Heavy-current short-network direct attached gas shield three-phase electric slag furnace

A gas-shielded, direct-connected technology, applied in the field of high-current short-circuit direct-connected gas-shielded three-phase electroslag furnaces, can solve the problems of long conduction medium, affecting operation time, and difficulty in installation, and reduce the furnace structure. damage, improve power utilization, and easy on-site operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

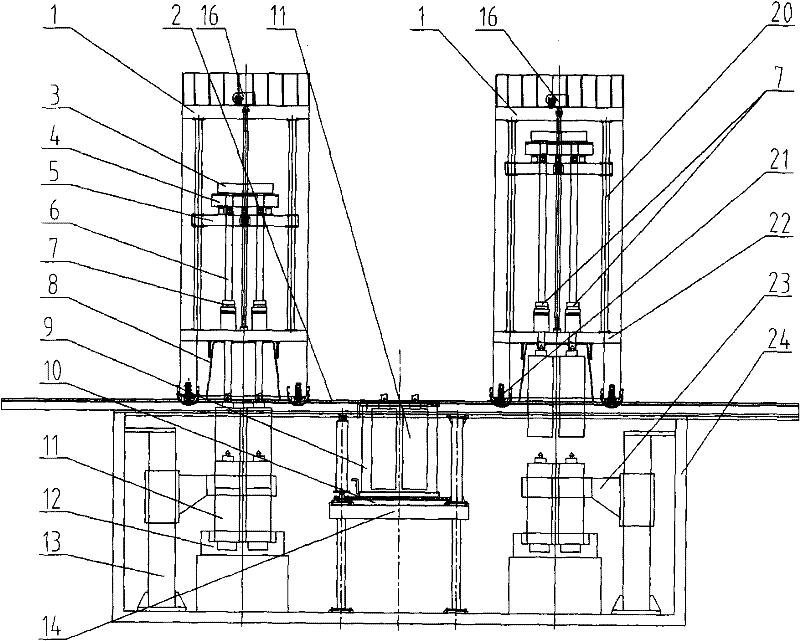

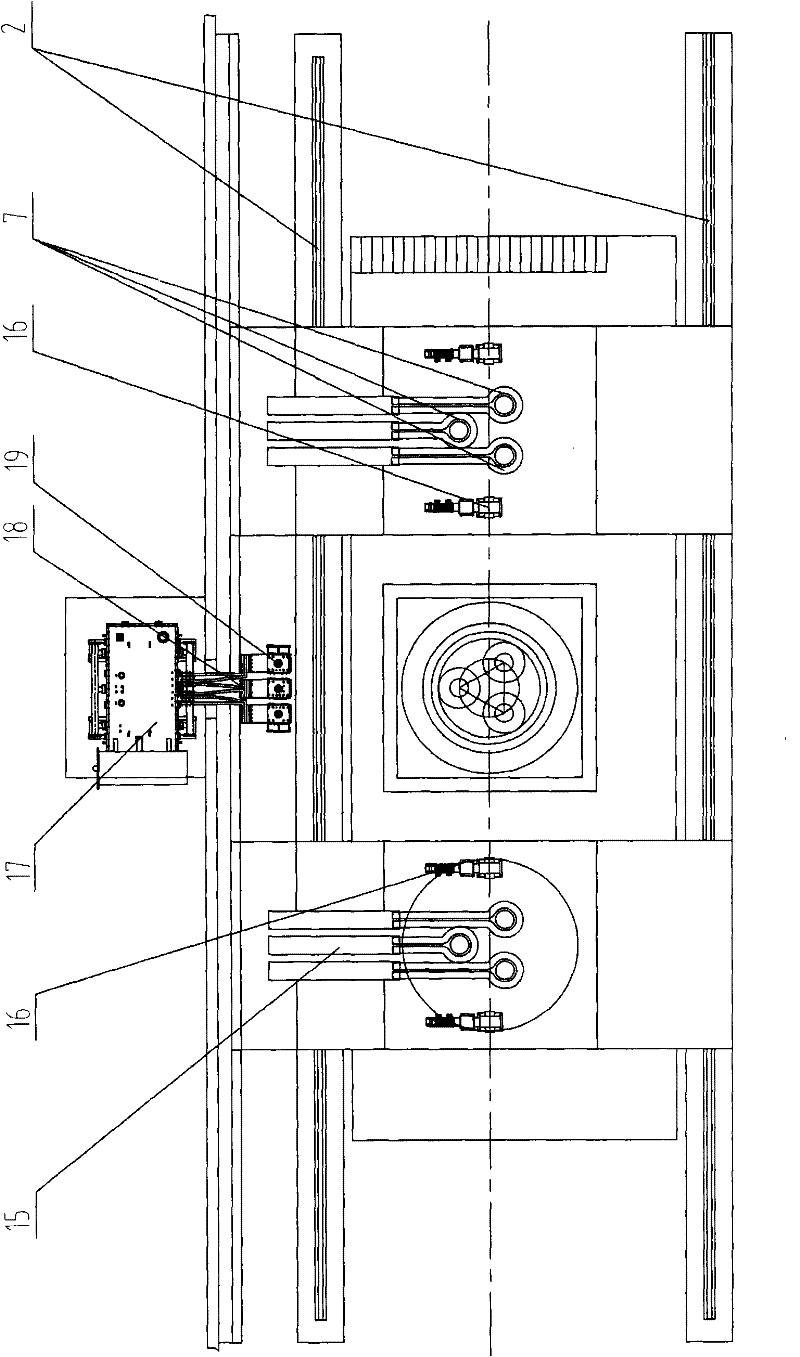

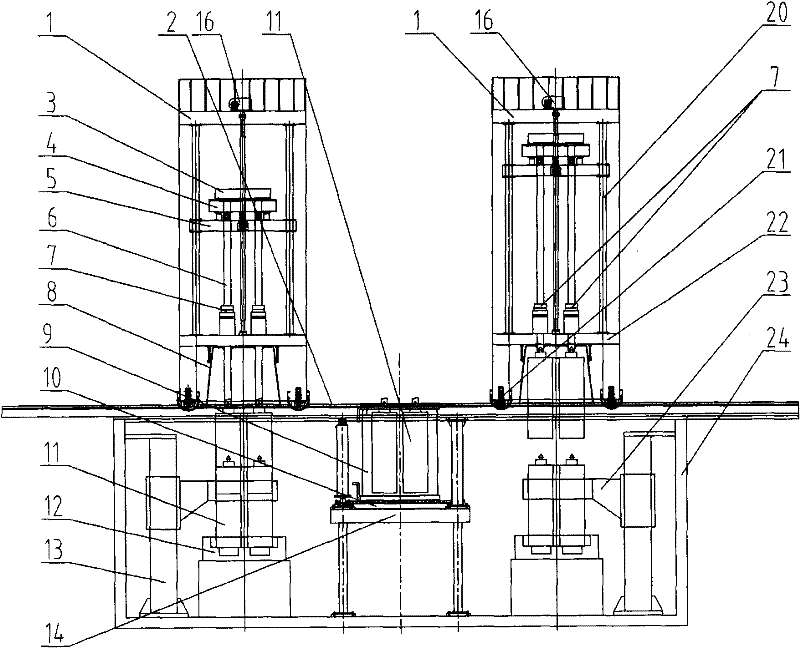

[0024] The specific embodiment of the present invention is as figure 1 , figure 2 and image 3 shown. The electroslag furnace according to the present invention includes a gantry-type movable furnace body 1, a casting elevating platform 5, a crystallizer 9, a bottom water tank 10, an end heating device 12, a consumable electrode positioning device column 13, a crystallizer elevating platform 14, an electrode Lifting system column guide rod 20, furnace body lower platform 22, consumable electrode positioning guide plate support 23.

[0025] like figure 1 As shown, a system weighing platform 4 is installed on the upper part of the casting lifting platform 5, and an electrode clamping and pulling system 3 is installed on the system weighing platform 4; the electrode clamping and pulling system 3 is fixed with 3 to 6 A load-bearing conductive material rod 6, each load-bearing conductive material rod 6 is equipped with a self-consumable electrode 11; each load-bearing conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com