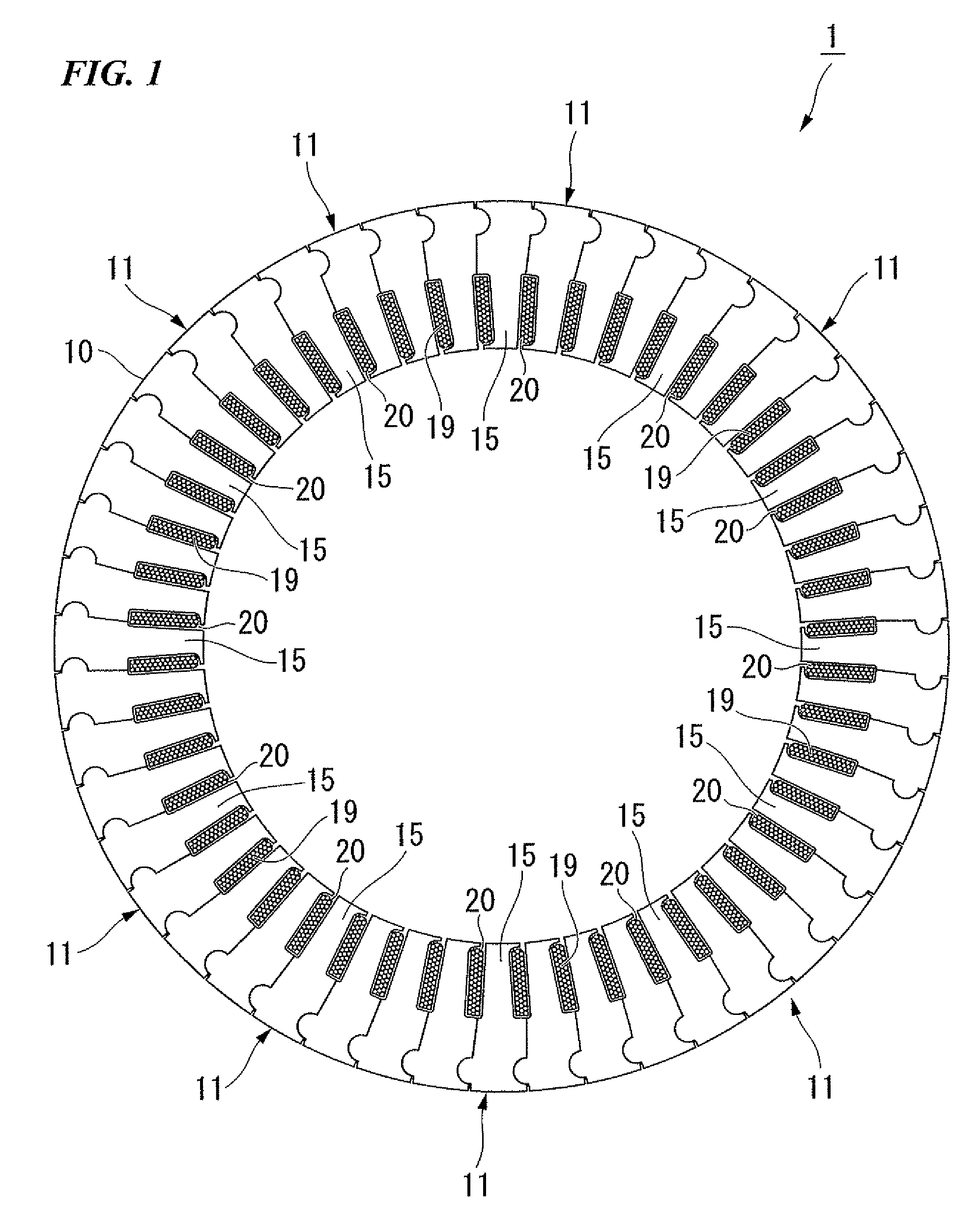

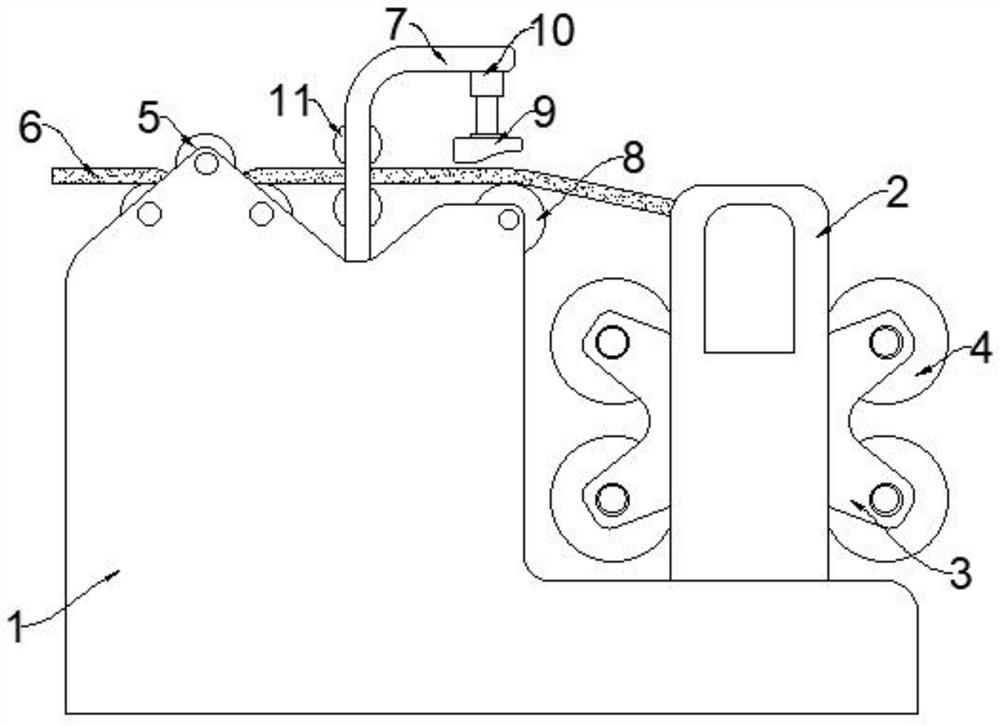

Motor

InactiveUS20100295405A1Increase distanceAvoid damageSynchronous machinesAsynchronous induction motorsEngineeringThree-phase

A motor includes: a stator including a stator core, a plurality of slot portions, and a plurality of coils, the stator core including a plurality of stator core pieces, the stator core piece including a teeth portion having a distal end portion and two side portions, a yoke portion, and a claw portion formed at one of the two side portions and at the distal end portion, the plurality of stator core pieces being connected so that a plurality of claw portions protrude in the same circumferential direction, the stator core thereby being formed in a cylindrical shape, each of the slot portions being formed between adjacent teeth portions and formed between the plurality of stator core pieces, the plurality of coils being inserted into the plurality of slot portions, the plurality of coils including a first coil, a second coil, and a third coil which form three phases, the first coil, the second coil, and the third coil being bridged between two of the slot portions, the first coil including a first coil end portion that protrudes from an edge face of the stator core in an axial direction, the second coil including a second coil end portion that protrudes from the edge face of the stator core in the axial direction, and the third coil including a third coil end portion that protrudes from the edge face of the stator core in the axial direction, the first coil, the second coil, and the third coil being arranged so that the first coil end portion, the second coil end portion, and the third coil end portion are intersected with each other; and a rotor disposed at an inner-peripheral side of the stator and rotatably supported.

Owner:HONDA MOTOR CO LTD

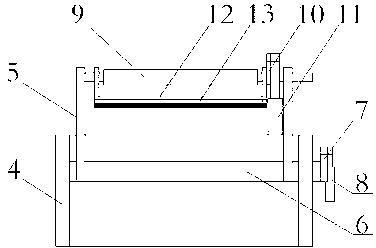

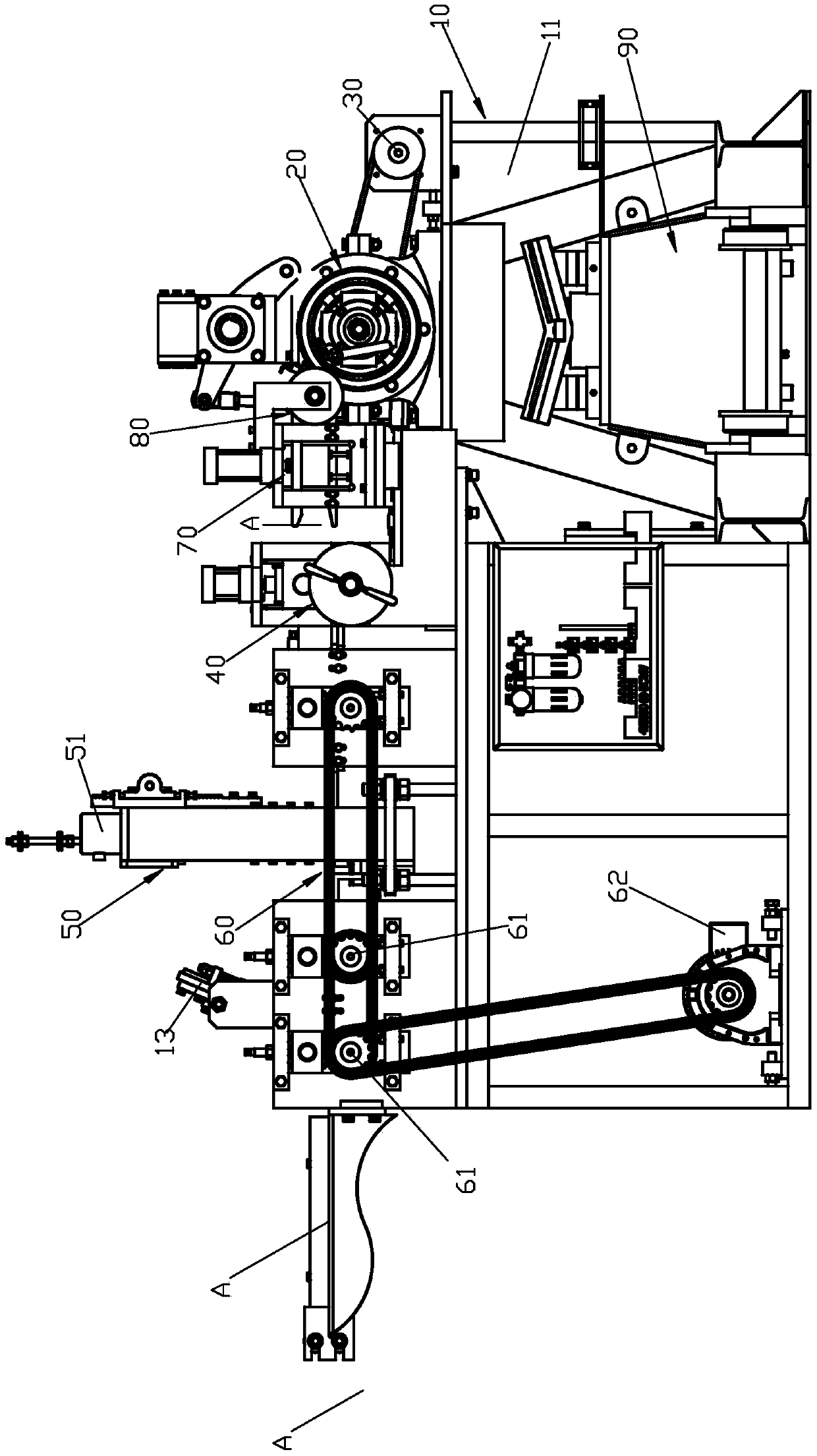

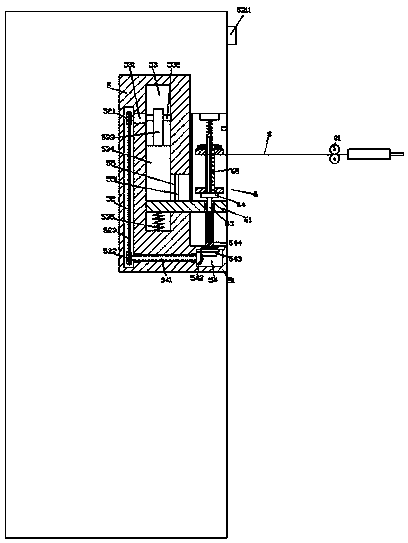

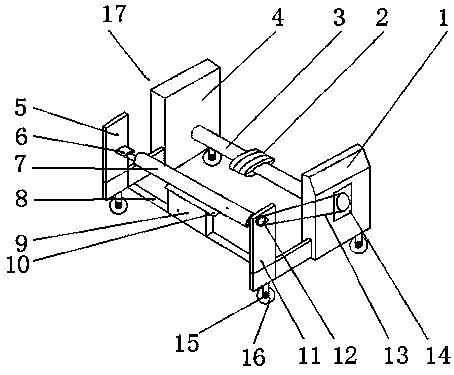

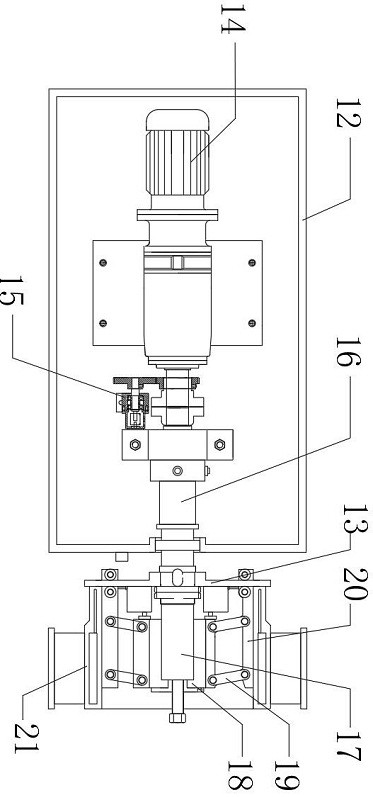

Winding, cutting and beginning device for coating machine

The invention relates to a winding, cutting and beginning device for a coating machine, which comprises a rotating mechanism and a cutting mechanism, wherein the rotating mechanism is arranged on the coating machine to be in a state rotationally corresponding to a receiving roller; and the cutting mechanism is arranged on the rotating mechanism to be in a state that while feeding to a feed roller, the coating machine for cutting is jointed with and feeds to another receiving roller. The winding, cutting and beginning device has the benefits that the structure is simple, the operation is convenient, stable cutting and winding can be performed, and the beginning of new winding is ensured to be level.

