Automatic packaging device for pipe coils

An automatic packaging and coiling technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of laborious packaging tightness, insufficient balance efficiency, etc., achieve balanced tightness, improve the scope of application, improve the coil The effect of volume efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

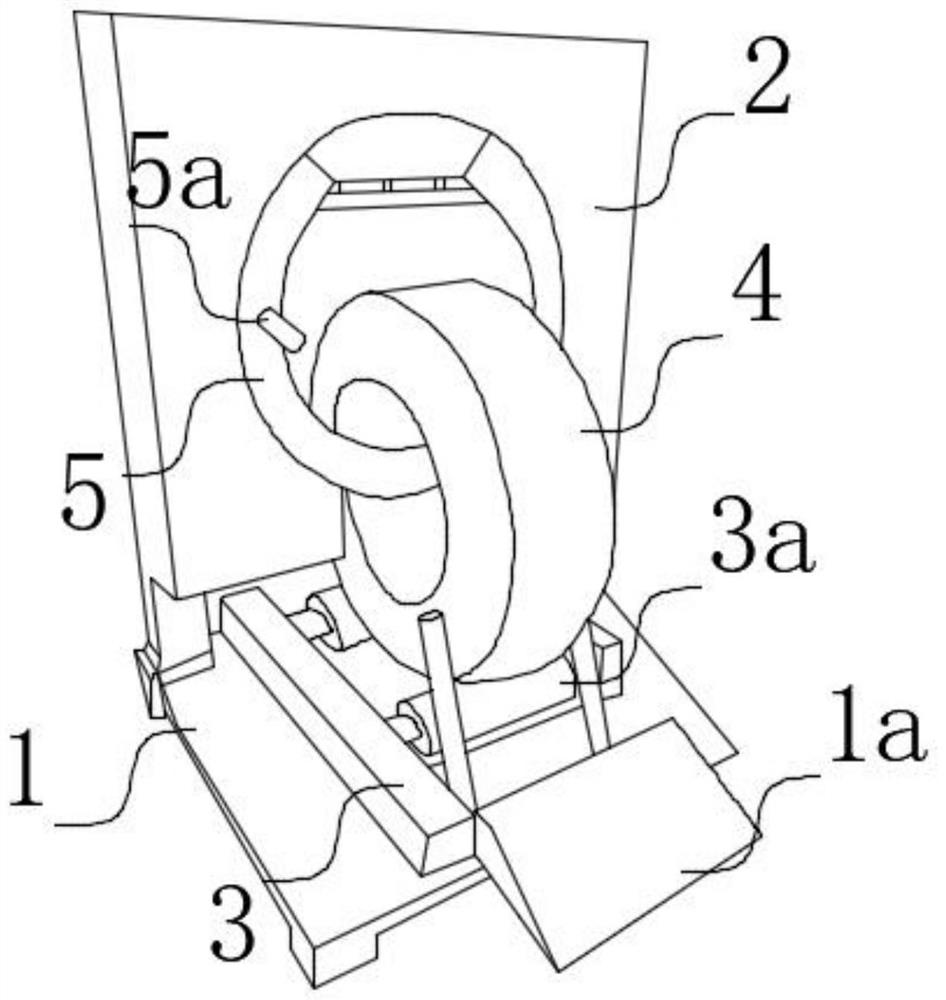

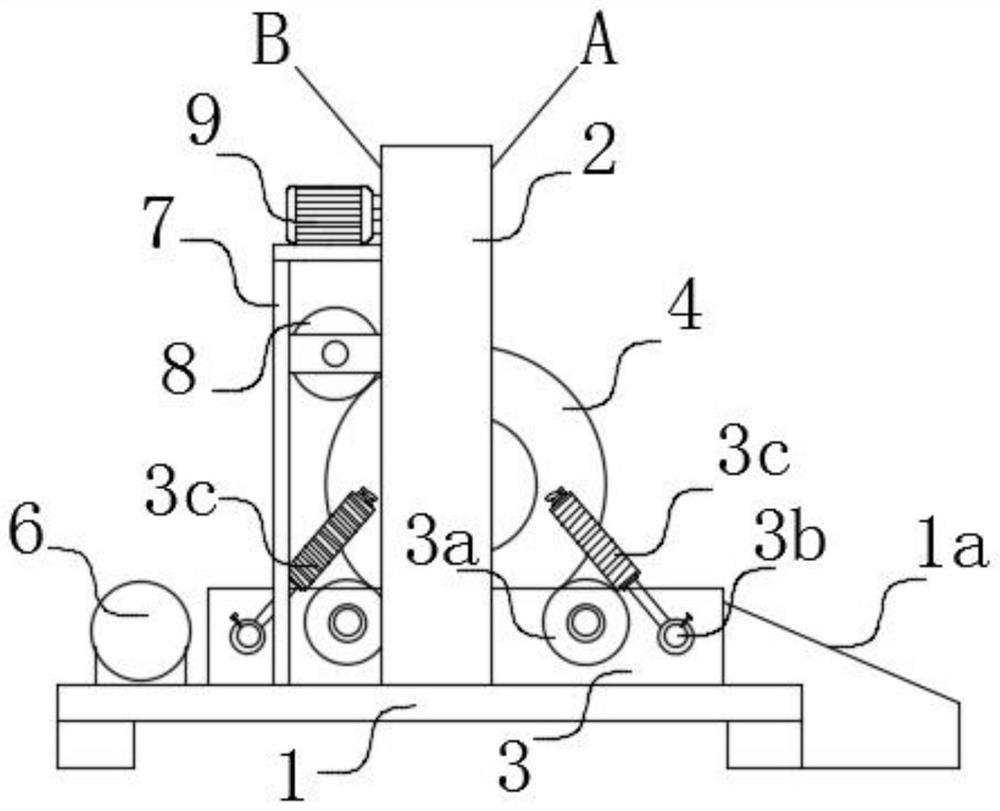

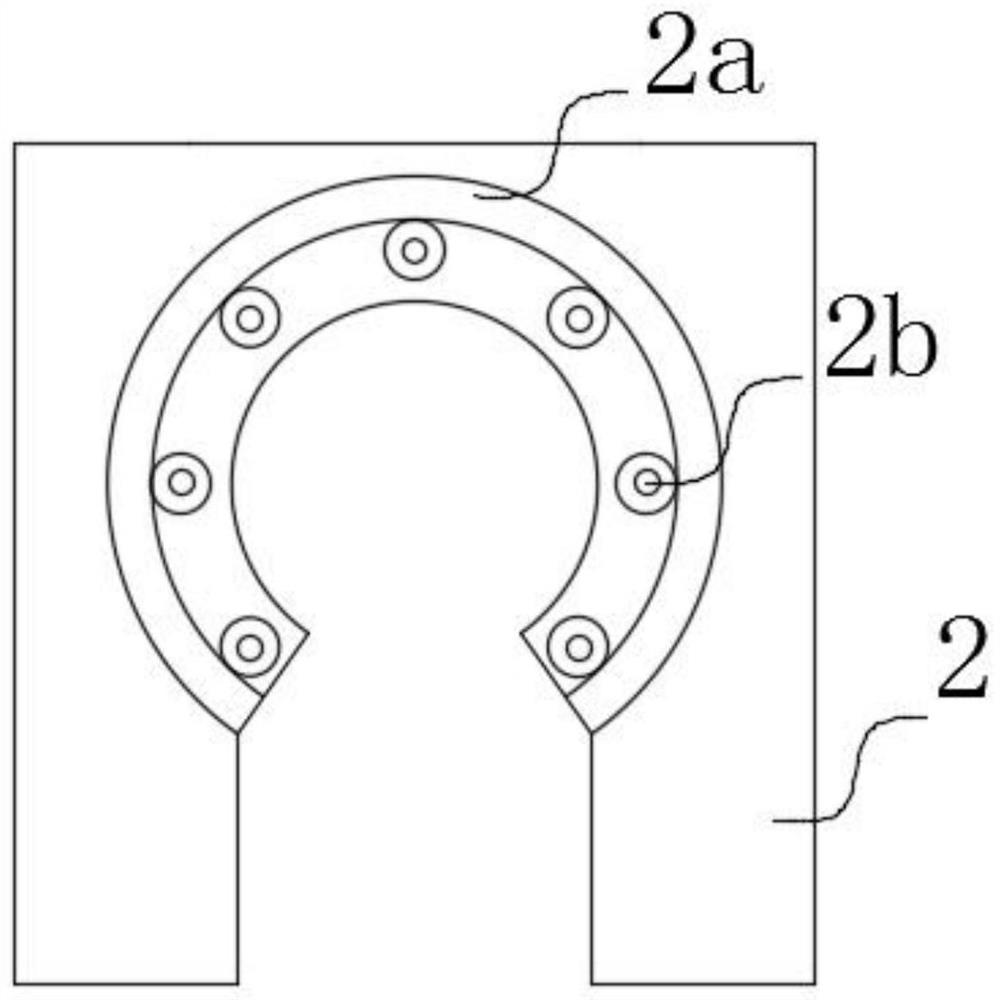

[0026] Such as figure 1 with figure 2 As shown, this embodiment discloses an automatic packaging device for pipe coils, which includes a base bottom plate 1, two parallel rotating fixed seats 3 fixed on the base bottom plate 1, and mounted on the said base bottom plate 1 through bearings. On the rotating fixed seat 3 and for placing the two placement rollers 3a of the pipe coil 4, fixed on the base bottom plate 1 and across the coil door frame 2 of the two rotating fixed seats 3, installed on the Coil the door frame 2 and use the ring-shaped fixing seat 2a that wraps the pipe coil 4 and the winding sliding ring 5 that is limitedly installed on the ring-shaped fixing seat 2a; wherein the ring-shaped fixing seat 2a and the Notches for the passage of the pipe coils 4 are respectively reserved on the winding sliding rings 5 , and a tape installation shaft 5 a is installed on the winding sliding rings 5 .

[0027] Wherein the end side of the base bottom plate 1 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com