Patents

Literature

46results about How to "Fine internal organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

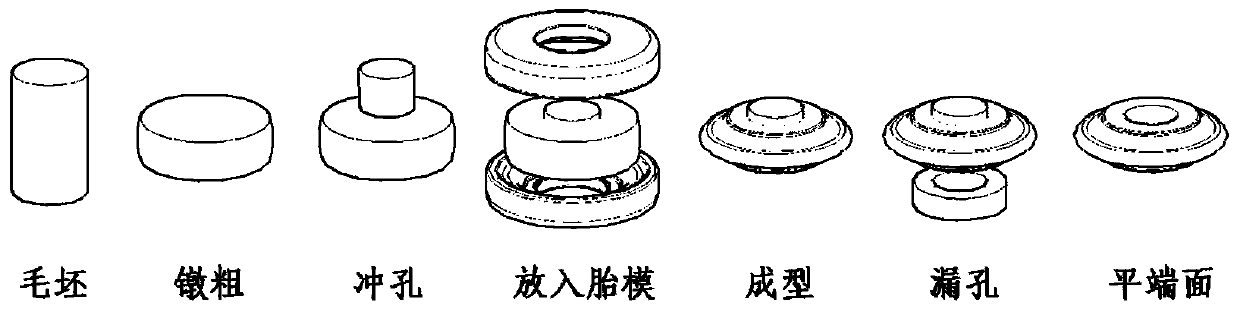

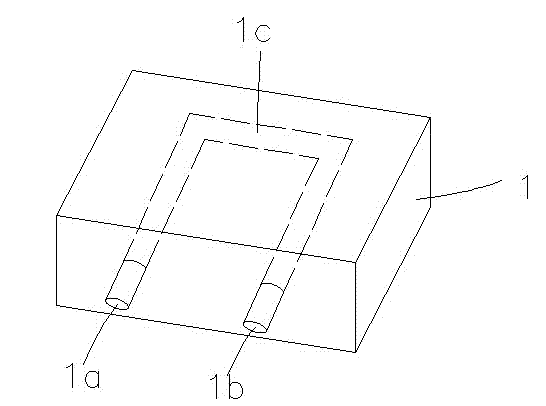

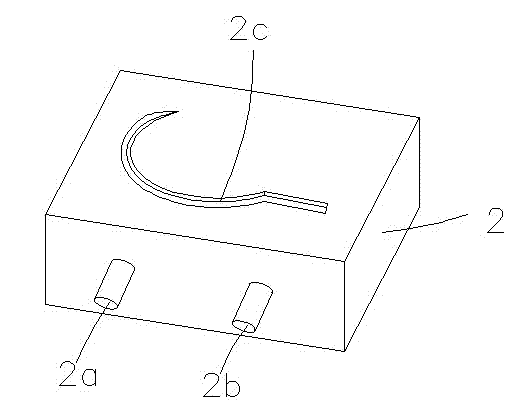

Casting extruding compound shaping method of magnesium alloy automobile hub

InactiveCN1429717AFine internal organizationDense internal organizationDisc wheelsGraphiteSuperficial mass

A technology for forming the Mg-alloy hub of car features three procedures of preshaping, upsetting-squeezing formation and fine trimming and includes such steps as casting a blank; after preshaping,making allowance for apsetting-squeezing formation; upsetting-squeezing formation and deformation degree during isothermal squeezing by using the critical-controlled deformation method; coating graphite lubricant inside the die; and fine trimming. Its advantages are fine crystal grains, and high mechanical performance and surface quality.