Owner:泰兴联创绝缘材料有限公司

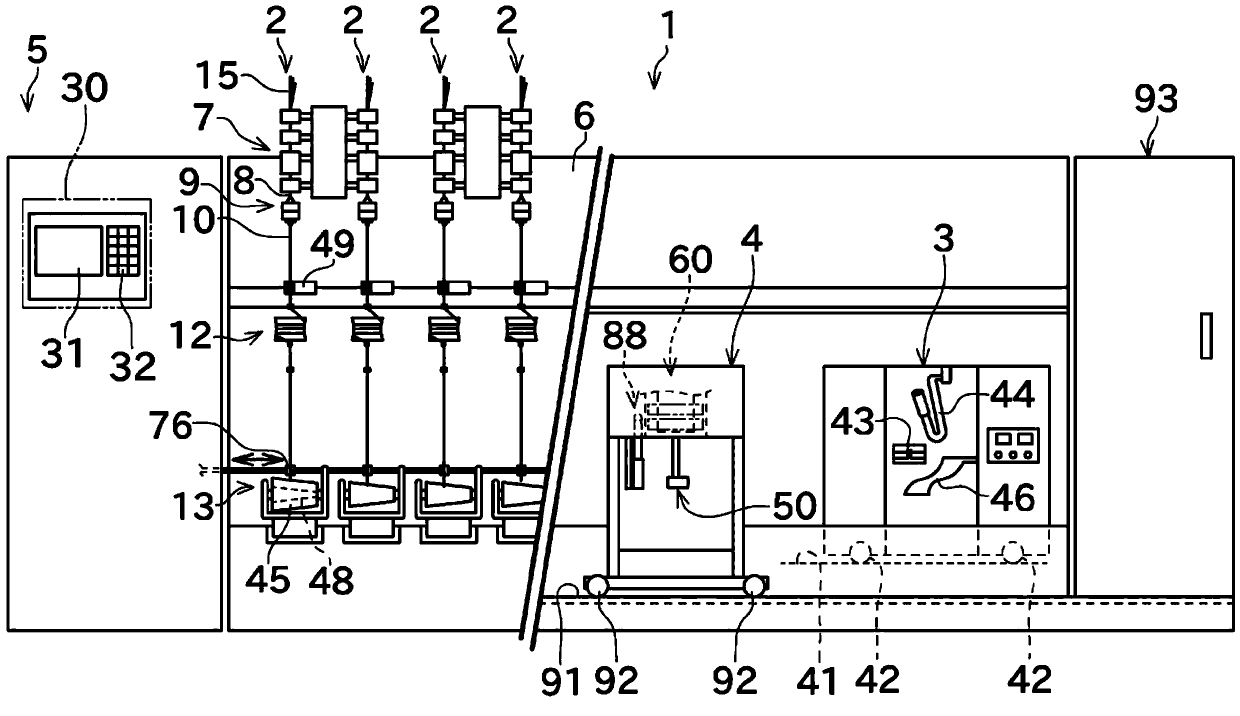

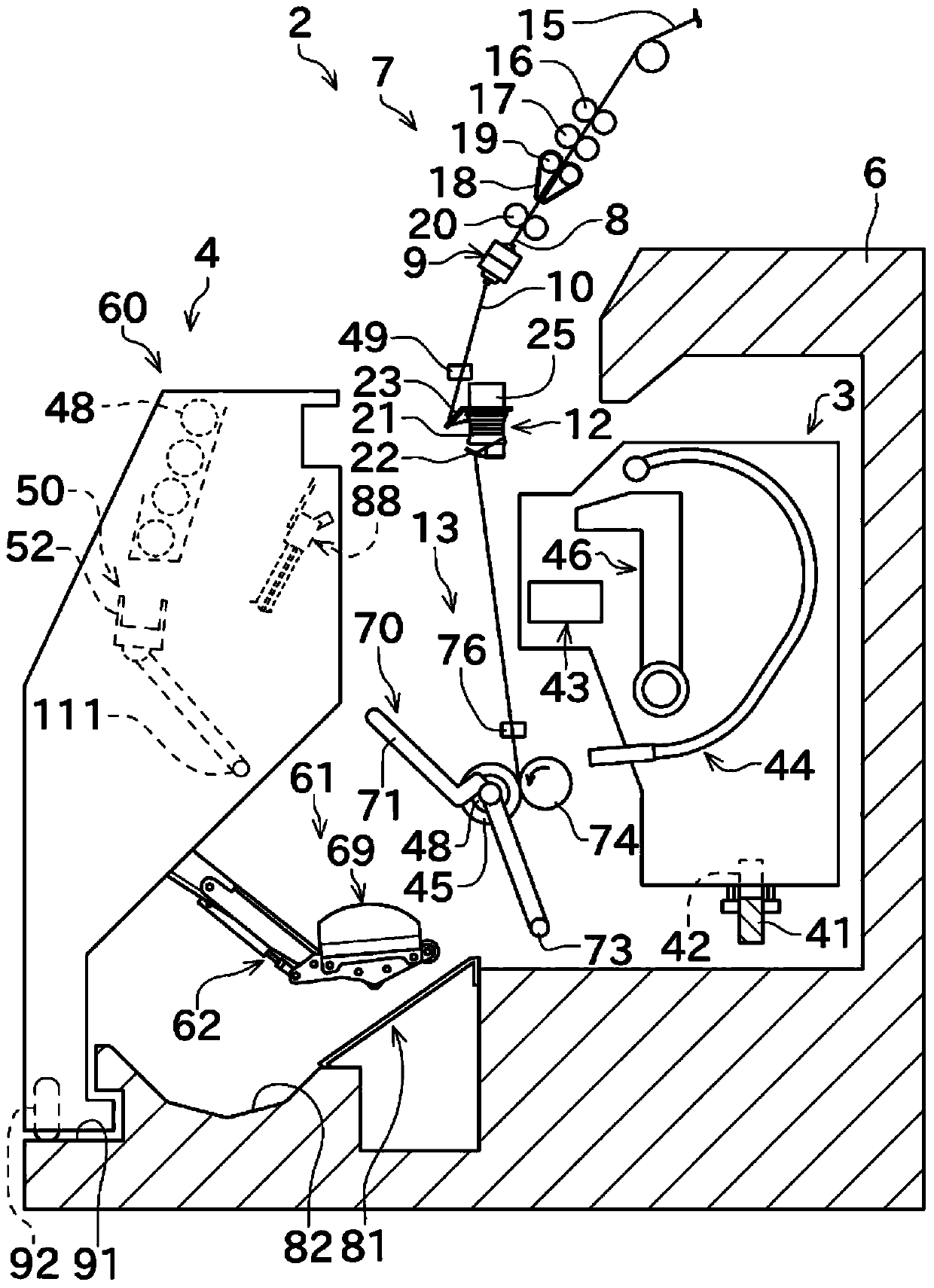

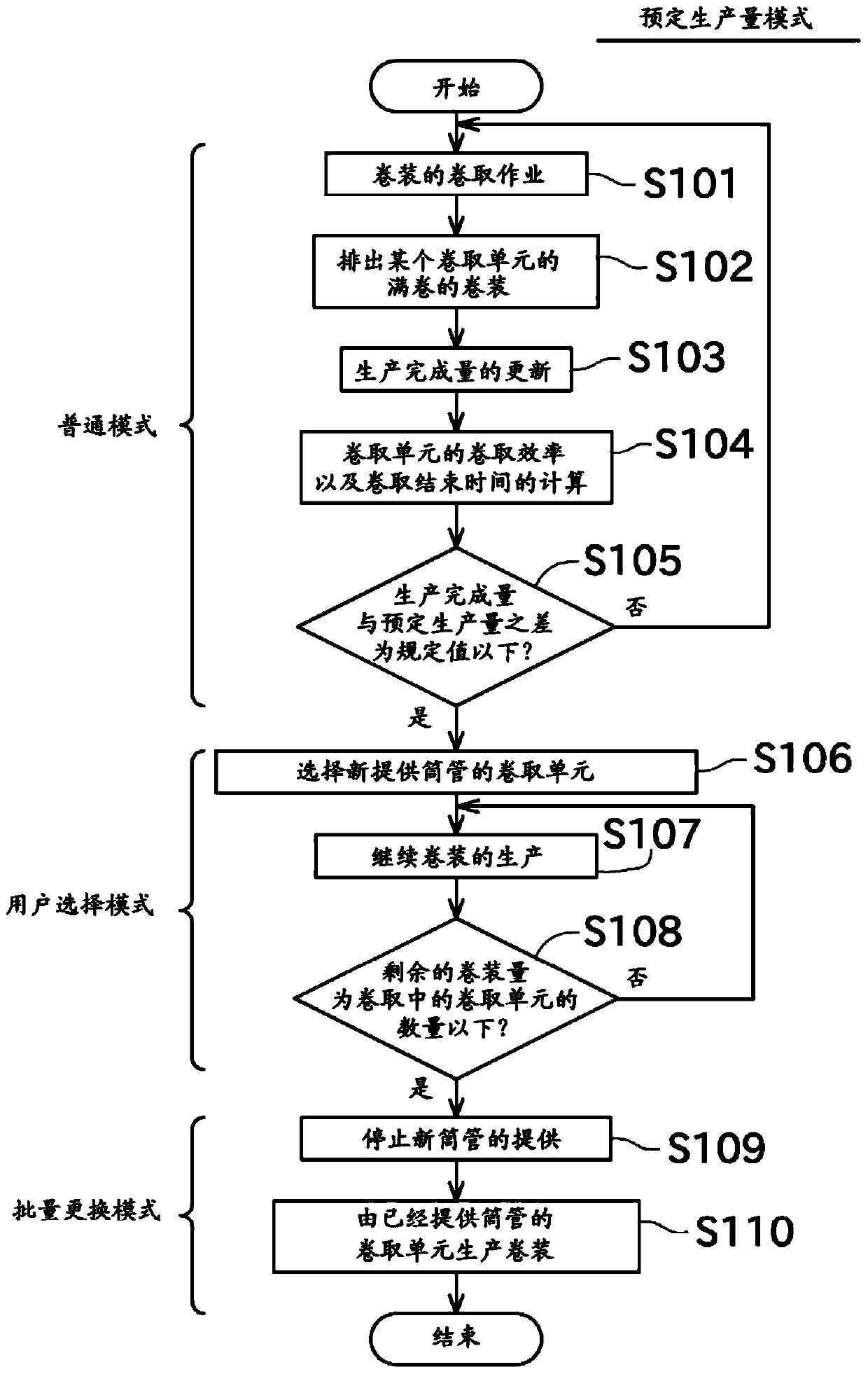

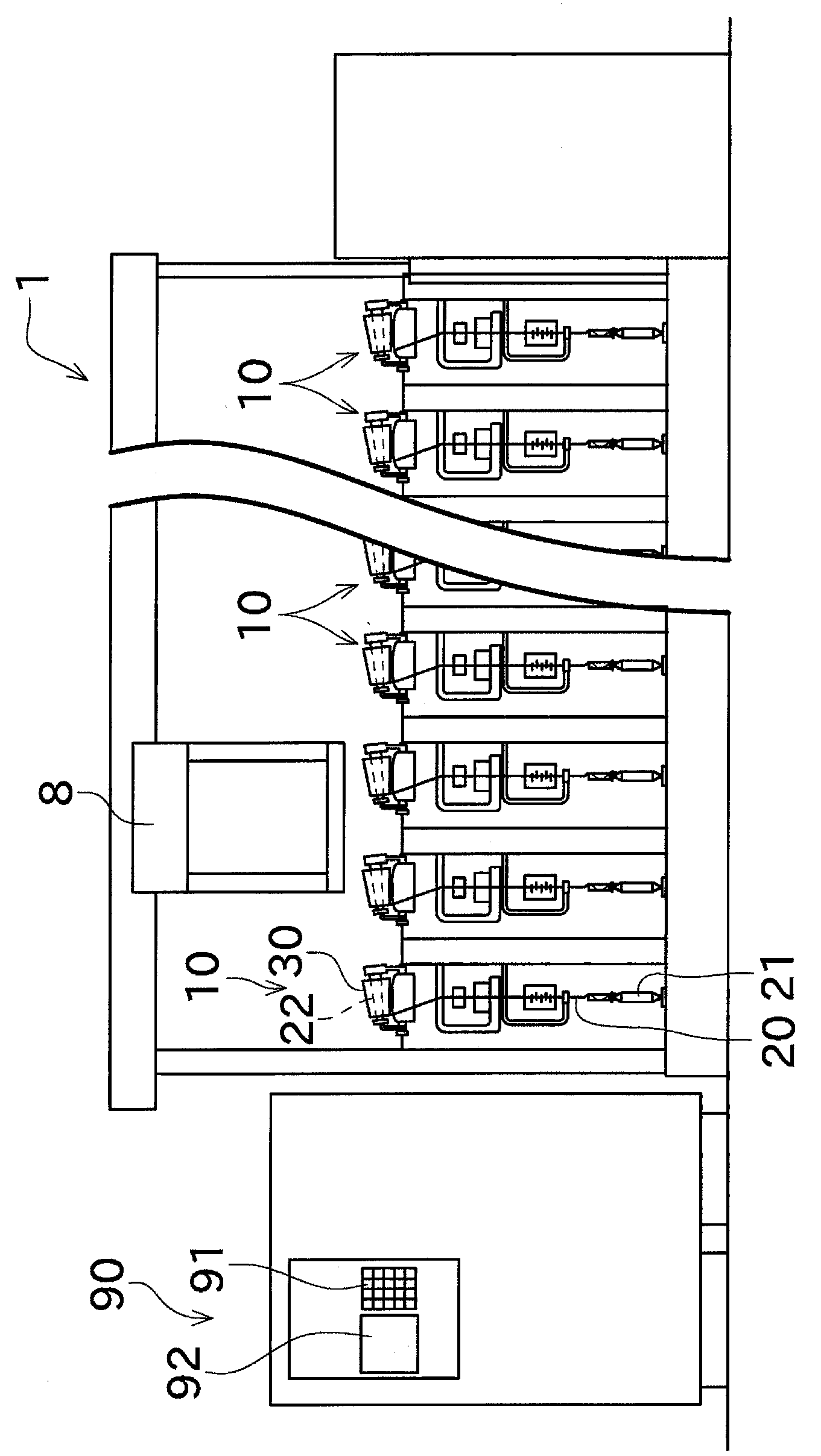

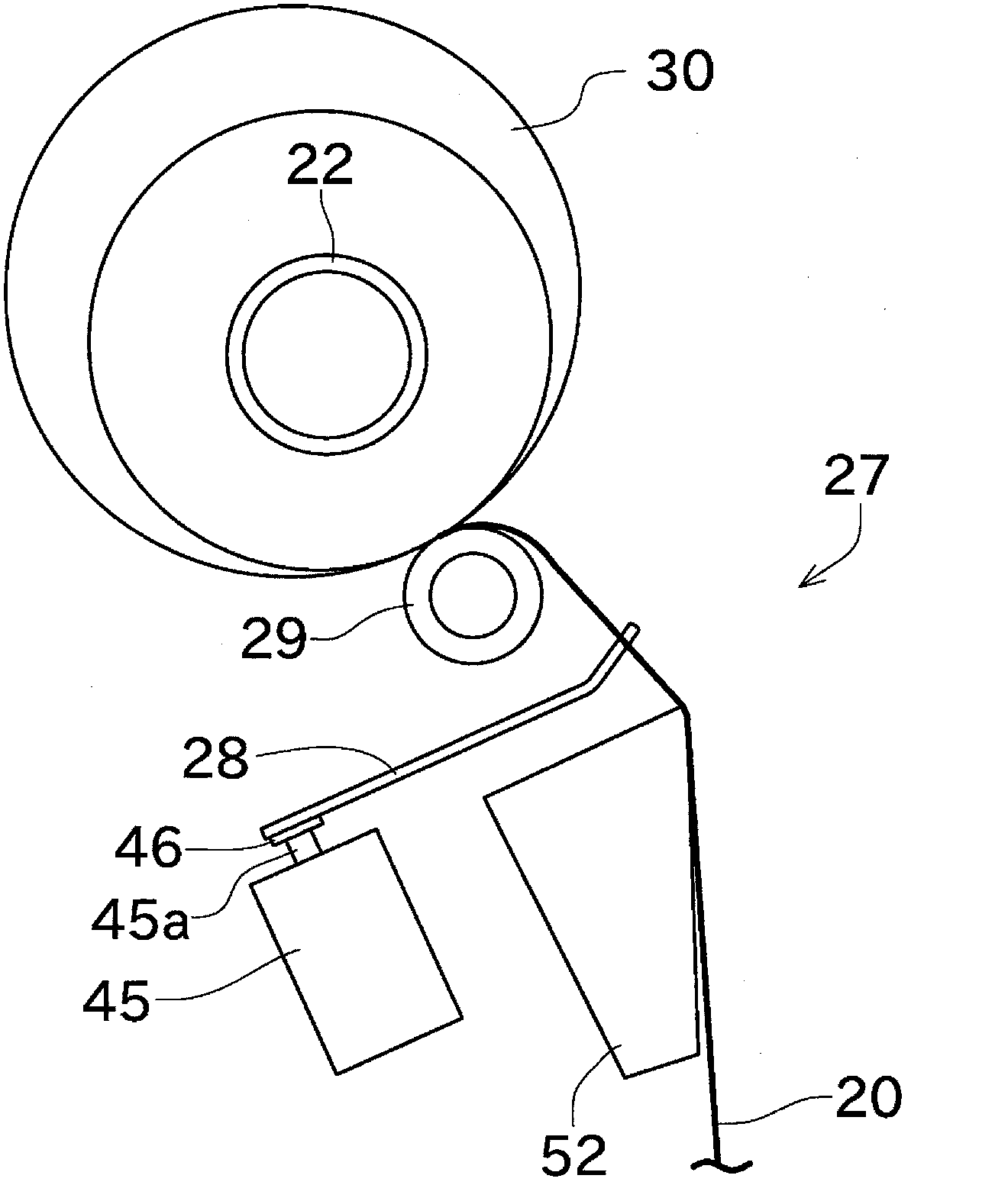

Yarn winding machine

A yarn winding machine (1) includes a plurality of winding units (2) and a control section (30). Each of the plurality of winding units (2) winds a package (45). The control section (30) controls the plurality of the winding units (2). The control section performs a control to calculate a winding-end expected time of the package in each of the winding units. The control section performs a control to store a produced quantity indicating a quantity of the package of which winding has been completed, and when a difference between the produced quantity and an expected production quantity is equal to or less than a predetermined value, to determine whether or not to supply a new bobbin (48) to the winding units in accordance with the winding-end expected time.

Owner:MURATA MASCH LTD

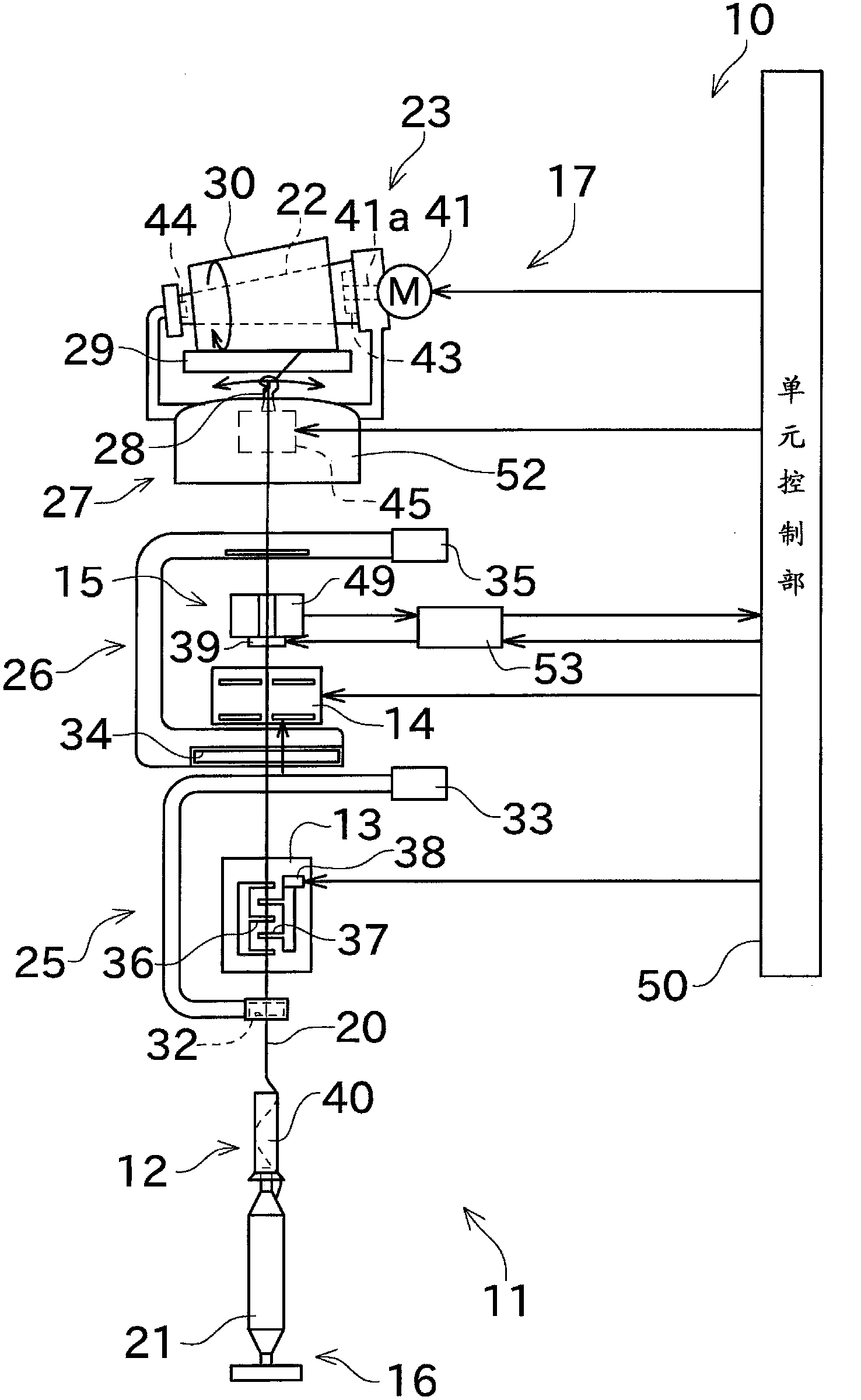

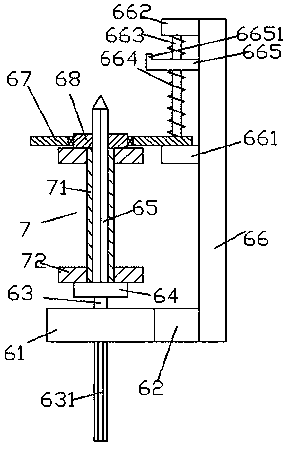

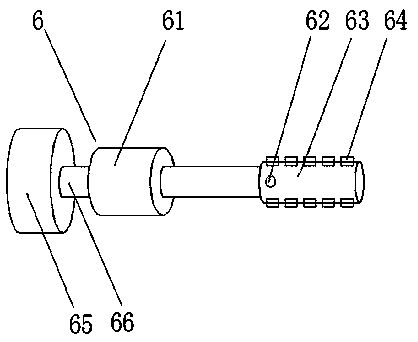

Cradle, winding unit, and yarn winding machine

A cradle includes a cradle main body, a larger-diameter side bobbin holding section, and a rotation preventing section. The larger-diameter side bobbin holding section is rotatably mounted on the cradle main body and adapted to hold a winding bobbin around which a yarn is wound. The larger-diameter side bobbin holding section includes a base member (70) and a contact member. The base member (70) is rotatably mounted on the cradle main body. The contact member is detachably mounted to the base member (70) by at least a portion of the contact member being elastically deformed, and adapted to hold the winding bobbin by making contact with the winding bobbin. The rotation preventing section is adapted to present relative rotation of the contact member with respect to the base member (70).

Owner:MURATA MASCH LTD

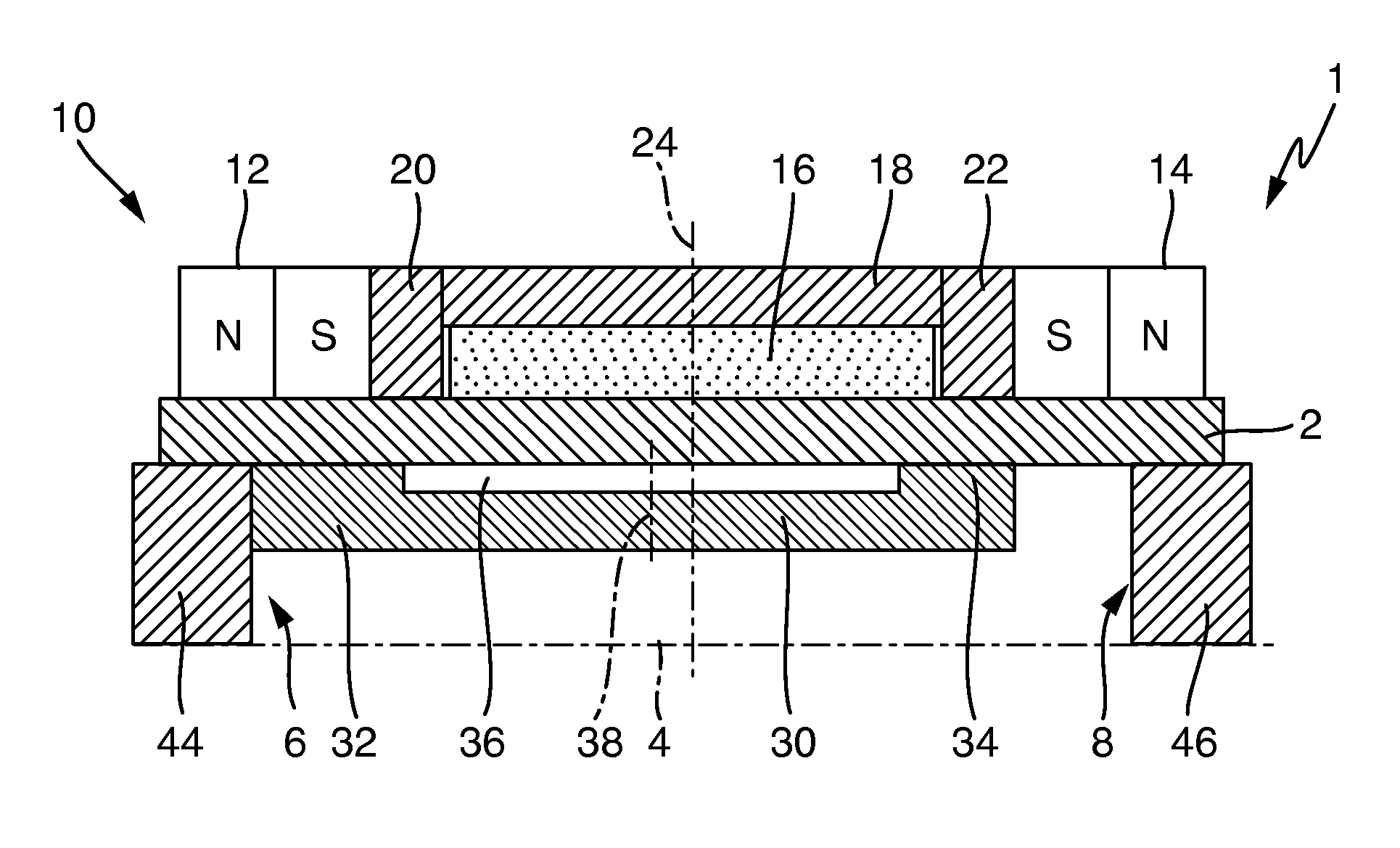

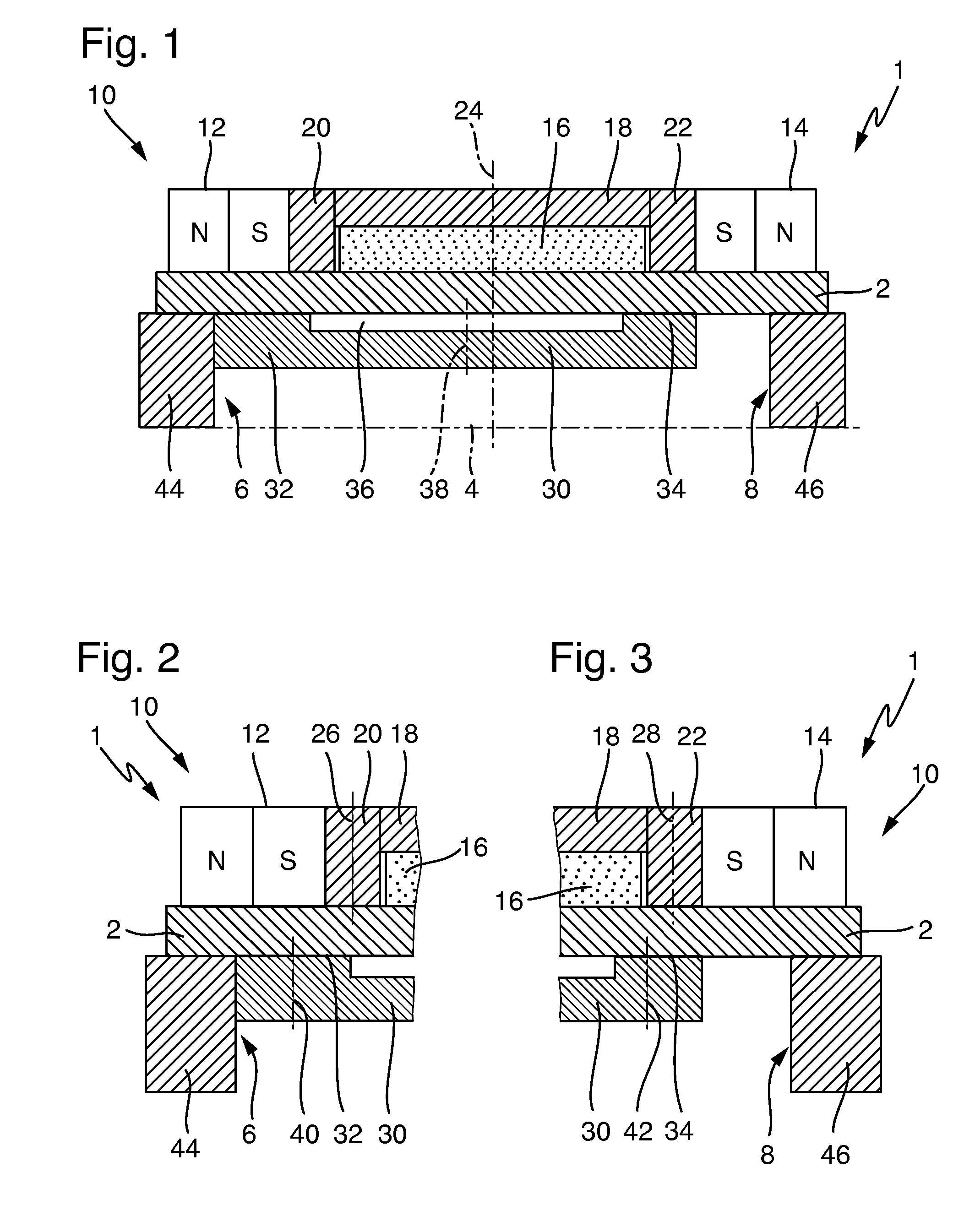

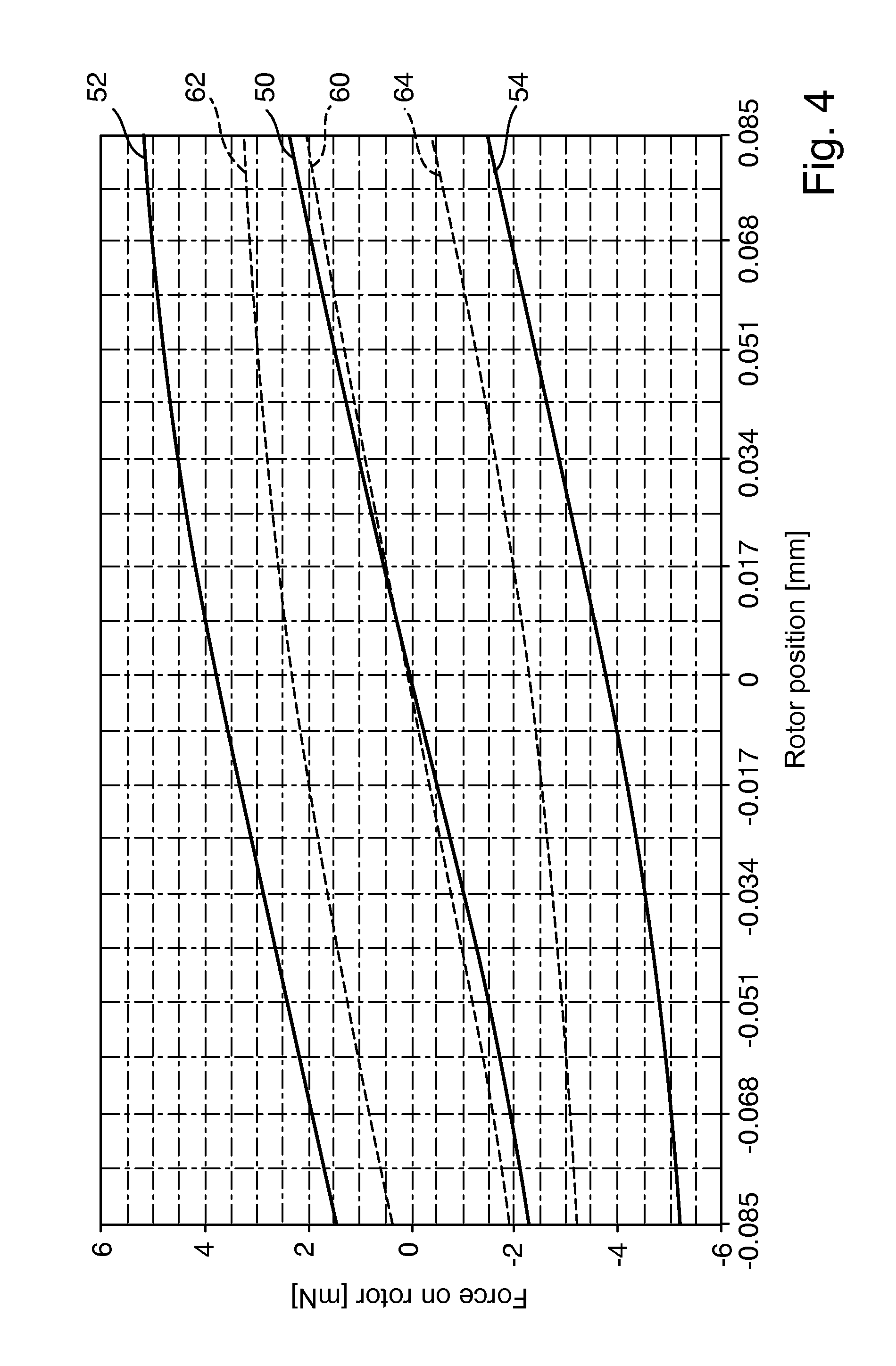

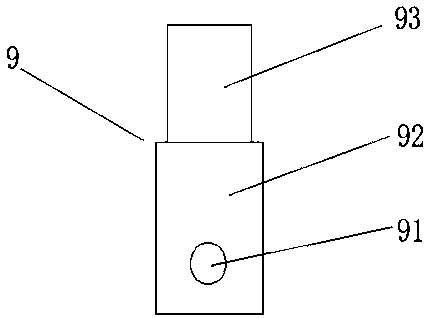

Bistable electromagnetic actuator and surgical instrument

InactiveUS20150340937A1Switching force can be increasedAdjust balanceMagnetsMagnetic circuit stationary partsEngineeringElectromagnetic actuator

A bistable electromagnetic actuator including: a tube; a stator arranged outside the tube, and a rotor mounted in the tube so as to be displaceable axially in the longitudinal direction, is the rotor being at least partially formed of one or more of a paramagnetic and ferromagnetic material, the rotor being reversibly moved between a first position and a second position by applying an electromagnetic field. Wherein the stator includes: two ring permanent magnets that are axially polarized in opposite directions, a coil for generating the electromagnetic field, and a magnetic return element having two stator pole shoes. Wherein, the magnetic return element with the stator pole shoes encloses the coil, one of the stator pole shoes is arranged on each of two sides of the coil between the coil and ring permanent magnets, the rotor has two rotor pole shoes, and an axial width of the stator pole shoes is smaller than an axial width of the rotor pole shoes.

