Laser-cladding powder

A laser cladding and powder technology, which is applied in the coating, metal material coating process, etc., can solve the problems of cladding layer cracks falling off, lack of cladding materials, etc., achieve fine molten pool, ensure cladding effect, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A laser cladding powder of this embodiment is composed of the following components and their mass percentages: Cr is 15% to 17%, C is 0.25% to 0.42%, Si is 2.1% to 3.1%, and B is 1.7% to 3.1%, the balance is Fe and unavoidable impurities. Specifically, the laser cladding powder in this embodiment is composed of the following components and their mass percentages: Cr is 17%, C is 0.42%, Si is 2.1%, B is 1.9%, and the balance is Fe and unavoidable impurities .

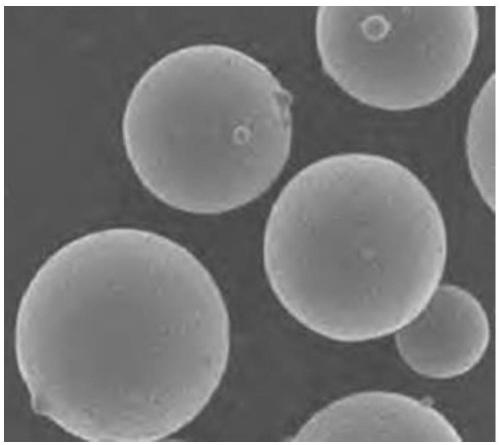

[0043] The laser cladding powder of this embodiment is an amorphous powder, and the steps of the preparation method of the laser cladding powder of this embodiment are as follows:

[0044] 1. Ingredients: According to the mass percentage in the formula, the corresponding alloying elements are prepared into mixed powder; each component is prepared with a powder whose purity is greater than or equal to 99%;

[0045] 2. Smelting: The prepared mixed powder is smelted in vacuum multiple times, and the smelting proces...

Embodiment 2

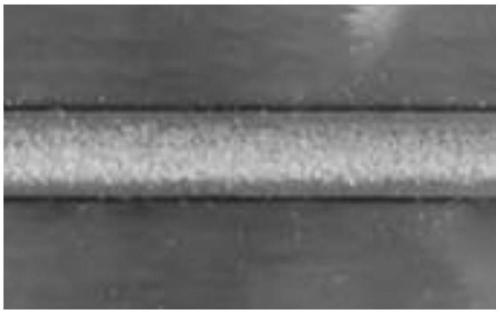

[0054] A laser cladding powder of this embodiment is composed of the following components and their mass percentages: Cr is 17%, C is 0.42%, Si is 2.1%, B is 1.9%, and the balance is Fe and unavoidable impurities . The laser cladding powder preparation method of this embodiment is the same as that of Example 1, and the laser cladding process is the same as that of Example 1. The process parameters are as follows, the laser power is 1500W, the spot diameter is 5mm, the cladding speed is 300mm / min, and the powder feeding speed is 32mg / s.

[0055] The hardness of the cladding layer obtained from the laser cladding powder in this implementation is 61.5HRC. After the wear test under the same experimental conditions, the weight loss of the cladding layer is 4.0mg. The wear resistance is slightly worse than that of Example 1, and the corrosion resistance is basically the same as that of Example 1. 1.

Embodiment 3

[0057] A laser cladding powder of this embodiment is composed of the following components and their mass percentages: Cr is 17%, C is 0.42%, Si is 2.1%, B is 2.4%, and the balance is Fe and unavoidable impurities . The laser cladding powder preparation method of this embodiment is the same as that of Example 1, and the laser cladding process is the same as that of Example 1. The process parameters are as follows, the laser power is 1500W, the spot diameter is 5mm, the cladding speed is 200mm / min, and the powder feeding speed is 32mg / s.

[0058] The hardness of the cladding layer obtained from the laser cladding powder in this implementation is 61.5HRC. After the wear test under the same experimental conditions, the weight loss of the cladding layer is 4.1 mg. The wear resistance is slightly worse than that of Example 1, and the corrosion resistance is basically the same as that of Example 1. 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com