Charging pile

A technology of charging piles and charging lines, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of difficult to remove the charging line from the reel, occupying internal space, uneven coiling, etc., to improve the working speed , Improve the uniformity and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

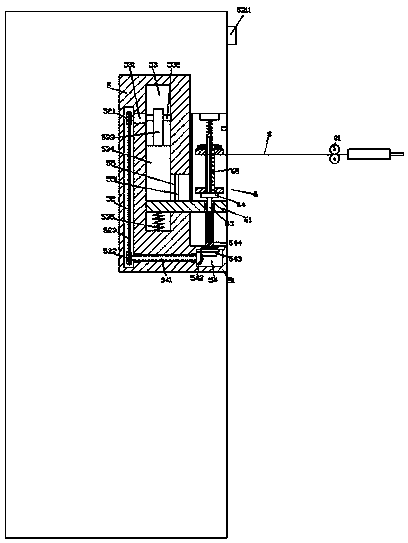

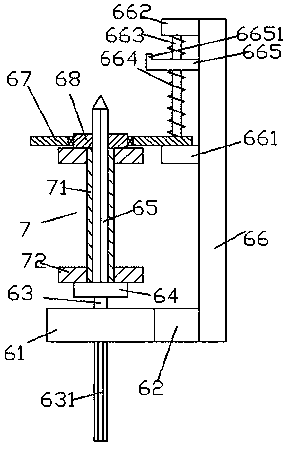

[0022] Such as Figure 1-Figure 5 As shown, a charging pile of the present invention includes a machine column 5 arranged inside the charging pile 4 and a finishing wheel 81 arranged on the right side of the machine column 5 and arranged up and down. The right side of the machine column 5 A base 51 is provided at the bottom, and a charging wire coiling device 6 is provided above the base 51. The charging wire coiling device 6 includes a sliding plate 61 extending left and right, and a sliding plate 61 fixed on the rear side of the sliding plate 61. The middle block 62, a wall panel 66 fixed on the rear side of the middle block 62 and extended upward, and a coil seat 64 arranged above the sliding plate 61, and a first rotating rod is fixed at the bottom of the coil seat 64 63. The bottom of the first rotating rod 63 passes through the sliding plate 61 and is connected in a rotationally fitting manner. The bottom of the first rotating rod 63 is fixedly provided with an external s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com