Owner:OLYMPUS WINTER & IBE

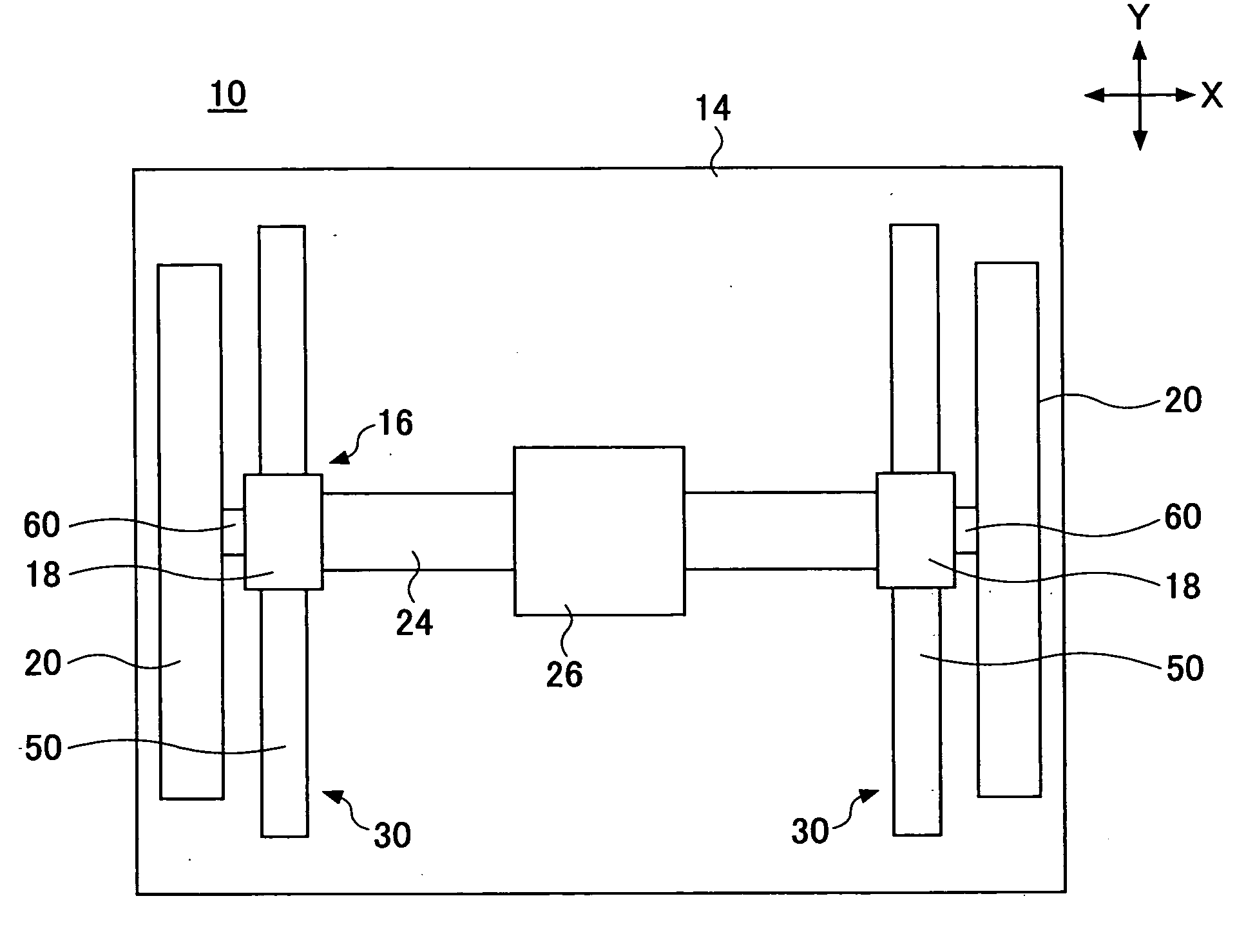

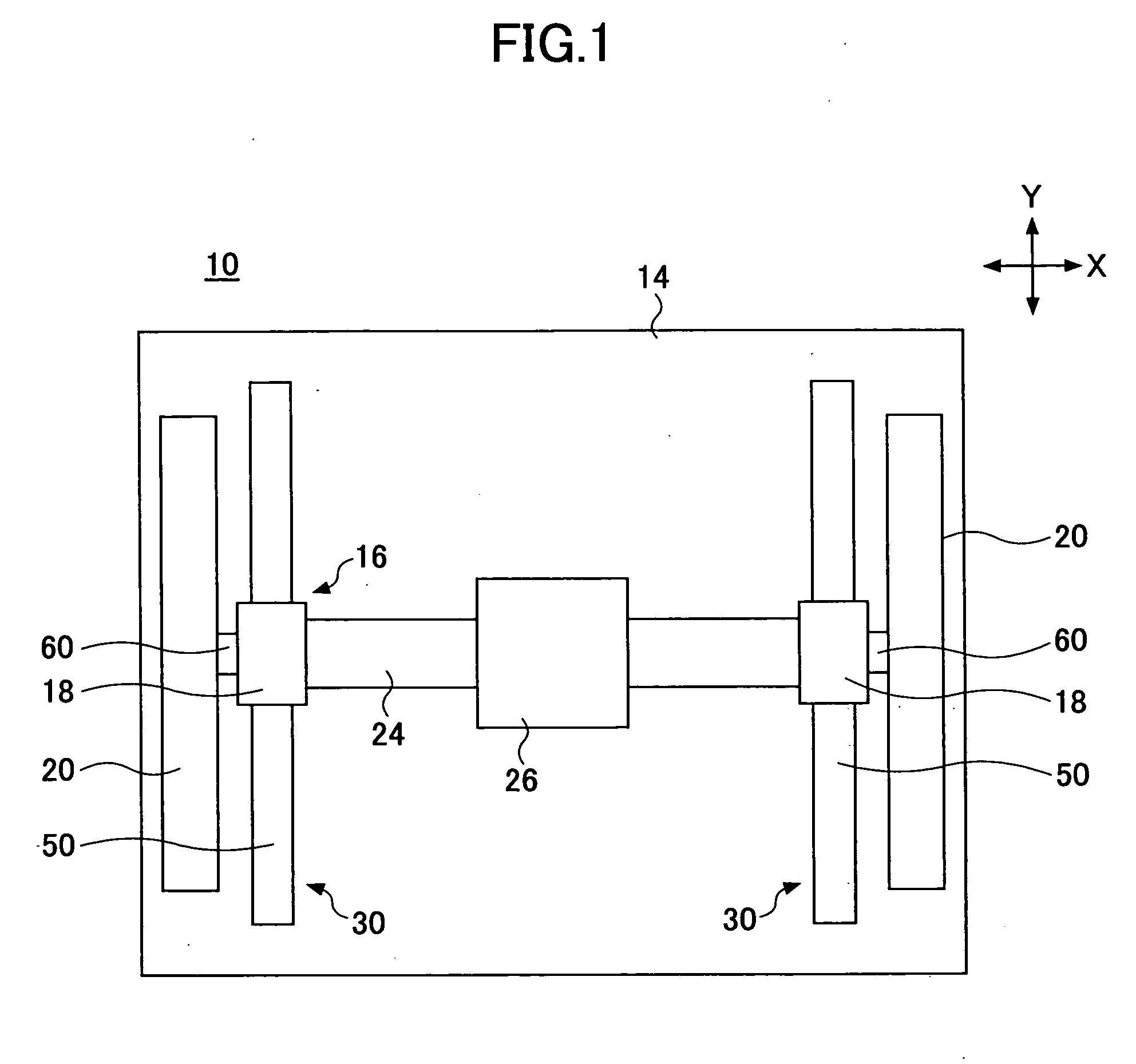

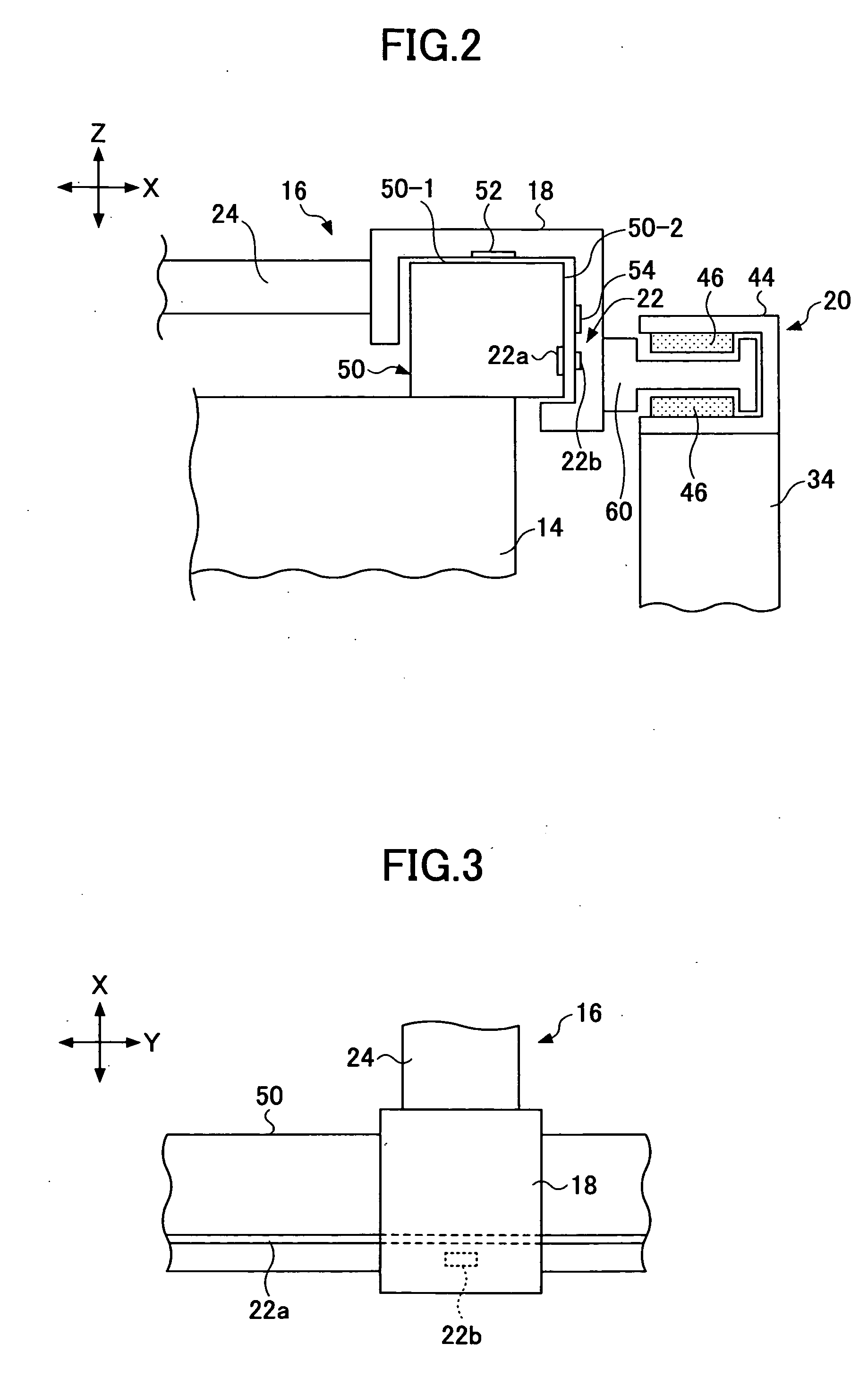

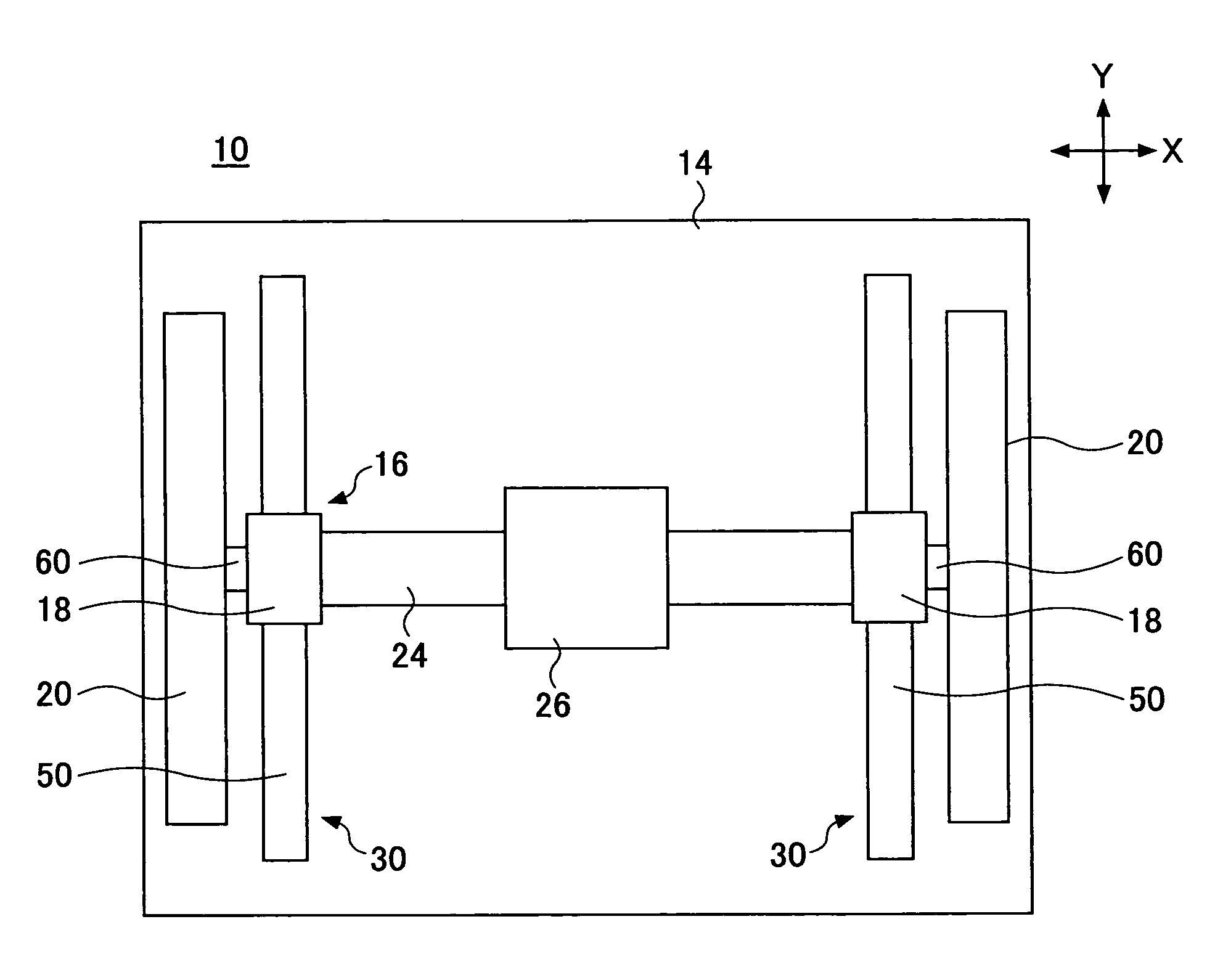

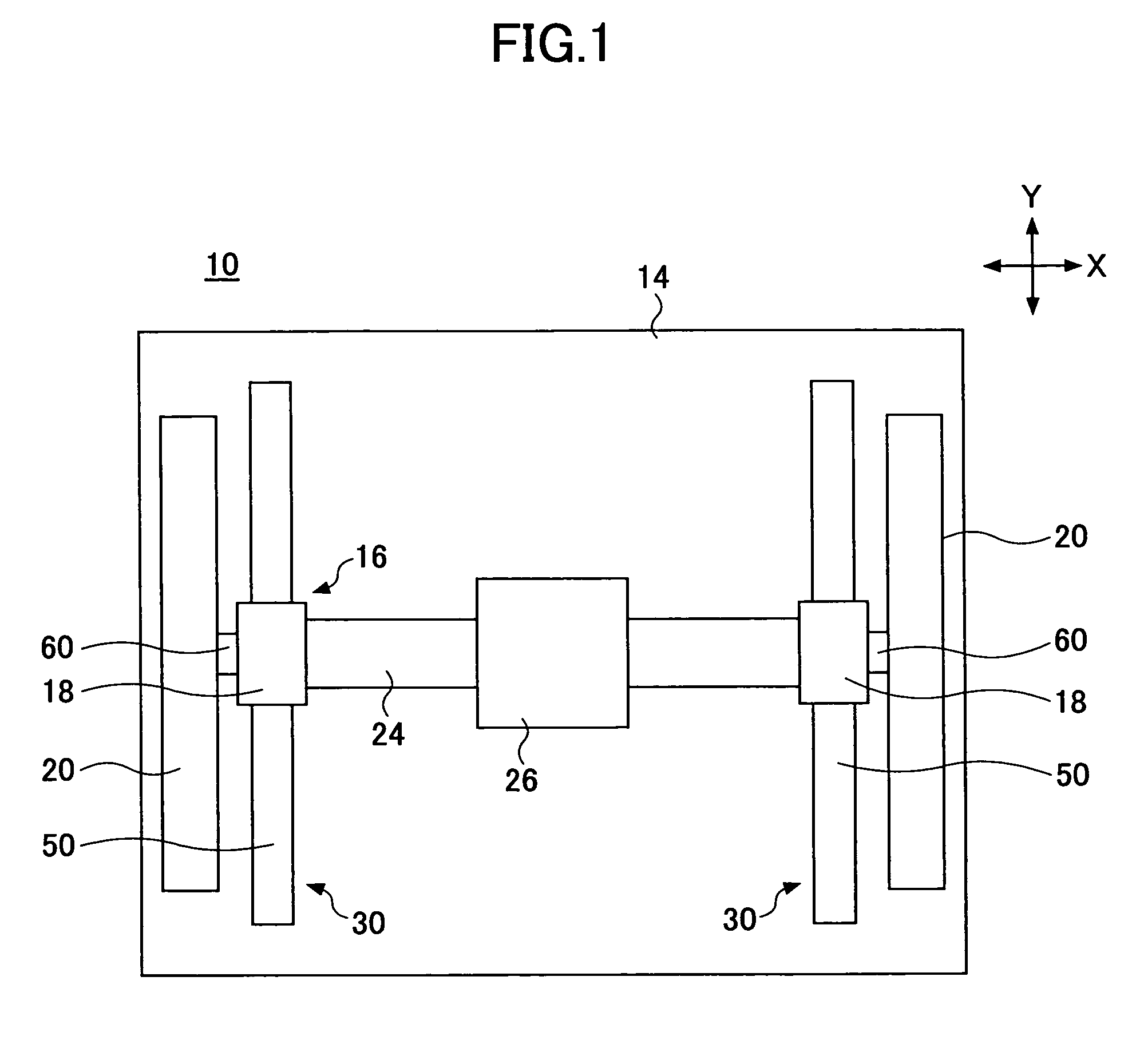

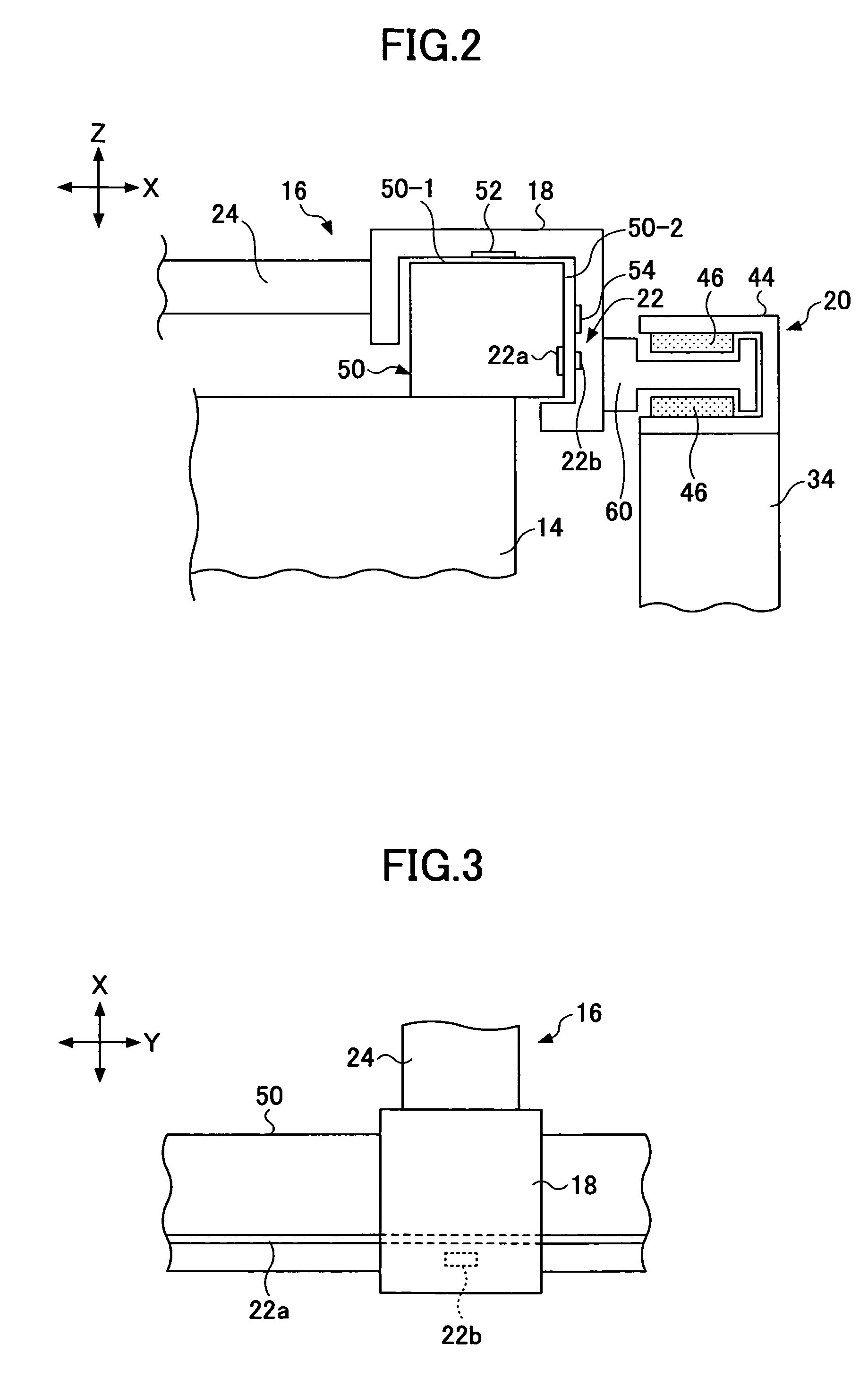

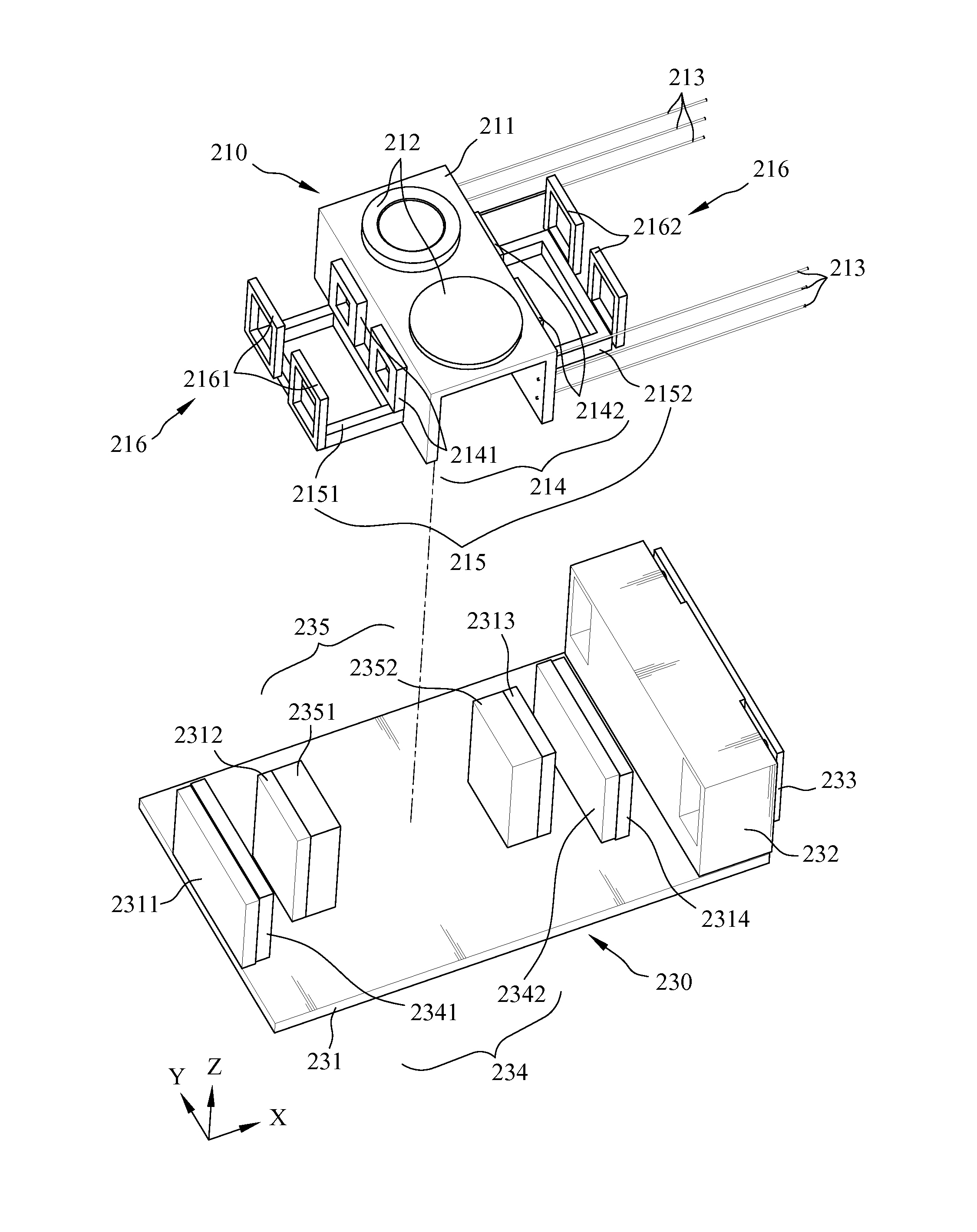

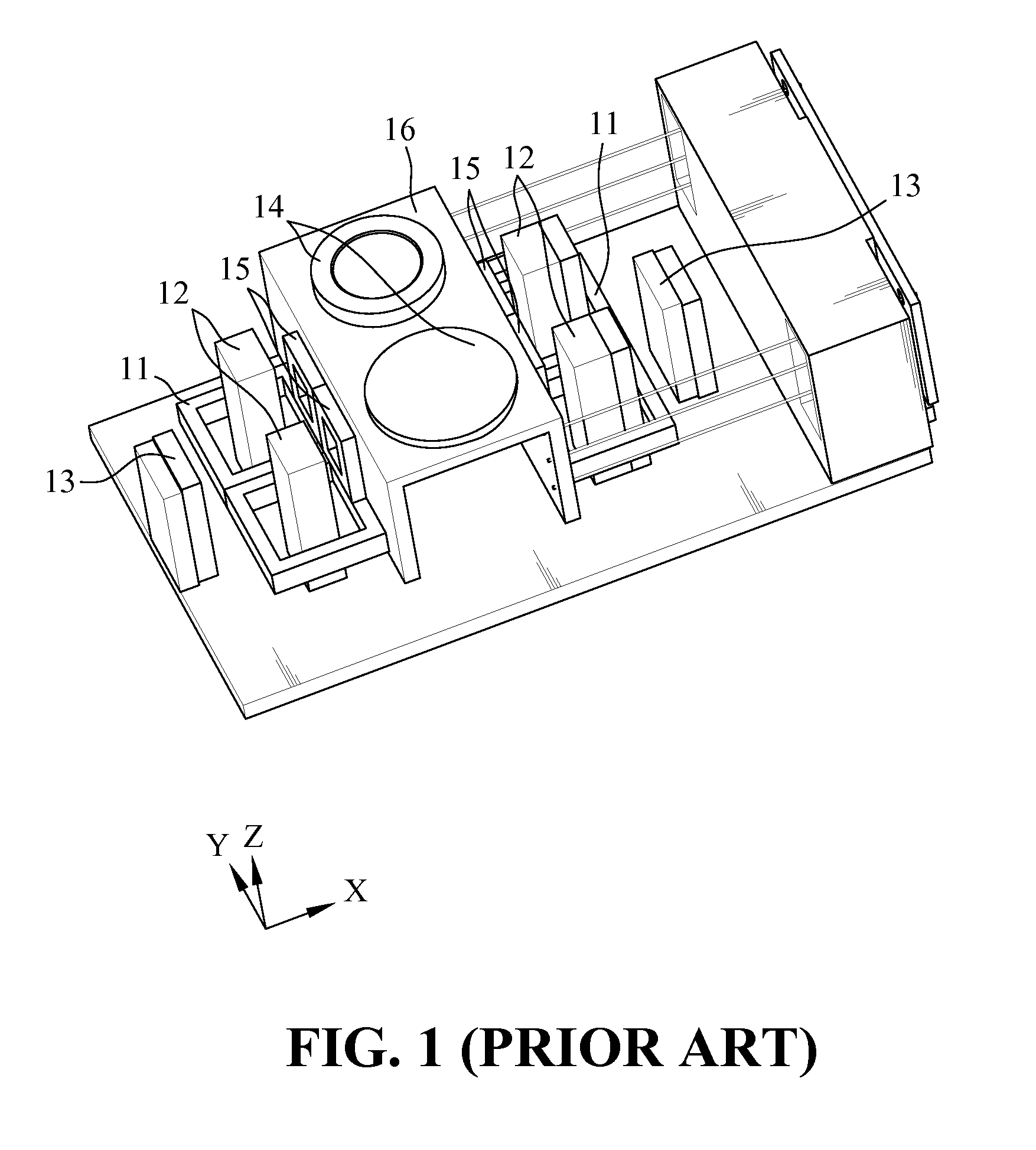

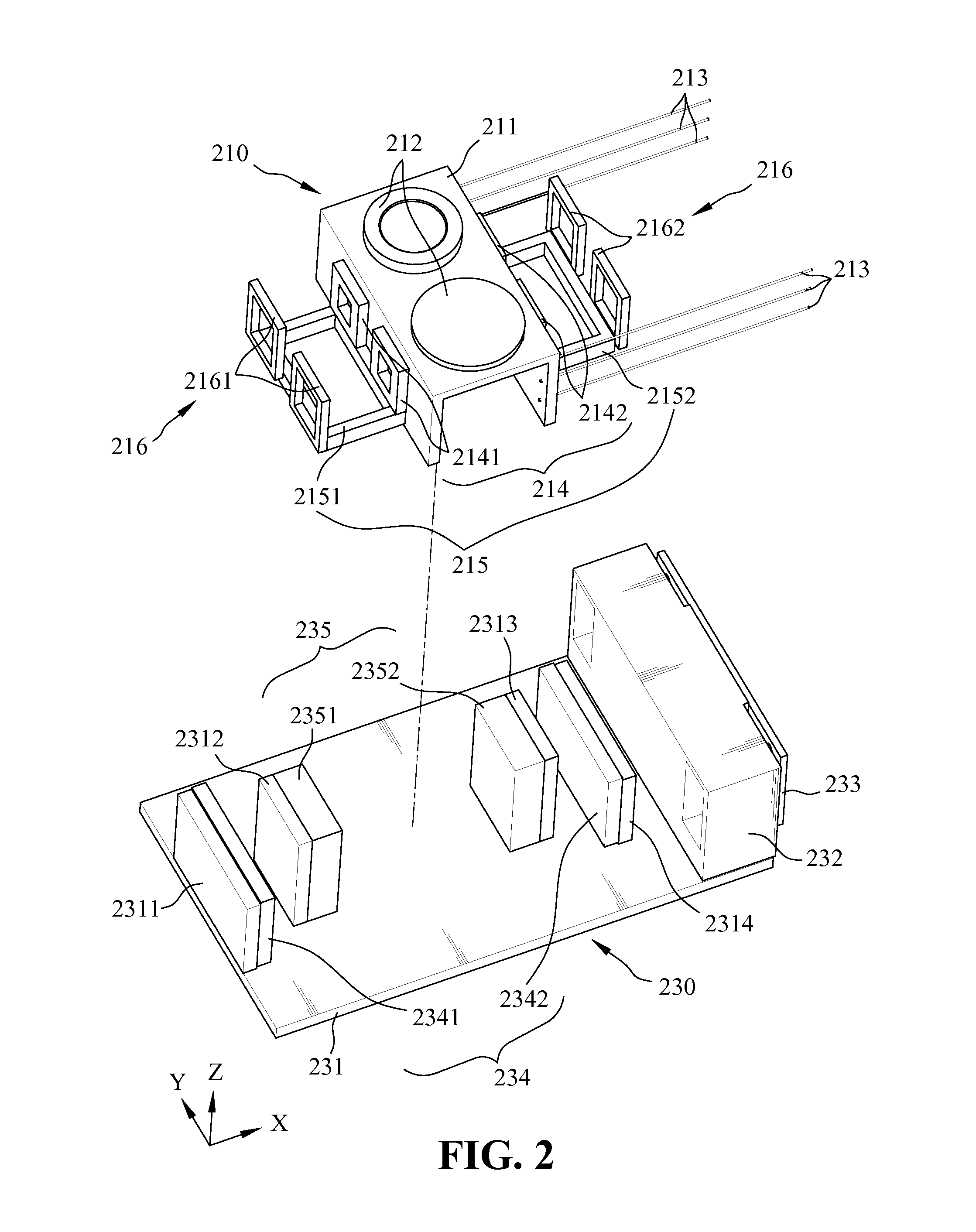

Linear motor and stage device using the linear motor

InactiveUS20070056958A1Improve coiling efficiencyImprove cooling efficiencyPropulsion systemsInduction heating apparatusEngineeringLinear motor

A linear motor can include a coil part having a plurality of coils forming a coil line; a magnet yoke part having a plurality of permanent magnets facing the coil line; and a coil cooling part configured to cool the coil part. The coil cooling part can include a cooling panel having a heat conductive element, the heat conductive element transferring heat of the coil part to an outside; and a heat radiation part connected to the cooling panel, the heat radiation part being configured to radiate the heat transferred from the heat conductive element to the outside.

Owner:SUMITOMO HEAVY IND LTD

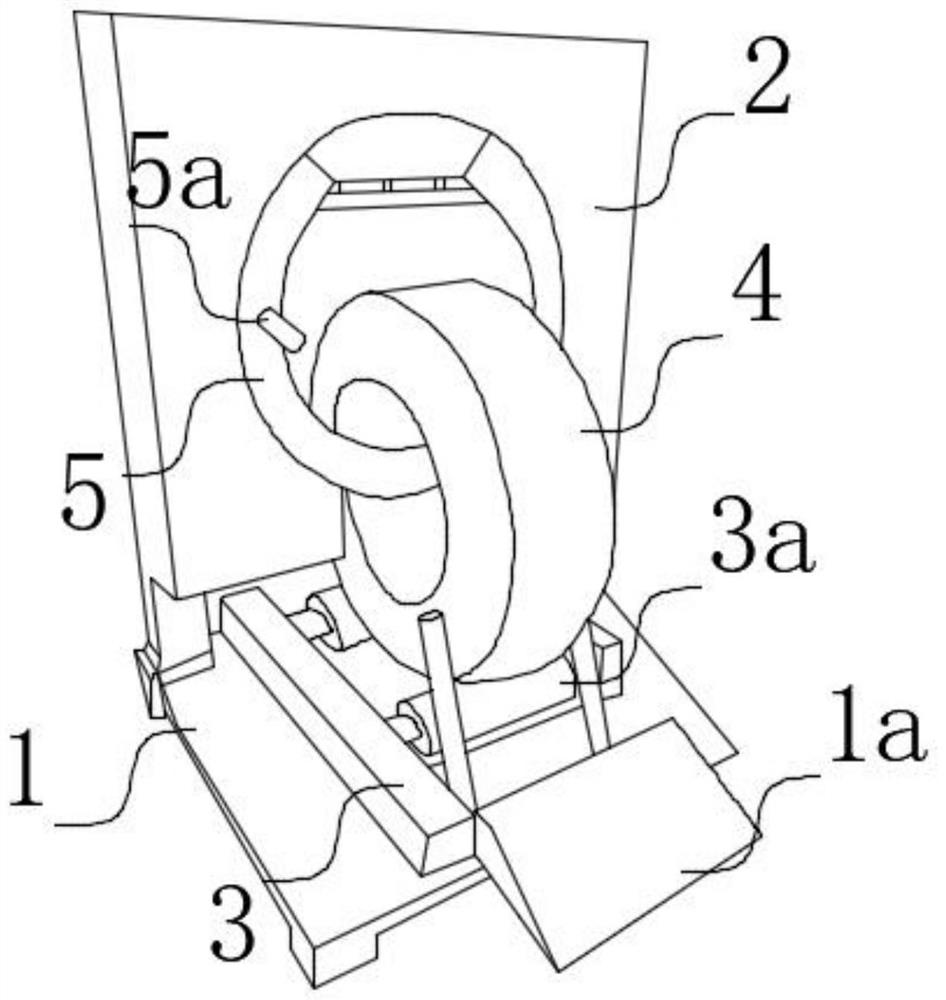

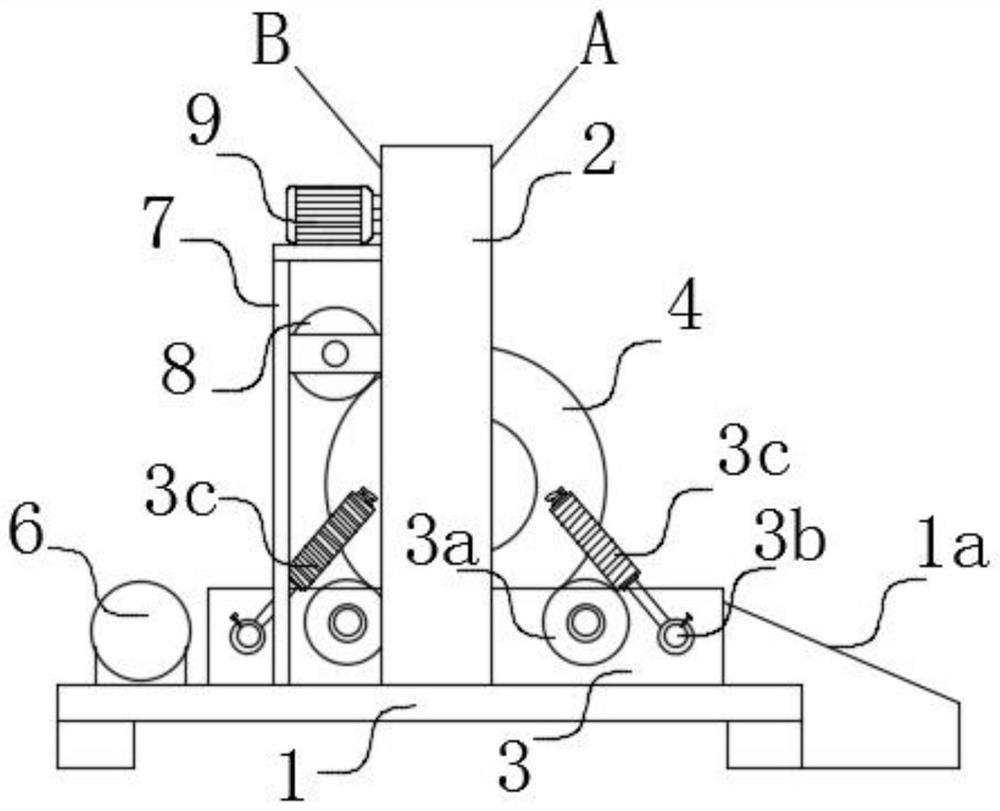

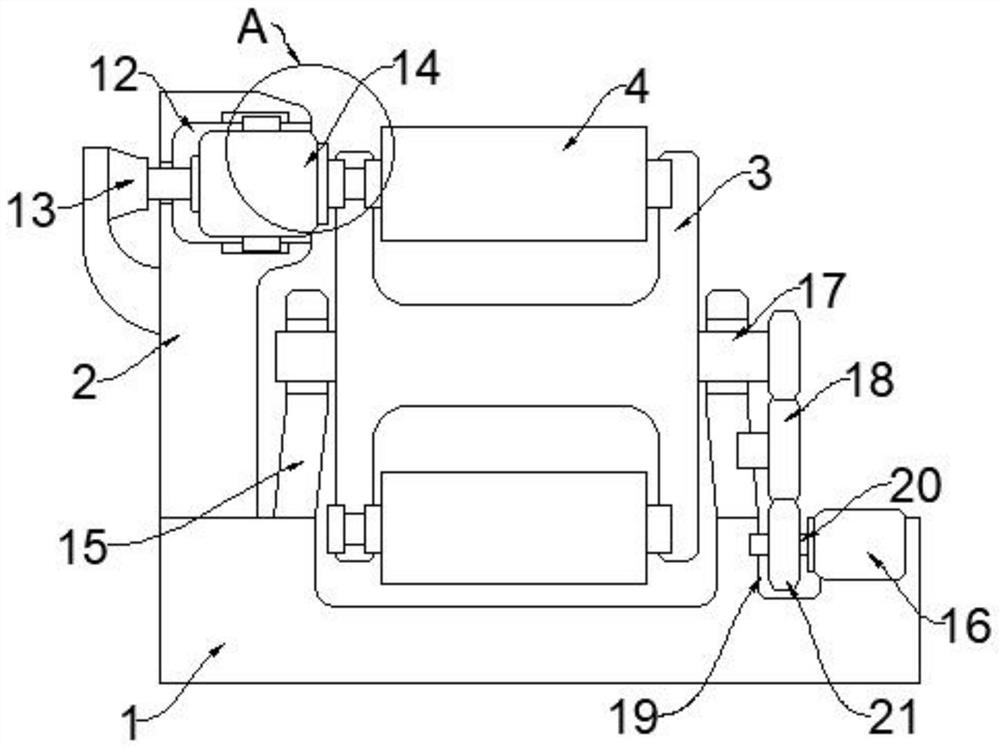

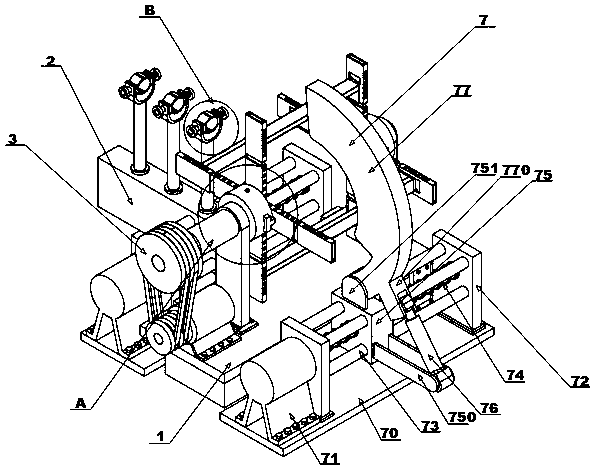

Automatic packaging device for pipe coils

PendingCN112046830AAutorotation speed stabilization controlUniform tightnessWrapping material feeding apparatusWrapping with article rotationStructural engineeringMechanical engineering

The invention discloses an automatic packaging device for pipe coils. The automatic packaging device comprises a base bottom plate, two parallel rotary fixing bases, two containing rotary rollers, coiling door frame, an annular fixing base and a winding sliding ring, wherein the two parallel rotary fixing bases are fixed to the base bottom plate, the two placement rotary rollers arranged on the rotary fixing bases and used for placing the pipe coils, the coiling door frame is arranged on the base bottom plate and stretching across the two rotary fixing bases, the annular fixing base is arranged on the coiling door frame and used for coiling and packaging the pipe coils, and the winding sliding ring is installed on the annular fixing base in a limited mode. According to the automatic packaging device for the pipe coils, the placement rotating rollers used for driving the pipe coils to rotate in a limited mode are installed on the base bottom plate, in addition, the pipe coils are coiledand packaged through the annular fixing base and the winding sliding ring which stretch across the coiling door frame of the pipe coils and a coiling belt installation shaft and a coiling guide rod which are arranged on the winding sliding ring, therefore, the coiling efficiency is improved, manpower is saved, the rotating speed of the coiling belt installation shaft and the autorotation speed ofthe pipe coils can be stably controlled, so that the tightness of the pipe coils is more balanced, and the product quality is guaranteed.

