Integral casting alloy steel shovel edge plate for loader and its manufacturing process and device

A technology for integral casting and production equipment, applied in quenching equipment, manufacturing tools, casting and molding equipment, etc., can solve the problems of wear resistance and impact toughness not meeting the requirements, increasing assembly difficulty and cost, and increasing construction costs for users. , to achieve the effect of no slag inclusion, improving hardness, correcting flatness and bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1: C: 0.26%, Mn: 1.10%, Si: 0.30%, Cr: 1.10%, Mo: 0.25%, the balance is iron, S, P≤0.035%.

example 2

[0028] Example 2: C: 0.20%, Mn: 1.20%, Si: 0.25%, Cr: 1.0%, Mo: 0.20%, the balance is iron, S, P≤0.035%.

example 3

[0029] Example 3: C: 0.28%, Mn: 0.90%, Si: 0.20%, Cr: 0.95%, Mo: 0.30%, the balance is iron, S, P≤0.035%.

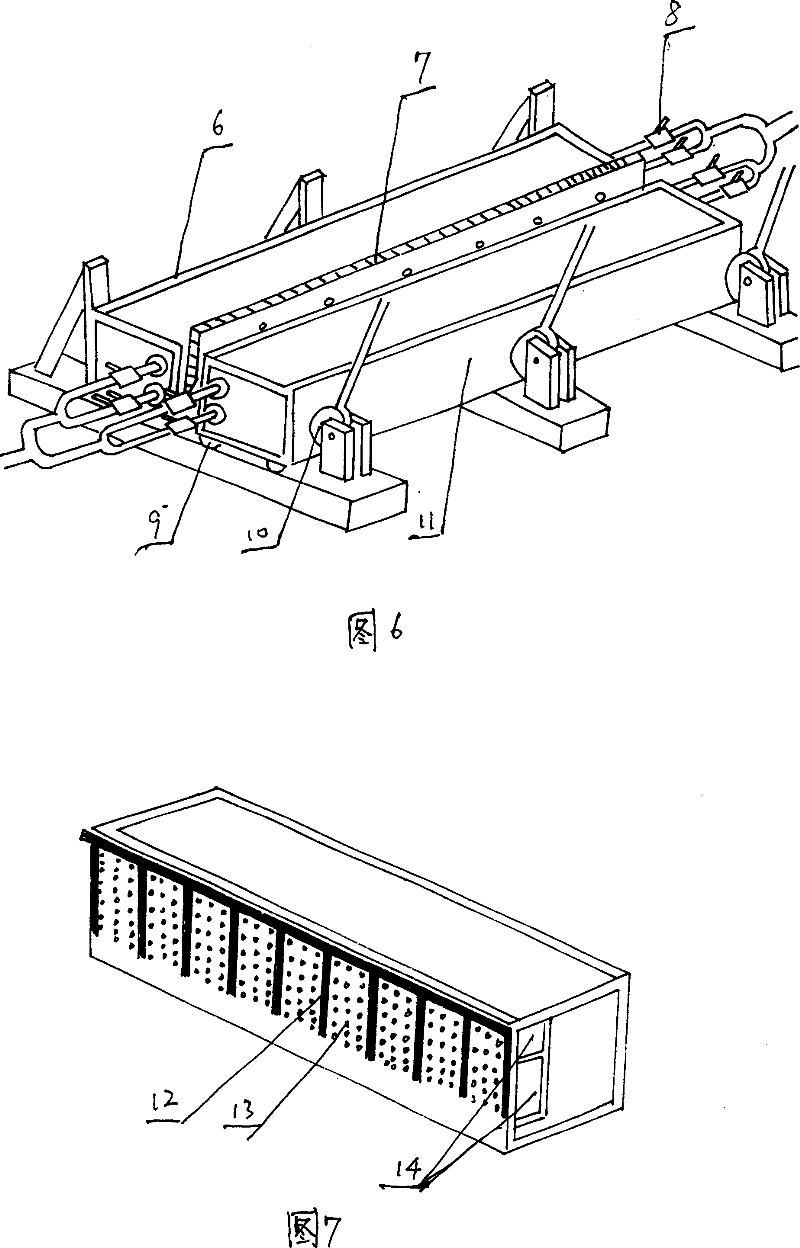

[0030] The shovel edge plate of the present invention is obtained through an integral casting molding process and a heat treatment process.

