Two phase stainless steel welding rod

A technology of duplex stainless steel and welding electrodes, which is applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of high price, environmental pollution of on-site welding work, and poor welding process performance of welding electrodes, etc., to achieve Low manufacturing cost, excellent welding process performance, and good slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The welding electrode coating in this embodiment is composed of the following components in percentage by weight: 35% calcium oxide, 20% calcium fluoride, 8% titanium dioxide, 9% silicon dioxide, 8% ferrosilicon, medium carbon manganese 3% iron, 4% ferromolybdenum, 4% ferrochromium nitride, 4% potassium oxide, 4% sodium oxide and 1% nickel, mix the above components evenly and add water glass accounting for 16% of the total weight of the coating As a binder, the mixture is coated on the welding wire, then pressed by a hydraulic welding rod coating machine, dried at a low temperature of 150°C for 1 hour, and then dried at a high temperature of 350°C for 0.5 hours.

Embodiment 2

[0017] The welding electrode coating in this embodiment is composed of the following components in percentage by weight: 40% calcium oxide, 18% calcium fluoride, 6% titanium dioxide, 8% silicon dioxide, 6% ferrosilicon, medium carbon manganese 4% iron, 4% ferromolybdenum, 4% ferrochromium nitride, 4% potassium oxide, 5% sodium oxide and 1% nickel. Mix the above components evenly and add 18% water glass to the total weight of the coating As a binder, the mixture is coated on the outside of the welding wire, then pressed by a hydraulic welding rod coating machine, dried at a low temperature of 150°C for 1 hour, and then dried at a high temperature of 360°C for 0.5 hours.

Embodiment 3

[0019] The electrode coating in this embodiment is made up of the following components in percentage by weight: 45% of calcium oxide, 15% of calcium fluoride, 5% of titanium dioxide, 7% of silicon dioxide, 7% of ferrosilicon, 4% of ferromanganese %, ferromolybdenum 3%, ferrochrome nitride 3%, potassium oxide 5%, sodium oxide 4% and nickel 2%, after mixing the above components evenly, add water glass accounting for 17% of the total weight of the coating as a binder As a binder, coat the mixture on the outside of the welding wire, then press it through a hydraulic welding rod coating machine, dry it at a low temperature of 150°C for 1 hour, and then dry it at a high temperature of 380°C for 0.5 hours.

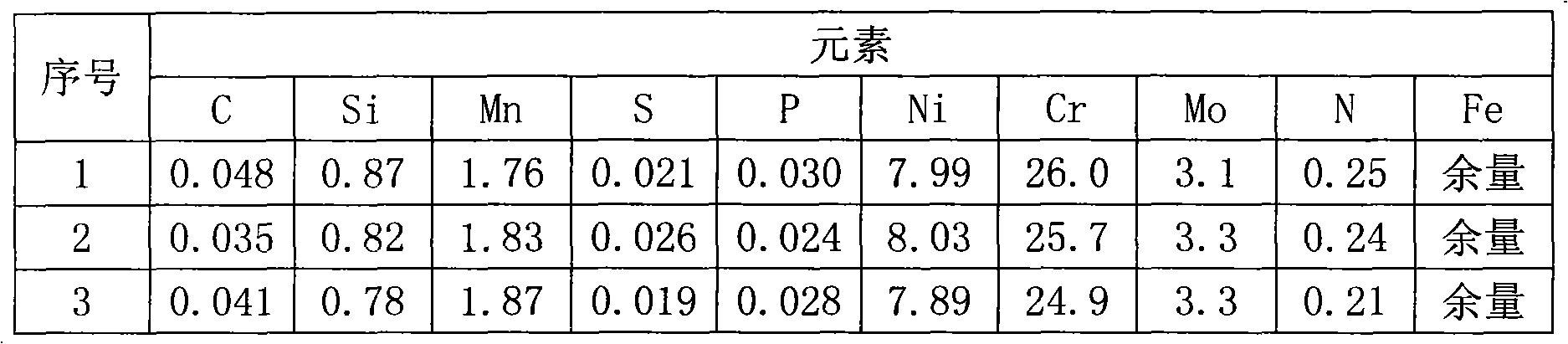

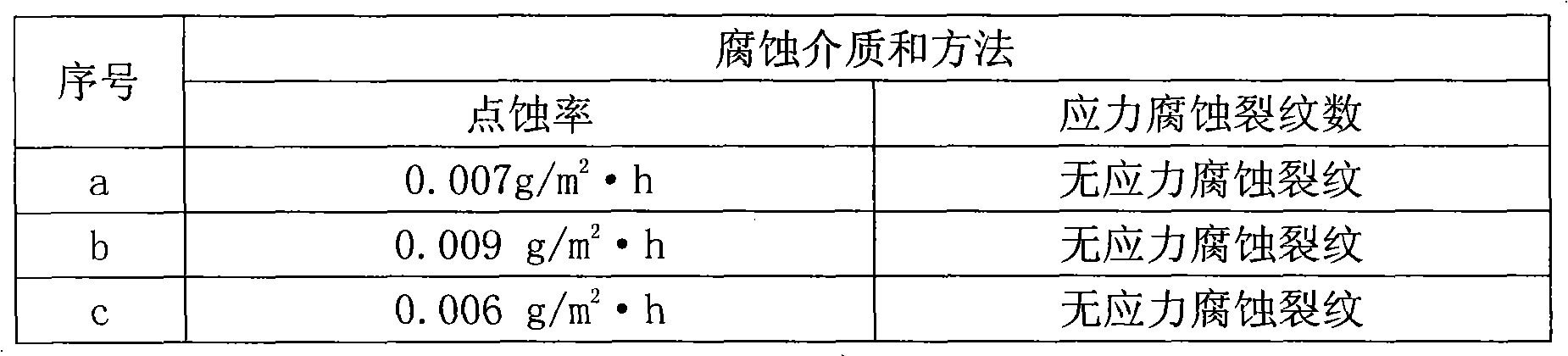

[0020] The weight percent of the deposited metal components of the electrode is: carbon ≤ 0.06%, manganese ≤ 2.0%, silicon ≤ 1.0%, sulfur ≤ 0.030%, phosphorus ≤ 0.030%, chromium 24.0-27.0%, nickel 5.5-8.5% , molybdenum 2.0-3.5%, nitrogen 0.10-0.30%, and the rest is iron. Embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com