Patents

Literature

53results about How to "No slag inclusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

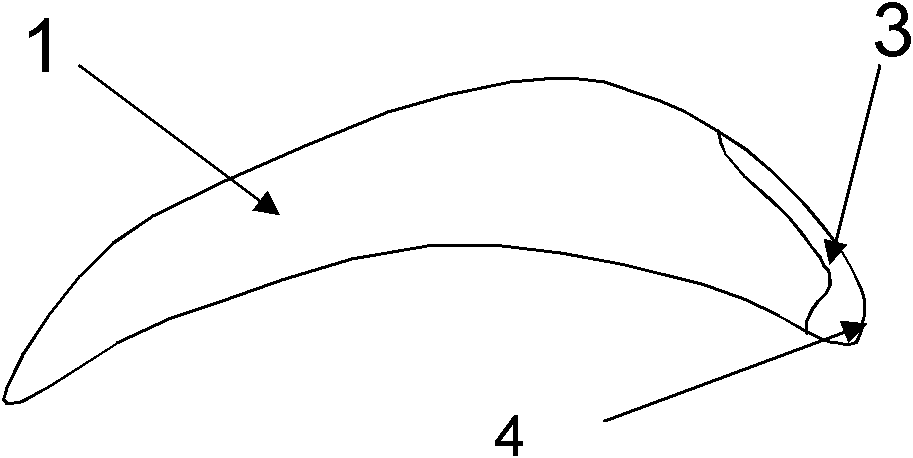

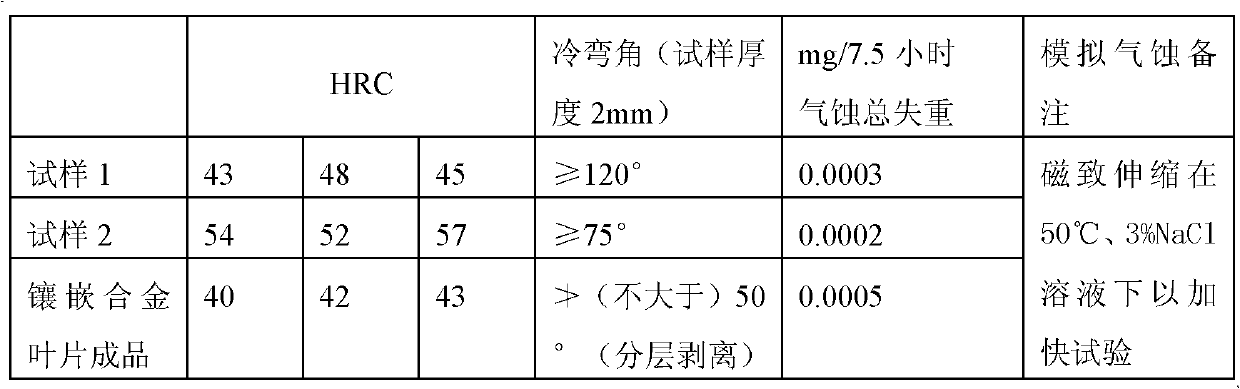

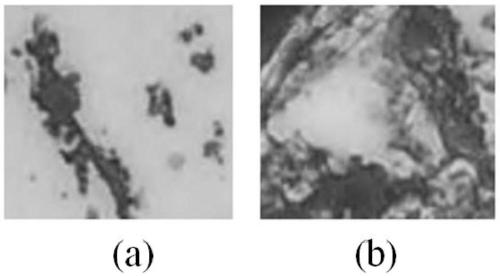

Laser cladding technological method and alloy material for laser cladding

ActiveCN102168210AUniform tissueSmall tissueMetallic material coating processesLaser beam welding apparatusCavitationSlag

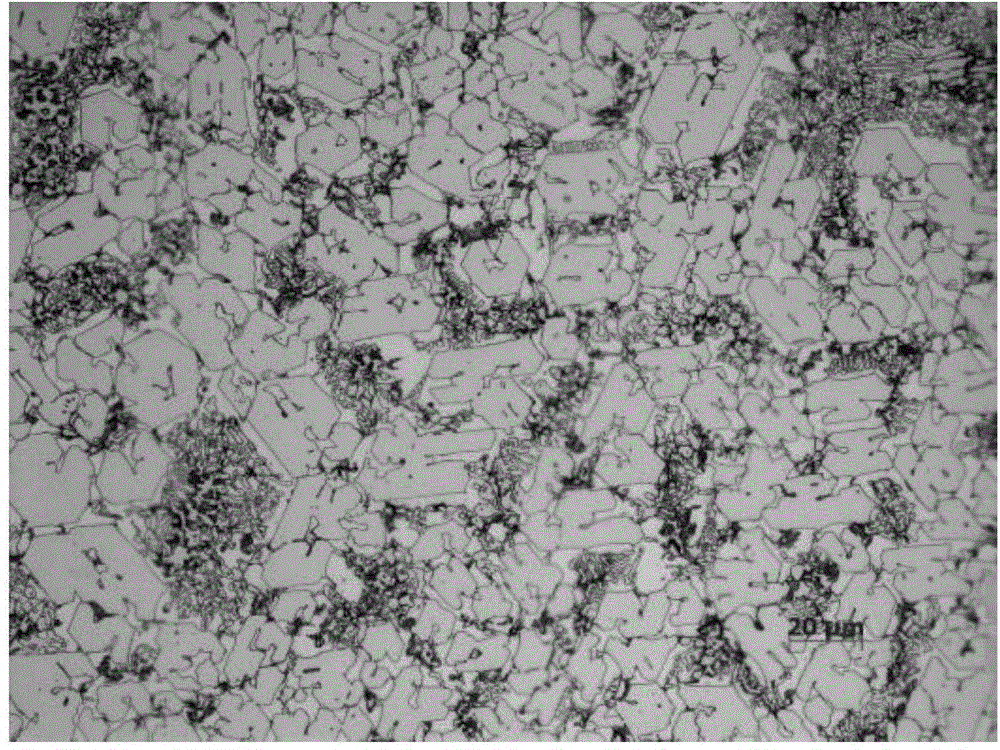

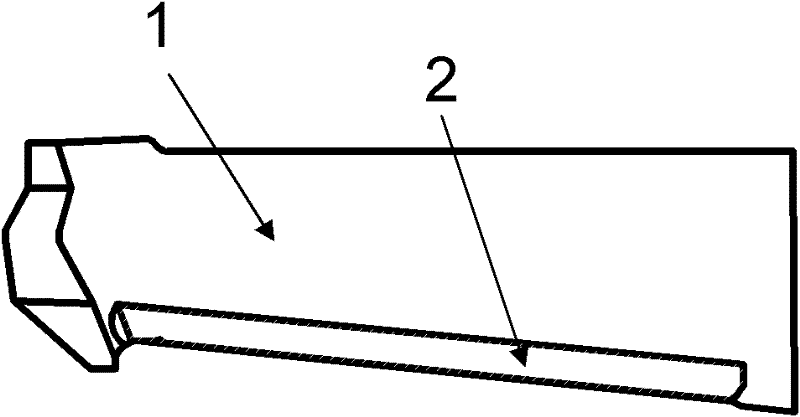

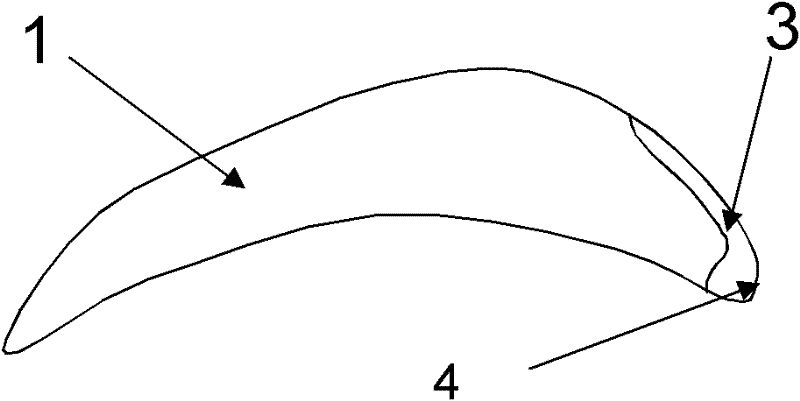

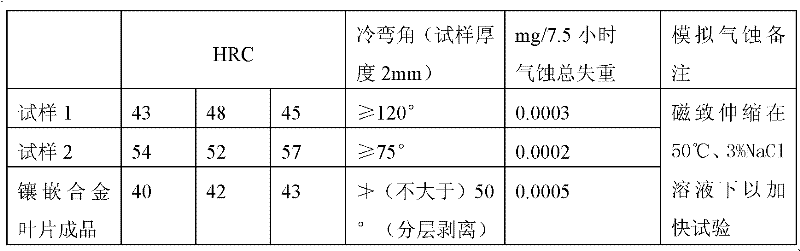

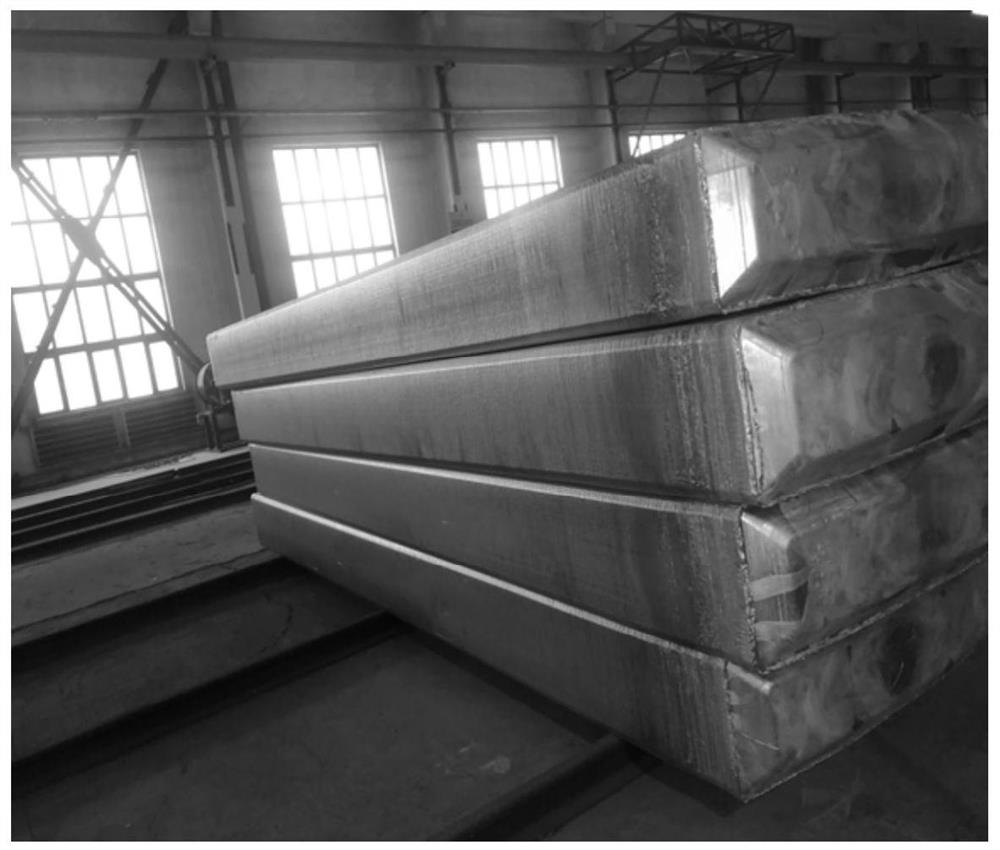

The invention discloses an alloy material for laser cladding. The alloy material is alloy powder and contains the following components in percent by weight: C: 0.85-0.98%, Cr: 35-45%, Fe: 3-5%, Si: 0.5-1.0%, W: 3.5-5.5%, Mo: 1 .0-1.5%, Ni: 6-8%, V: 1.5-2.0%, Ti: 1.0-2.0%, B: 0.5-1.5%, Nb: 0.10-0.50%, Re: 0.5-1.5%, and Co: the balance. The invention also discloses a laser cladding technological method adopting the alloy material. In the technical scheme, under the combined action of the added alloy elements, cladding layer tissue is uniform and tiny and has no pore, no inclusion and no included slag; and preheating is not needed when a blade is cladded and crack does not emerge. The alloy material has high rigidity and excellent cavitation resistance; without follow-up heating treatment, a cladded part can be directly fine machined to use; and the laser treatment technology has good adaptivity and is simple and feasible in operation.

Owner:HANGZHOU BOHUA LASER TECH

Production method of multi-element aluminum alloy standard sample

ActiveCN101294875AHigh yieldImprove distribution uniformityPreparing sample for investigationColor/spectral properties measurementsMulti elementStandard samples

The invention relates to a method for preparing a standard multi-element aluminum alloy sample. The method comprises the steps of proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and is characterized in that the standard sample contains the following 20 chemical elements in pure aluminum: Si, Fe, Cu, Mg, Mn, Zn, Sn, Pb, Ni, Ti, Cr, Sr, Ca, V, Ga, Zr, Cd, Be, B and P. The standard sample is manufactured sequentially through proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and finally, standard samples are prepared according to the requirements for the standard samples. By adopting the preparation method, the multi-element aluminum alloy sample with uniform composition and good stability can be obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Refining agent for smelting aluminum alloy

The invention relates to a refining agent for smelting an aluminum alloy. The refining agent is characterized by comprising the following components by mass percent: 35% to 45% of NaCl, 25% to 35% of KNO3, 3% to 8% of CaF2, 6% to 10% of Na2SiF6, 7% to 12% of Na3AlF6, 5% to 10% of graphite and 0.5% to 1.5% of rare earth. The refining agent has the characteristics of good refining effect, strong degassing capacity and the like, and cannot generate noxious gas during a production process.

