Process for treating heavy metal contaminated soil

A technology that pollutes soil and heavy metals, applied in the field of soil pollution control, can solve problems that threaten people's health and property safety, restrict sustainable economic development, destroy the ecological environment, etc., and achieve the effect of abundant raw materials, low price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A process for remediating heavy metal-contaminated soil containing nickel, zinc, arsenic, lead, and copper, the remediation of heavy metal-contaminated soil has the following specific steps,

[0031] a. Select 500g of the heavy metal-contaminated soil to be repaired from the above-mentioned polluted site, air-dry, grind and crush the heavy metal-contaminated soil to be repaired, and then sieve it with a 20-mesh nylon sieve;

[0032] b. Add 25g of calcium oxide to the heavy metal-contaminated soil to be repaired and mix it. After mixing evenly, place it for maintenance for 12 hours;

[0033] c. Continue to add 10g of apatite and 5g of calcium sulfide to the mixed heavy metal-contaminated soil to be repaired, stir evenly and place it for curing for 36 hours;

[0034] d. Continue to add 20g of cement to the heavy metal-contaminated soil to be repaired, place it after being evenly stirred, and continue to maintain it for 24 hours;

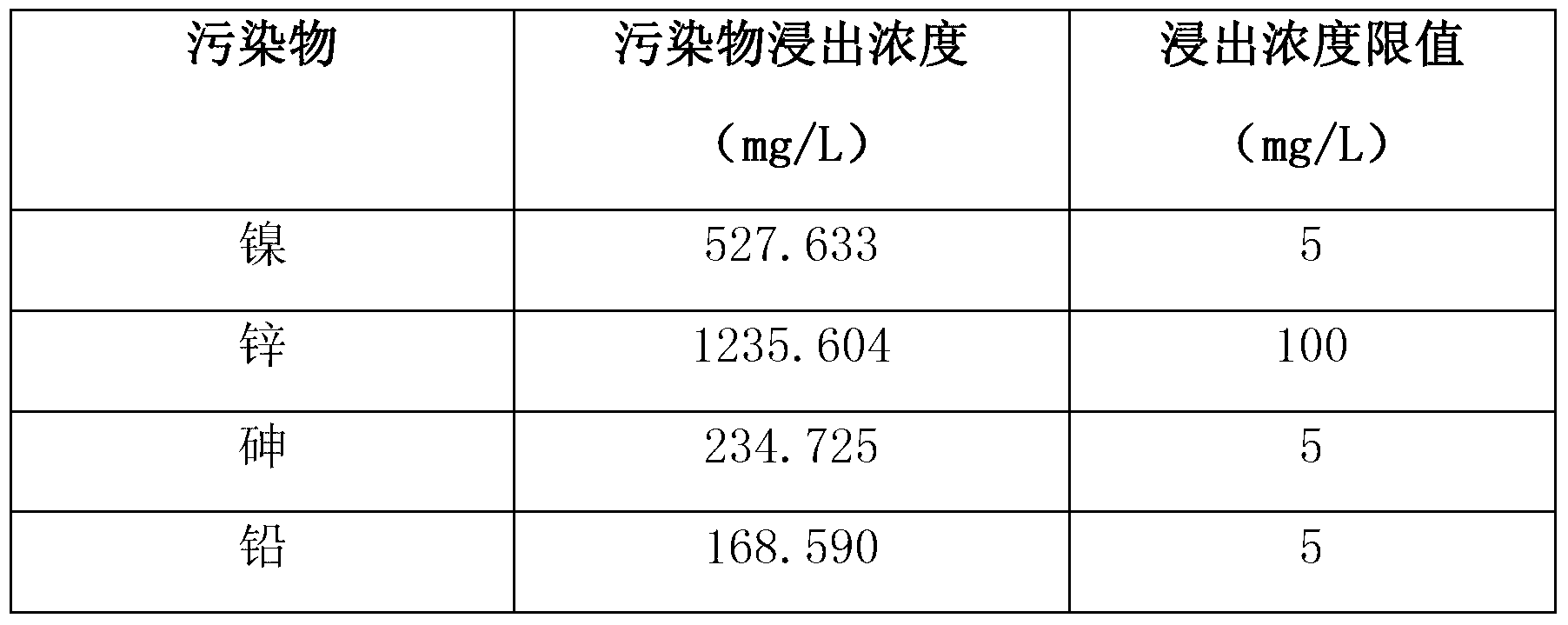

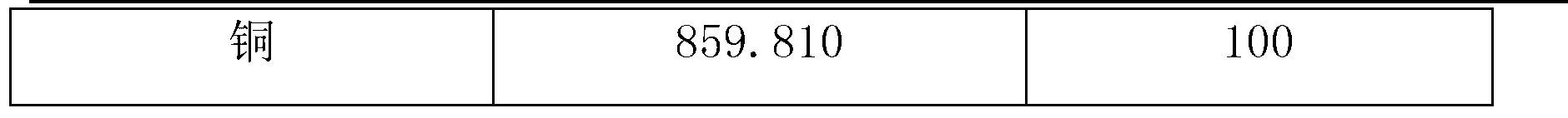

[0035] e. Sampling and testing the heavy...