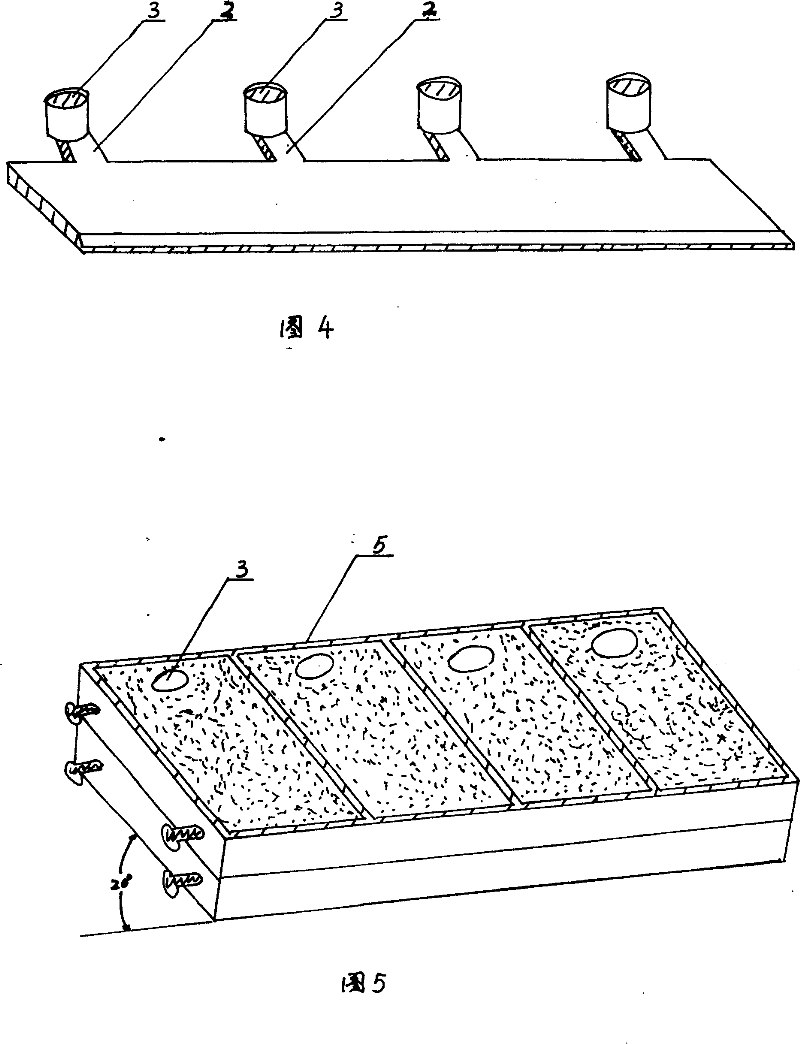

[0031] In the casting process, the sand mold made of quartz sand and water glass as a binder is the same as the sand mold material of the existing casting process. A single direct feeding riser is used, that is, the riser is used as the sprue and the feeding port, and each riser is connected to the mold by a single feeding riser.

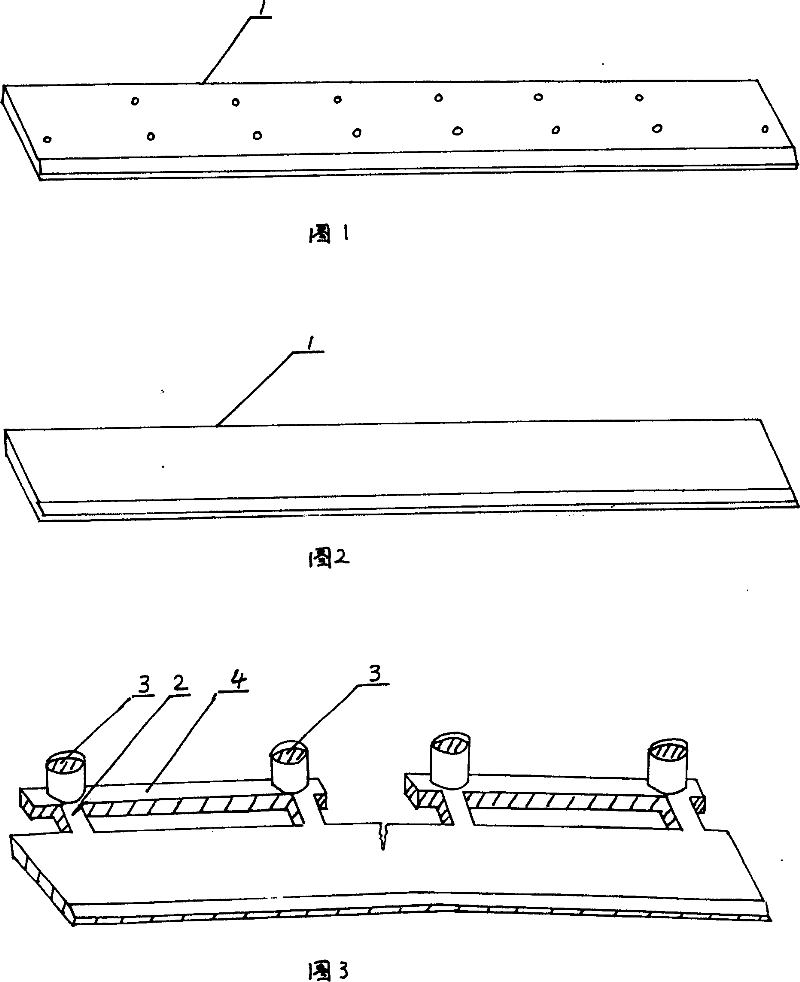

[0032]Since the cutting edge plate 1 is a narrow and long thin plate, it is very difficult to cast, and the existing casting process is prone to deformation, uneven thickness, internal shrinkage and slag inclusion defects. When pouring plates in the existing casting process, the pouring system needs to connect the riser 3 with two channels 4, as shown in Figure 3, the castings produced by this process a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com