Owner:COSCO W M J ALUMINUM DEV CO LTD

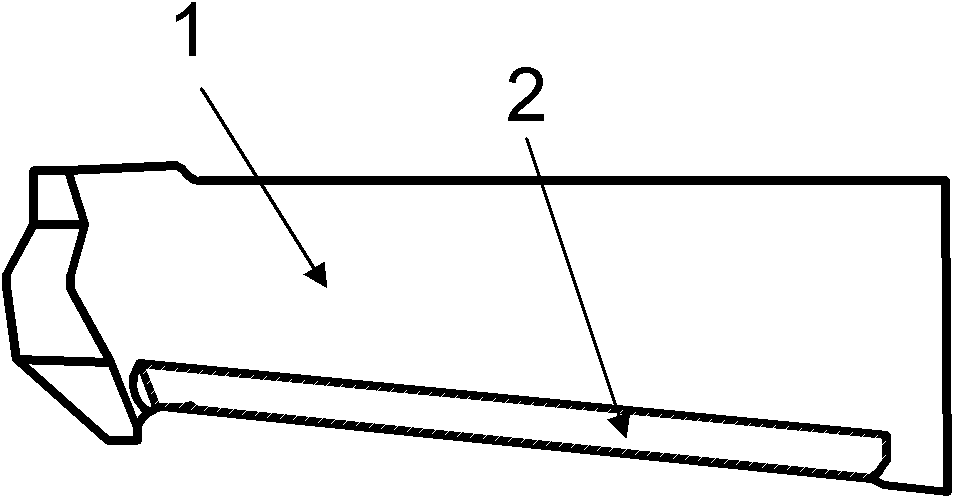

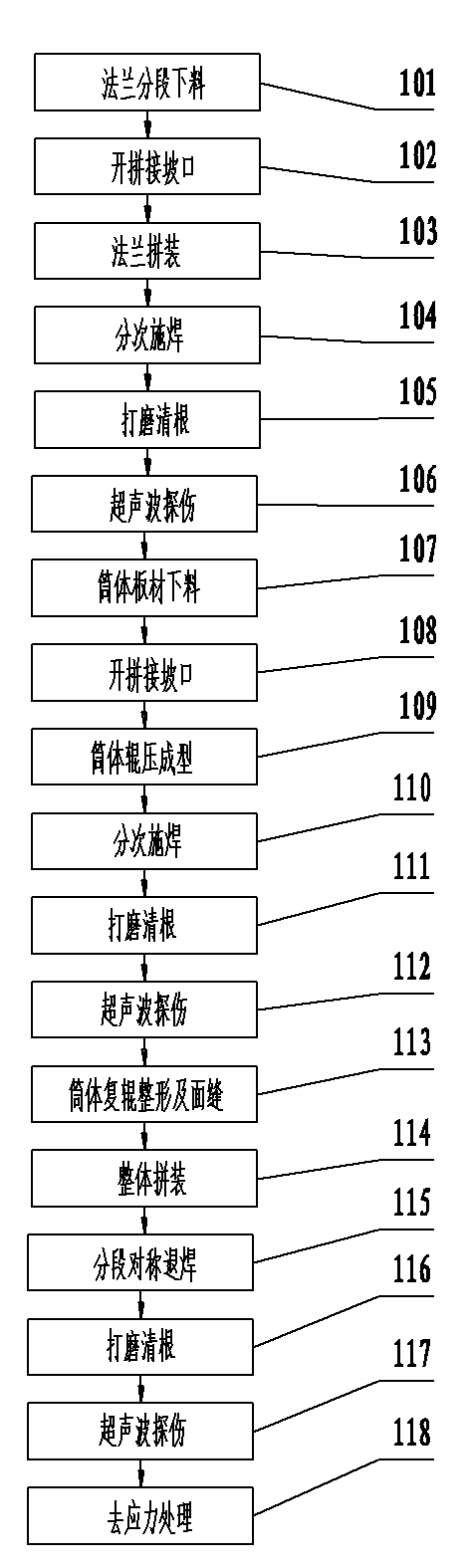

Welding technology for large connecting cylinder

The invention discloses a welding technology for a large connecting cylinder. The welding technology comprises the following steps of dividing a large flange material into a plurality of small sections for blanking and opening a splicing groove, and then forming a flange shape; welding at each butt joint front and back by several times; polishing and cleaning a welded seam after welding each time; carrying out ultrasonic detection on all welded seams after welding; carrying out blanking on a panel and opening the splicing groove on the panel according to the shape of the cylinder and molding through rolling; welding at the butt joint front and back by several times, polishing and cleaning the butt joint and carrying out ultrasonic detection on the butt joint, then reshaping the cylinder by rolling again and seaming the side of the cylinder; and finally, splicing the two welded flanges at the upper end surface and the lower end surface of the cylinder for integral splicing, and removing welding stress of a whole welded piece. Compared with the prior art, the welding technology solves the problems that the welded seam is easy to have residues and the welded pieces are deformed too much when the traditional ordinary welding method for the connecting cylinder is used for welding large flanges.

Owner:SOUTH CHINA MARINE MACHINERY

High-carbon high-chrome high-vanadium wearable surfacing self-shielded flux-cored wire

InactiveCN105798484AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

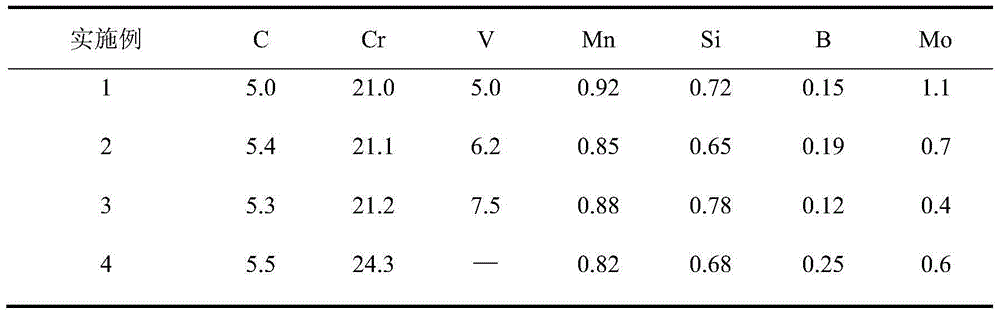

The invention discloses a high-carbon high-chrome high-vanadium wearable surfacing self-shielded flux-cored wire. According to the flux-cored wire, the core is prepared from the following components in mass percentage: 5-25% of high carbon ferro-chrome, 30-60% of chromium carbide, 15-35% of ferrovanadium, 0.5-5% of ferromolybdenum, 1-4% of electrolytic manganese, 1-4% of ferrosilicon, 1-4% of ferroboron, 1-5% of graphite, 1-5% of aluminium magnesium, 0-3% of zircon sand, 0-4% of marble, 0-3% of barium fluoride, 0-5% of barium carbonate, 0-3% of sodium fluosilicate, and 0-5% of fluorite; the skin of the flux-cored wire is a mild-carbon steel strip, the diameter is 1.6-4.0mm, and the counterweight ratio is 44-53%. According to the flux-cored wire disclosed by the invention, the rigidity and wearability of surfacing alloy can be greatly improved and the toughness of the surfacing alloy cannot be reduced; and the prepared surfacing alloy can be widely applied to surfacing repair of parts with severe low and intermediate stress abrasion at low temperature, intermediate temperature and high temperature and manufacture of new parts.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Two phase stainless steel welding rod

InactiveCN102019518AImprove mechanical propertiesImprove pitting resistanceWelding/cutting media/materialsSoldering mediaChromium nitrideMechanical property

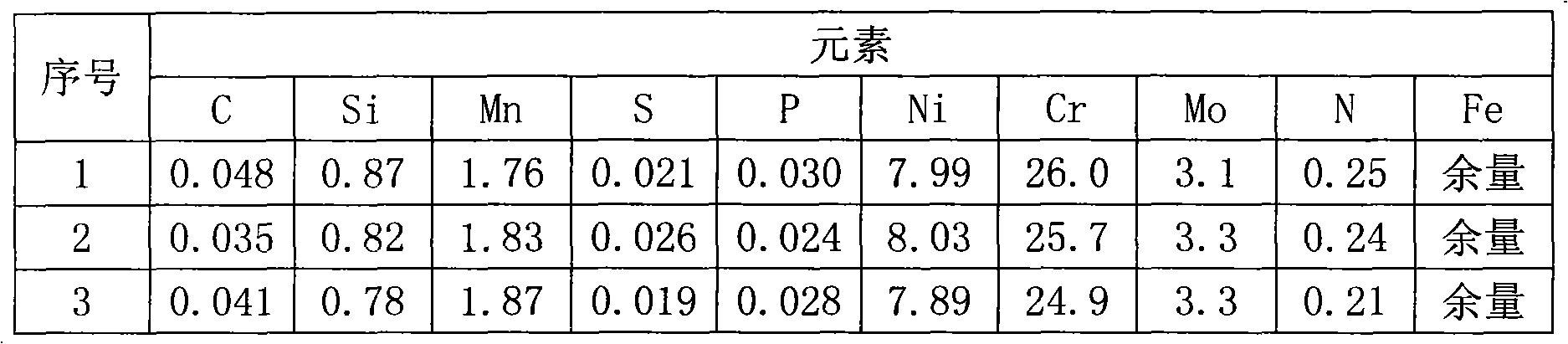

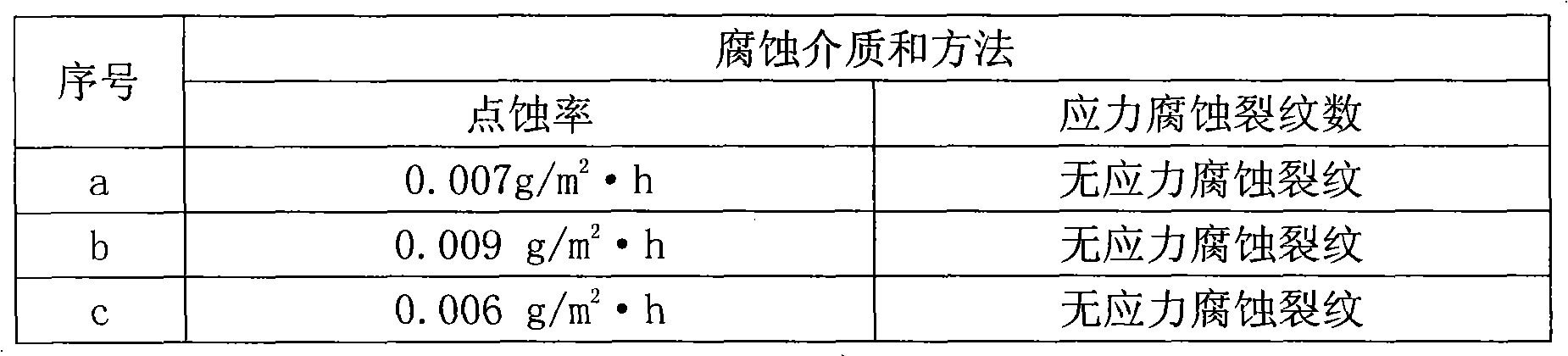

The invention discloses a two phase stainless steel welding rod which comprises a solder wire and a coating, wherein the coating comprises the following components in percentage by weight: 35-45 percent of calcium oxide, 16-25 percent of calcium fluoride, 5-10 percent of titanium white, 5-10 percent of silica, 4-8 percent of silicon iron, 3-5 percent of medium carbon ferromanganese, 2-4 percent of ferro-molybdenum, 3-5 percent of chromium nitride iron, 3-5 percent of potassium oxide, 4-6 percent of sodium oxide and 1-3 percent of nickel. The metal clad with the corrosion-resisting high-strength two phase stainless steel welding rod has excellent mechanical property, welding performance and pitting and stress corrosion resistance.

Owner:上海狮百盛焊材科技有限公司 +1

Preparation method of high-zinc magnesium alloy ingot casting

The invention discloses a preparation method of a high-zinc magnesium alloy ingot casting and relates to the preparation method of the alloy ingot casting. The invention aims to solve the problems that the existing high-zinc magnesium alloy ingot casting is easy to generate element segregation in the casting process and due to improper selection on a cooling water pressure, a casting speed and a melt temperature, a great number of cracks are generated. The preparation method comprises the following steps: 1, weighing materials; 2, feeding the materials; 3, smelting; 4, refining and standing; 5, casting. The preparation method has the advantages that 1, the high-zinc magnesium alloy ingot casting prepared by the preparation method is uniform in tissues and has no phenomena of pore loosening and slag inclusion and a melt has low impurity content; 2, the high-zinc magnesium alloy ingot casting prepared by the preparation method has a diameter of 405 mm to 485 mm, complete appearance and no obvious cracks. The high-zinc magnesium alloy ingot casting can be obtained by the preparation method.

