Rotary furnace cooling agent and manufacturing method thereof

A manufacturing method and coolant technology, which are applied in the directions of manufacturing converters and improving process efficiency, can solve the problems of inefficient utilization of carbon-containing and iron-containing wastes, affecting smelting operations, and limiting the addition amount, so as to achieve good promotion and use value, The effect of slag removal is good and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

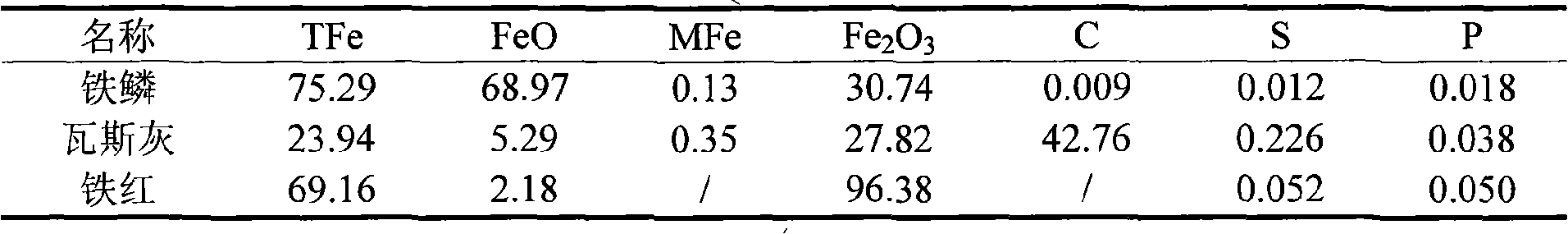

[0029] Carbon-containing and iron-containing agglomerates are made of iron scale, gas ash and iron red from iron and steel plant waste, and the composition of the raw materials is shown in Table 2.

[0030] Table 2 The raw material composition of carbon-containing and iron-containing agglomerates

[0031]

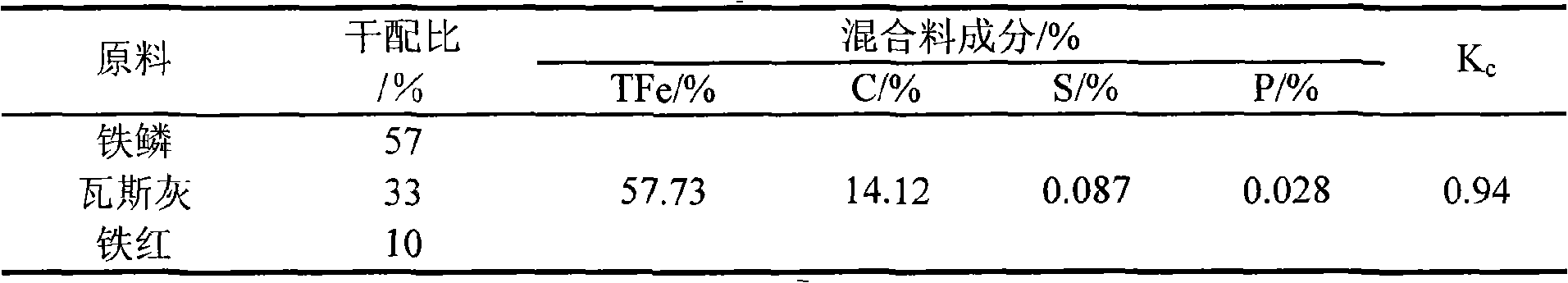

[0032] The ingredient scheme of carbon-containing and iron-containing agglomerates is shown in Table 3.

[0033] Table 3 Ingredients scheme of carbon-containing and iron-containing agglomerates

[0034]

[0035] Manufacturing method: firstly send the iron scale, gas ash and iron red into the mixer and mix for 5 minutes, then add the sodium silicate aqueous solution with a modulus of 4 and 6% by weight and stir for 5 minutes, and then send the materials into the mixer for mixing Grinding for 5 minutes, then sent to the double roller briquetting machine, the briquetting pressure is set to 60KN, the mixture is pressed into agglomerates, and the extruded agglomerates are...

Embodiment 2

[0039] Carbon-containing and iron-containing agglomerates are made of iron and steel plant waste iron scale, coke ash (ie, coke mine ash) and converter dedusting ash (ie, converter flue gas dry dedusting ash). The raw material composition is shown in Table 4.

[0040] Table 4 The raw material composition of carbon-containing and iron-containing agglomerates

[0041]

[0042] The batching scheme of carbon-containing and iron-containing agglomerates is shown in Table 5.

[0043] Table 5 Carbon-containing iron-containing agglomerate batching scheme

[0044]

[0045] Manufacturing method: first send iron scale, coke ash and converter dedusting ash into the mixer and mix for 5 minutes, then add a sodium silicate aqueous solution with a modulus of 4 and a weight percentage of 4% and stir for 5 minutes, mix the materials and then send them into the mixer Mix and grind for 5 minutes, then send it to the double-roller ball briquetting machine, set the briquetting pressure to 70K...

Embodiment 3

[0049] Carbon-containing and iron-containing agglomerates are made of iron and steel plant waste iron scale, gas ash, coke ash and secondary dust removal ash. The raw material composition is shown in Table 6.

[0050] Table 6 The raw material composition of carbon-containing and iron-containing agglomerates

[0051]

[0052] The ingredient scheme of carbon-containing and iron-containing agglomerates is shown in Table 7.

[0053] Table 7 Ingredients scheme of carbon-containing and iron-containing agglomerates

[0054]

[0055] Manufacturing method: first send iron scale, gas ash, coke ash and secondary dedusting ash into the mixer and mix for 7 minutes, then add a potassium silicate aqueous solution with a modulus of 2 and a weight percentage of 6% and stir for 5 minutes, mix the materials and then send them into the Mix and grind in the mixer for 5 minutes, then send it to the double roller briquetting machine, set the briquetting pressure to 60KN, press the mixture int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com