Owner:ZHONGBEI UNIV

Production method of multi-element aluminum alloy standard sample

ActiveCN101294875AHigh yieldImprove distribution uniformityPreparing sample for investigationColor/spectral properties measurementsMulti elementStandard samples

The invention relates to a method for preparing a standard multi-element aluminum alloy sample. The method comprises the steps of proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and is characterized in that the standard sample contains the following 20 chemical elements in pure aluminum: Si, Fe, Cu, Mg, Mn, Zn, Sn, Pb, Ni, Ti, Cr, Sr, Ca, V, Ga, Zr, Cd, Be, B and P. The standard sample is manufactured sequentially through proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and finally, standard samples are prepared according to the requirements for the standard samples. By adopting the preparation method, the multi-element aluminum alloy sample with uniform composition and good stability can be obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Toughening and deformation processing method of magnesium alloy

The invention discloses a toughening and deformation processing method of a magnesium alloy, which performs toughening and deformation processing on a melted and homogenized magnesium alloy billet. The method is combined by any more than two methods of metal plastic deformation processing methods containing forging deformation processing, extruding deformation processing, rolling deformation processing and stamping deformation processing, a latter deformation processing method is carried out on the magnesium alloy directly after the former deformation processing method or after the magnesium alloy is split when the former deformation processing method is finished, heating is not carried out between the two deformation processing methods, the magnesium alloy material after deformation processing is immediately subjected to water spray cooling or blow cooling when the last deformation processing method is finished, and the cooled magnesium alloy material is performed with aging heat treatment. The method in the invention can obviously and evenly refine the interior textures of the magnesium alloy material, improve the mechanical property and uniformity of the magnesium alloy material, avoid texture coarsening of a magnesium alloy deformation workpiece in reheating and heat insulation processes, and save energy.

Owner:GRIMAT ENG INST CO LTD

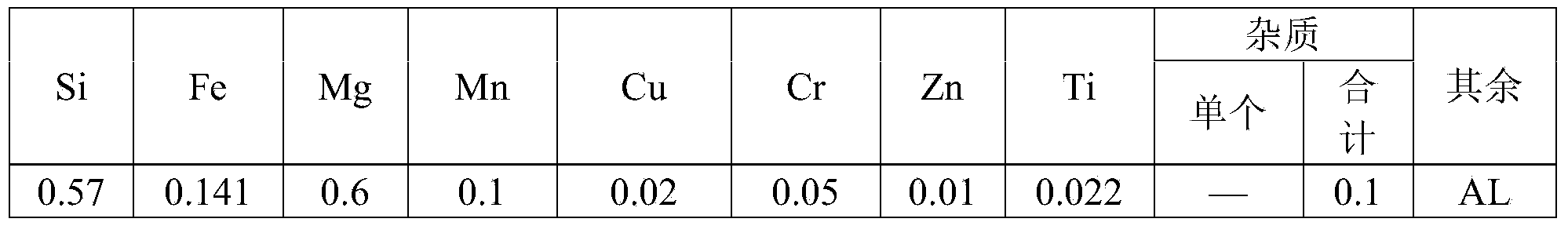

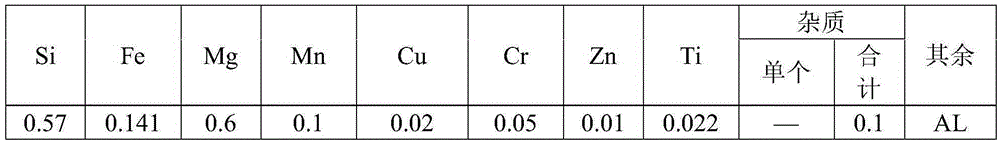

Aluminum profile for motor train unit running in high and cold regions and preparation method thereof

ActiveCN104046852AMeet the standard requirements for low temperature fatigueHigh strengthImpurityMetal

The invention discloses an aluminum profile for a motor train unit running in high and cold regions. The aluminum profile comprises the following metal substances in percentage by weight: 0.4-0.7% of Si, less than or equal to 0.20% of Fe, 0.5-0.75% of Mg, 0.01-0.2% of Mn, less than or equal to 0.05% of Cu, less than or equal to 0.1% of Cr, less than or equal to 0.08% of Zn, 0.02-0.04% of Ti, less than or equal to 0.05% of single impurities, less than or equal to 0.15% of total impurities and the balance of Al. The invention further discloses a preparation method of the aluminum profile for the motor train unit running in high and cold regions. The aluminum profile for the motor train unit running in high and cold regions provided by the invention satisfies the standard requirements of low-temperature fatigue of the motor train unit running in high and cold regions. The application temperature of the common motor train unit ranges from 25 DEG C below zero to 40 DEG C. The aluminum profile disclosed by the invention is not broken in low-temperature fatigue test which is carried out for 107 cycles at 40 DEG C below zero.