Owner:NORTHEAST LIGHT ALLOY CO LTD

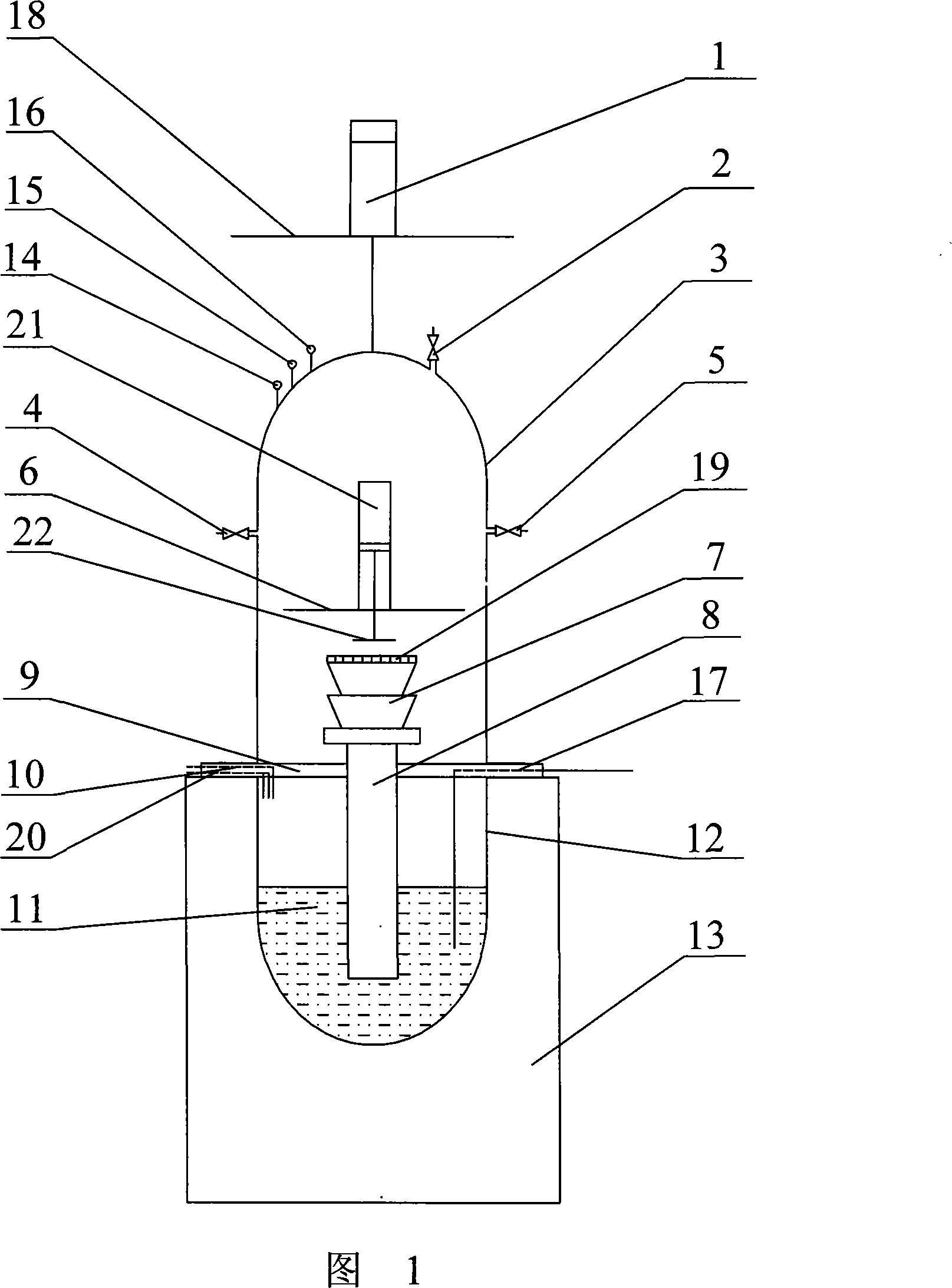

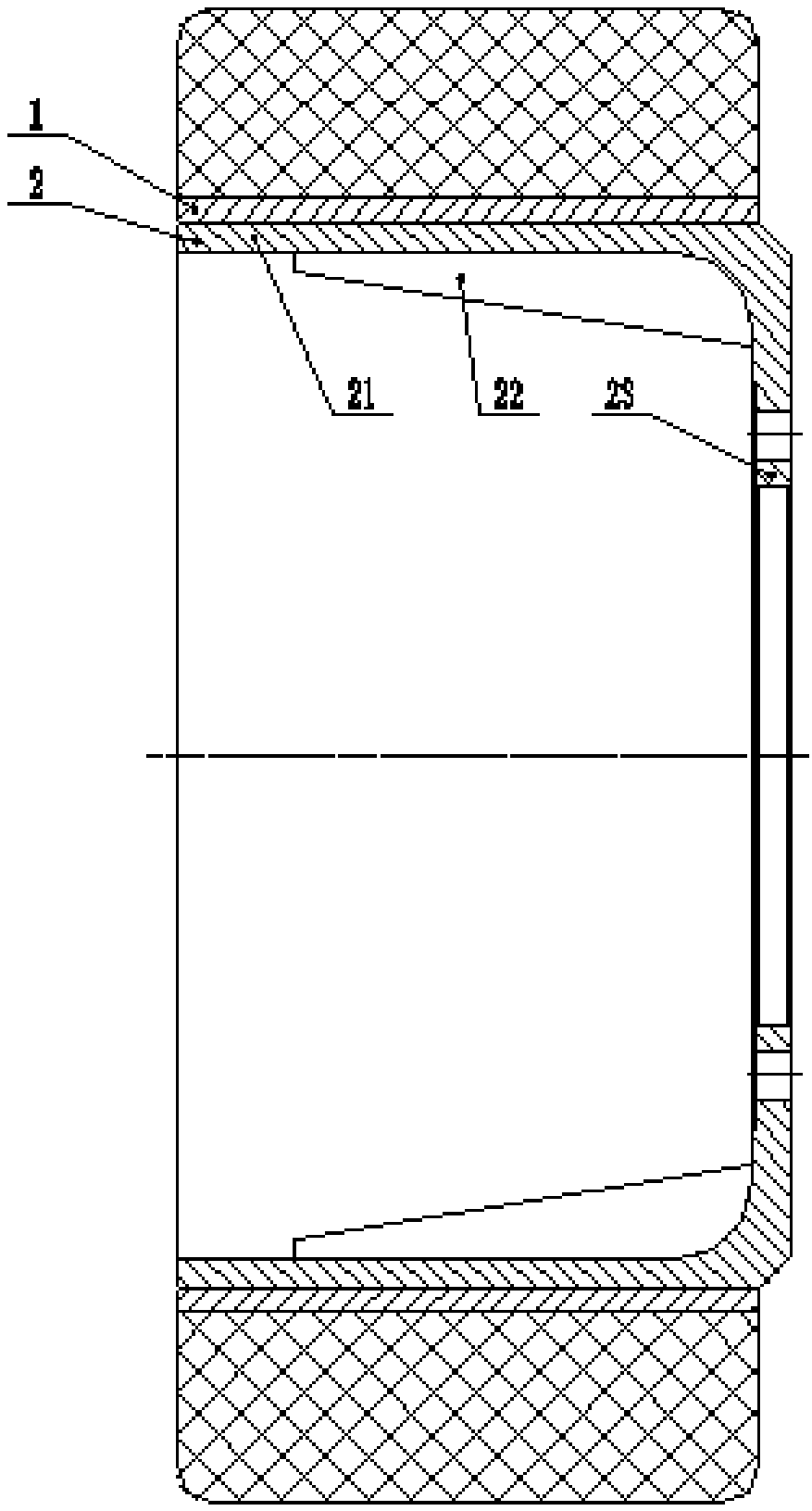

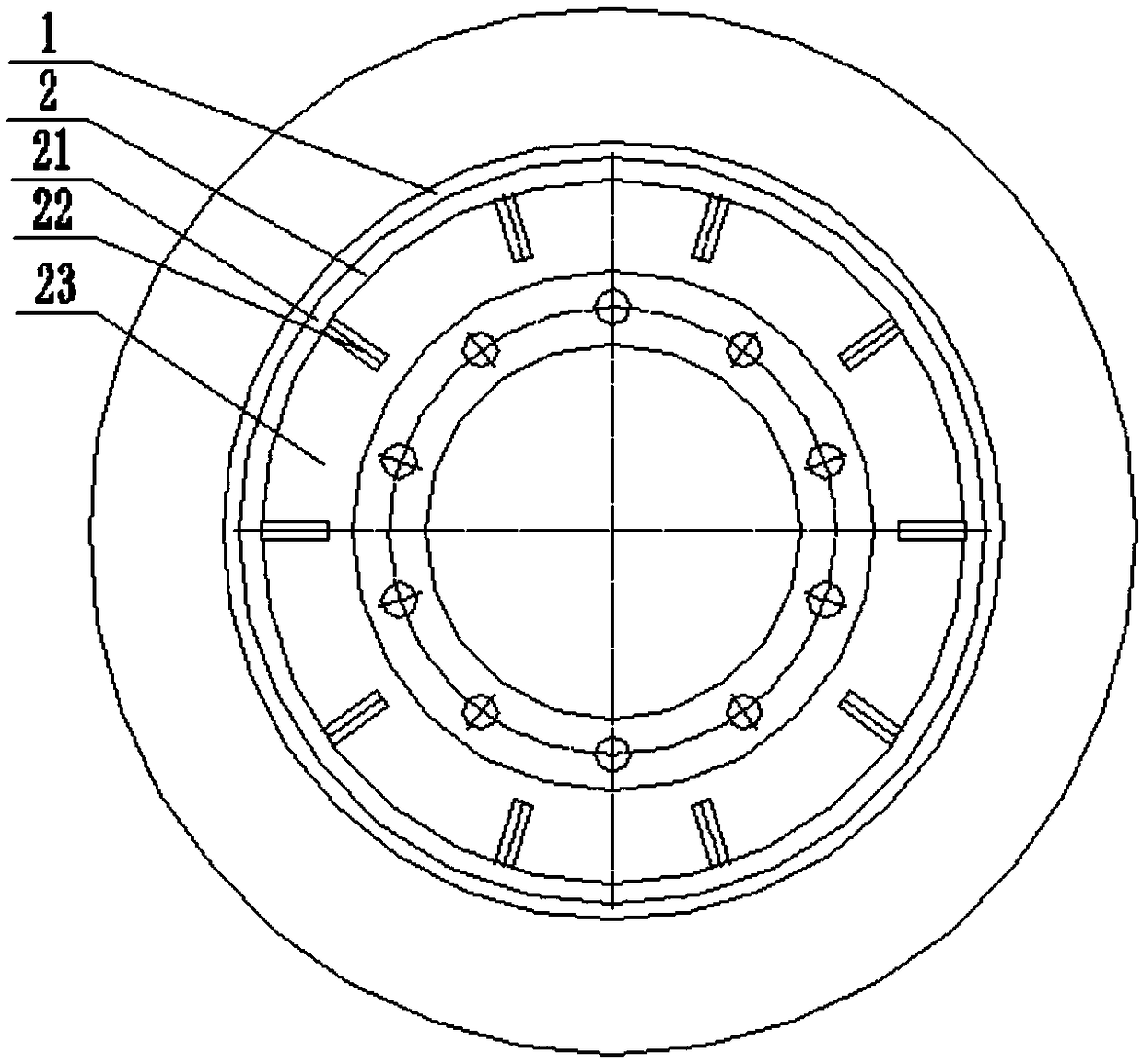

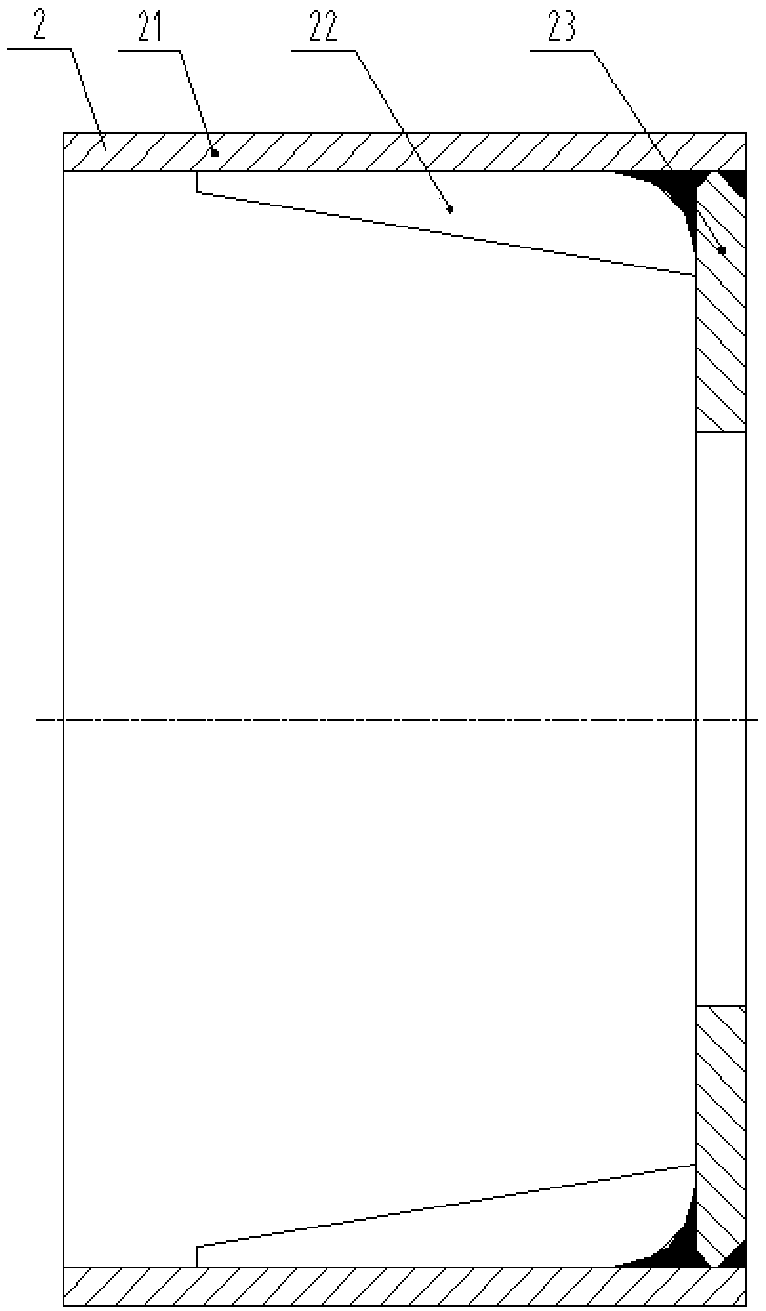

Vacuum pressure absorbing and casting device

The invention provides a vacuum pressure suction casting device. A melting furnace is provided with a pot; the opening of the pot is covered by a sealing pot cover by which the internal space of the pot is enclosed; the pot is provided with an air inlet valve; the sealing pot cover is provided with a liquid lifting pipe; the lower opening of the liquid lifting pipe is inserted into the pot through the sealing pot cover; a sealing vacuum cover is arranged above the pot; the vacuum cover is internally provided with a die assembly frame which is provided with a casting pattern die; the upper opening of the liquid lifting pipe is arranged in the vacuum cover and matched with the casting pattern die; the vacuum cover is connected with a lifting device; the vacuum cover is provided with a vacuum pumping valve and a vacuum breaking valve which control the internal space of the vacuum cover. The vacuum pressure suction casting equipment of the invention is suitable for various castings with extremely complex and fine externality and internal structures, thin walls, extremely high integral dimension precision and finish, extremely high requirement to mechanical performances and air sealing performance, etc. The invention is also suitable for the castings which are easy to generate hole shrinkage and loosening when being cast.

Owner:无锡刚正精密吸铸有限公司

Method for producing base steel abrasion-proof duplex metal compound material with centrifugal casting

The centrifugal casting process of producing wear resistant steel-base bimetal composite material includes the following steps: producing steel base blank, drilling compounding holes, alkaline pickling, acid pickling, eliminating acid, coating compounding agent into the holes, forming mouth, drying at room temperature, preheating to 300-350 deg.c, pouring molten non-ferrous metal or alloy into the holes, centrifugally forming at 850-1300 deg.c and 1200-1800 rpm, cooling and machining. The wear resistant steel-base bimetal composite material thus produced has compact compounding surface, no slag inclusion, great adhesion, great tensile strength and wide use.

Owner:ZIBO JINJUSHUANG METAL PRODS

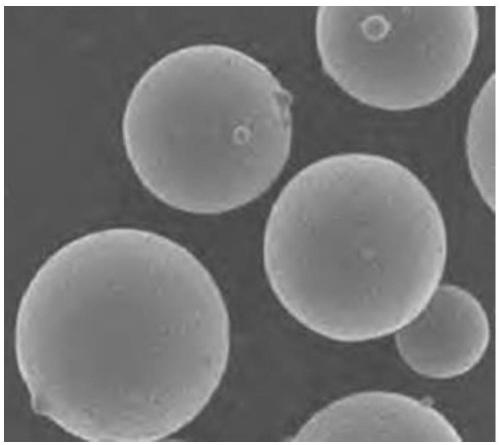

Laser-cladding powder

PendingCN109234729AAchieve protectionImprove performanceMetallic material coating processesGranularityWear resistance

The invention discloses laser-cladding powder and belongs to the field of cladding materials. The laser-cladding powder disclosed by the invention is prepared from the following components in percentage by mass: 14 to 17 percent of Cr, 0.25 to 0.42 percent of C, 2.1 to 3.1 percent of Si, 1.7 to 3.1 percent of B, 2 to 5 percent of Ni and the balance of Fe and unavoidable impurities; when the mass percent of Cr is 15 to 17 percent, Fe with the mass percent which is the same as that of Ni is used for replacing Ni; each component is powder with the purity which is greater than or equal to 99 percent; the granularity of the laser-cladding powder is 45 to 50microns; the laser-cladding powder is amorphous-state powder. When the laser-cladding powder is used for carrying out laser welding, technological parameters are as follows: the laser power is 1400 to 1600W, the light spot diameter is 5mm, the laser cladding speed is 200 to 350mm / min and the powder feeding speed is 30 to 42mg / s; a claddedmatrix is casting iron. The laser-cladding powder provided by the invention has very good metallurgy compatibility with the casting iron; compared with an existing cladding layer formed by laser-cladding powder, higher rigidity, wear resistance and corrosion resistance are achieved, and the preparation cost is lower.