Owner:TIANJIN ZHONGCAI PROFILES

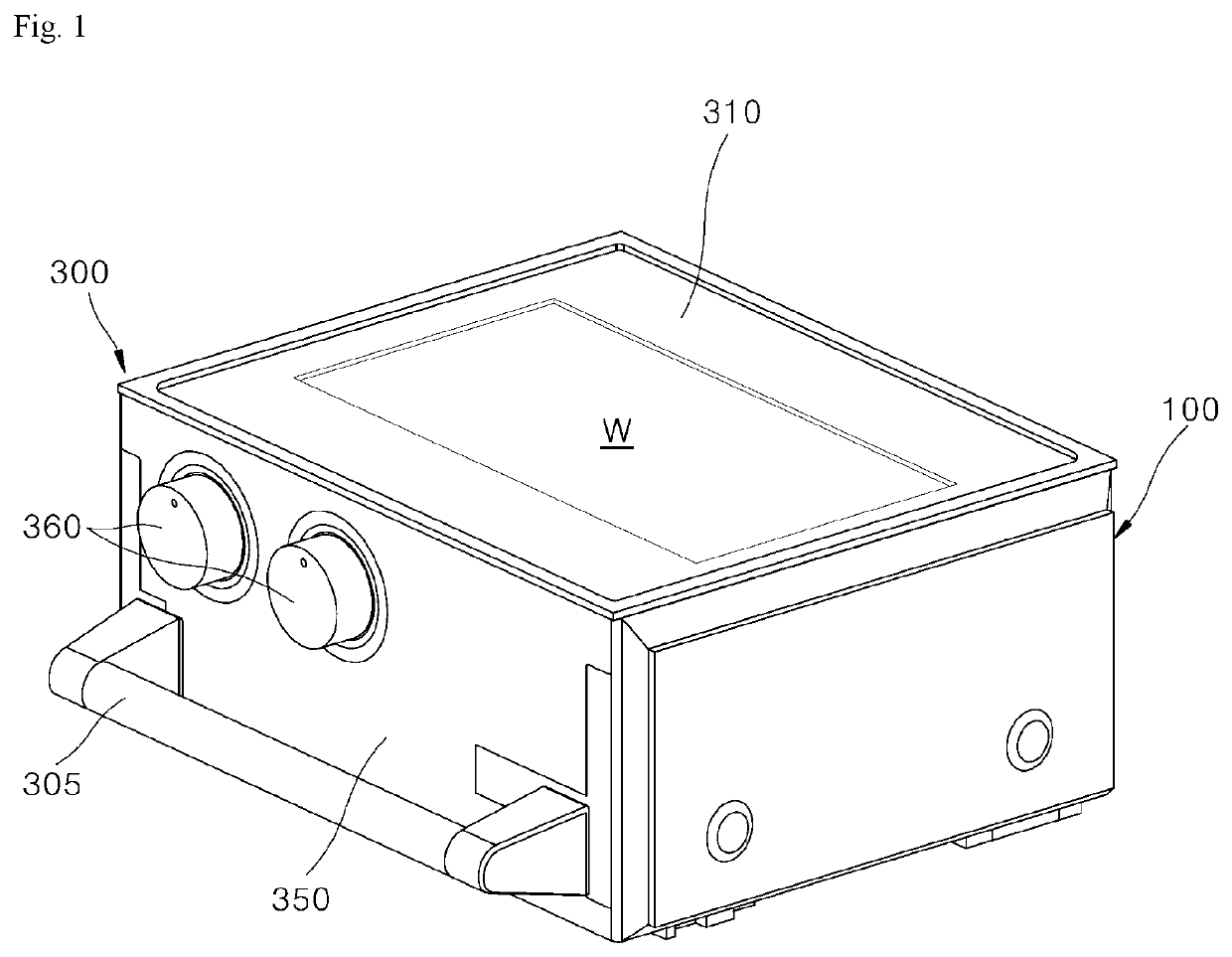

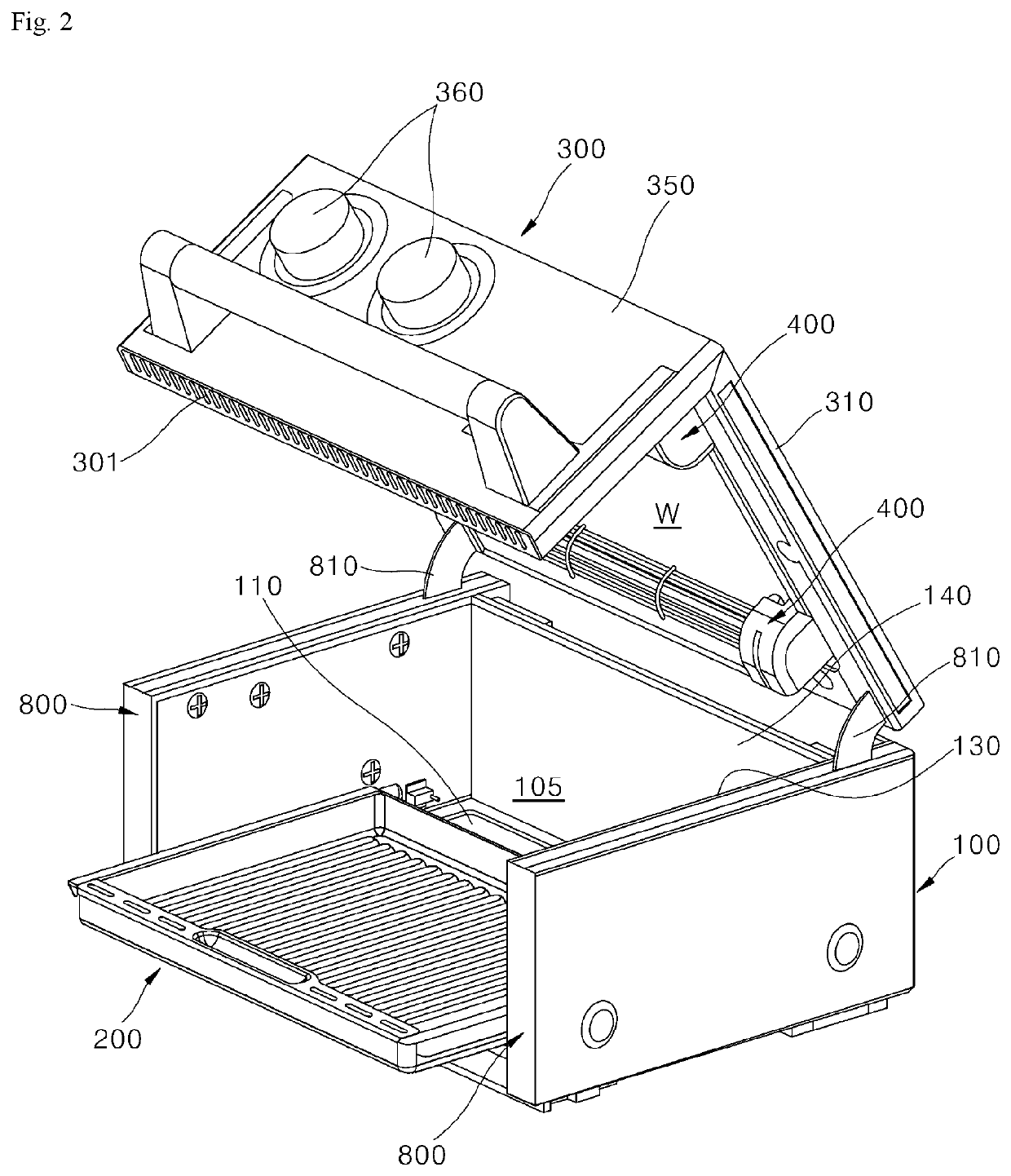

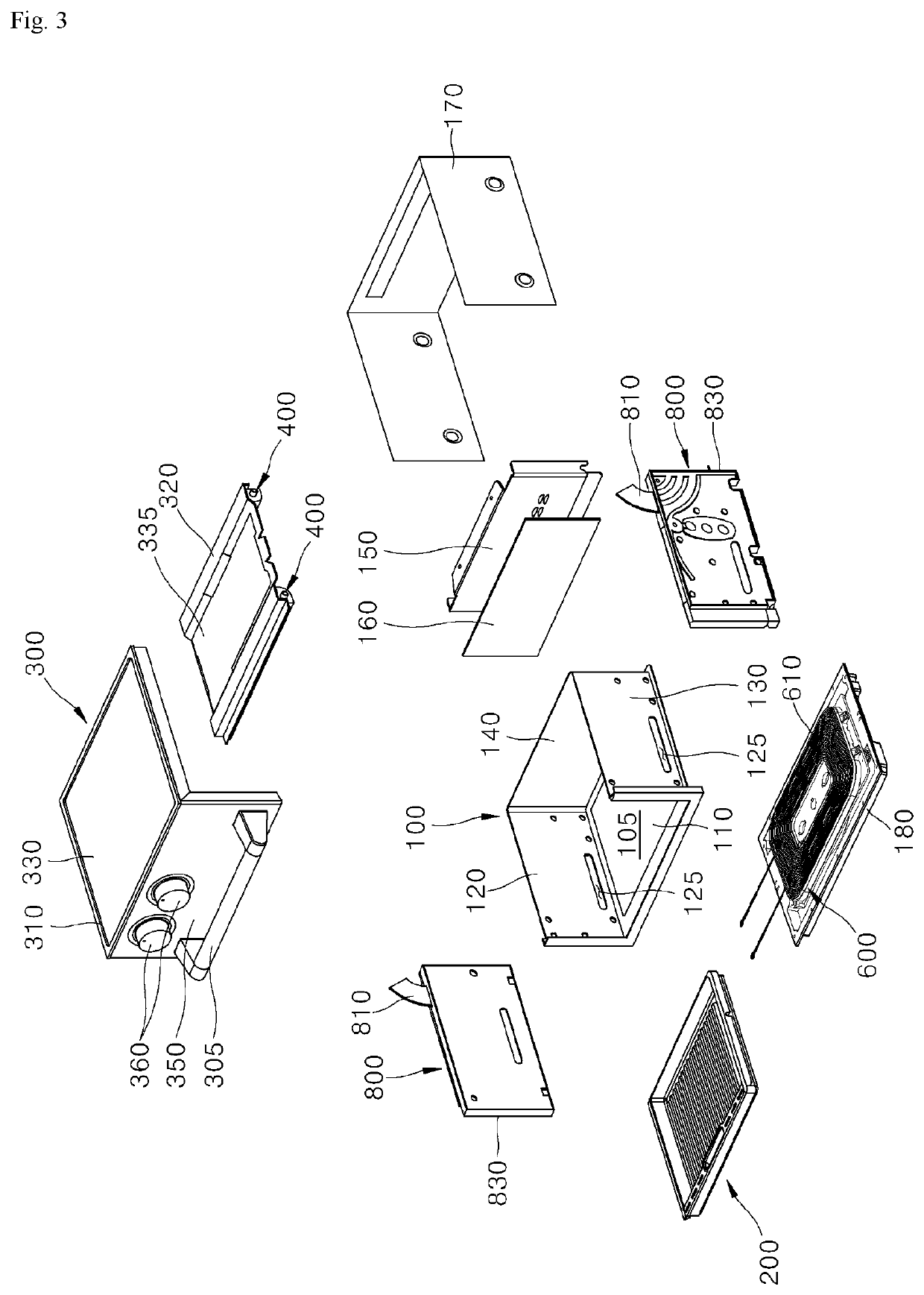

Cooking applicance

ActiveUS20200229276A1Easy to changeIncrease in sizeDomestic stoves or rangesLighting and heating apparatusEngineeringReceiver coil

Disclosed herein is a cooking appliance. A working coil is provided at a lower portion of the cooking appliance. The working coil heats a tray disposed in a cooking compartment in an IH mode. A receiver coil wirelessly receiving external power is stacked below the working coil. An electromagnetic shielding plate is installed between the working coil and the receiver coil to partition a space in which the two coils are installed. The electromagnetic shielding plate shields an electromagnetic field or electromagnetic waves such that the electromagnetic field or electromagnetic waves in one of the two partitioned spaces does not leak to the other space located across the electromagnetic shielding plate.

Owner:LG ELECTRONICS INC

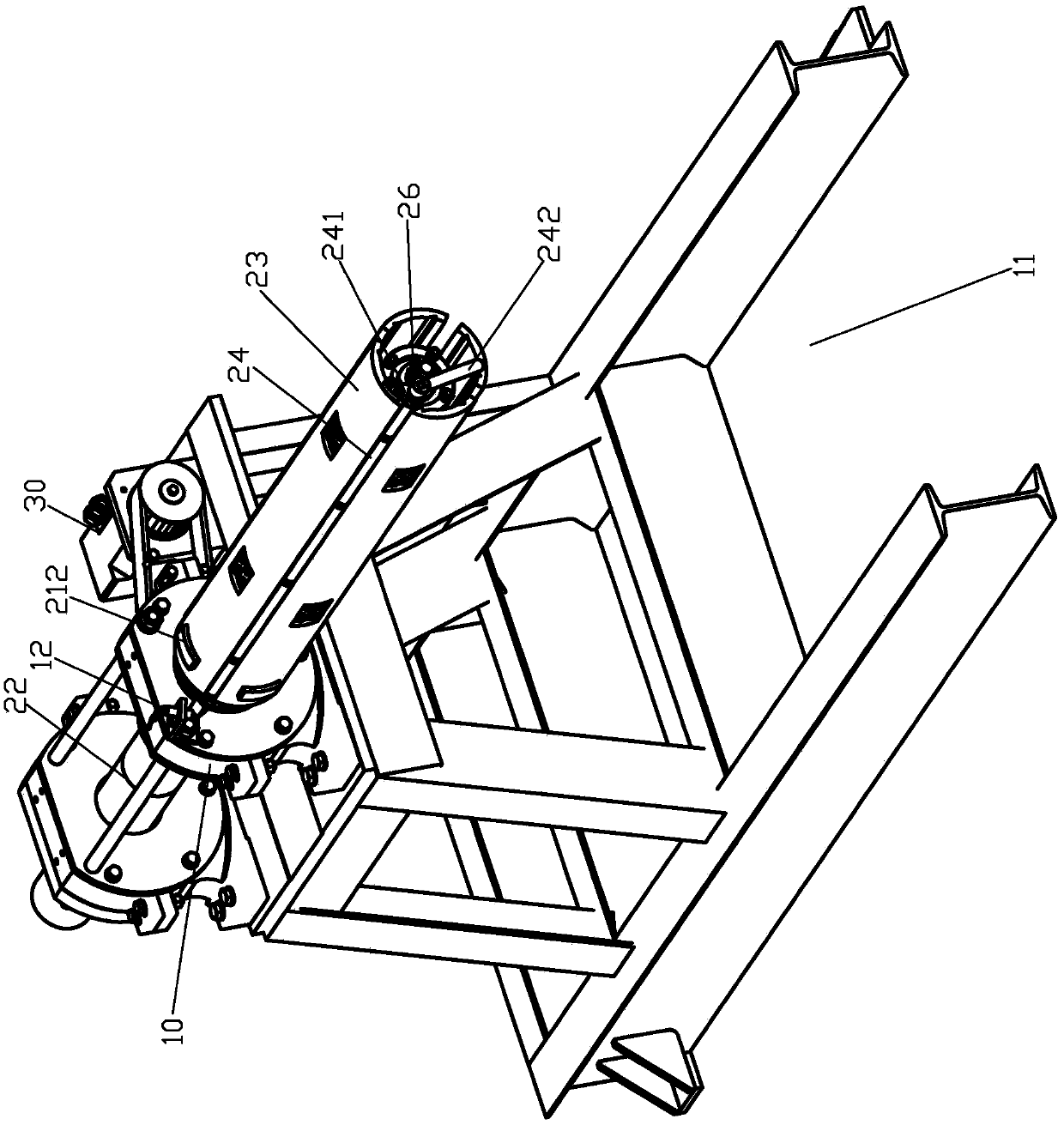

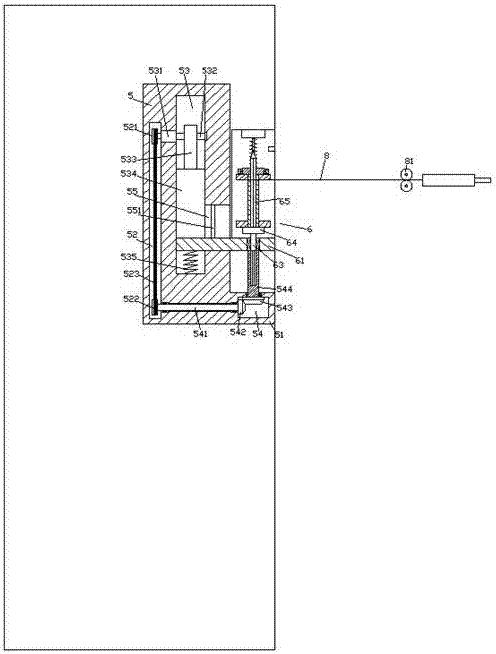

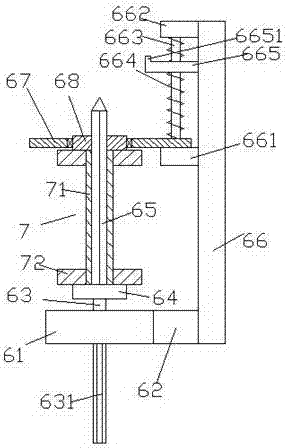

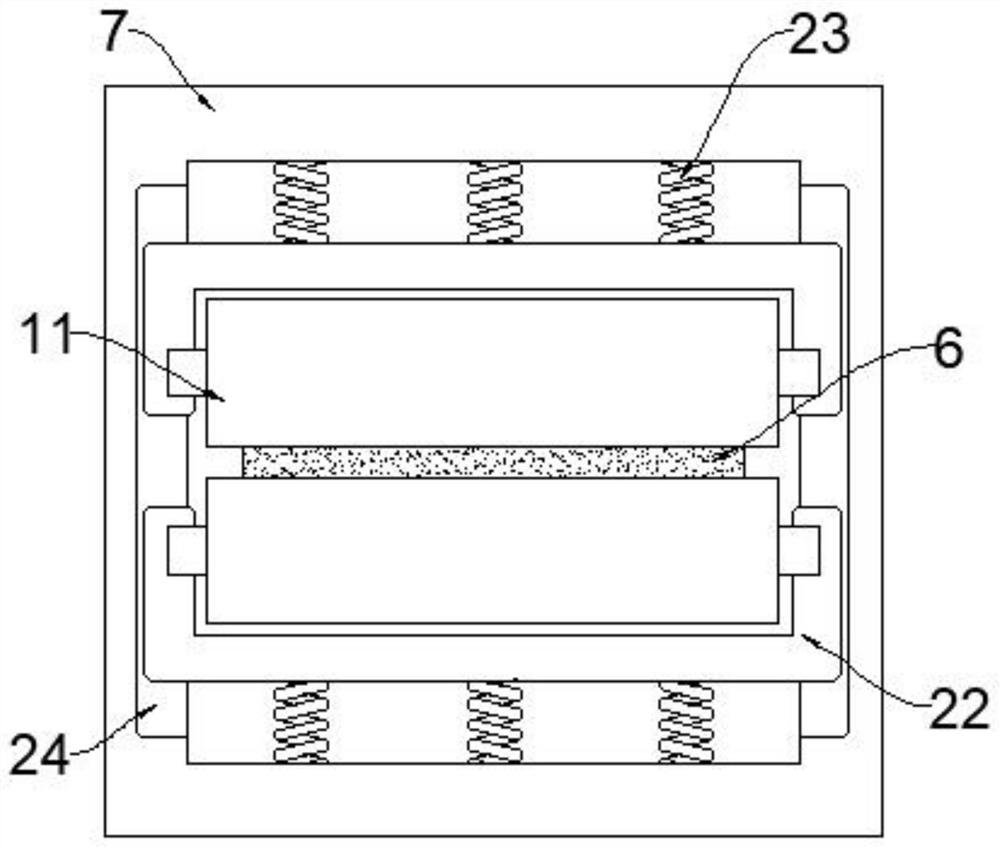

Automatic reeling equipment

PendingCN109250553ASimple structureCompact and reasonable layoutWebs handlingEngineeringSheet material

The invention discloses automatic reeling equipment, comprising a reeling mechanism and a first driver. The reeling mechanism comprises a rotation unit, a second driver and a material-end clamping mechanism; the rotation unit comprises a plurality of moving units capable of doing radial movement relative to the rotation axis of the rotation unit; the first driver is in drive connection with the rotation unit to drive the same to rotate to reel a sheet material automatically, thereby improving reeling efficiency and uniformity while reducing labor cost. The material-end clamping mechanism comprises clamping units capable of moving between a clamping position and a loosening position relative to the moving units; the clamping units at the clamping position are matched with the moving units to clamp a sheet material end, and the clamping units at the loosening position can release the clamping, thereby facilitating clamping of the material end and removing the inconvenience in moving thematerial end manually.

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

Linear motor and stage device using the linear motor

InactiveUS7462959B2Improve coiling efficiencyImprove cooling efficiencyPropulsion systemsInduction heating apparatusLinear motorMagnet

Owner:SUMITOMO HEAVY IND LTD

Charging pile

InactiveCN108068645AWork fasterEasy maintenanceCharging stationsElectric vehicle charging technologyAutomatic controlWall plate

Owner:CIXI QICHENG MACHINERY TECH CO LTD

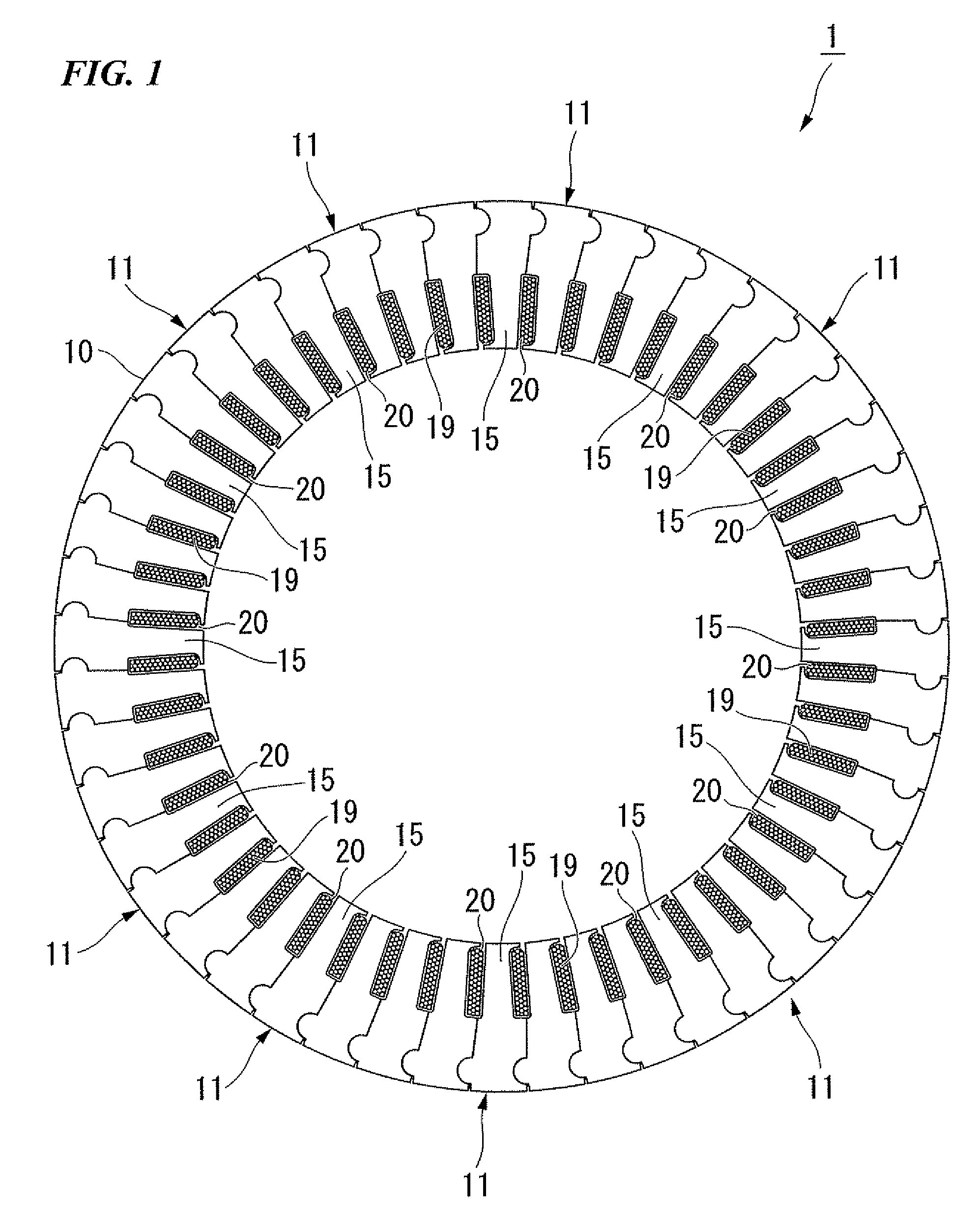

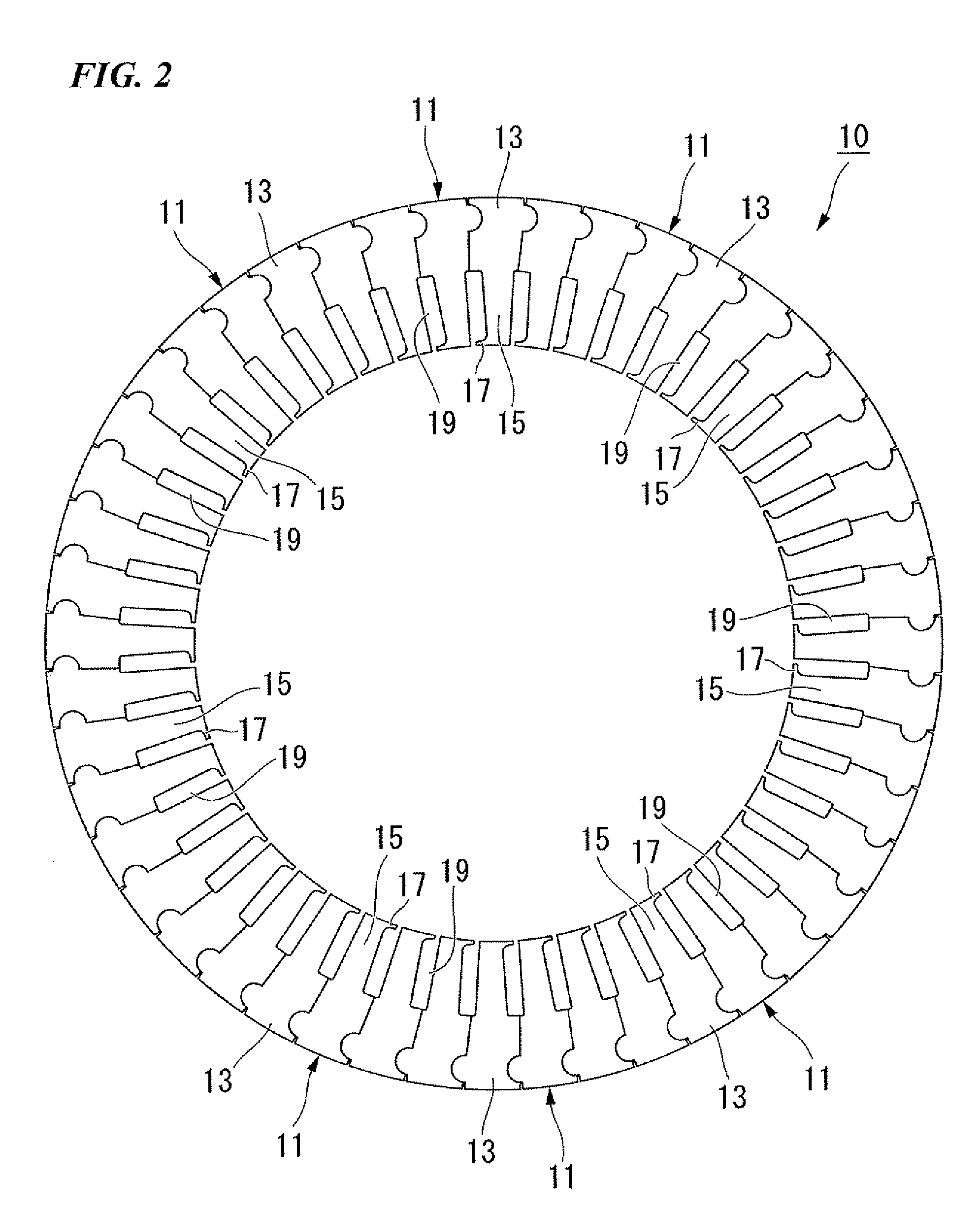

Motor with stator configuration for increased coil length and coil space factors

InactiveUS8258669B2Increase spacingReduce the amount requiredMagnetic circuit rotating partsSynchronous machinesLoop lengthThree-phase

A motor including a stator and rotor. The stator includes a stator core, slot portions and coils. The stator core includes stator core pieces with teeth portion having a distal end portion and two side portions, a yoke portion, and a claw portion formed at one of the two side portions. At the distal end portion, the stator core pieces are connected so that claw portions protrude in the same circumferential direction to form the stator core into a cylindrical shape. The slot portions are formed between adjacent teeth portions and between the stator core pieces. The coils form three phases which are inserted into the slot portions, are bridged between two of the slot portions and include end portions that protrude from an edge face of the stator core in an axial direction. The coils are arranged so that the end portions are intersected with each other.

