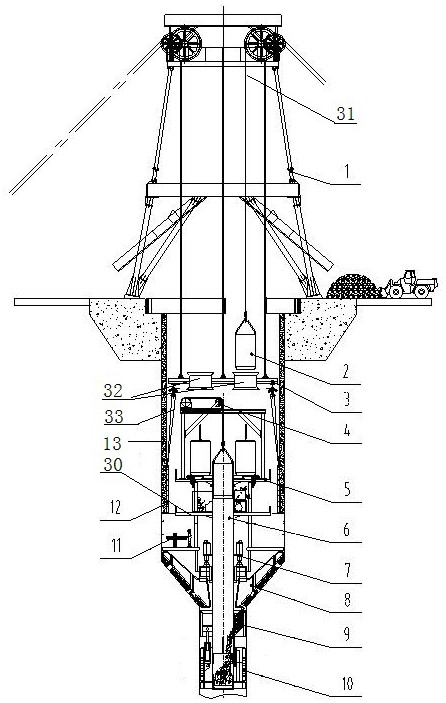

A shaft expansion excavator and its construction method

A technology for roadheaders and shafts, which is applied in shaft equipment, sinking, earthwork drilling and mining, etc. It can solve problems such as the difficulty of shaft expansion and excavation, the long construction period of shafts, and the difficulty of shaft construction, so as to shorten the construction period of expansion and excavation , Improve the tunneling efficiency, the effect of high tunneling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

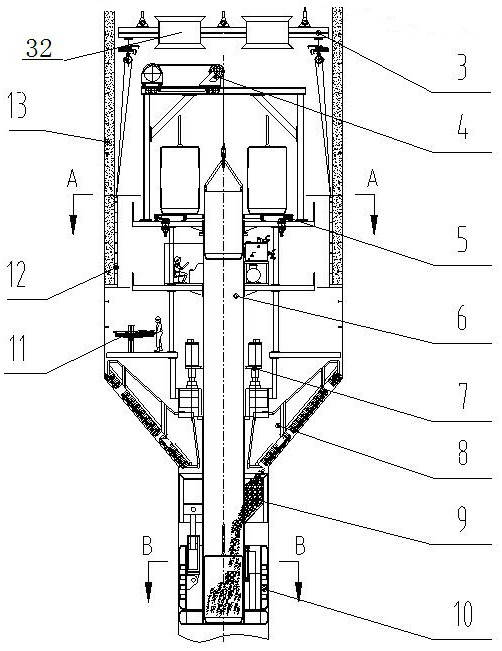

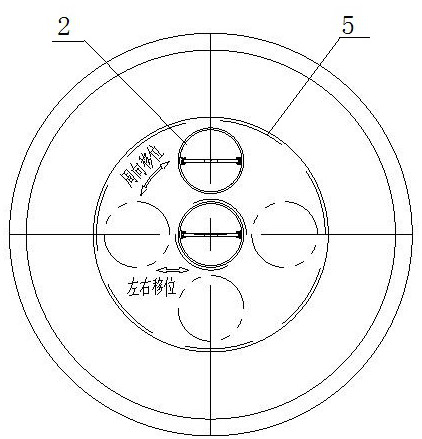

[0037] Example 2, such as Figure 5 As shown, a shaft expansion excavator, when the diameter of the original small-diameter shaft is not enough to place the lower propulsion device 10, the propulsion device can be arranged on the upper part of the cutter head and the main drive, and the rear part of the shoe cylinder is connected to the central column through Structure 17 is hinged, the front end of the shoe cylinder is hinged with the slider, the slider can slide up and down along the shoe plate, one end of the push cylinder is hinged with the shoe plate, and the other end is hinged with the central column connection structure. The shoe cylinder tightens the shoe plate, so that the shoe plate is pressed against the well wall rock, and the pushing cylinder generates pressure, which is transmitted to the center column, the main drive, and the conical cutterhead, and the pushing reaction force is transmitted from the shoe plate to the well wall rock. The slagging system include...

Embodiment 3

[0040] Embodiment 3: A construction method of the shaft expansion excavator as in Embodiment 2, the steps are as follows: S1: Excavation process: lift the main engine into the shaft hole to be expanded, and the cutter head system drives the cone The cutter head rotates to expand the shaft wall. During the expansion process, the gravity of the main engine and the pulling force of the propulsion device act together on the cutter head system to make the cutter head system move forward efficiently;

[0041] S2: Rock slag transportation: The rock mass is broken into rock slag under the action of the cutter head system, and the rock slag, under the disturbance of gravity and the rotation of the conical cutter head, moves closer to the center of the wellbore along the conical excavation face and slips into the center column Then the primary slag discharge mechanism of the slag discharge system lifts the bucket to the hoisting place of the secondary slag discharge mechanism, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com