Owner:马鞍山市申马机械制造股份有限公司

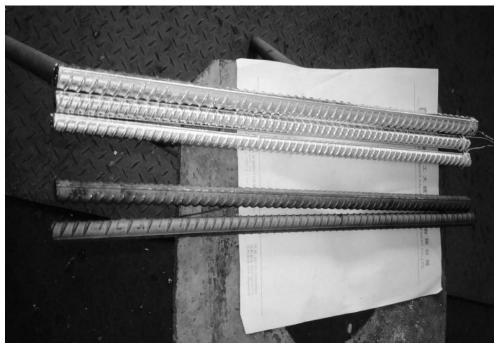

Novel plating auxiliary for single hot-dipping of Galfan alloy in solvent method and a preparation method thereof

ActiveCN108624831AQuality improvementGuaranteed Metallurgical BondingHot-dipping/immersion processesZinc bromidePotassium fluoride

The invention provides a novel plating auxiliary for single hot-dipping of a Galfan alloy in a solvent method and a preparation method thereof. According to the plating auxiliary, per liter of the plating auxiliary is prepared from the following components of 100-150 g / L of ZnCl2, 50-100 g / L of ZnBr, 10-20 g / L of SnCl, 8-12 g / L of KF, 0-0.5 g / L of bismuth chloride, 0.5-2 g / L of sodium borohydride,0.1-0.3 g / L of hydrochloric acid, 5-15 g / L of active alkali metal chloride salt and the balance water. The plating auxiliary has the advantages that the zinc bromide, the sodium borohydride and the potassium fluoride are introduced into the plating auxiliary, so that a surfactant and rare-earth chloride which are expensive in price are avoided, the application range is wider, almost all steel products are covered, and therefore the problems of serious skip plating, air holes, list edges, slag inclusion and the like in the Galfan alloy hot-dipping process in the prior art can be effectively solved; and the plating auxiliary can play a good plating assisting role when being used at room temperature, the production cost is greatly saved, the components of the plating auxiliary are stable, the cost is low, and industrial popularization is facilitated.

Owner:HEBEI UNIV OF TECH

Diamond cutting pick and machining method thereof

PendingCN111088948AImprove impact resistanceImprove wear resistanceDrill bitsSoldering apparatusDiamond cuttingSlag (welding)

The invention belongs to the technical field of rock roadway tunneling, coal mining and engineering tunnel construction, and discloses a production method of a mushroom-shaped diamond tooth head cutting pick. The production method comprises the following steps that diamond micro-powder and a hard alloy substrate are compounded into a mushroom-shaped diamond composite tooth head under the conditions of high temperature and high pressure; and a low-melting-point high-strength silver-based solder is adopted to be melted on the bottom planes of diamond composite teeth, the solder is in a water drop shape after being solidified due to surface tension, and meanwhile the solder is placed in a cutting pick base body embedding hole preheated to a certain temperature to be welded into a whole. The method is characterized in that during welding, the top end of the water-drop-shaped solder makes contact with the hole bottom first to be molten, and hole bottom gas can be fully exhausted, so that itis guaranteed that a solder layer is free of slag inclusion, gas inclusion and insufficient solder faces, and the problem that insufficient soldering is formed due to the fact that during traditionalblind hole welding, gas at the hole bottom cannot be fully discharged is solved; and according to the soldering process, adverse effects caused by high-temperature soldering of the diamond compositeteeth are avoided, the soldering strength between the diamond composite teeth and a cutting pick body is effectively enhanced, and the diamond cutting pick produced through the process has higher impact resistance and abrasion resistance.

Owner:杨政龙

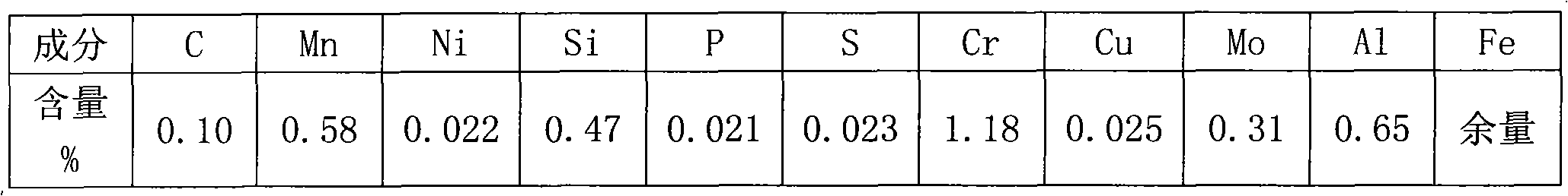

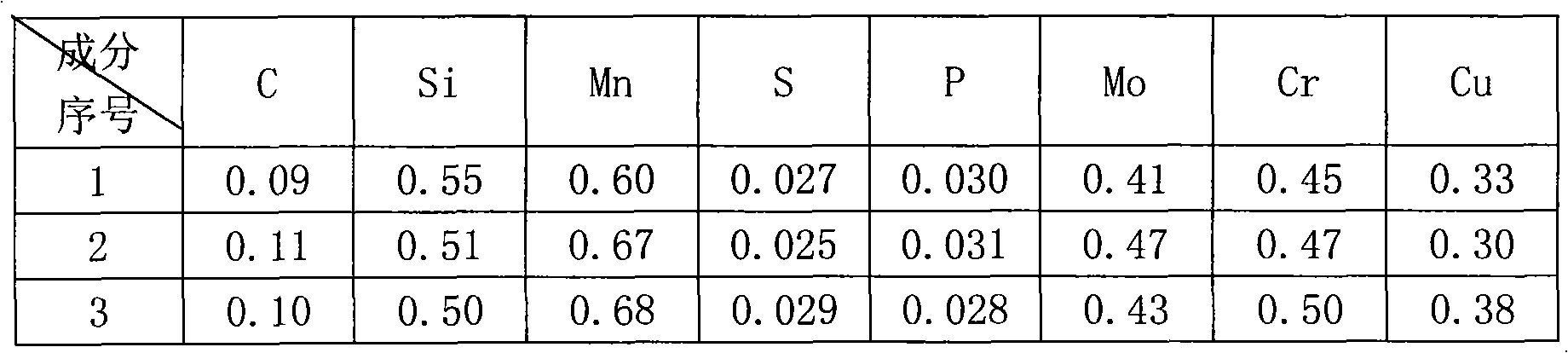

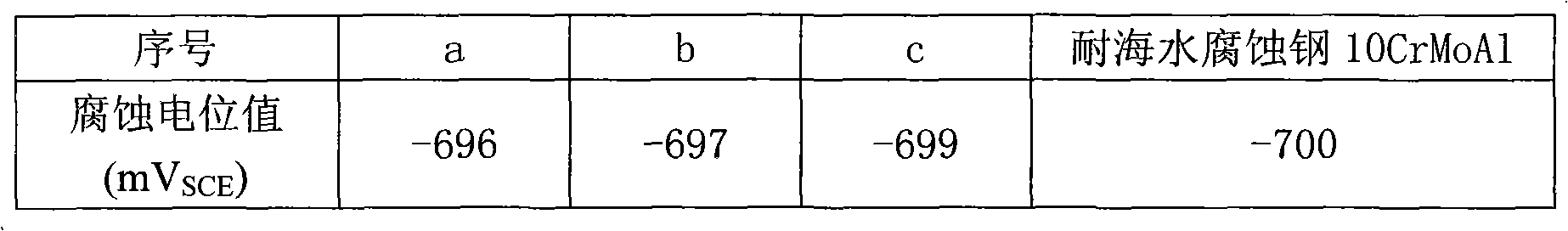

Cr-Mo-Al series welding rod for low-alloy and high-strength steel

InactiveCN102091885AReduce manufacturing costSmooth beadWelding/cutting media/materialsSoldering mediaSilicon dioxideMechanical property

The invention discloses a Cr-Mo-Al series welding rod for low-alloy and high-strength steel, comprising a core wire and a coating, wherein the coating comprises the following components in percentage by weight: 32-42 percent of calcium oxide, 16-20 percent of calcium fluoride, 5-10 percent of titanium white, 8-12 percent of silicon dioxide, 3-5 percent of mid-carbon ferromanganese, 3-5 percent of ferromolybdenum, 4-6 percent of low-carbon ferromanganese, 3-4 percent of potassium oxide, 4-6 percent of sodium oxide, 2-3 percent ofaluminum oxide and 3-5 percent of copper. The welding rod provided by the invention has low manufacture cost, and the deposited metal of the welding rod has favorable mechanical property, welding performance and seawater corrosion resistance.

Owner:上海狮百盛焊材科技有限公司 +1

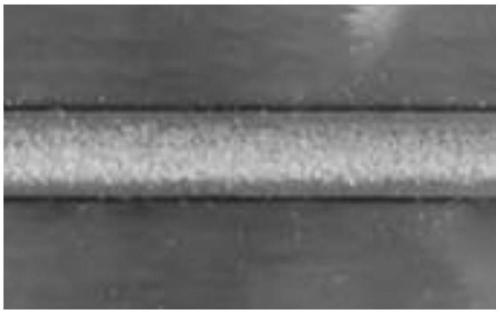

X80 pipeline steel submerged arc welding flux-cored wire with excellent low temperature performance and preparation method thereof

InactiveCN110385546AWith metallic lusterNo poresWelding/cutting media/materialsWelding/soldering/cutting articlesSlagManganese

The invention discloses an X80 pipeline steel submerged arc welding flux-cored wire with excellent low temperature performance and a preparation method thereof. The flux-cored wire comprises a flux core and a welding skin, wherein the flux core consists of the following components in percentage by mass: 1.3-2.6% of manganese, 0.1-0.3% of silicon, 0.3-0.5% of molybdenum, 1.1-1.5% of nickel, 0.005-0.01% of boron, 0.01-0.04% of copper, 0.003-0.008% of titanium, 0.1-0.25% of cerium dioxide, and the balance iron; and the sum of the abovementioned components in percentage by mass is 100%. The flux-cored wire has the beneficial effects that: Ni, Mn, Mo and other elements are added through proportioning control to obtain a welded joint deposited metal component similar to an X80 pipeline steel base material; the surface of a welding line is smooth and clean, has metallic luster, and is free from air holes and slag inclusion; and moreover, the impact power Akv-45DEG C under the temperature of -45 DEG C is not less than 105J, so that the working condition under the temperature of -45 DEG C applies.

Owner:XIAN UNIV OF TECH

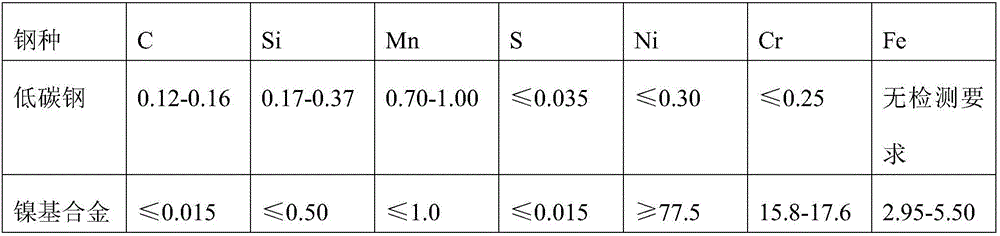

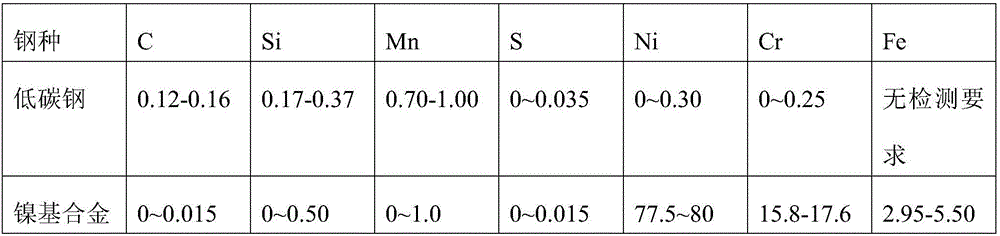

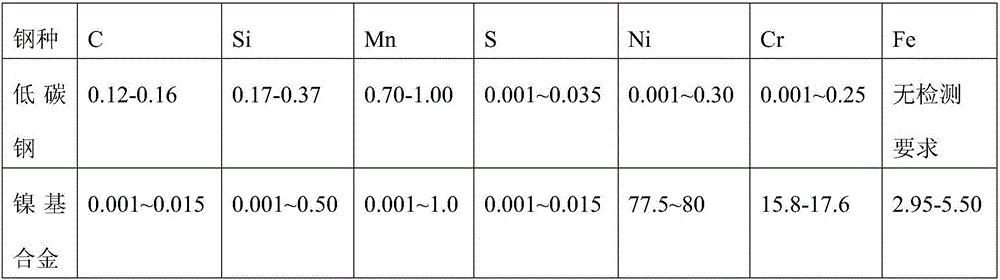

Preparation method of nickel-based duplex metal composite used for fluorine chemical production equipment

The invention discloses a preparation method of a nickel-based duplex metal composite used for fluorine chemical production equipment. The preparation method of the nickel-based duplex metal composite used for the fluorine chemical production equipment comprises the following steps that (1) base materials and composite materials are selected according to working condition requirements; (2) smelting and refining are conducted, specifically, the base materials and the composite materials are melted through a medium-frequency induction furnace, and then refining is conducted through a refining surface for composition adjustment; (3) centrifugal pressure casting is conducted on a composite tube blank, specifically, a refined metal solution is subjected to centrifugal pressure casting through a centrifugal combined steel casting machined, and the composite tube blank is obtained; (4) external descaling is conducted, specifically, inner boring and external descaling are conducted on the poured composite tube blank, and defected portions are removed; (5) hot extrusion and cogging are conducted, the composite tube blank is subjected to initial deformation, and thermal treatment is conducted; and (6) a finished product is obtained through cold rolling. According to the material prepared through the preparation method, a base layer is in complete metallurgical bonding with a composite layer (the bonding force of a composite surface is high), the structure is compact, and the strength is high.