Owner:HONDA MOTOR CO LTD

Movable high voltage cable binding device

The invention discloses a movable high voltage cable binding device. The binding device comprises a first supporting seat, an anti-deflection supporting roller, a second supporting seat, a second L-shaped steel frame, a winding and placing device, a pneumatic telescopic table, a first L-shaped steel frame, rolling wheels and a motor; the left lower end of the first supporting seat is fixedly connected with the first L-shaped steel frame, and the left lower end of the second supporting seat is fixedly connected with the second L-shaped steel frame; the middle of a connecting cross rod is fixedly connected with the lower end of the pneumatic telescopic table, and one side of the upper end of the first supporting seat is fixedly connected with the winding and placing device; one side of the upper end of the second L-shaped steel frame is fixedly connected with the winding and placing device, the transmission end of the motor is connected with a rotary roller through a transmission belt, and the rotary roller is fixedly connected with a bearing through a bearing block; and the middle of a rotating shaft is fixedly connected with the anti-deflection supporting roller, and the rolling wheels are arranged on the periphery of the lower end of a device body. The device has the beneficial effects of being high in winding efficiency, convenient and fast to use, capable of preventing deviation, and convenient and fast to move and use.

Owner:镇江亚昆机械有限公司

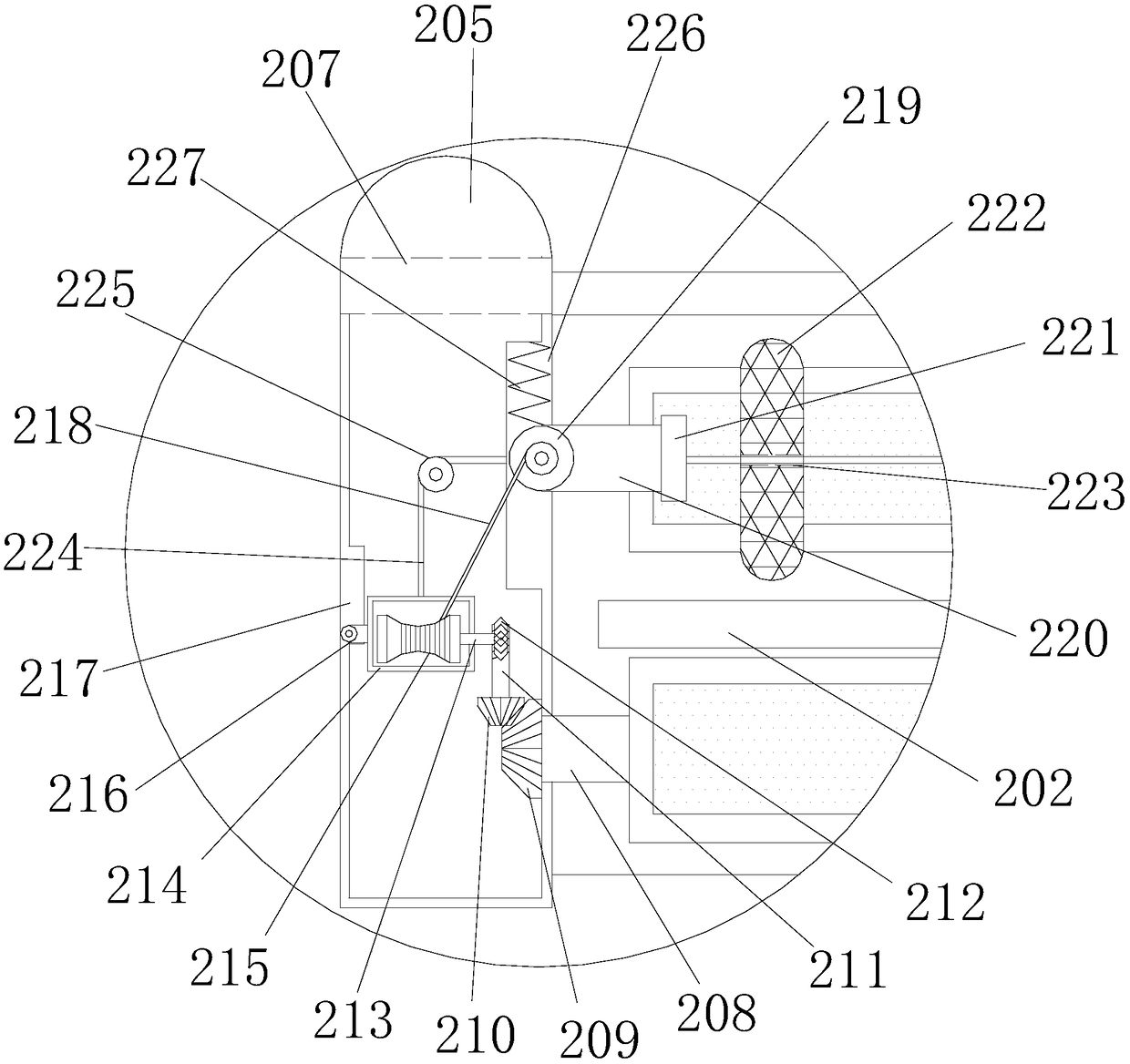

Fast new energy vehicle charging pile

InactiveCN108068644AWork fasterFast installation workCharging stationsElectric vehicle charging technologyAutomatic controlNew energy

The invention discloses a fast new energy vehicle charging pile. The fast new energy vehicle charging pile comprises a machine column and finishing wheels, wherein the machine column is arranged in the charging pile, and the finishing wheels are arranged on the right side of the machine column, and are arranged in a up and down mode with equal distance. The bottom of the right side of the machinecolumn is provided with a base platform. A charging wire coiling device is arranged above the base platform. The charging wire coiling device comprises a sliding joint plate, a middle block; a wall plate and a coiling seat, wherein the sliding joint plate is arranged in a left and right extending mode; the middle block is fixedly arranged on the back side of the sliding joint plate; the wall plateis fixedly arranged on the back side of the middle block, and is arranged in an upward extending mode; and the coiling seat is arranged above the sliding joint plate. The bottom of the coiling seat is fixedly provided with a first rotating rod. The bottom of the first rotating rod penetrates through the sliding joint plate, and is connected with the sliding joint plate in a rotating and matched mode. An external spline shaft is fixedly arranged on the bottom of the first rotating rod, and is arranged in a downward extending mode. A screw-shape rod is fixedly arranged on the top of the coilingseat. A first conversion cavity is formed in the base platform. An inner spline shaft is connected with the top wall of the first conversion cavity in a rotating and matched mode, and is arranged inan upward and downward extending mode. The fast new energy vehicle charging pile has simple structure; the automatic control towards up and down mobile charging line coiling work is achieved; the uniformity of the coiling of the charging wire is improved; the fast disassembly towards a reel is achieved; and the coiling stability of the charging line is improved.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

New energy automobile charging pile

The invention discloses a new energy automobile charging pile which comprises a column arranged inside the charging pile, and arrangement wheels arranged on the right side of the column in a vertically symmetric manner; a base platform is arranged at the bottom of the right side surface of the column; a charging line winding device is arranged above the base platform; the charging line winding device comprises a sliding connection plate arranged in a left and right extending manner, a middle block fixed to the rear side of the sliding connection plate, a wall plate being fixed to the rear side of the middle block and extending upwards, and a winding seat arranged above the sliding connection plate; a first rotating rod is fixedly arranged at the bottom of the winding seat; the bottom of the first rotating rod perpetrates through the sliding connection plate and is connected with the sliding connection plate in a rotary matching manner; an external spline shaft extending downwards is fixedly arranged at the bottom of the first rotating rod; a spiral rod is fixedly arranged at the top of the winding seat; a first conversion cavity is formed in the base platform; and an internal spline shaft extending towards the upper side and the lower side is connected with the inner top wall of the first conversion cavity in a rotary matching manner. The new energy automobile charging pile is simple in structure, automatic control on winding work of an up-down moving charging line is realized, the charging line winding uniformity is improved, rapid disassembly and assembly of a reel are realized, and the charging line winding stability is improved.

Owner:ANHUI DYNAMIC POWER

Automatic steel belt coiling and packing device

ActiveCN114570785ANo manual operationHigh degree of automationFinal product manufactureArticle deliveryWinding machineAdhesive belt

The invention relates to the technical field of steel belt machining, in particular to an automatic steel belt winding and packing device which comprises a winding rack, a swing arm, an adhesive tape pasting mechanism installed at the free end of the swing arm, a winding head and a hydraulic linkage clamping mechanism installed on the winding head. A swing arm driving motor is fixedly installed on the winding machine frame, an output shaft of the swing arm driving motor is fixedly connected with one end of a swing arm, and the swing arm driving motor drives the swing arm to swing. A first-stage steel belt guide wheel, a steel belt shearing mechanism, a second-stage steel belt guide wheel, an adhesive tape pasting mechanism and a steel belt pressing roller are sequentially mounted on the swing arm from the fixed end to the free end. The adhesive tape pasting mechanism is additionally arranged on the swing arm of the device, the adhesive tape can be automatically pasted on the steel strip coil when each steel strip coil is coiled, the device can sense the steel strip head, automatically clamp the steel strip head when the coil head expands, and automatically loosen the steel strip head when the coil head contracts after coiling and adhesive tape pasting are completed, and the automation degree and the operation safety are improved.

Owner:JIANGSU JU HONG BUNDLE BRING MFG

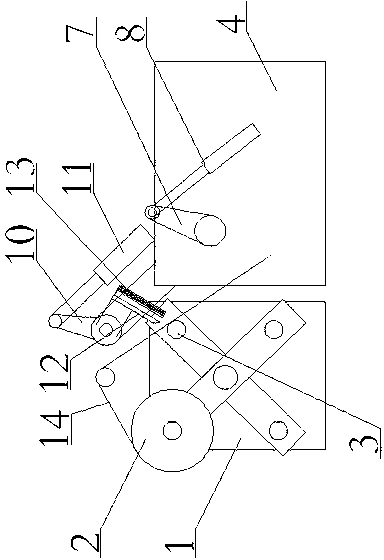

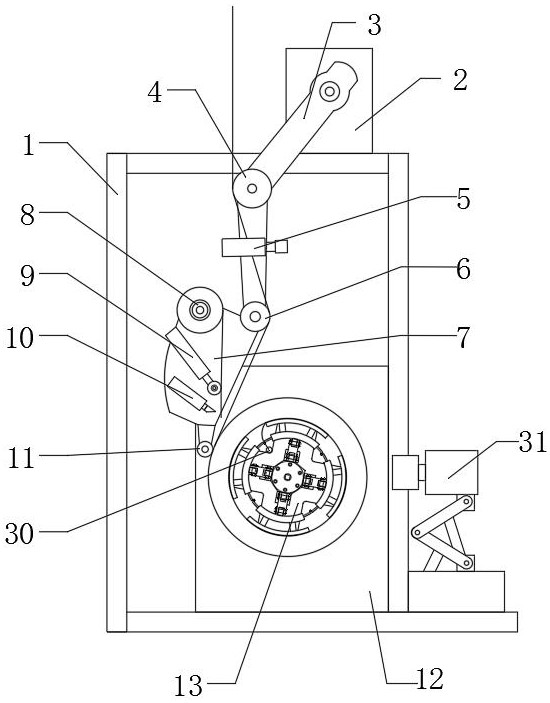

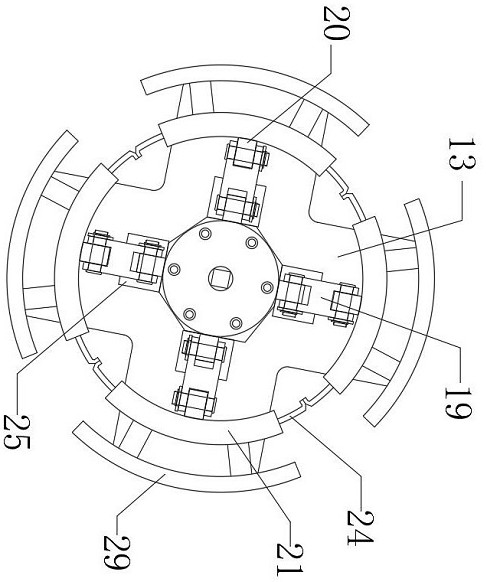

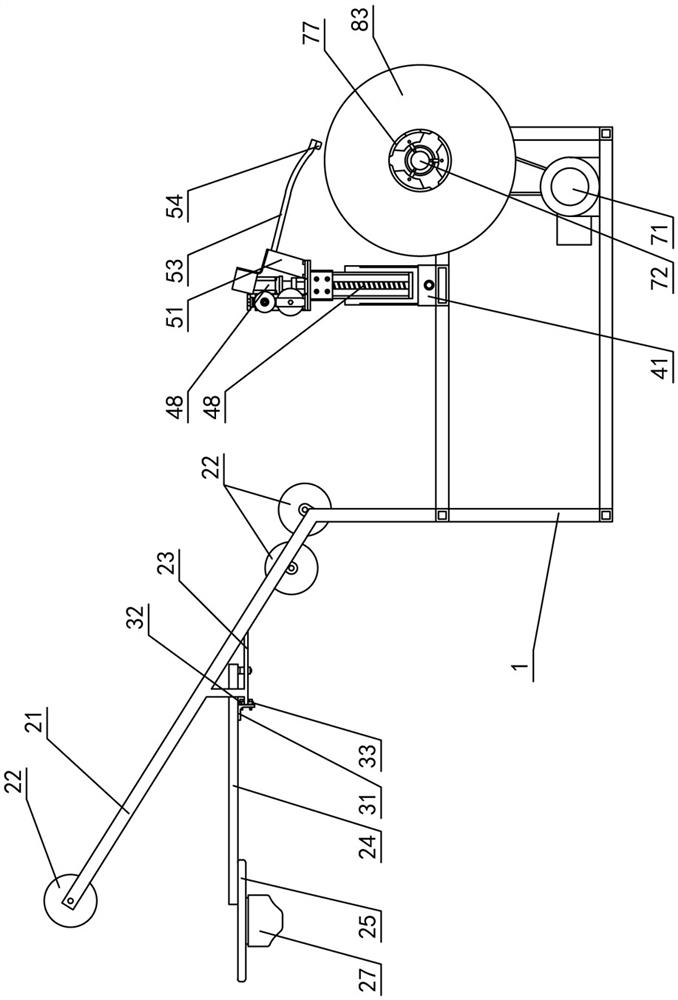

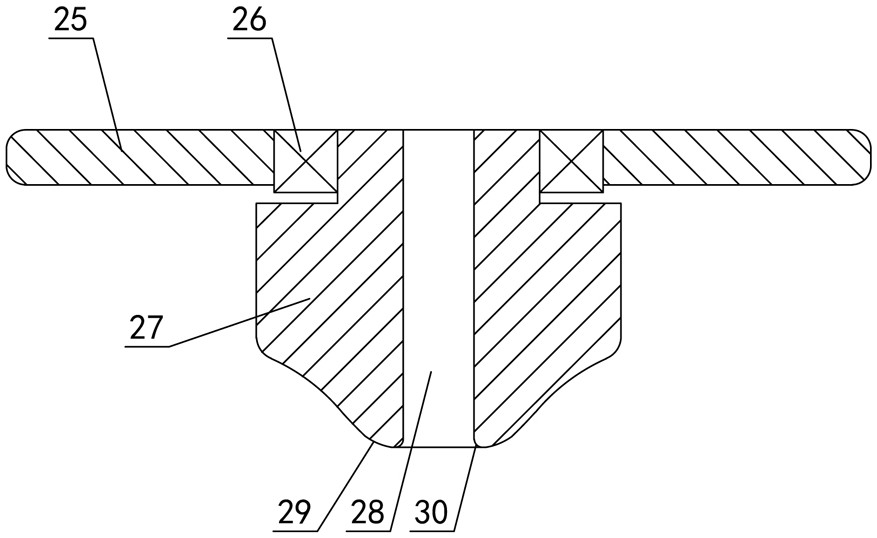

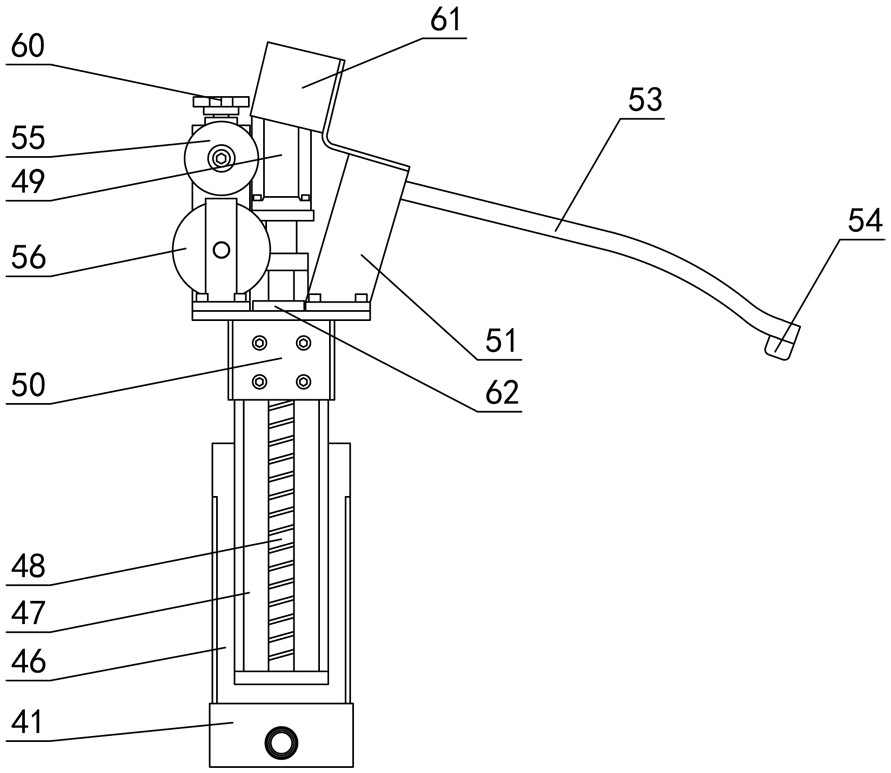

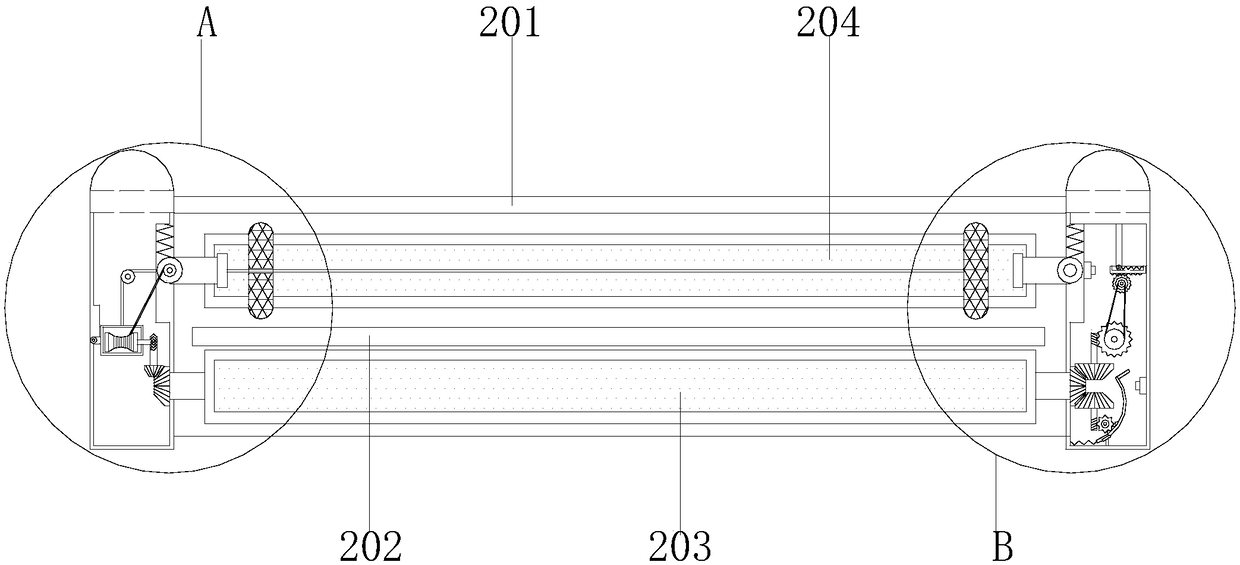

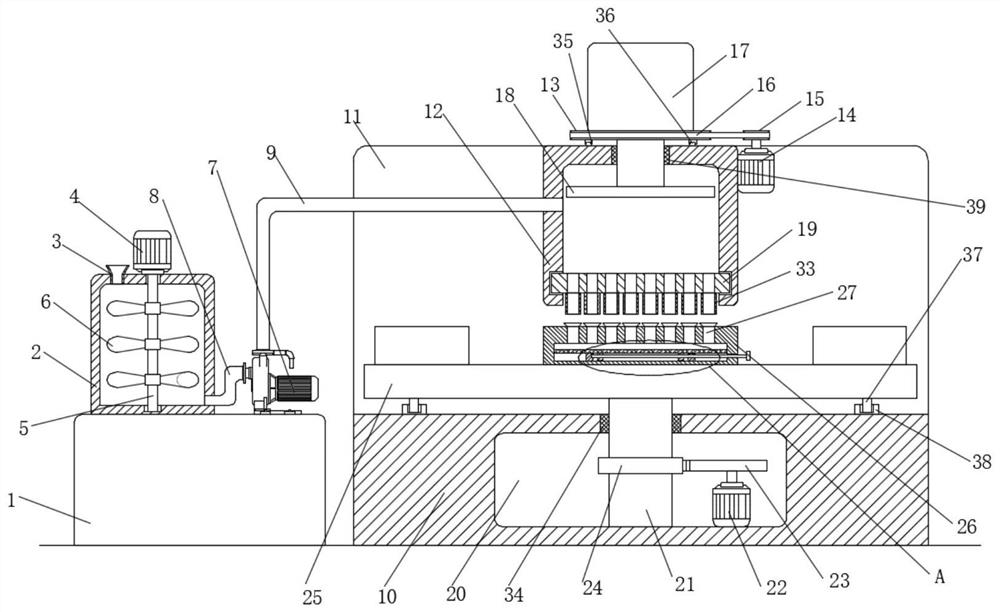

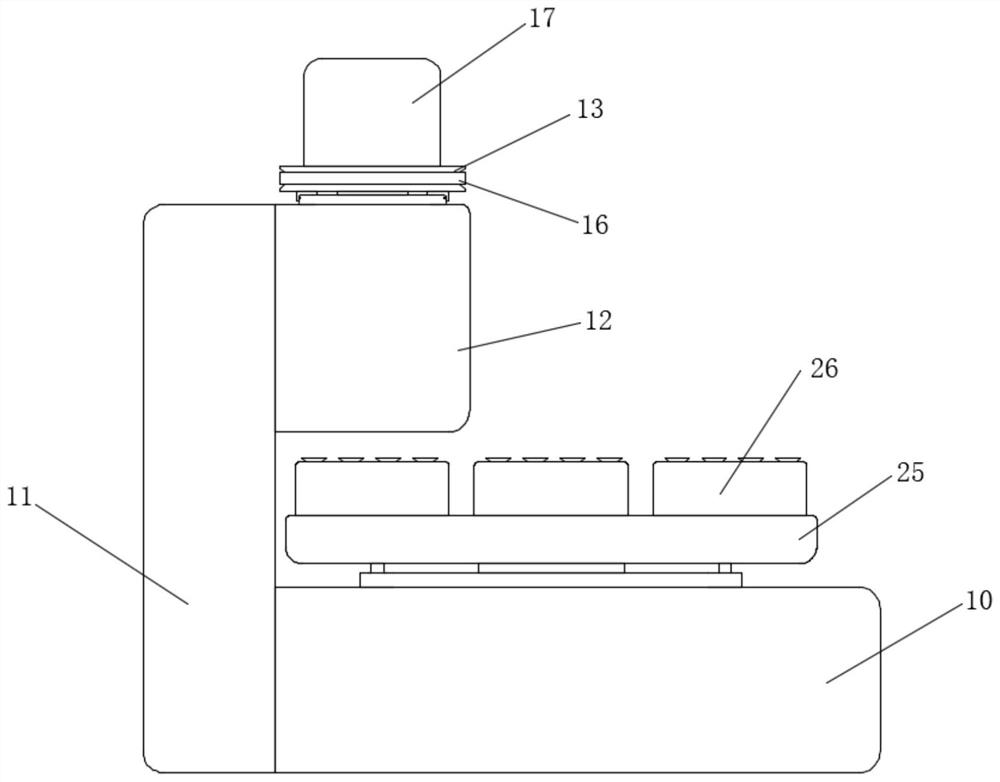

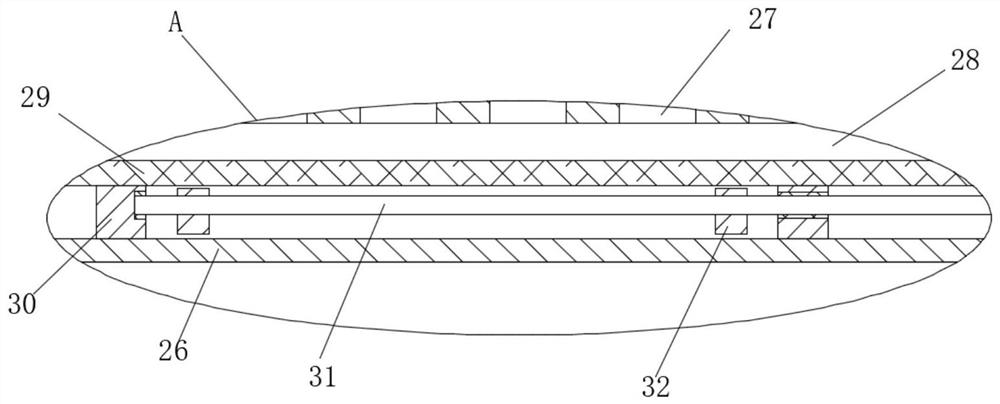

Semi-automatic pipe winding and arranging machine

PendingCN112173843AReduce labor intensitySave labor costsFilament handlingSemi automaticStructural engineering

The invention relates to a semi-automatic pipe winding and arranging machine. The semi-automatic pipe winding and arranging machine comprises a rack, wherein a dredging device, a pipe arranging deviceand a winding roller rotating and loosening device are arranged on the rack. Firstly, pipes can be automatically wound and arranged by the machine, so that the pipe winding efficiency is effectivelyimproved, the labor intensity of workers is reduced, and the labor cost is reduced; secondly, a dredging seat is arranged, so that adhered pipes are automatically separated when passing through a dredging hole, the smooth operation of the machine is guaranteed, and the dredging seat is connected through a transverse swing rod, so that the dredging seat can swing at the corresponding amplitude along with the swinging amplitude of the pipes in a pipe dredging process, the swinging amplitude of the pipes can be reduced, and the stable operation of the machine is guaranteed; and thirdly, elastic plates of the winding roller rotating and loosening device are connected with a main shaft through connecting rod structures, and after the pipes are wound, only the main shaft needs to be rotated reversely, so that all of the elastic plates can retract inwards synchronously, the outer diameter of a roller is reduced, people can take out the wound pipes conveniently, and parts are taken conveniently.

