Non-core surface coiling method and device

A technology of core roll and mandrel, applied in the field of coiling equipment, can solve problems such as wrinkling and wrinkles, difficulty in coiling flexible materials, slipping, etc., to ensure surface coiling tightness, high coiling efficiency, and simplify machinery structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

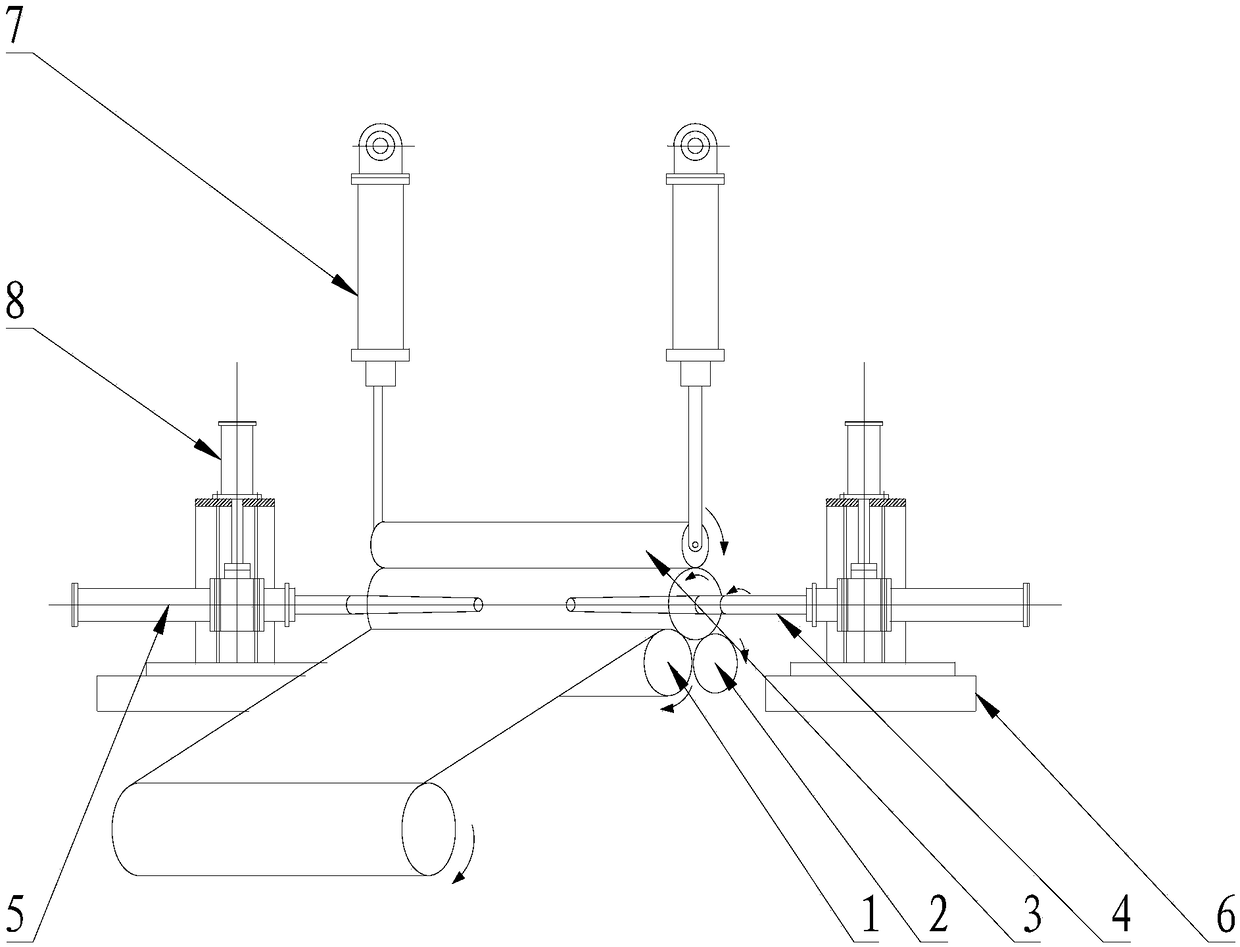

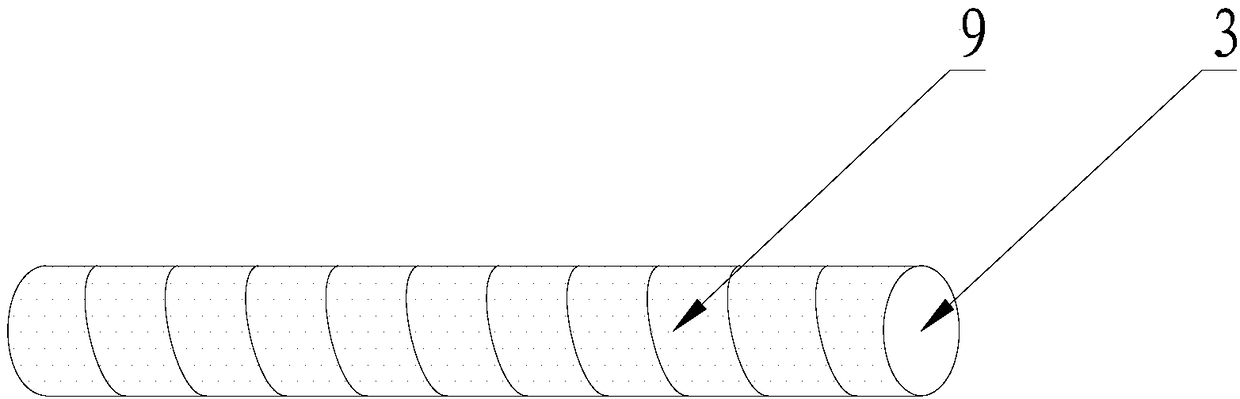

[0048] Please refer to figure 1 as well as figure 2 , Embodiment 1 of the present invention is: a coreless surface coiling device, including a rear support roller 1, a front support roller 2, a pressing roller 3, a pressing roller cylinder 7 and symmetrically arranged at the end of the pressing roller 3 Mandrel 4, mandrel cylinder 5 and mandrel lifting cylinder 8 on both sides;

[0049] The axes of the back support roll 1, the front support roll 2, the press roll 3 and the mandrel 4 are parallel to each other, the turning and linear speed of the back support roll 1 and the front support roll 2 are the same, and the back support roll 1 and the There is a gap between the front support rollers 2, the pressing roller 3 is located above the gap, the top height of the front support roller 2 is lower than the top height of the rear support roller 1, and the mandrel cylinder 5 is located On the axis where the mandrel 4 is located, the piston rod of the mandrel cylinder 5 is connect...

Embodiment 2

[0050] Please refer to figure 1 as well as figure 2 , the second embodiment of the present invention is: a coreless surface coiling device, including a rear support roll 1, a front support roll 2, a pressing roll 3, a pressing roll cylinder 7 and symmetrically arranged at the end of the pressing roll 3 Mandrel 4, mandrel cylinder 5 and mandrel lifting cylinder 8 on both sides;

[0051] The axes of the back support roll 1, the front support roll 2, the press roll 3 and the mandrel 4 are parallel to each other, the turning and linear speed of the back support roll 1 and the front support roll 2 are the same, and the back support roll 1 and the There is a gap between the front support rollers 2, the pressing roller 3 is located above the gap, the top height of the front support roller 2 is lower than the top height of the rear support roller 1, and the mandrel cylinder 5 is located On the axis where the mandrel 4 is located, the piston rod of the mandrel cylinder 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com