Preparation method of nickel-based duplex metal composite used for fluorine chemical production equipment

A technology of chemical production and composite materials, which is applied in the field of nickel-based bimetallic composite materials preparation, can solve the problems of metals being difficult to transmit and balance external forces, damage of long-term pipeline connection ends, and no composition transition zone, etc., to reduce crack sensitivity, The effect of uniform stress distribution and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1 is used for the preparation method of the nickel-based bimetallic composite material of fluorine chemical production equipment

[0065] A preparation method for a nickel-based bimetallic composite material used in fluorine chemical production equipment, comprising the following steps:

[0066] (1) Base material and composite material selection: choose No. 10 steel as the base material, and choose GH600 nickel-based alloy as the composite material;

[0067] (2) Melting and refining: Melting the base material and composite material through an intermediate frequency induction furnace, and then refining and adjusting the composition through a refining furnace, including deoxidation, dehydrogenation, and impurity removal;

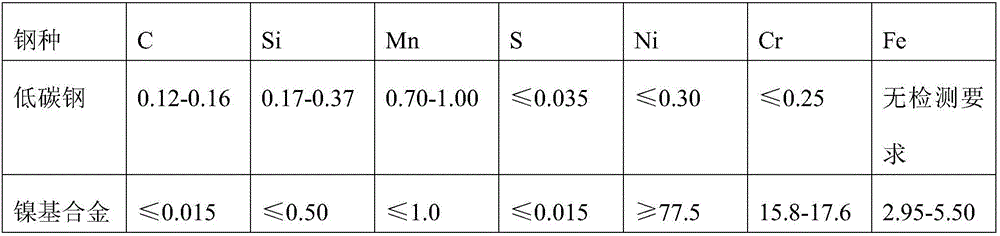

[0068] The range of composition adjustment during the refining process is as follows:

[0069]

[0070] (3) Centrifugal casting of composite billet: the refined metal solution is centrifugally cast into a composite billet through a centrifu...

Embodiment 2

[0121] Embodiment 2 is used for the preparation method of the nickel-based bimetallic composite material of fluorine chemical production equipment

[0122] A preparation method for a nickel-based bimetallic composite material used in fluorine chemical production equipment, comprising the following steps:

[0123] (1) Base material and composite material selection: choose No. 20 steel as the base material, and choose GH800 nickel-based alloy as the composite material;

[0124] (2) Melting and refining: Melting the base material and composite material through an intermediate frequency induction furnace, and then refining and adjusting the composition through a refining furnace, including deoxidation, dehydrogenation, and impurity removal;

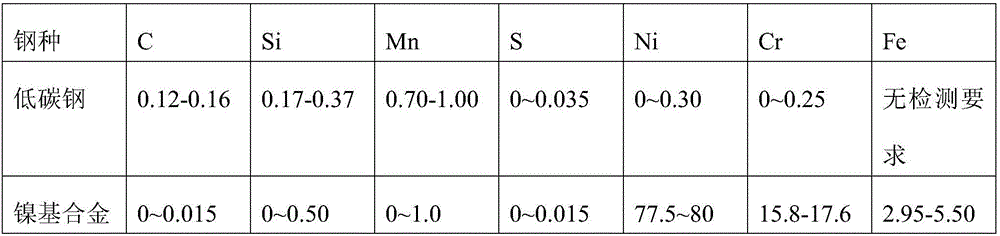

[0125] The scope of composition adjustment during the refining process is as follows:

[0126]

[0127] (3) Centrifugal casting of composite billet: the refined metal solution is centrifugally cast into a composite billet through a centri...

Embodiment 3

[0151] Embodiment 3 is used for the preparation method of the nickel-based bimetallic composite material of fluorine chemical production equipment

[0152] A preparation method for a nickel-based bimetallic composite material used in fluorine chemical production equipment, comprising the following steps:

[0153] (1) Base material and composite material selection: choose No. 20 steel as the base material, and choose GH600 nickel-based alloy as the composite material;

[0154] (2) Melting and refining: Melting the base material and composite material through an intermediate frequency induction furnace, and then refining and adjusting the composition through a refining furnace, including deoxidation, dehydrogenation, and impurity removal;

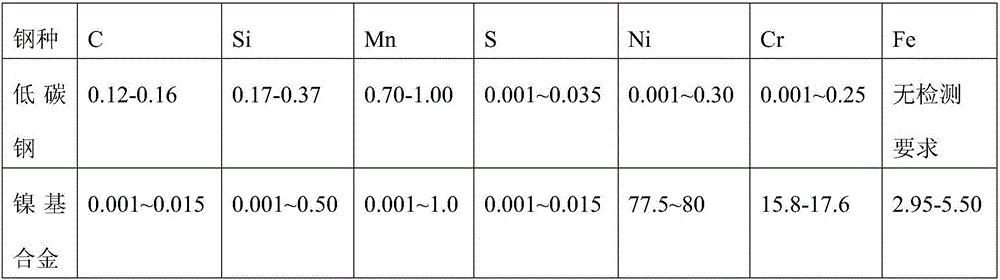

[0155] The scope of composition adjustment during the refining process is as follows:

[0156]

[0157] (3) Centrifugal casting of composite billet: the refined metal solution is centrifugally cast into a composite billet through a centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com