Cr-Mo-Al series welding rod for low-alloy and high-strength steel

A low-alloy, high-strength, cr-mo-al technology, used in welding media, welding equipment, metal processing equipment, etc., can solve the problems of unfavorable long-term use of deposited metal, unsuitable manual repair welding, and narrow application range. Achieve wide application and practical value, excellent welding process performance, good fusion effect

Inactive Publication Date: 2011-06-15

上海狮百盛焊材科技有限公司 +1

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After searching the documents of the prior art, it is found that the CN101148008A patent is an electric welding electrode used in a corrosion-resistant and wear-resistant environment. Precious metal components, such as nickel powder, rare earth, ferroniobium and copper, make the price expensive; CN101288924A patent is specially used for wire rod and welding wire of Q345C-NHY3 seawater corrosion-resistant steel, and is mainly used in submerged arc welding, not suitable for Manual repair welding or welding at special positions narrows its application range; CN1939649A patent is a welding material specially used for underwater wet welding, but it contains few corrosion-resistant alloy elements, and its deposited metal is in the marine environment. Not good for long-term use

Through the above search, it is found that there is no economical welding electrode with good mechanical properties and seawater corrosion resistance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

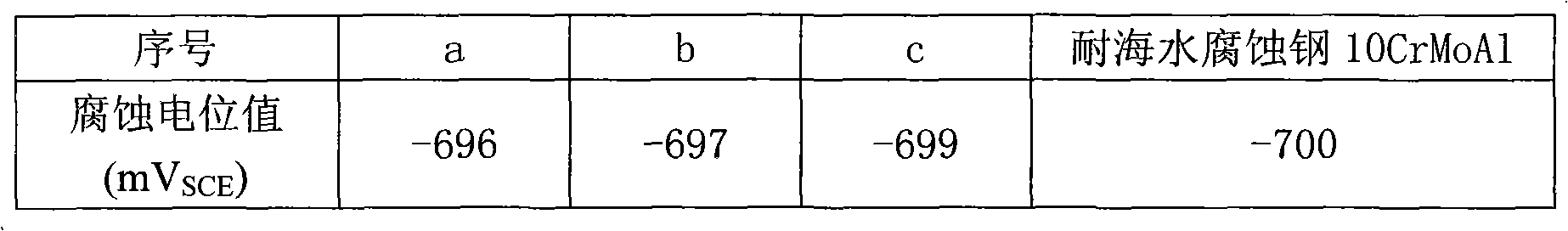

Effect test

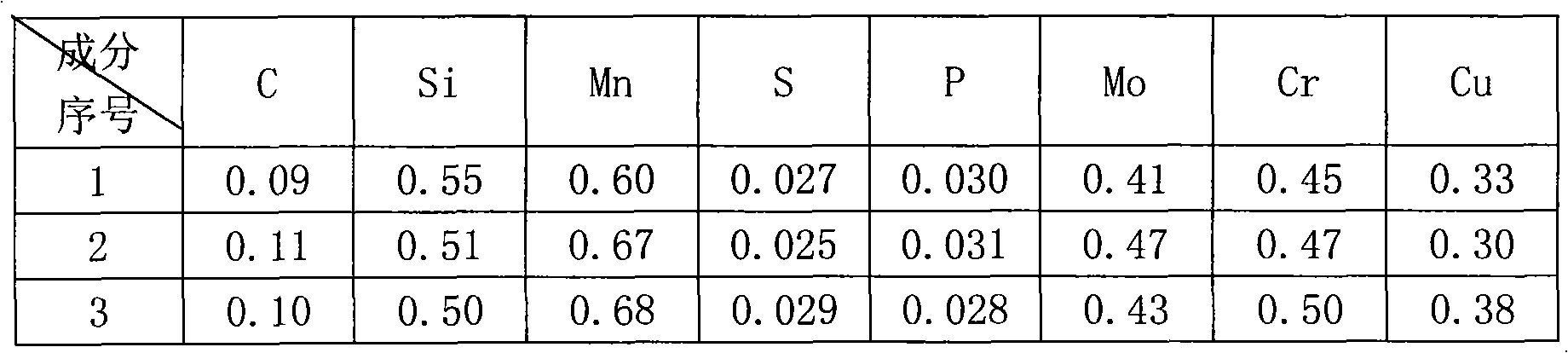

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

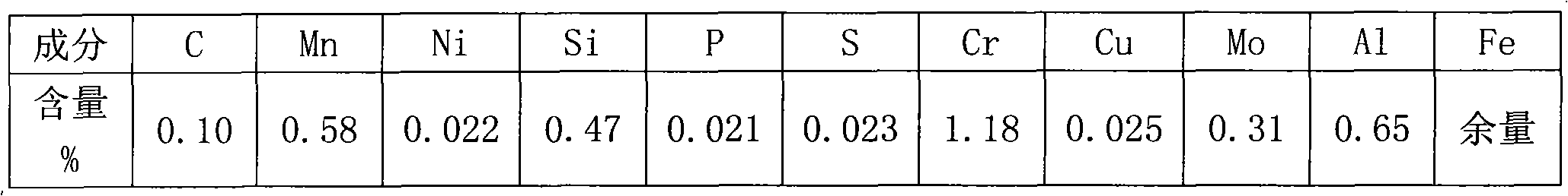

The invention discloses a Cr-Mo-Al series welding rod for low-alloy and high-strength steel, comprising a core wire and a coating, wherein the coating comprises the following components in percentage by weight: 32-42 percent of calcium oxide, 16-20 percent of calcium fluoride, 5-10 percent of titanium white, 8-12 percent of silicon dioxide, 3-5 percent of mid-carbon ferromanganese, 3-5 percent of ferromolybdenum, 4-6 percent of low-carbon ferromanganese, 3-4 percent of potassium oxide, 4-6 percent of sodium oxide, 2-3 percent ofaluminum oxide and 3-5 percent of copper. The welding rod provided by the invention has low manufacture cost, and the deposited metal of the welding rod has favorable mechanical property, welding performance and seawater corrosion resistance.

Description

A kind of Cr-Mo-Al series low-alloy high-strength steel welding rod technical field The invention belongs to the technical field of welding materials, in particular, the invention relates to a Cr-Mo-Al series low-alloy high-strength steel welding rod. Background technique At present, with the in-depth development and utilization of marine resources by humans, the steel structure parts required in marine engineering are also increasing day by day, such as: seawater pipelines, seawater heat exchangers, evaporators for salt making equipment, seabed containers and ship water Lower steel structure, etc. Because the marine environment is a complex corrosive environment, seawater itself is a strong corrosive medium, and waves, tides, and currents have low-frequency reciprocating stress impacts on steel components. This requires a class of seawater corrosion-resistant steel that can be applied to the above-mentioned environment. 10CrMoAl is one of them. It belongs to the Cr-Mo-A1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/40B23K35/30B23K35/365

Inventor 何国匡俊杨晋慧马玉顺余天乐于清波区天仁

Owner 上海狮百盛焊材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com