Owner:沈传良

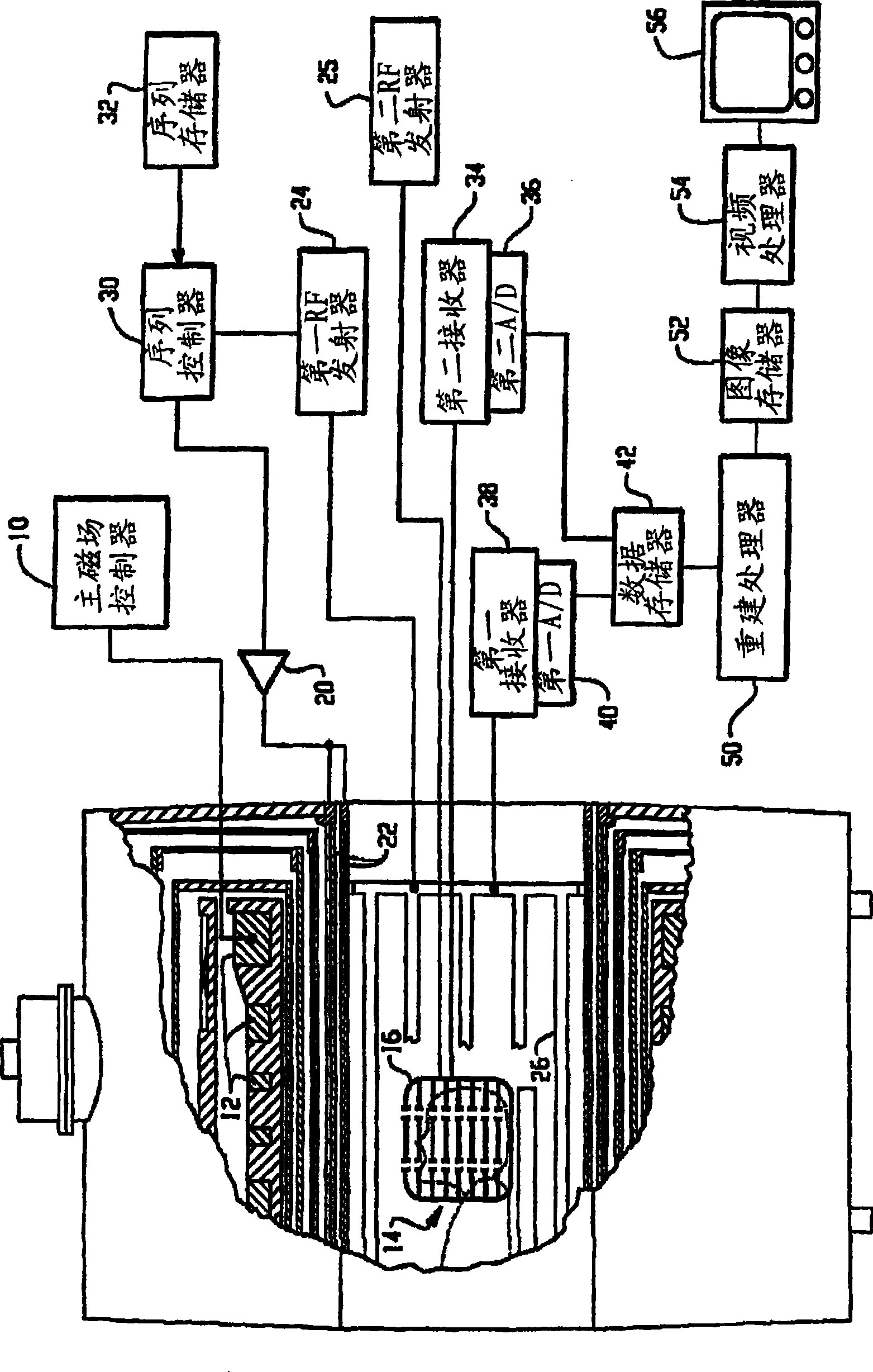

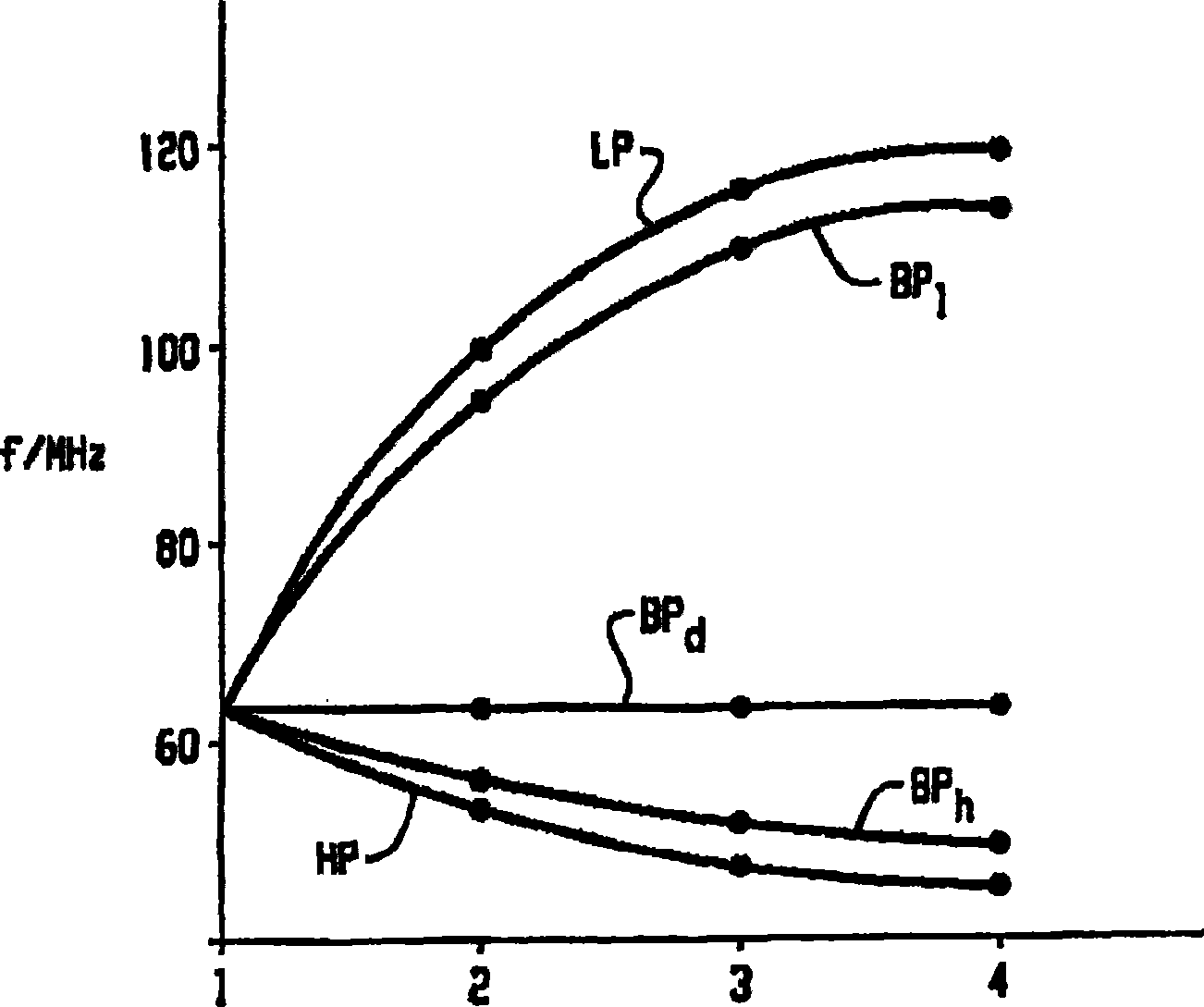

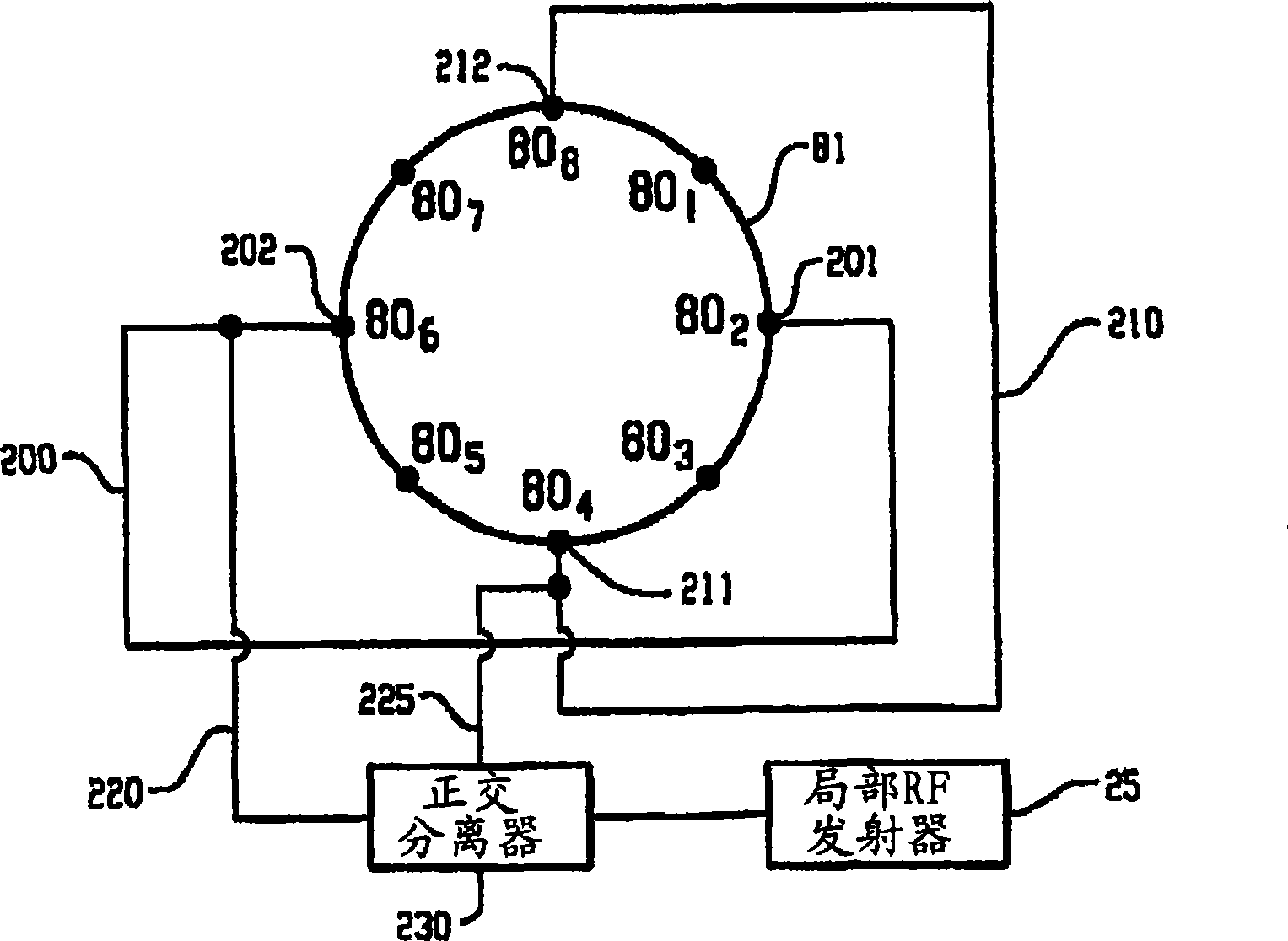

Degenerate birdcage coil and transmit/receive apparatus and method for same

InactiveCN100526906CReduce local absorption rateImprove coil efficiencyMeasurements using magnetic resonanceRf transmissionReceiver coil

A birdcage coil (16) used in conjunction with a magnetic resonance imaging device includes a first conductive loop (81, 581), a second conductive loop (82, 582), and a plurality of conductive loops located between the first and second conductive loops A first conductor bar (80, 580). The third conductor (83, 83", 583) is coupled at the resonant frequency to the second conductive loop, for example via a second conductor bar (84, 84", 584). The birdcage coil also includes a switch (590) for switching the birdcage coil in at least the following modes: 1) RF transmit mode, as an RF transmit coil; and 2) RF receive mode, as an RF receive coil.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Winding device for protective film production

PendingCN112919176AAchieve replacementReduce the waste of time for removal and replacementWebs handlingContact positionSupport plane

The invention discloses a winding device for protective film production, relates to the technical field of protective film production, and aims to solve the problems that a winding roller needs to be shut down to be taken down and replaced with a new winding roller after winding is completed, the replacement mode is complicated, the consumed time is long, protective film production equipment stops working at the same time when the replacement time interval exists, and the material receiving efficiency is not good. A winding frame is arranged above a device base, six winding rollers are arranged outside the winding frame, the six winding rollers are sequentially arranged on the winding frame, mounting frames are arranged on the two sides of the winding frame respectively, the winding frame is rotationally connected with the mounting frames, a supporting frame is arranged on one side of the winding frame, a connecting mechanism is arranged at the contact position of the winding rollers and the winding frame, the connecting mechanism is in joggle joint with the winding rollers, three material conveying rollers and a material guiding roller are arranged at the upper end of the device base, and the material conveying rollers and the material guiding roller are both attached to a protective film.

Owner:东莞市金恒晟新材料科技有限公司

An aluminum plate coiling device for the production of auto parts

Owner:扬州易达利机械科技有限公司

Moxa stick production and processing equipment added with ultramicro poria cocos powder and application method thereof

PendingCN112356488AEasy to collectWell mixedDevices for heating/cooling reflex pointsPharmaceutical product form changeManufacturing engineeringIndustrial engineering

The invention discloses moxa stick production and processing equipment added with ultramicro poria cocos powder and an application method thereof. The moxa stick production and processing equipment comprises a base, a stirring box is fixedly connected to the top of the base, and a stirring assembly used for stirring moxa and the ultramicro poria cocos powder is arranged in the stirring box. A workbench is arranged on one side of the base, one side of the workbench is fixedly connected with a support, one side of the support is fixedly connected with a storage box, the top of the storage box isprovided with a compaction assembly used for compacting the moxa, the top of the workbench is rotationally connected with a rotating disc, and a rotating assembly used for driving the rotating disc to rotate is arranged in the workbench. In the equipment, the moxa and the ultramicro poria cocos powder can be fully mixed through the stirring box and stirring blades, it is guaranteed that the pharmaceutical effect of moxa sticks is better, a second pressing disc can rotate to moved ownwards to compact and wind the moxa, winding of the multiple moxa sticks can be completed at a time, manual winding is not needed, the winding efficiency is improved, and the labor intensity of workers is reduced.

Owner:湖南汉众农业发展有限公司

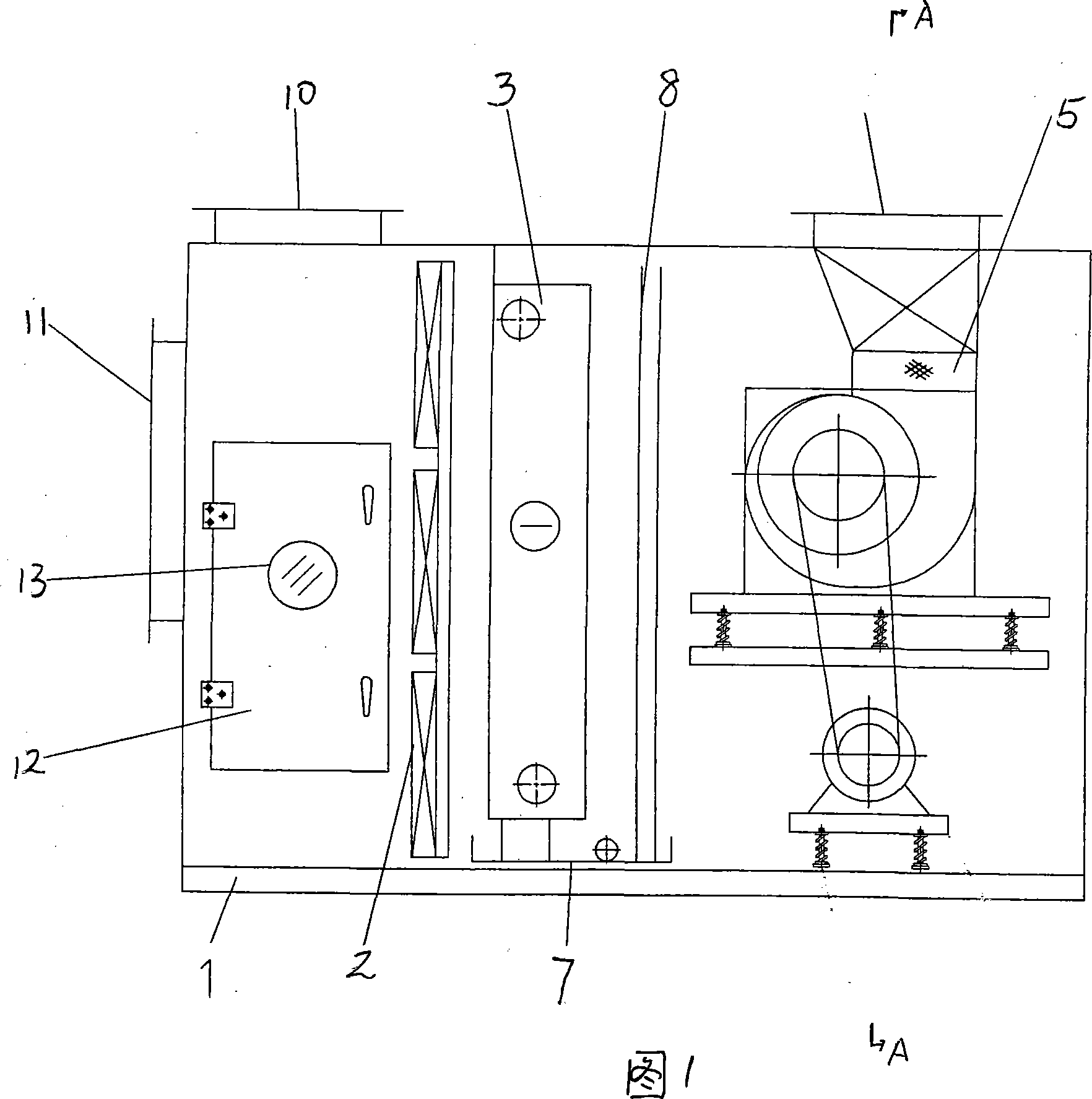

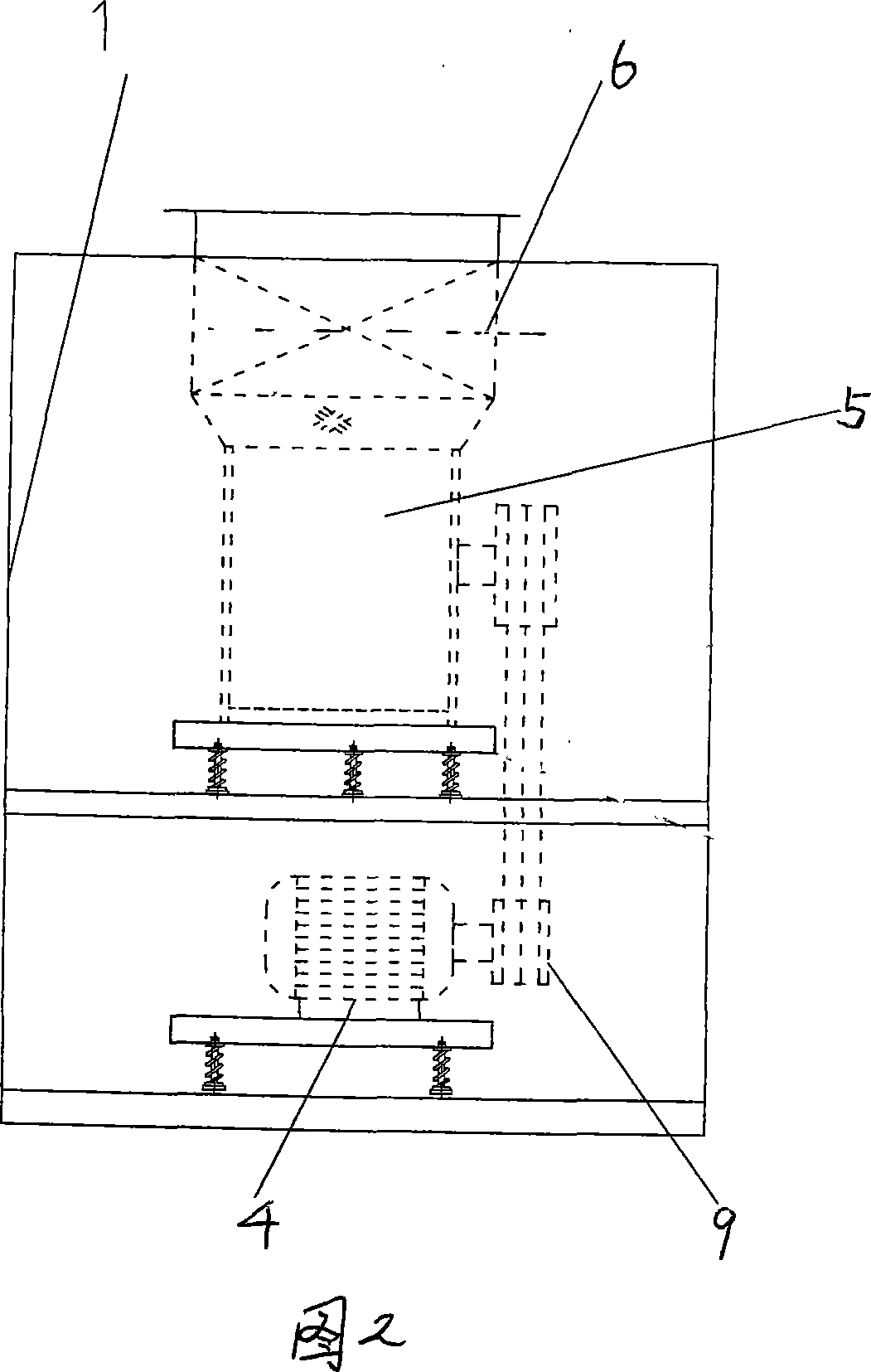

Intensified and compact air conditioner set

InactiveCN101149180AReduced internal windage lossImprove coiling efficiencyLighting and heating apparatusSpace heating and ventilation detailsHoneycombEngineering

This invention discloses an intensive compact type air conditioner unit. It includes casing, primary-efficiency filter, heat exchanger and fan. The fan, which is driven by motor, is arranged in the back of the heat exchanger. The heat exchanger uses oval copper pipe. The heat exchanger fin uses honeycomb type aluminum fin. This invention has compact structure and good working capability.

