Semi-automatic pipe winding and arranging machine

A semi-automatic, pipe-arranging machine technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of high labor costs, low processing efficiency, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

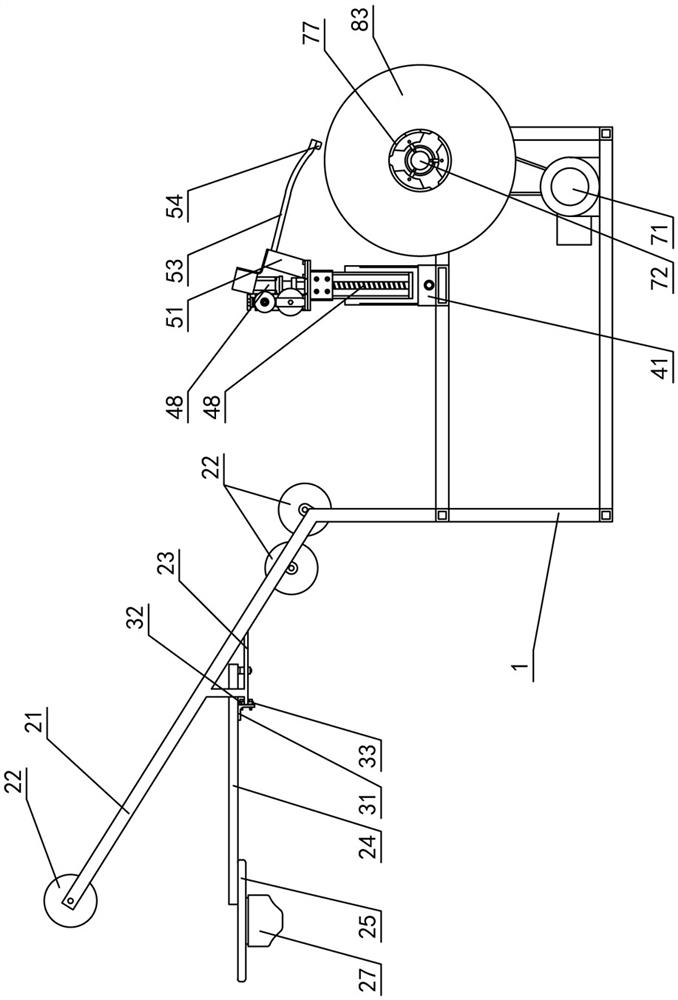

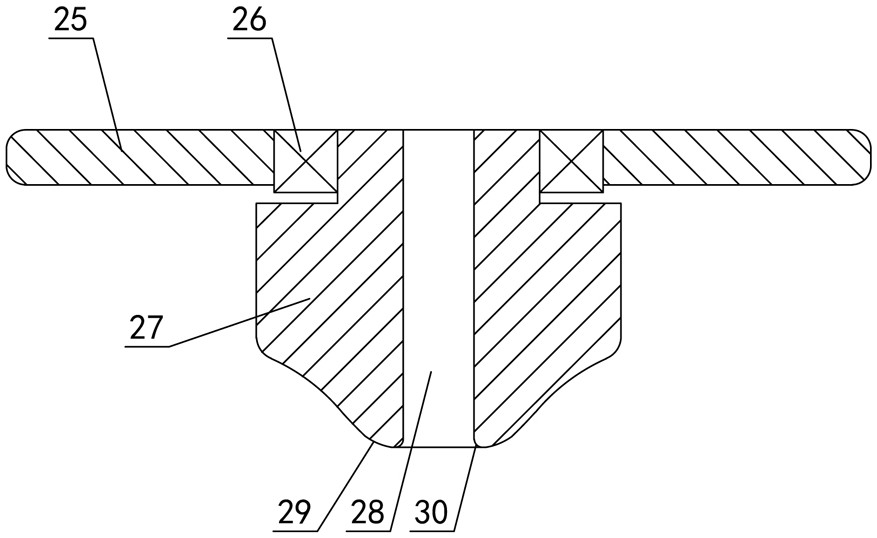

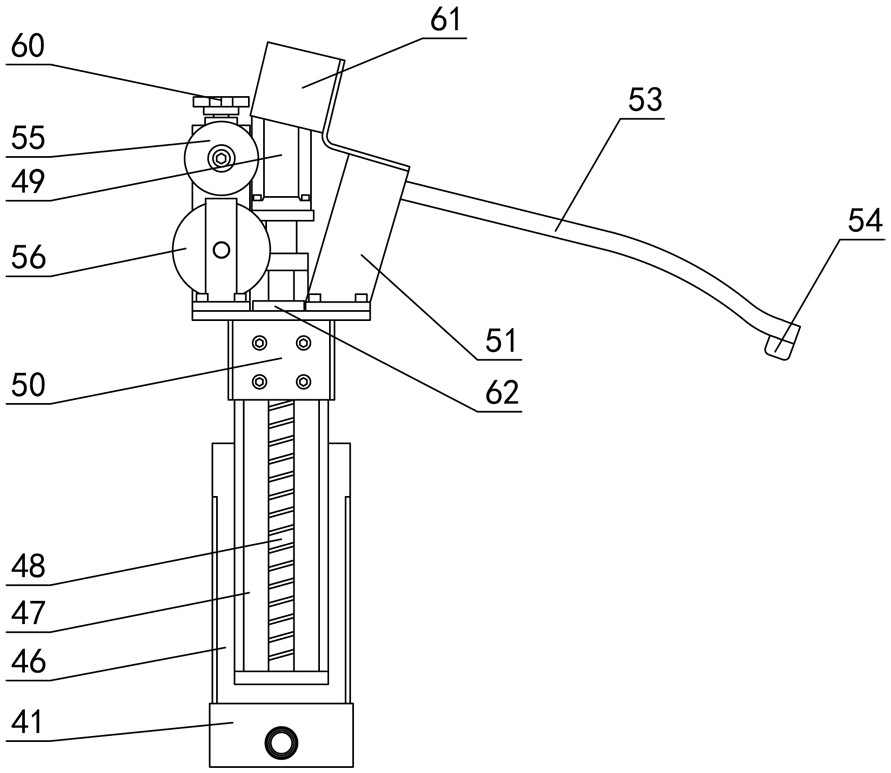

[0022] The invention relates to a semi-automatic pipe rolling and pipe arrangement machine, such as figure 1 — Figure 8As shown, it includes a frame 1, on which a dredging device, a pipe arrangement and a rolling roller rotating and tightening device are arranged; Above guide wheel 22, guide wheel is rotatably connected with dredging bracket through rotating shaft, and the middle part of dredging bracket is shaped on transverse plate 23, and transverse plate connects transverse fork 24, and one end of transverse fork is connected with transverse plate swing through rotating shaft, and the side of transverse fork The other end is connected to the fixed disc 25, the first bearing 26 is set in the fixed plate, and the dredging seat 27 is connected under the first bearing, and the dredging hole 28 is provided in the dredging seat; The first screw mandrel 42 is set, one end of the first screw mandrel is driven to rotate by the first motor 43, the front and rear slide rails 44 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com