Owner:SICHUAN XINDING NEW MATERIALS

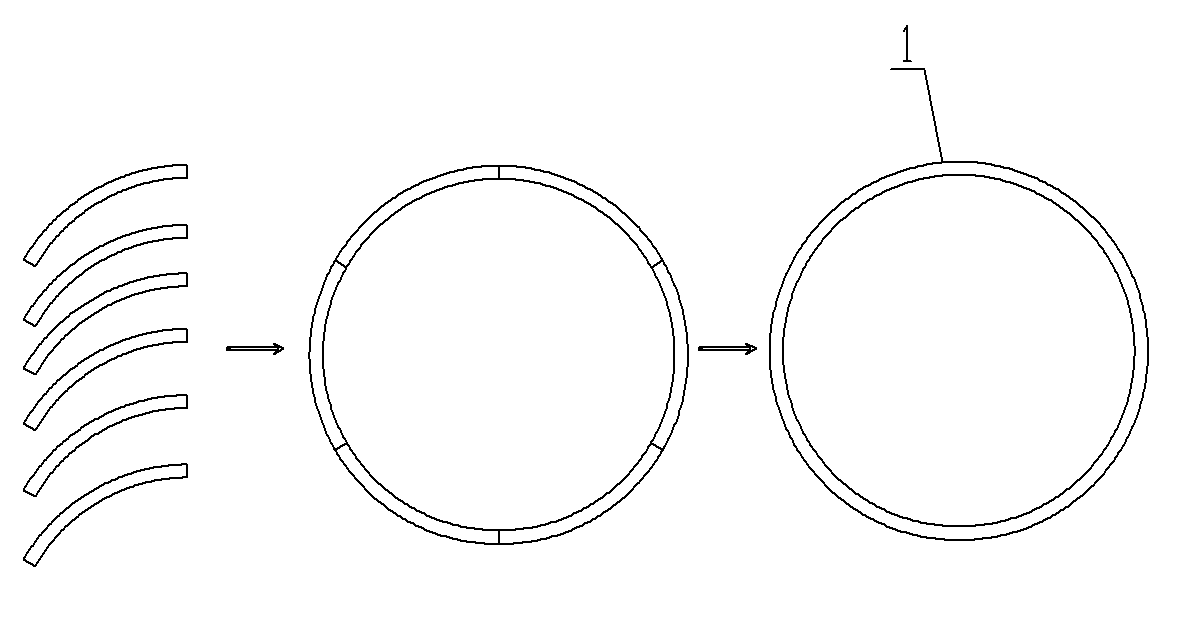

Processing technology for press-fit wheel structure

The invention provides a processing technology for a press-fit wheel structure. The processing technology comprises the steps of processing of a radial plate ring and processing of a press-fit ring; the processing of the radial plate ring comprises the steps of processing of a barrel, processing of a radial plate, assembly welding of the barrel and the radial plate, processing of a ribbed plate, assembly welding of the ribbed plate, turning and drilling. The processing technology for the press-fit wheel structure has the advantages of stable dimensions, high dimensional accuracy, no splashingor slag inclusion, large weld penetration depth, high weld strength, welding efficiency and product consistency, stable and reliable performance, low cost, high efficiency and no cracking phenomenon during press-fit.

Owner:HONGYUAN JINGGONG WHEEL CO LTD

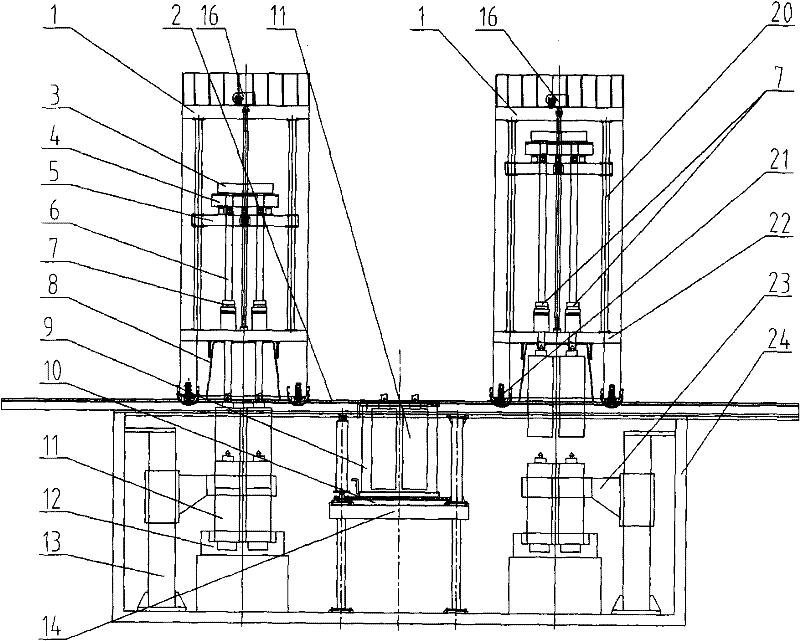

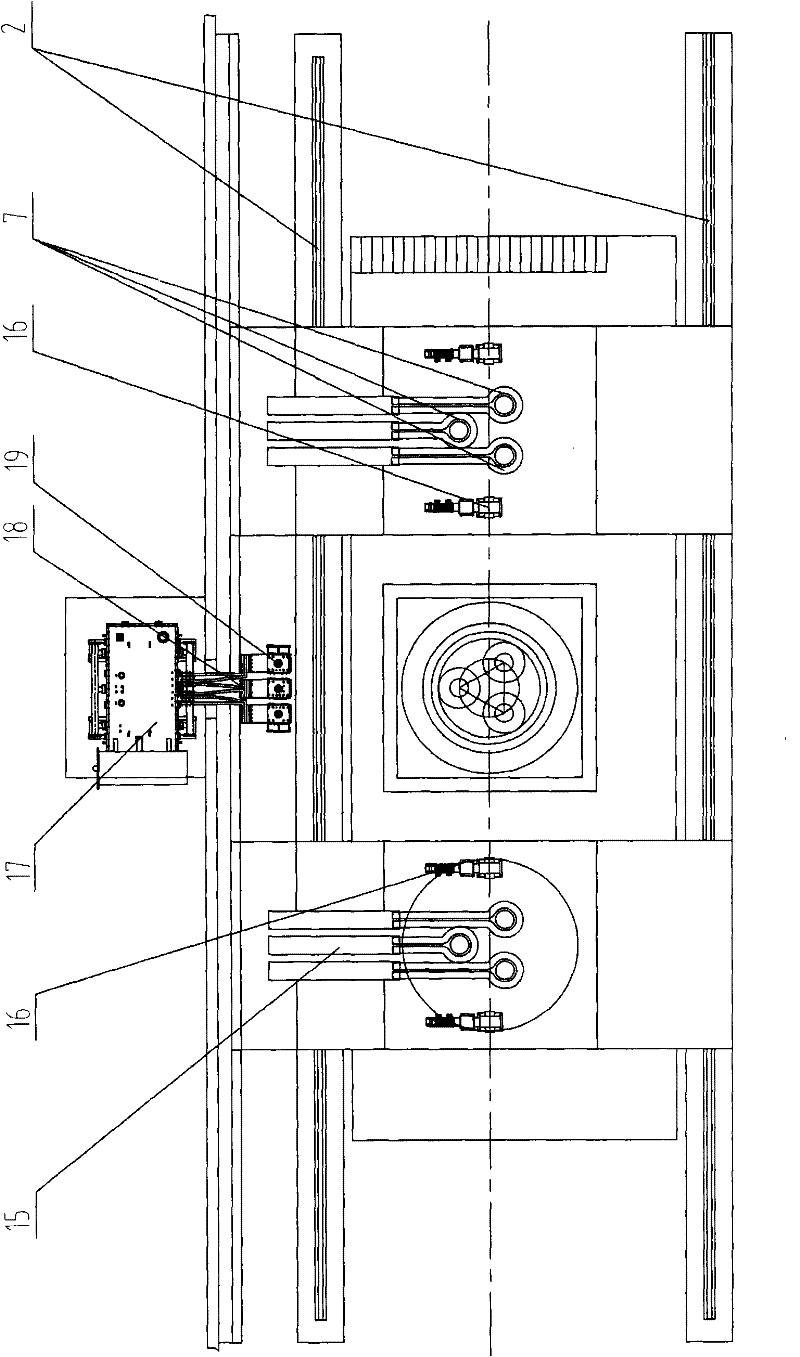

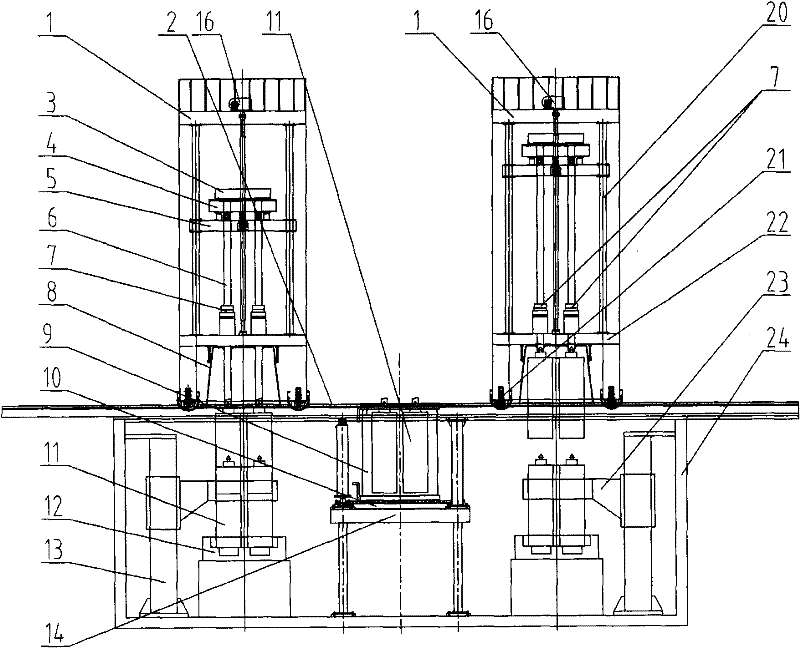

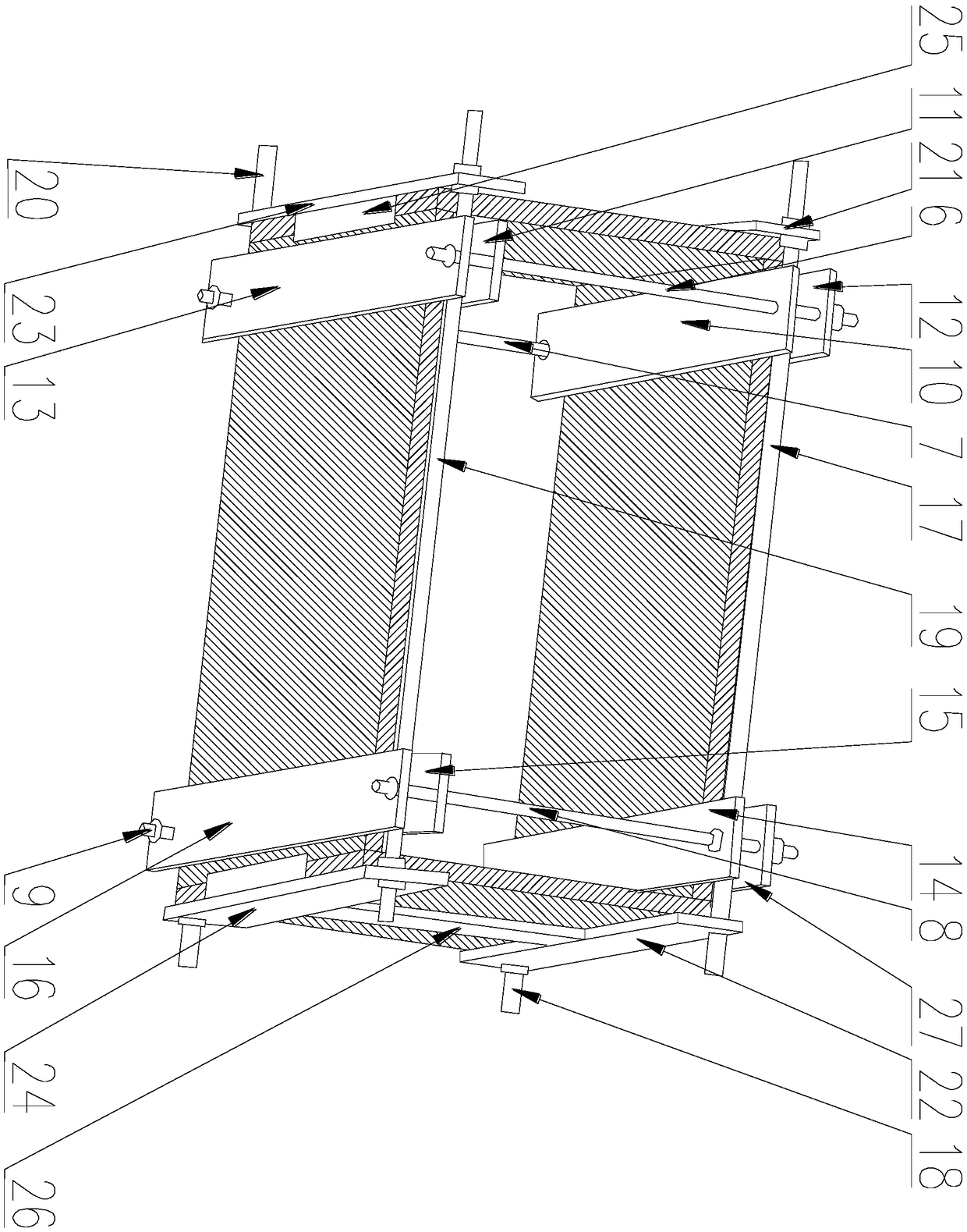

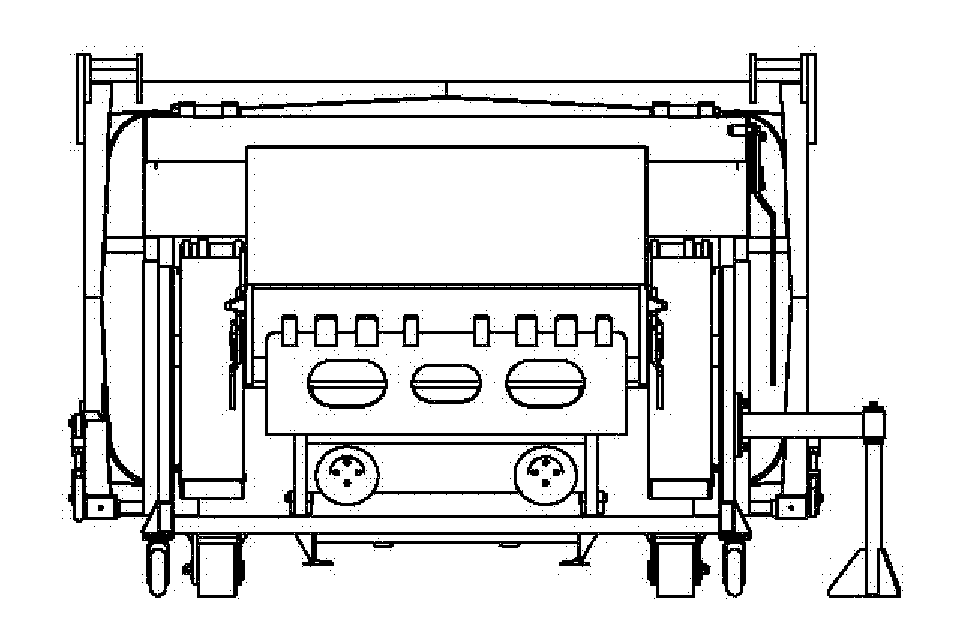

Heavy-current short-network direct attached gas shield three-phase electric slag furnace

The invention provides a heavy-current short-network direct attached gas shield three-phase electric slag furnace, comprising a gantry type movable furnace body, a casting lifting platform, a crystallizer, a bottom water tank, an end heating device, a consumable electrode locating device upright, a crystallizer lifting platform, an electrode lifting system upright guide rod, a furnace body lower platform and a consumable electrode locating guide plate support, wherein the upper part of the casting lifting platform is provided with a system weighing platform, the system weighing platform is provided with an electrode clamping and lifting system, the electrode clamping and lifting system is fixed with 3-6 bearing conductive material rods which are symmetrically distributed, a consumable electrode is arranged and blocked below each bearing conductive material rod, each bearing conductive material rod is sheathed with a current collection slip ring, the current collection sliding ring is internally provided with a conductive electric brush, the bearing conductive material rod is contacted with the current collection slip ring in a sliding way, the current collection sliding ring is connected with one end of a direct attached short network, and the other end of the direct attached short network is directly connected with a transformer outlet terminal of a three-phase transformer, thus the electrical energy utilization ratio is improved.

