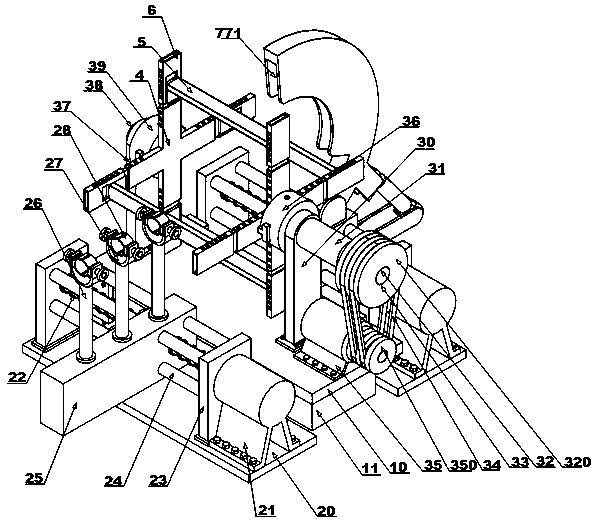

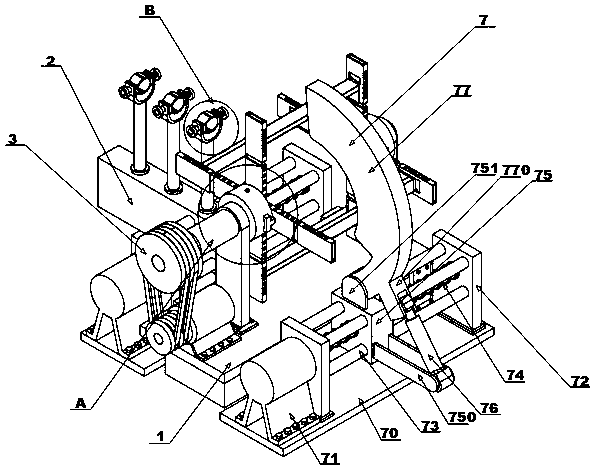

Device for wire coiling of thin-round aluminum rods

A round aluminum rod and coiled wire technology is applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc. take out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

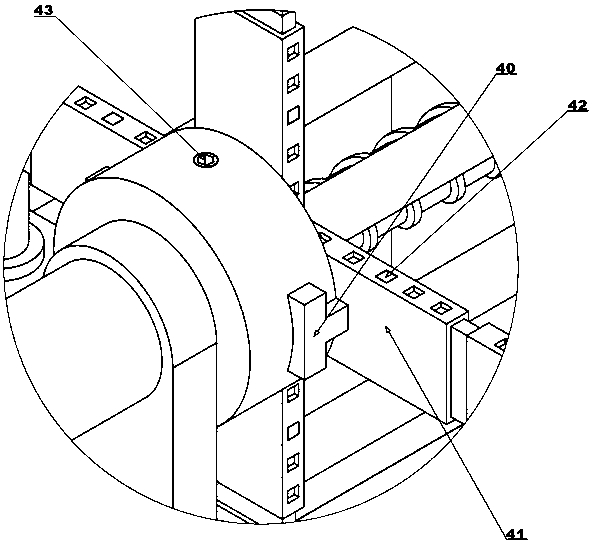

[0061] 1. Pass the thin round aluminum rod through the clamping parts 28 sequentially from front to back, and after passing through, make the passing end into a hook shape and place it on one of the wire coil parts 50;

[0062] 2. Rotate the two rotating rods 282 respectively until the size of the clamping claw 280 and the thin round aluminum rod match;

[0063] 3. Start the horizontal motion motor 21 and the limit drive motor 71 at the same time, so that the thin round aluminum rod and the limit piece 77 move to the side of the horizontal motion motor 21 and the limit drive motor 71, and ensure that the thin round aluminum rod is located at the limit Inside the groove 771;

[0064] 4. Press the upper locking block 55 to adjust the length of the outer guard plate 6 relative to the wire coil member 50;

[0065] 5. Start the driving motor 35, so that the winding mechanism 5 and the outer guard plate 6 start to rotate. At the same time, start the horizontal motion motor 21 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com