Cryogenic high-tensile thick steel sheet and method for producing same

A manufacturing method and high-tensile technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of low-temperature toughness reduction, austenite instability, expensive Ni alloy elements, etc., and achieve excellent cold workability, improved safety, Effective effect of stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

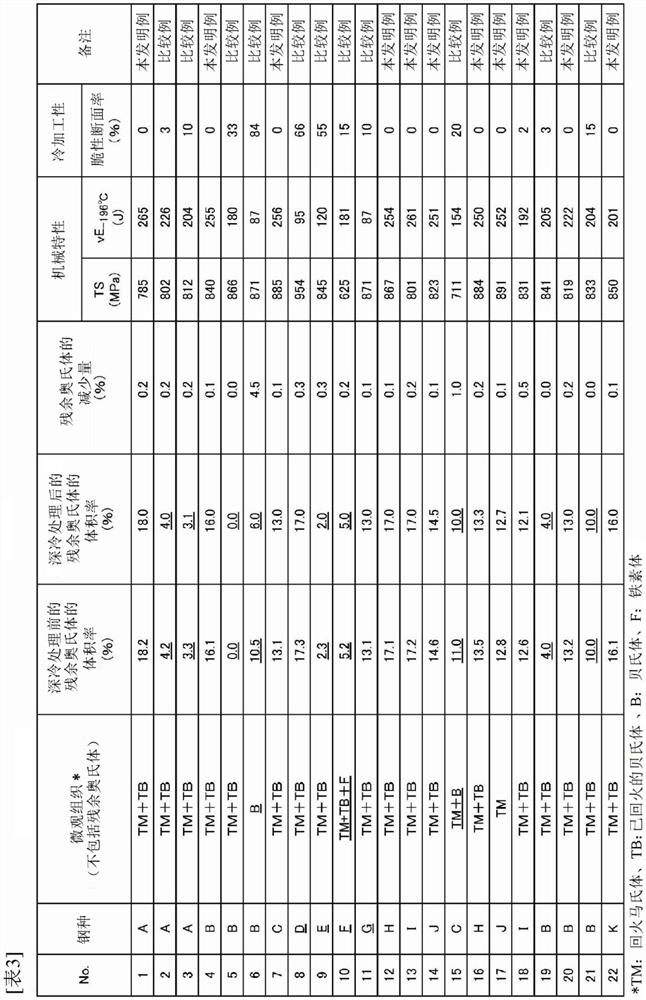

[0156] A high-tensile high-tensile steel plate for extremely low-temperature use was manufactured in accordance with the procedure described below, and properties of the obtained high-tensile-strength steel plate for extremely low-temperature use were evaluated.

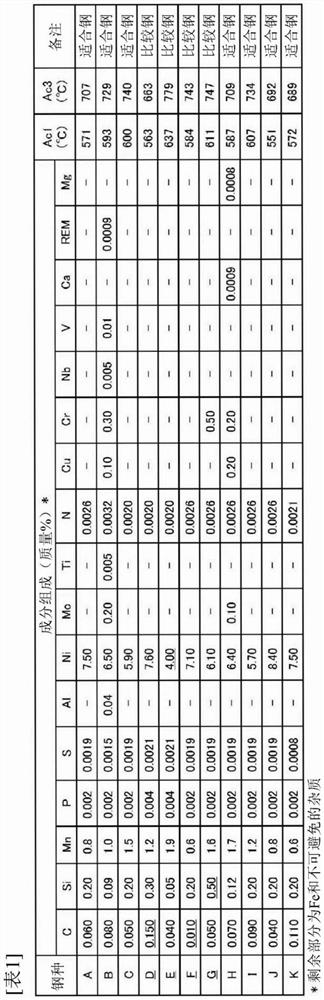

[0157] First, molten steel having the composition shown in Table 1 was melted in a converter, and a billet (thickness: 250 mm) was produced as a billet material by a continuous casting method. In addition, the Ac1 point (°C) obtained by the above formula (1) and the Ac3 point (°C) obtained by the formula (2) are shown in Table 1 together.

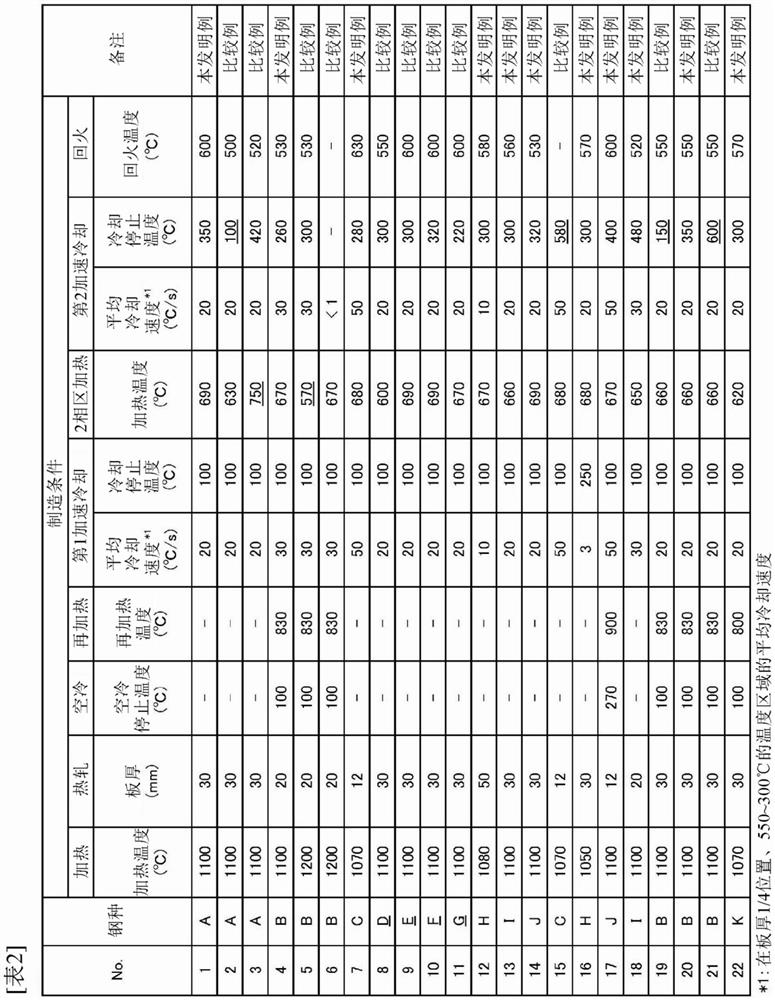

[0158] Next, the obtained slabs were heated to the heating temperatures shown in Table 2, and hot-rolled to obtain hot-rolled steel sheets with the thicknesses shown in Table 2. Next, first accelerated cooling is performed on the hot-rolled steel sheet. Table 2 shows the average cooling rate and cooling stop temperature of the above-mentioned first accelerated cooling. In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com