Owner:沈阳金正冶金技术有限公司

Preparation method of exothermic welding powder for grounding grid

ActiveCN107020448ANo splashingOperational securityAlumino-thermic welding apparatusExothermic weldingSlag

The invention relates to a preparation method of an exothermic welding powder for a grounding grid, and belongs to the technical field of welding powder. The preparation method aims to solve the problems that exothermic welding powder currently produced domestically splashes in the welding process, which influences the welding personnel safety, and pores and slag exist in joints. According to the preparation method, aluminum isopropoxide is evenly dispersed in isopropanol, pH is adjusted through a nitric acid solution, alumina sol is obtained, then copper oxide and a surfactant are added for activation modification so that the copper oxide and aluminum are mixed more evenly, polyethylene glycol is used as a carrier, aluminum and copper are subjected to adsorption combination through a silane coupling agent, meanwhile, silicon elements are added, copper-aluminum crystals are obtained through freezing treatment, the welding effect is improved by adding platinum for assisting, finally, materials are mixed with fluorite powder for lowering the melting point, and the exothermic welding powder for the grounding grid is prepared through fusion and atomizing. The exothermic welding powder for the grounding grid is free of splashing phenomenon in the welding process, and pores and slag do not exist in the joints.

Owner:日照大正焊接材料有限公司

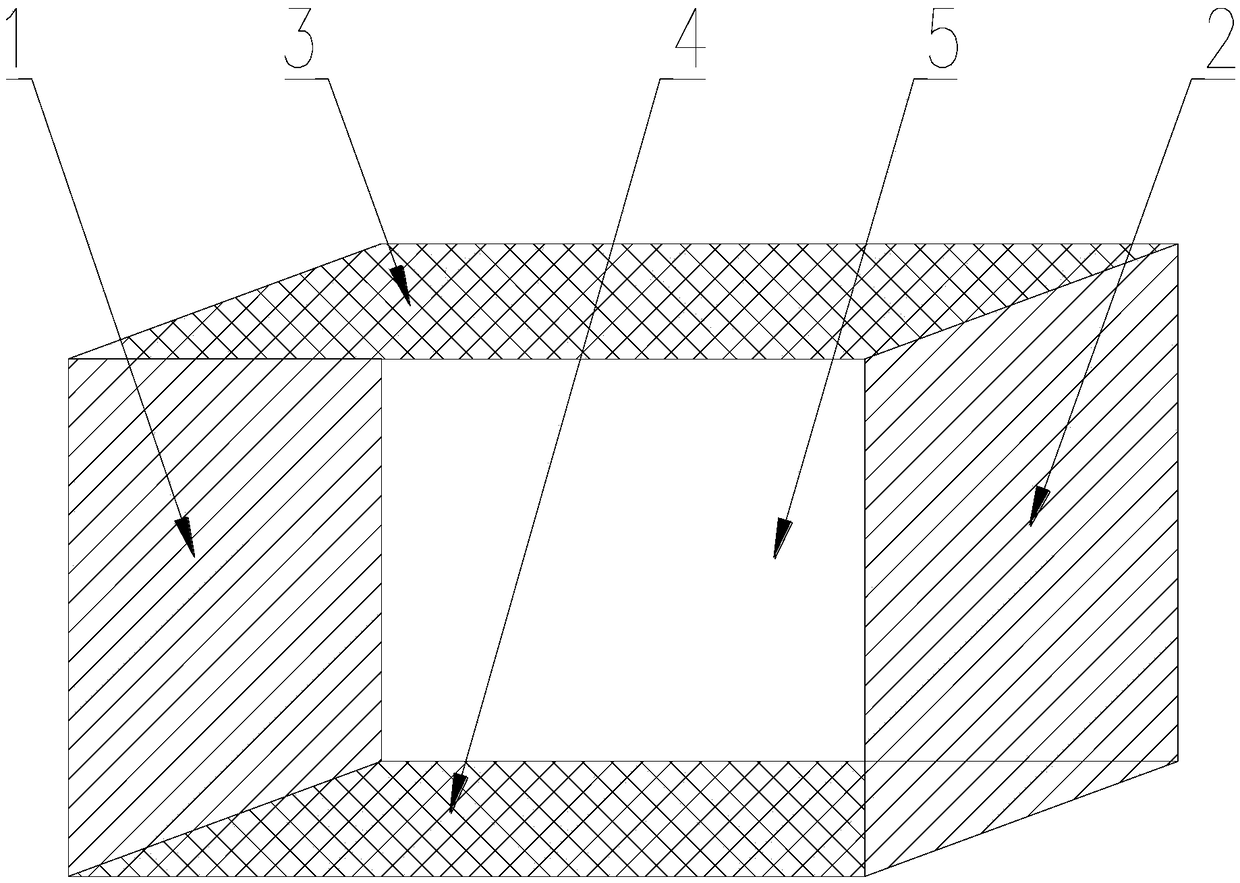

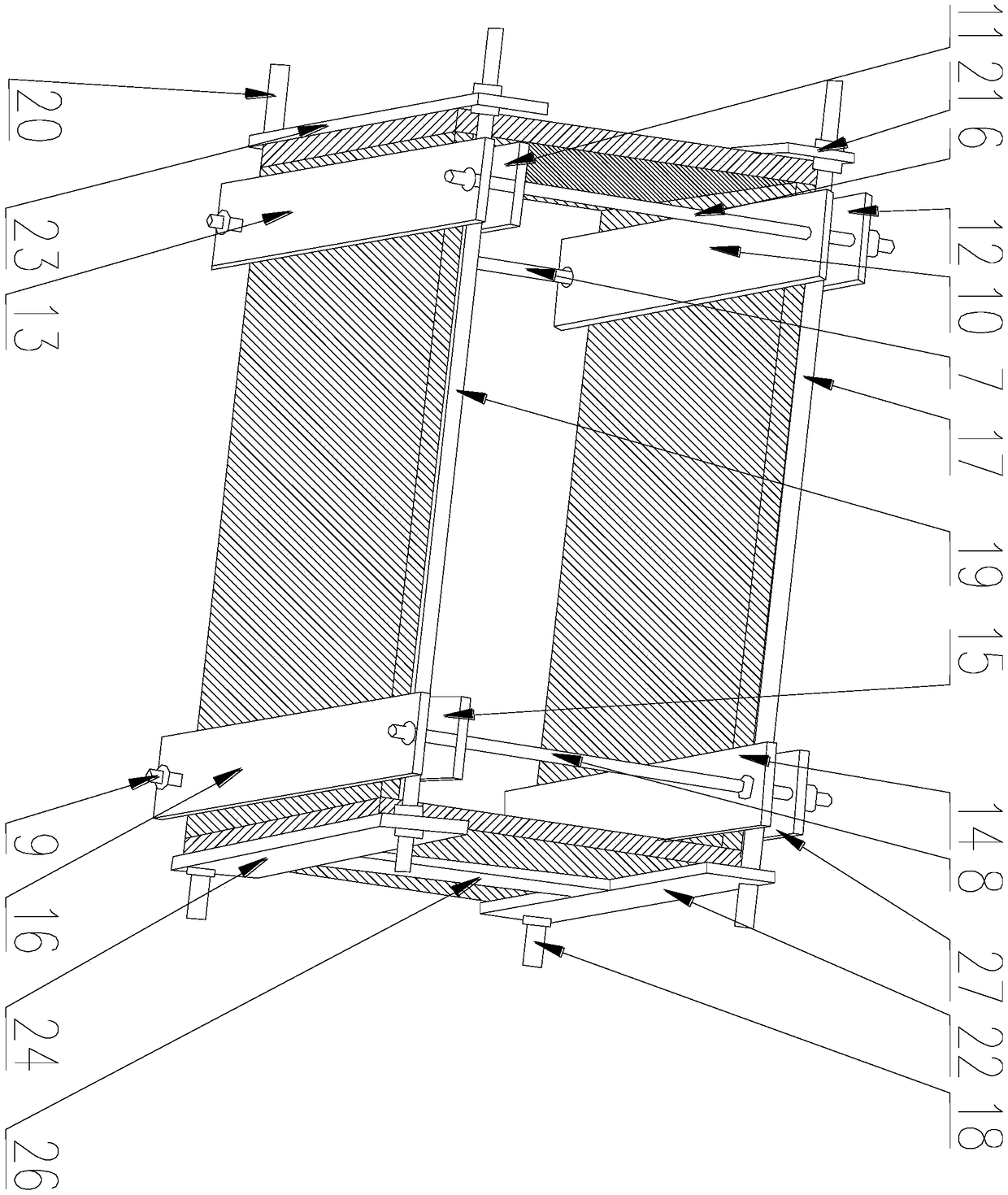

Square shielding case and assembling tool thereof

PendingCN108637578ASimple structural designReduce manufacturing costsInstrument screening arrangementsWelding/cutting auxillary devicesSlagManufacturing engineering

The invention discloses a square shielding case and an assembling tool thereof. The problems that as for a traditional shielding case, the structure is complex, the production cost of an enterprise ishigh, the assembling difficulty is high, welding is poor, and flux leakage is prone to occurring are solved. The square shielding case formed by sequentially welding a left side plate, a right side plate, a top plate, a bottom plate and a rear cover and the assembling tool for assembling the square shielding case are mainly included. According to the shielding case, the structural design is simple, the production and manufacturing cost is low, a routine thought is broken through, and the shielding demand of an electronic instrument is met through the extremely simple structure; according to the assembling tool, the structural design is simple and ingenious, operation is easy, the assembling accuracy is high, it is effectively ensured that welding joints of the shielding case are smooth, flat and free of flux leakage in welding, and the phenomena of slag inclusion and incomplete penetration are avoided; and the operation efficiency of workers is further greatly improved, the reject ratio of a product is greatly decreased, the very high practicability is achieved, considerable economic benefits can be created for the enterprise, and considerable social benefits can be created for the society.

Owner:YANG ZHOU MEIHUA ELECTRIC CO LTD

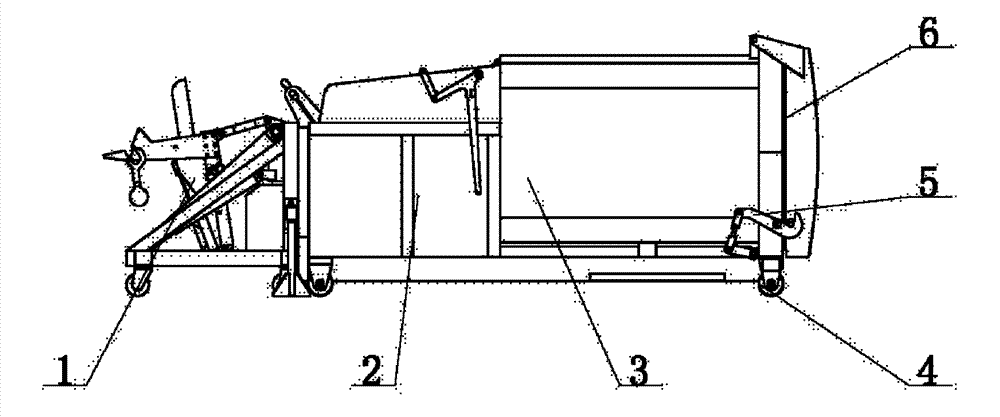

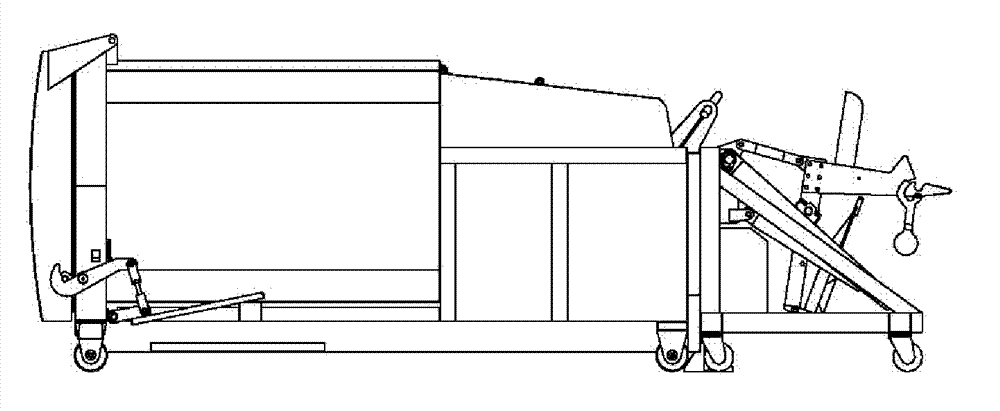

Movable garbage compression box and boxing method thereof

ActiveCN102167207BBody weight reductionHigh energy consumptionRefuse vehiclesPressesLight equipmentElectrical control

The invention relates to the technical field of garbage compression boxes, in particular to a movable garbage compression box and a boxing method thereof. The compression box is characterized in that: a movable lifting device and a compression head are of a split structure; the movable lifting device is connected with the front end of the compression head; power units of a hydraulic power system and an electric control system are arranged on the movable lifting device; each power unit is connected with a hydraulic quick joint; the hydraulic quick joint is detachably connected with a compression part hydraulic system; the movable lifting device comprises a walking mechanism, a lifting mechanism and an electrical appliance control button; the compression head has a totally-enclosed structure; the back part of the compression head is connected with the front part of a charging box; and the compression head and the charging box are of an integrated structure. Compared with the prior art, the movable garbage compression box has the advantages of light equipment, small floor area, low energy consumption, large compression volume reduction capability, energy conservation, environmental friendliness, easiness of cleaning, no residual of garbage or percolate, high durability and long service life.