Embodiment 2

[0041] A process for remediating heavy metal-contaminated soil containing nickel, zinc, arsenic, lead, and copper, the remediation of heavy metal-contaminated soil has the following specific steps,

[0042] a. Select 500g of the heavy metal-contaminated soil to be repaired from the above-mentioned polluted site, air-dry, grind and crush the heavy metal-contaminated soil to be repaired, and then sieve it with a 20-mesh nylon sieve;

[0043] b. Add 15g of calcium oxide to the heavy metal-contaminated soil to be repaired and mix it. After mixing evenly, place it for maintenance for 12 hours;

[0044] c. Continue to add 5g of apatite and 10g of calcium sulfide to the mixed heavy metal-contaminated soil to be repaired, stir evenly and place it for maintenance for 36 hours;

[0045] d. Continue to add 15g of cement to the heavy metal-contaminated soil to be repaired, place it after being evenly stirred, and continue to maintain it for 24 hours;

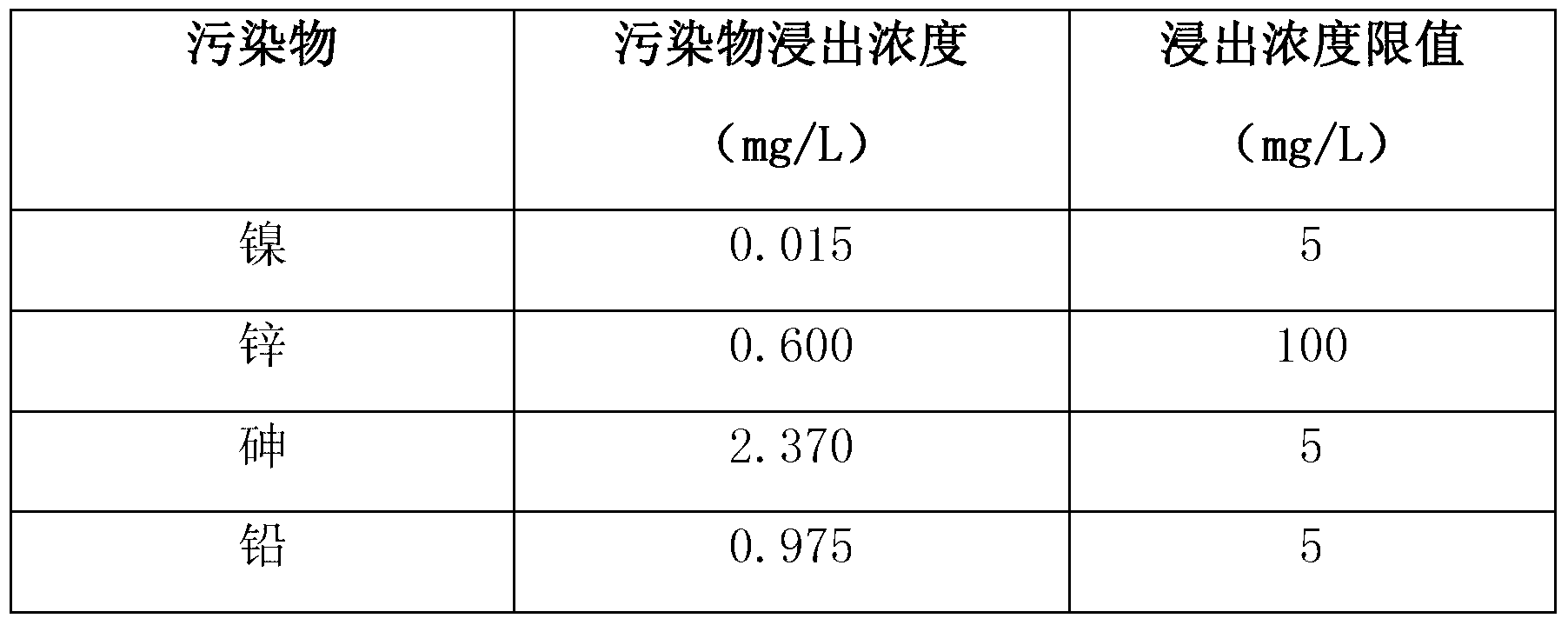

[0046] e. Sampling and testing the ...

Embodiment 3

[0051] A process for remediating heavy metal-contaminated soil containing nickel, zinc, arsenic, lead, and copper, the remediation of heavy metal-contaminated soil has the following specific steps,

[0052] a. Select 500g of the heavy metal-contaminated soil to be repaired from the above-mentioned polluted site, air-dry, grind and crush the heavy metal-contaminated soil to be repaired, and then sieve it with a 20-mesh nylon sieve;

[0053] b. Add 25g of magnesia to the heavy metal-contaminated soil to be repaired and mix it. After mixing evenly, place it for maintenance for 12 hours;

[0054] c. Continue to add 10g of apatite and 5g of calcium sulfide to the mixed heavy metal-contaminated soil to be repaired, stir evenly and place it for 48 hours of maintenance;

[0055] d. Continue to add 35g of cement to the heavy metal-contaminated soil to be repaired, place it after being evenly stirred, and continue to maintain it for 18 hours;

[0056] e. Sampling and testing the heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com