Owner:JIANGSU FENGSHEN AIR CONDITIONING GRP

Slitter edge coiling machine

The invention discloses a slitter edge coiling machine, which comprises a coiling device and a wiring device, wherein the coiling device and the wiring device are arranged independently respectively; the wiring device is matched with the coiling device, and is used for guiding slitter edges; the wiring device comprises a wiring bracket; a gear motor and a guide lever are arranged fixedly on the wiring bracket; a bilateral lead screw is arranged on the wiring bracket in a way of being rotationally matched with the wiring bracket; the bilateral lead screw and the gear motor rotate synchronously; the bilateral lead screw is provided with a left threaded section and a right threaded section respectively corresponding to a left coiling block and a right coiling block; the left threaded section and the right threaded section are provided with guide blocks which are in threaded fit with the left threaded section and right threaded section respectively; the guide blocks are provided with through holes for sleeving the guide blocks on the guide lever; the axis of the guide lever is parallel to the axis of the bilateral lead screw; and the guide blocks are provided with guide grooves for threading and guiding slitter edges. Due to the adoption of the slitter edge coiling machine disclosed by the invention, full-range coiling of the coiling blocks can be realized, and the coiling uniformity is high; and the slitter edge coiling machine has the advantages of simple structure and low manufacturing cost.

Owner:CISDI ENG CO LTD

Non-core surface coiling method and device

The invention relates to the technical field of coiling devices, in particular to a non-core surface coiling method and device. The non-core surface coiling method is used for coiling a base materialinto a non-core coiled material. The base material is placed on two roller bodies, wherein the axes of the two roller bodies are parallel, and the steering directions of the two roller bodies are thesame. Core shafts are pressed and attached to the positions between the two roller bodies through a pressing roller, the base material is wound around the surface of the core shaft through friction force between the roller bodies and the core shafts, the core shafts are drawn out along the axis after the base material is coiled, and the base material is gradually coiled into the non-core coiled material. The non-core surface coiling device comprises a rear supporting roller, a front supporting roller, the pressing roller, a pressing roller air cylinder, the core shafts symmetrically arranged on the two ends of the end portion of the pressing roller, core shaft air cylinders and core shaft lifting air cylinders. By means of the non-core surface coiling method and device, the structure is simple, implementation is easy, the coiling efficiency is high, the effect is good, the beneficial effects that the coiling rate is 100%, the coiling rate is adjustable, and the coiling end face is flatare achieved, and the method and device are suitable for full-automatic non-core surface coiling work of flexible materials.

Owner:福建富易天龙智能科技有限公司

Device for wire coiling of thin-round aluminum rods

ActiveCN108821001AGuaranteed uptimeNeat appearanceFilament handlingEngineeringMechanical engineering

Owner:眉山市博眉启明星铝业有限公司

Electromagnetic actuator of optical pickup head

InactiveUS20120174138A1Improve coiling efficiencyFast and precise data readingRecord information storageOptical recording/reproducingOptical pickupMagnetic tension force

An electromagnetic actuator is provided, including an object lens holder hanged by a set of wires forming suspended object. A focus coil set is fixed to object lens holder and placed surrounding focus and track shared magnet set. The focus coil located between object lens holder and focus and track shared magnet set is within magnetic field of focus and track shared magnet set. The focus coil located between tilt magnet set and magnetic field of focus and track shared magnet set is within the effective field of tilt magnet set and focus and track shared magnet set due to shielding effect of the yoke protruding plates. When a current runs through focus coil, a magnetic force in the focus direction is induced simultaneously within the range of tilt magnet set and focus and track shared magnet set so that object lens holder can focus.

Owner:TOPRAY MEMS

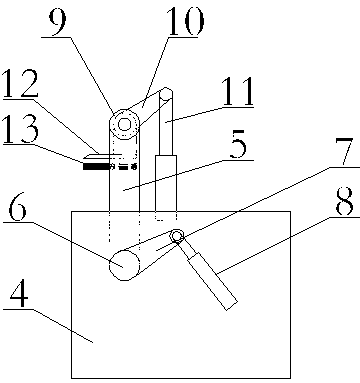

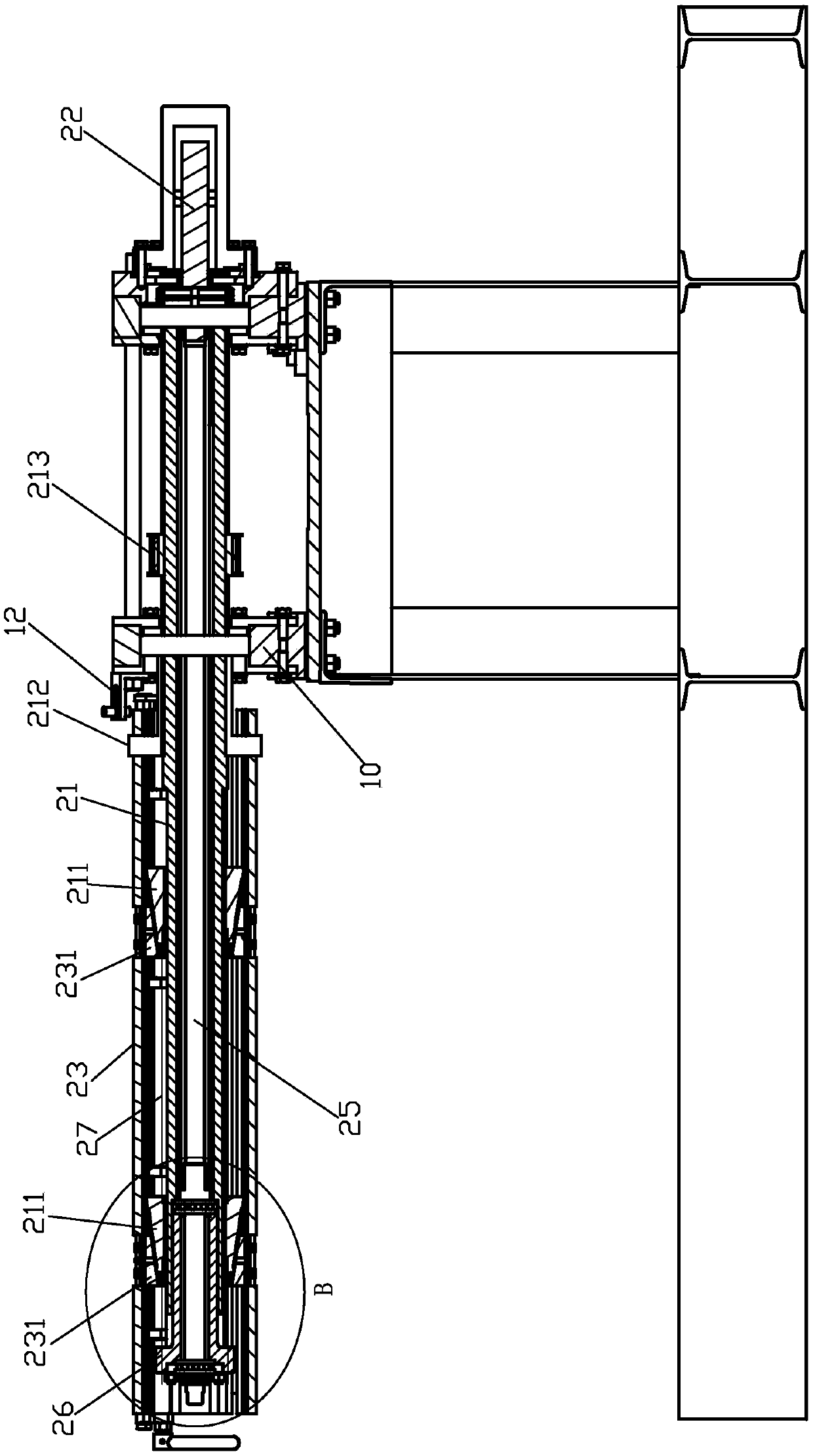

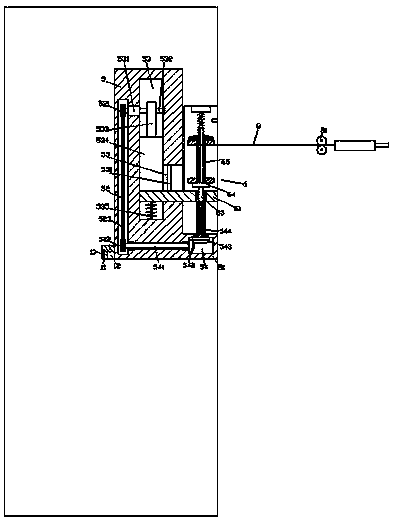

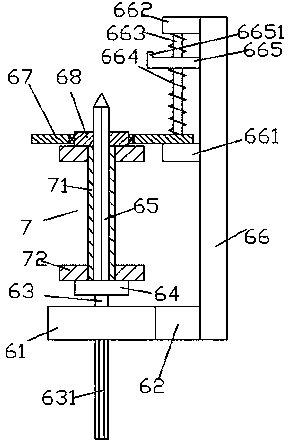

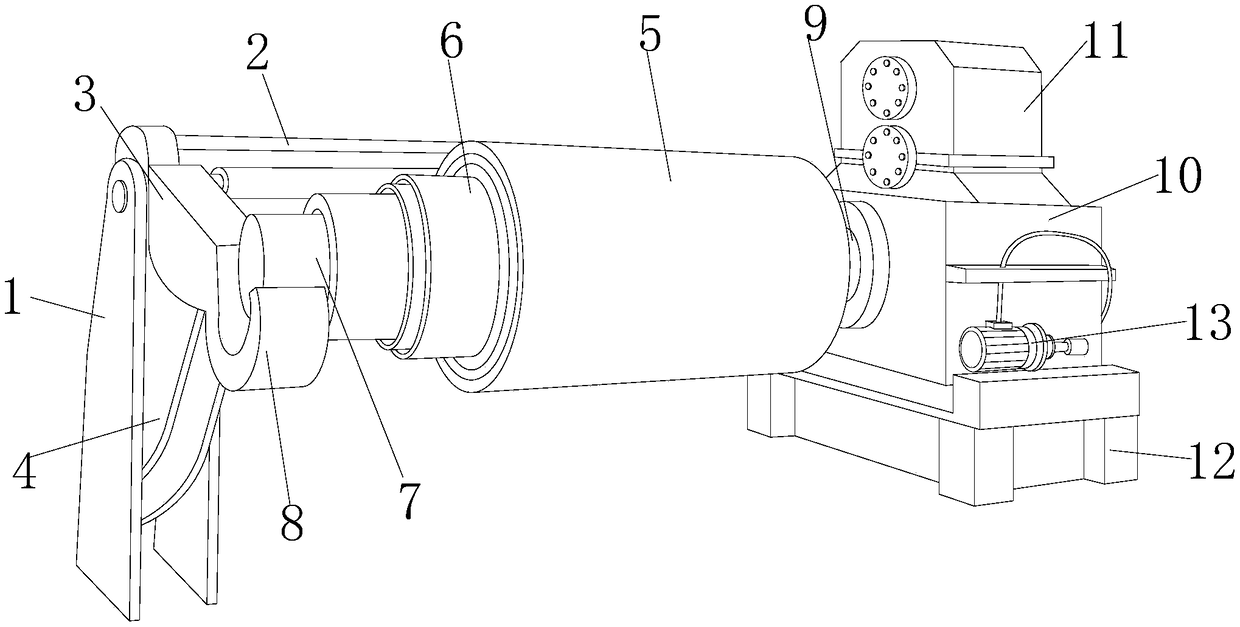

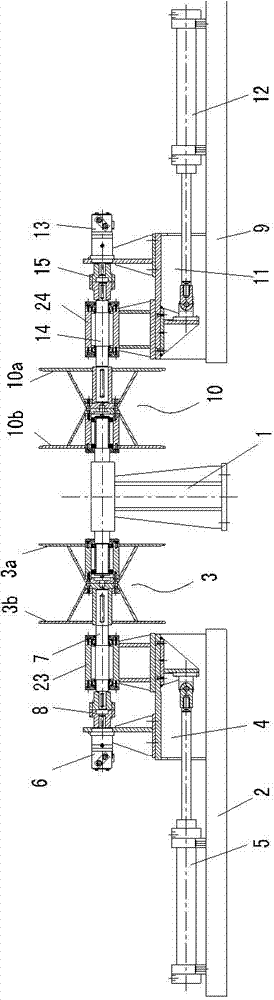

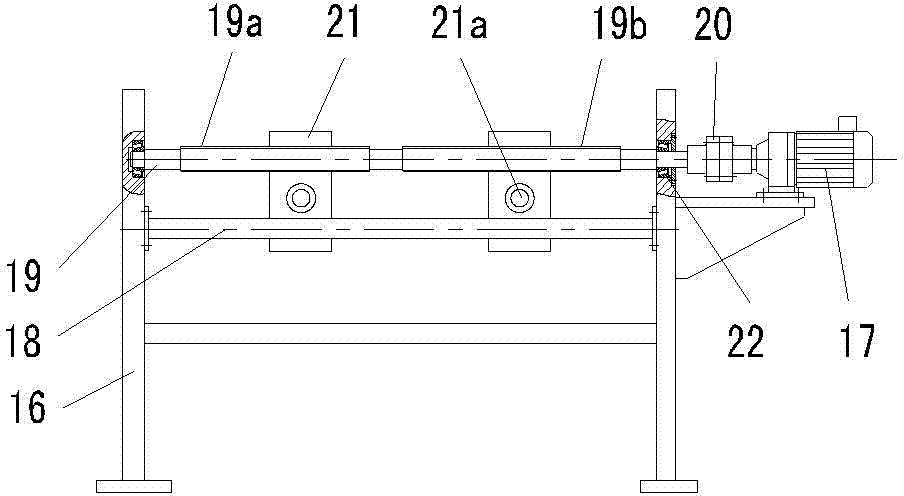

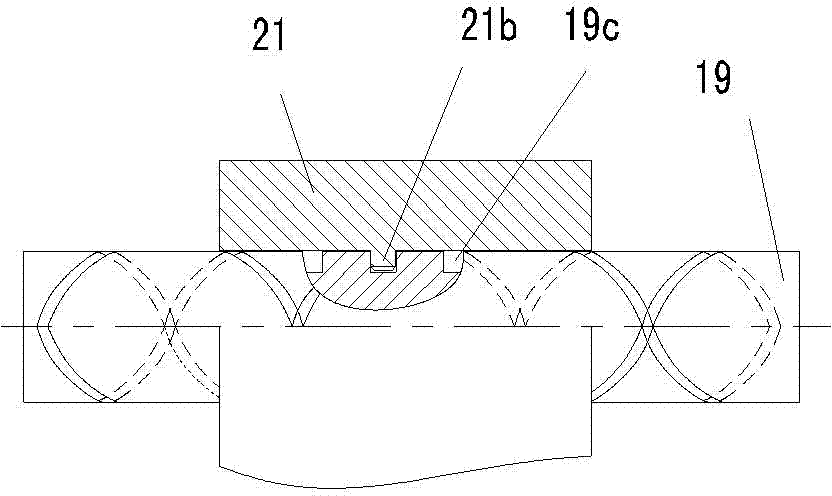

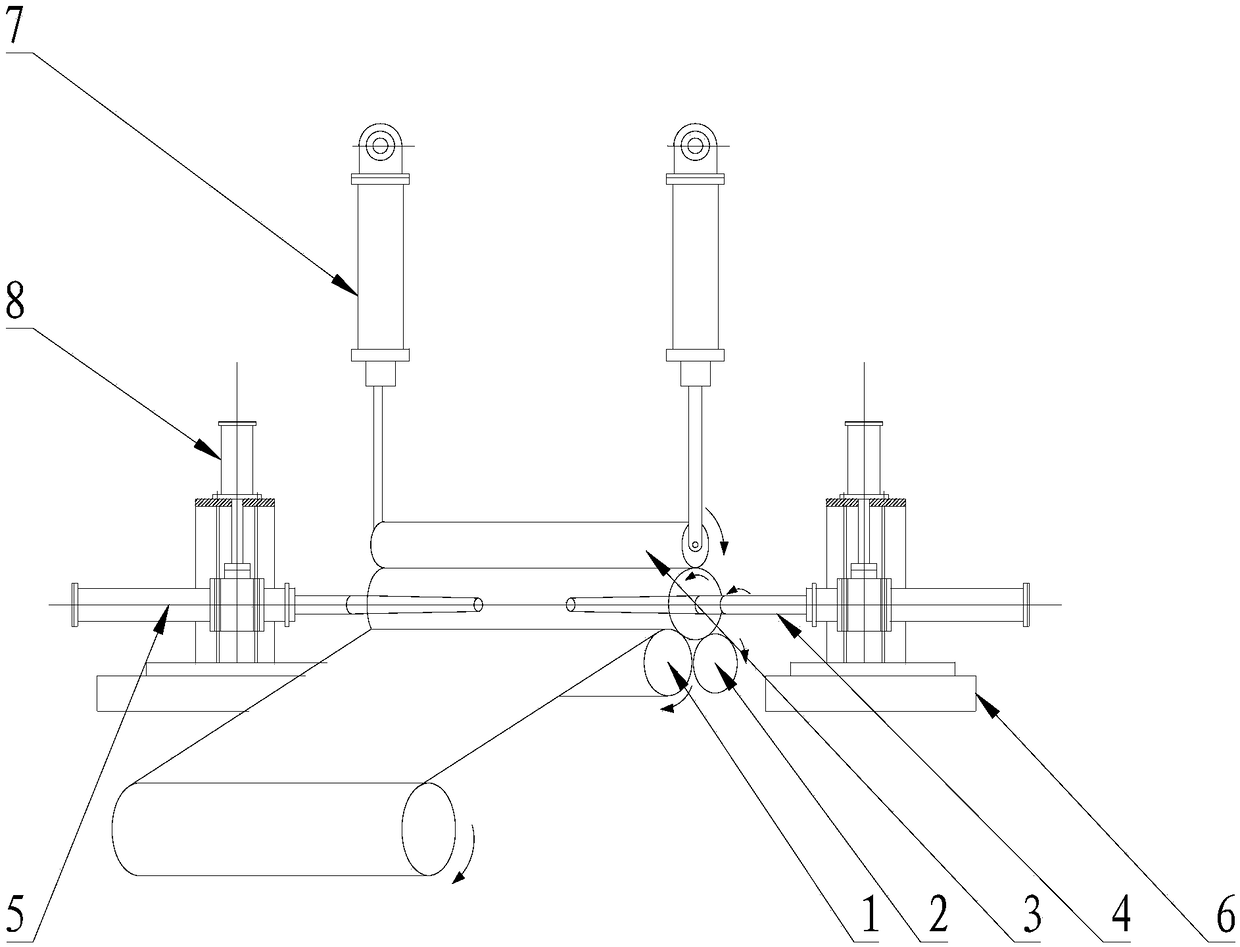

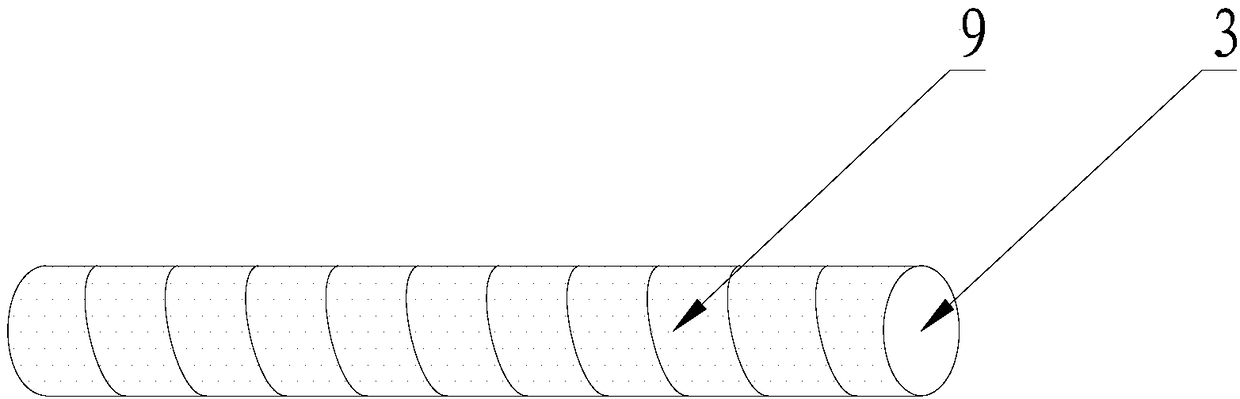

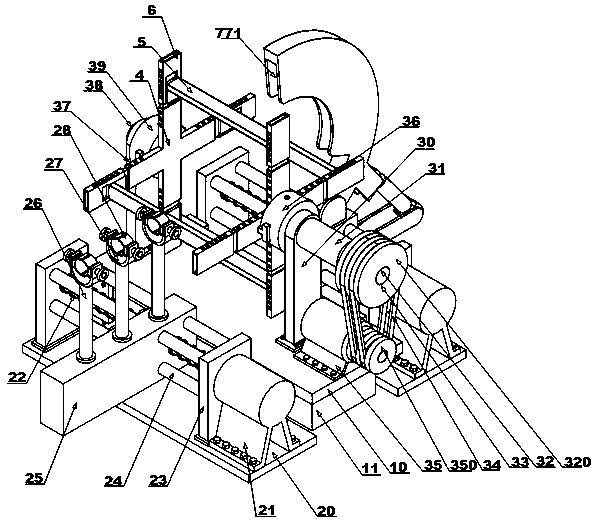

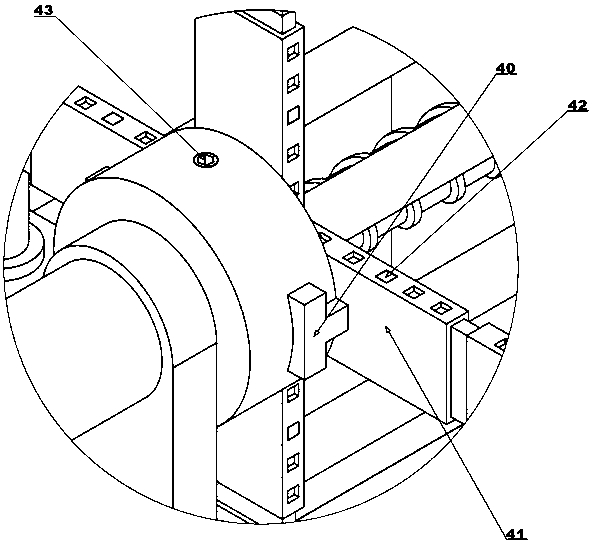

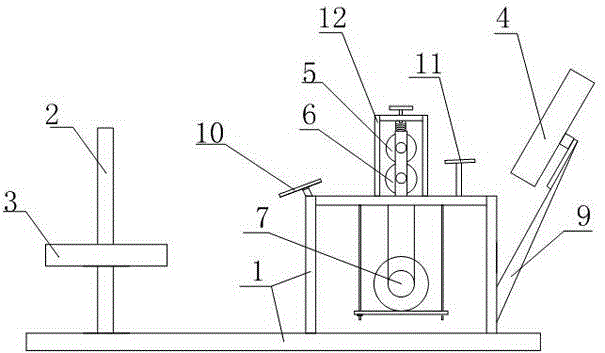

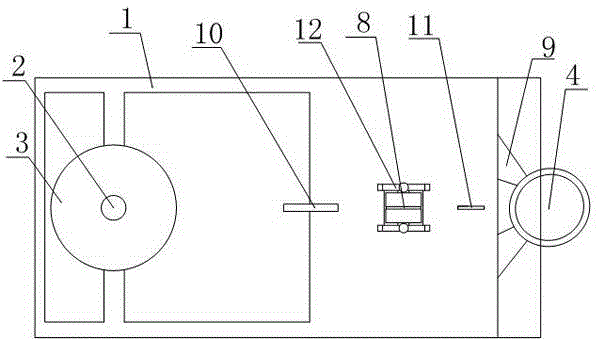

Automatic coiling method for welding wire in welding wire box of submerged arc welding machine

InactiveCN105565071AImprove coiling efficiencySave human effortFilament handlingSubmerged arc weldingHuman power

The invention discloses an automatic coiling method for a welding wire in a welding wire box of a submerged arc welding machine. The method involves a working rack (1), a wire clamping device connected to the working rack (1), and a wire unreeling device and a standard wire box (4) which are located on two sides of the wire clamping device, respectively; the wire unreeling device and the standard wire box (4) are connected to the working rack (1) or the wire clamping device; an axis of the standard wire box (4) forms an included angle beta with a horizontal plane, and beta is greater than 0, and less than or equal to 90; the wire clamping device comprises two clamping roller portals (12) that are connected to the working rack (1), arranged in parallel and perpendicular to the working rack (1), and a clamping roller (5) and a driving wheel (6) which are placed between the two clamping roller portals (12); and the driving wheel (6) is located directly below the clamping roller (5), and also connected with a driving mechanism (7). The automatic coiling method for the welding wire in the welding wire box of the submerged arc welding machine has the advantages that the driving wheel is driven by a motor, such that the efficiency of coiling a submerged arc welding wire can be effectively improved, less human power is input, and the amount of work is reduced, and moreover, the structure is simple, convenient, and practical.

Owner:CHENGDU BAIRUI BUILDING INSTALLATION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com