Owner:SHANGHAI LOEP PRIVATE VEHICLES CO LTD

Laser cladding technological method and alloy material for laser cladding

ActiveCN102168210BUniform tissueSmall tissueMetallic material coating processesLaser beam welding apparatusMaterials scienceHeat treated

Owner:HANGZHOU BOHUA LASER TECH

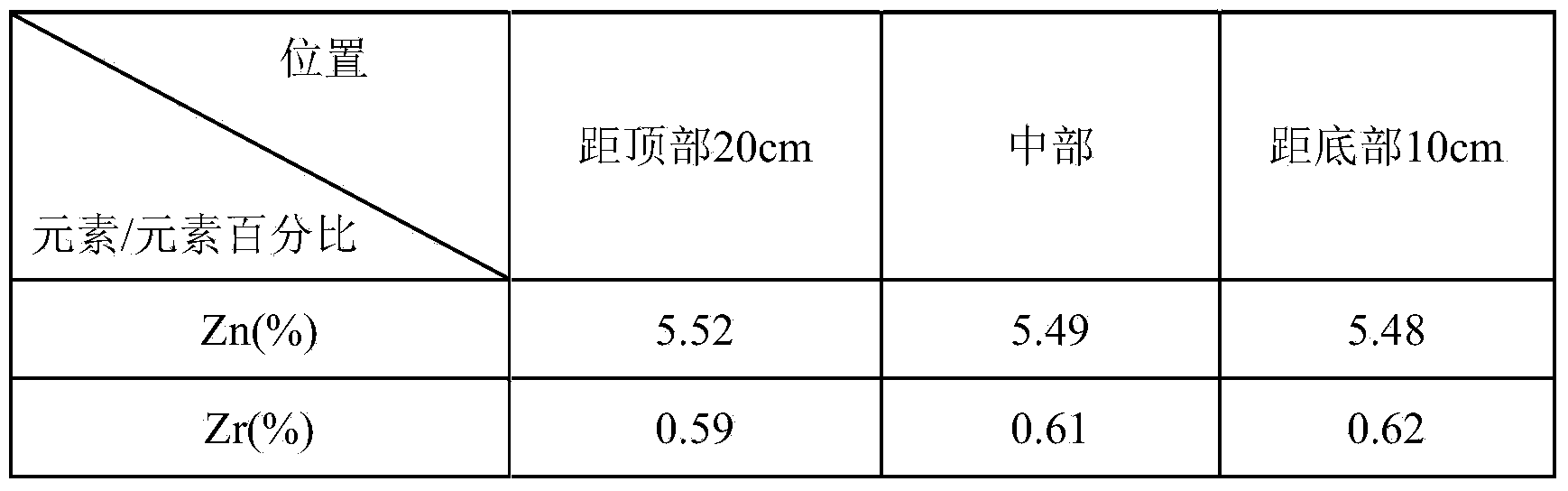

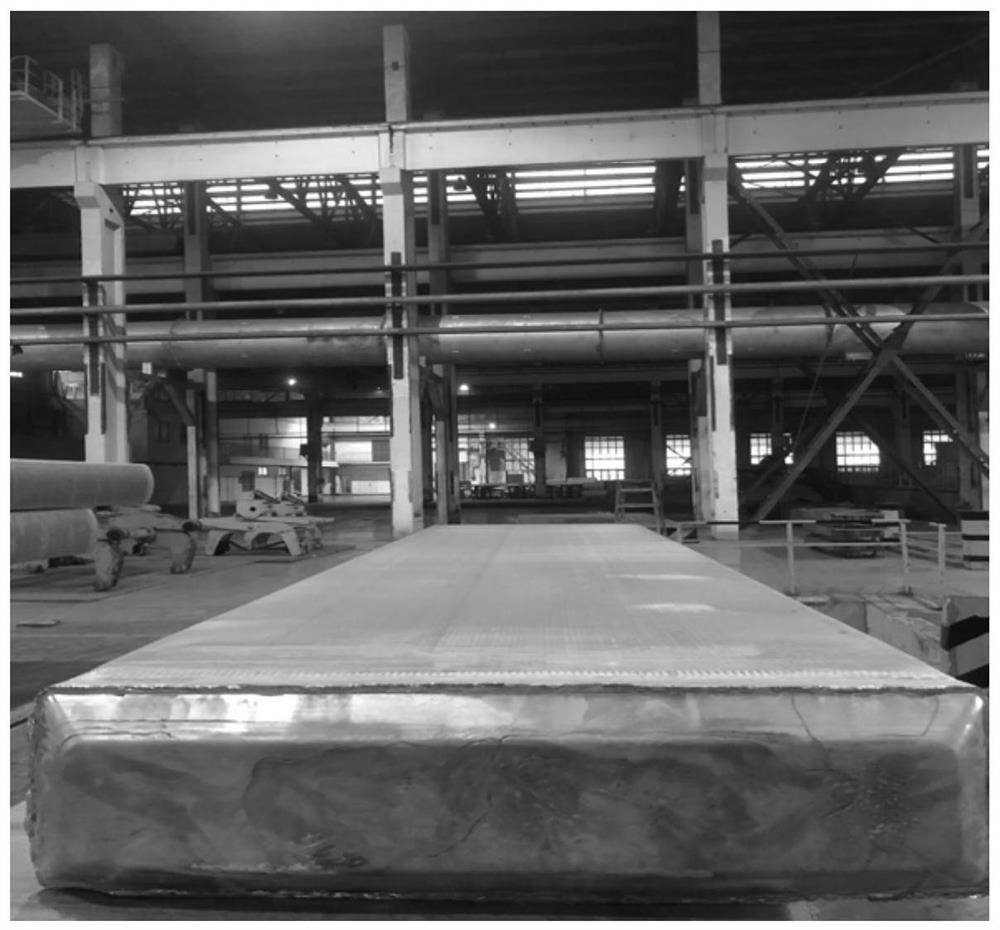

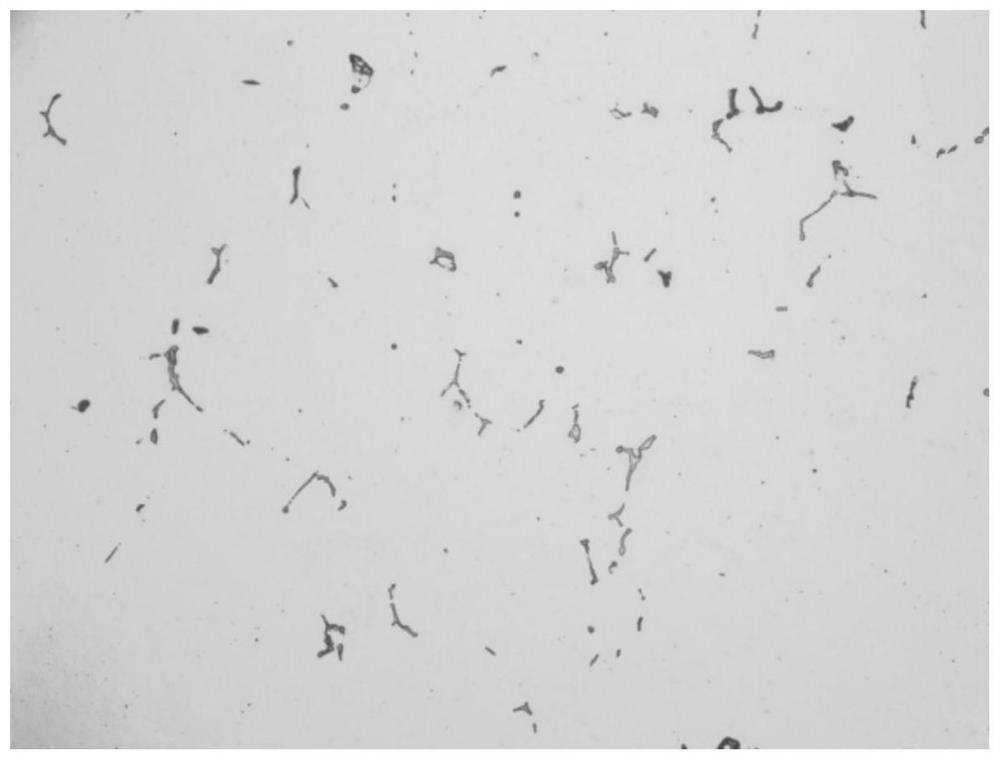

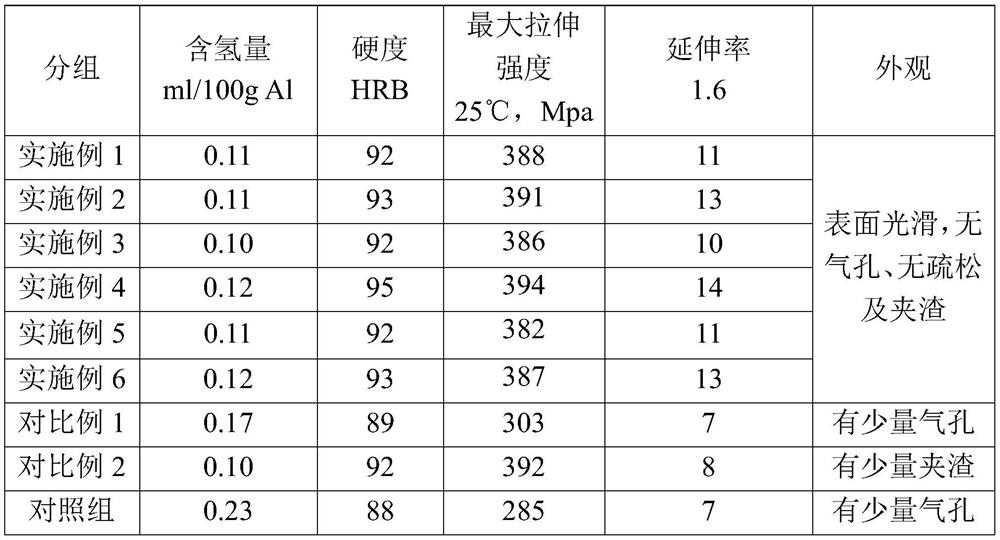

Composite core material aluminum alloy flat cast ingot and manufacturing method thereof

ActiveCN112593124AGuaranteed uniformityGuaranteed steady moldingGas emission reductionSlagCrack free

The invention discloses a composite core material aluminum alloy flat cast ingot and a manufacturing method thereof, and belongs to the field of alloy cast ingot manufacturing. The problems of high crack tendency and low casting yield in the existing method for producing a composite core material aluminum alloy with higher Ti content are solved. The materials are composed of Si, Fe, Cu, Mn, Mg, Zn, Zr, Ti and the balance aluminum. The preparation method comprises the following steps of 1, weighing the materials, 2, smelting to obtain an aluminum alloy melt, 3, preparing a casting melt, and 4,forming. According to the composite core material aluminum alloy flat cast ingot and the manufacturing method thereof, the problems that in the prior art, when the composite core material aluminum alloy with the high Ti content is produced, the crack tendency is large, and consequently casting beginning aluminum leakage and hanging defects are caused are effectively solved, and forming is guaranteed; the cast ingot is good in surface forming, free of surface defects, cracks, slag inclusion and air holes, and the rate of finished products reaches 95%; the internal metallographic structure of the cast ingot manufactured through the method is free of looseness, overall uniform and free of coarse grain defects, and the internal performance reaches the standard; and the preparation method is suitable for manufacturing the composite core material aluminum alloy flat cast ingot.

Owner:NORTHEAST LIGHT ALLOY CO LTD

A kind of solvent method single plating galfan alloy plating flux and preparation method thereof

ActiveCN108624831BQuality improvementGuaranteed Metallurgical BondingHot-dipping/immersion processesZinc bromideChloride salt

The invention provides a novel plating auxiliary for single hot-dipping of a Galfan alloy in a solvent method and a preparation method thereof. According to the plating auxiliary, per liter of the plating auxiliary is prepared from the following components of 100-150 g / L of ZnCl2, 50-100 g / L of ZnBr, 10-20 g / L of SnCl, 8-12 g / L of KF, 0-0.5 g / L of bismuth chloride, 0.5-2 g / L of sodium borohydride,0.1-0.3 g / L of hydrochloric acid, 5-15 g / L of active alkali metal chloride salt and the balance water. The plating auxiliary has the advantages that the zinc bromide, the sodium borohydride and the potassium fluoride are introduced into the plating auxiliary, so that a surfactant and rare-earth chloride which are expensive in price are avoided, the application range is wider, almost all steel products are covered, and therefore the problems of serious skip plating, air holes, list edges, slag inclusion and the like in the Galfan alloy hot-dipping process in the prior art can be effectively solved; and the plating auxiliary can play a good plating assisting role when being used at room temperature, the production cost is greatly saved, the components of the plating auxiliary are stable, the cost is low, and industrial popularization is facilitated.

Owner:HEBEI UNIV OF TECH

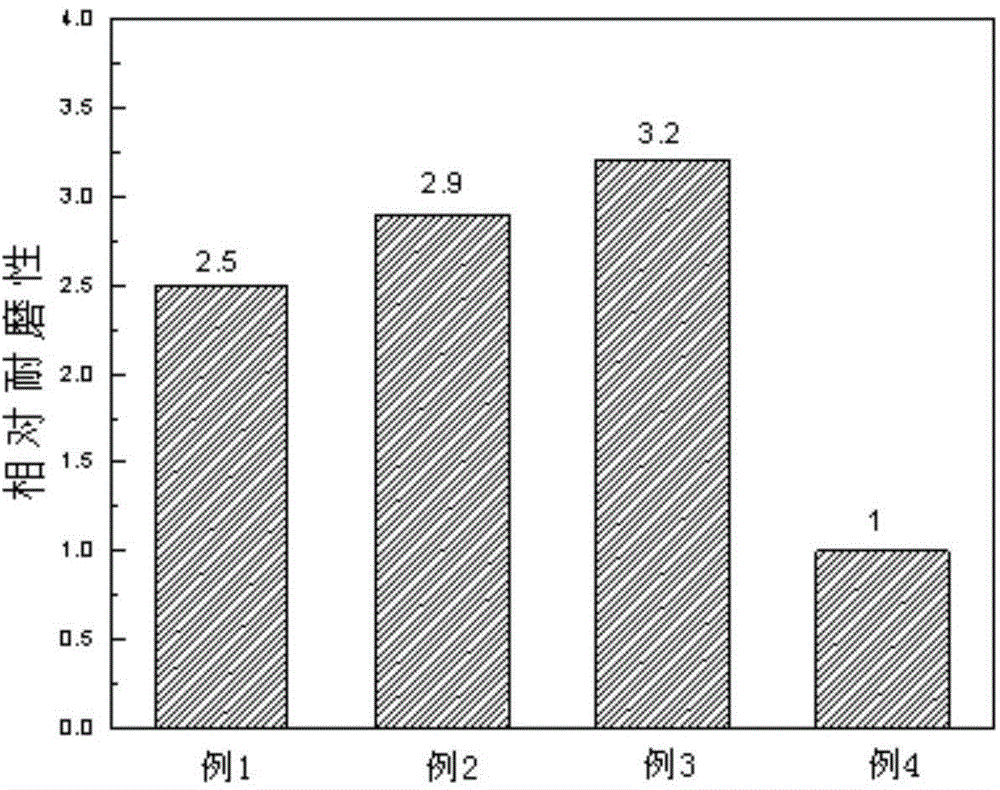

Instantly soluble hard alloy block and preparation method and application thereof

The invention discloses an instantly soluble hard alloy block and a preparation method and application thereof. The instantly soluble hard alloy block is made from materials in following percent by weight by binding with an adhesive: 25-35% of high carbon ferro-chrome, 0.5-1%. of rare earth, 15-40% of ferro-boron, 25-55% of ferro-vanadium, 2-6% of ferrosilicon, and 2-3% of ferronickel, wherein the adhesive is a resin adhesive. The instantly soluble hard alloy block has high hardness (Rockwell hardness HRC > / =73), good wear resistance, manufacture process simplicity, low cost, low surfacing current, convenience of selecting dimensions and shape, low time and labor consumption for a welder, etc., the problem that a quick-wear apparatus is short in life is solved, and the life of an original member is prolonged by 3-10 times.

Owner:苑俊奎

Production method of multi-element aluminum alloy standard sample

ActiveCN101294875BHigh yieldImprove distribution uniformityPreparing sample for investigationColor/spectral properties measurementsChemical elementMulti element

The invention relates to a method for preparing a standard multi-element aluminum alloy sample. The method comprises the steps of proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and is characterized in that the standard sample contains the following 20 chemical elements in pure aluminum: Si, Fe, Cu, Mg, Mn, Zn, Sn, Pb, Ni, Ti, Cr, Sr, Ca, V, Ga, Zr, Cd, Be, B and P. The standard sample is manufactured sequentially through proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and finally, standard samples are prepared according to the requirements for the standard samples. By adopting the preparation method, the multi-element aluminum alloy sample with uniform composition and good stability can be obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Production technology of yellow copper busbar for electrical device

The invention provides a production technology of a yellow copper busbar for an electrical device. The production technology comprises the following steps: (1) adding manganese dioxide powder into thebottom of a medium-frequency induction furnace, and adding electrolytic copper, a zinc ingot and an aluminum ingot into the medium-frequency induction furnace, vacuum-melting for 40-50 minutes in a temperature of 1,220-1,260 DEG C, and cooling the temperature to 1,080-1,110 DEG C, melting in non-vacuum for 20-30 minutes; (2) importing to a maintaining furnace, consolidation-forming by a crystallizer, continuously pulling out the copper busbar by using a drawing mechanism, and sawing; (3) heating a sawed ingot blank to 300-350 DEG C, heat-insulating for 30-40 minutes, and warming to 710-740 DEG C, extruding by an extruding machine, cutting, head-rolling by a head rolling machine, and performing first drawing; (4) performing subzero treatment, warming to a room temperature; (5) warming to 350-410 DEG C, heat-insulating for 2.5-3 hours, and cooling to the room temperature along with the furnace; and (6) performing second head-rolling, performing second drawing and aligning, sawing by a sawing machine, checking, and packaging, to obtain the yellow copper busbar. The prepared yellow copper busbar is high in strength, good in corrosion resistance, and excellent in electrical property, and is capable of satisfying the requirements of the electrical device to the high quality of the copper busbar.

Owner:苏州绿导精密模具有限公司

Energy-saving environment-friendly continuous casting device material

The invention discloses an energy-saving environment-friendly continuous casting device material which comprises the following components in parts by weight: 20-30 parts of ethylene copolymer elastomer, 10-25 parts of nano calcium carbonate, 11-21 parts of ethylene-acrylate, 12-19 parts of high-density polyethylene, 30-40 parts of carbon black, 10-20 parts of carburizing agent, 2-8 parts of calcite, 2-9 parts of wetting agent, 10-16 parts of dispersant, 15-20 parts of thickener, 20-30 parts of flame retardant, 21-22 parts of defoamer, 25-30 parts of bactericide, 30-40 parts of organosilicon modified epoxy resin, 10-15 parts of mixed solvent, 16-20 parts of inorganic thickener and 1-9 parts of toughener. The material disclosed by the invention has the advantages of higher melting point, higher viscosity, higher melting rate, small slag strip and favorable lubricating property, improves the phenomenon of nonuniform inflow, and prevents breakout due to cohesiveness. The casting blank surface does not have the phenomenon of slag inclusion or viscous slag, and thus, the casting blank has high surface quality.

Owner:QINGDAO JIZHI ENERGY SAVING ENVIRONMENTAL PROTECTION

High-strength casting material and preparation technology thereof

The invention discloses a high-strength casting material and a preparation technology thereof. The casting material comprises components in parts by weight as follows: 20-30 parts of graphite powder,10-20 parts of bauxite powder, 8-18 parts of nano-silica, 2-8 parts of titanium dioxide, 6-12 parts of nano calcium carbonate, 8-16 parts of hollow glass beads, 2-8 parts of molybdenum, 2-10 parts ofchromium, 4-10 parts of silicon, 3-9 parts of nickel and 4-12 parts of manganese. The preparation technology is simple, the prepared casting material has properties of high strength and high wear resistance, and casting surface quality is improved.

Owner:MAANSHAN SONGHAK INFORMATION TECH CO LTD

Refining agent and smelting technology of fusion casting aluminum bar for aluminum profile

The invention discloses a refining agent and smelting technology of a fusion casting aluminum bar for an aluminum profile. The refining agent comprises, by mass, 30%-65% of NaCl, 15%-30% of Na2SiF6, 10%-25% of B4C and 5%-20% of NaSO4. The refining agent is simple in component, the refining agent is high in grain refining effect, good in impurity removal effect and high in degassing capacity when the refining agent is applied to an aluminum alloy smelting technology, the obtained aluminum bar is excellent in performance, and the refining agent is suitable for industrial popularization.

Owner:湖北华力科技有限公司

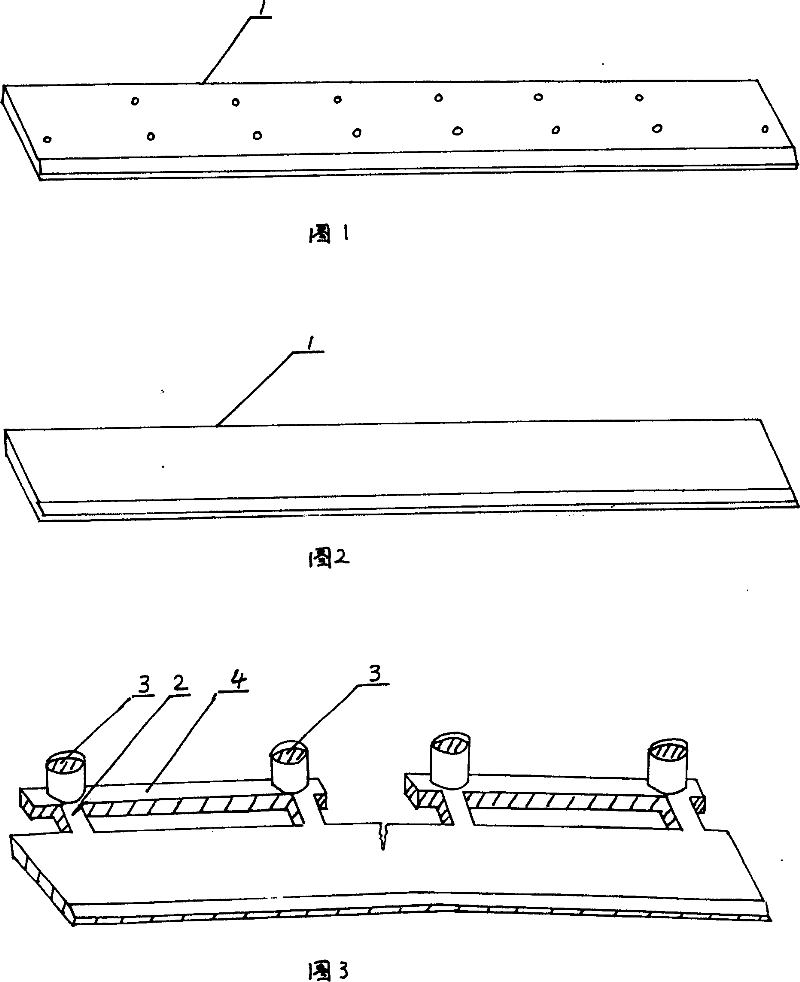

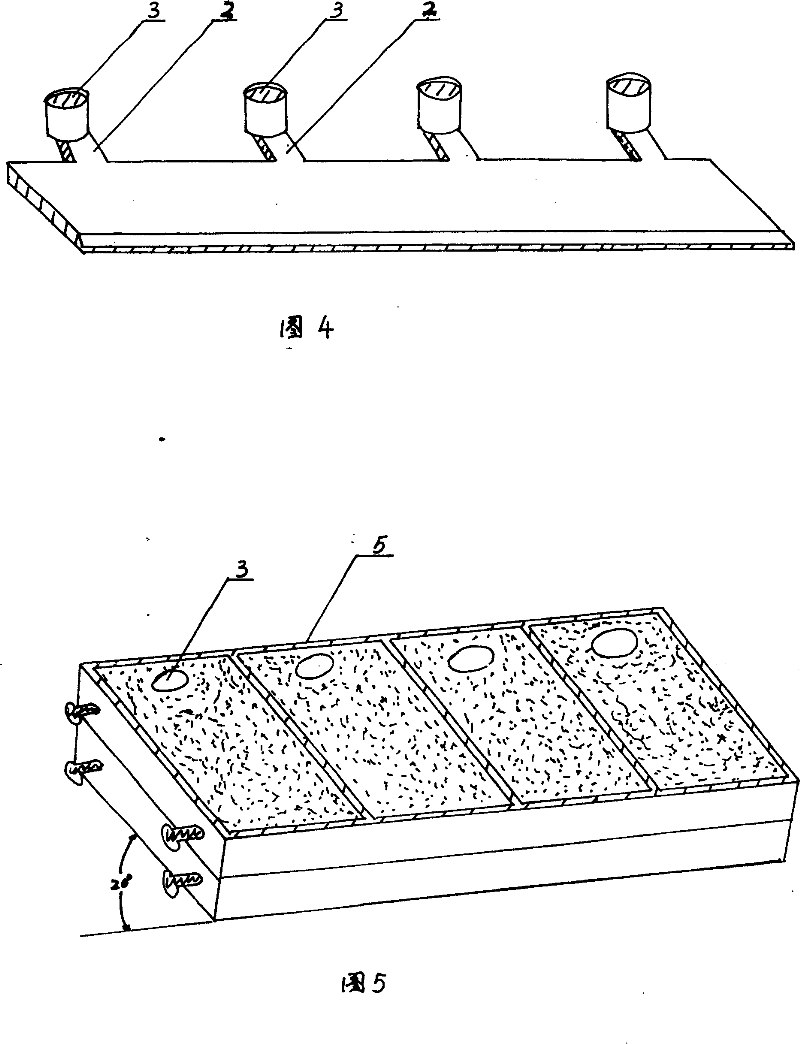

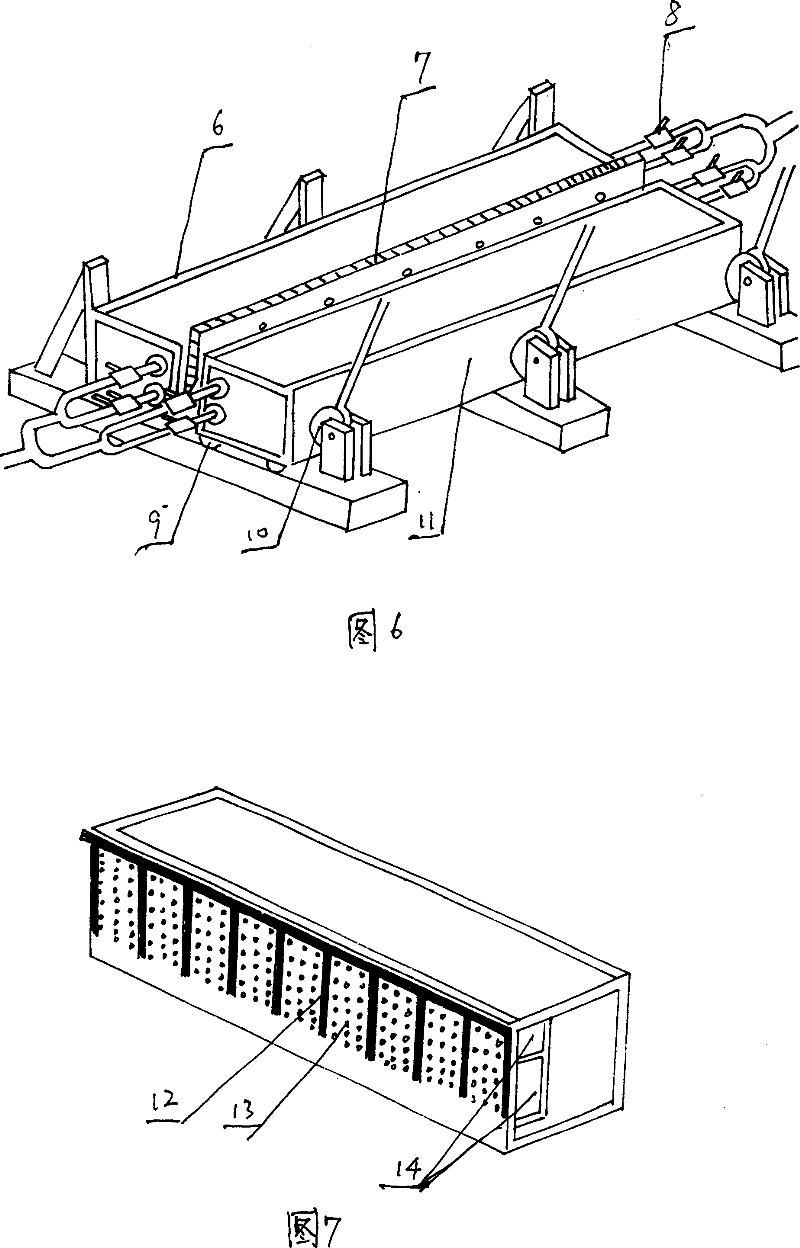

Integral casting alloy steel shovel edge plate for loader and its manufacturing process and device

ActiveCN100355992CEasy to installHigh wear resistance requirementsMechanical machines/dredgersFoundry mouldsQuenchingHeat treated

This invention provides loader main part-shovel edge board technology. Monoblock casting alloy steel shoved edge board and the board manufacturing technique and equipment is provided. AG25CrMnMo material is used, the main elements content of the material is that C: 0.02~0.28%, Mn: 0.90~1.20%, Si: 0.20~0.37%, Cr: 0.90~1.20%, Mo: 0.20~0.30%, rest is iron. The board is achieved by monoblock casting forming technique and through heat treatment. In quenching technology, board integer heated in quenching furnace is used, the type of board both sides clamping, both sides spraying quenching and parts spraying quenching is used, that is the whole board is quenched in quenching furnace, then the board is both sides clamped for both sides spraying quenching. The back parts of the board and connecting part of bucket body is out spraying quenching area, the two parts don't spraying quenching.

Owner:洛阳市钢峰工程机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com