Owner:龙口市丛林铝材有限公司

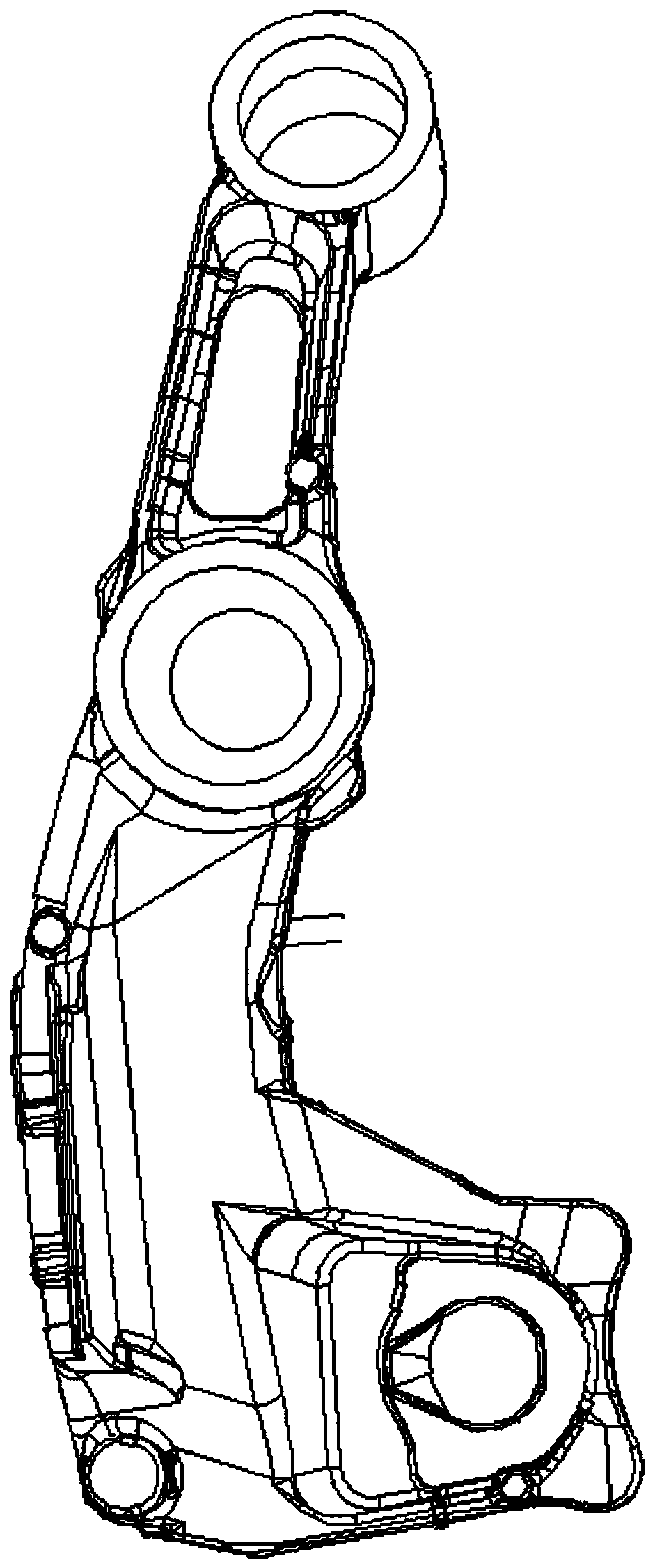

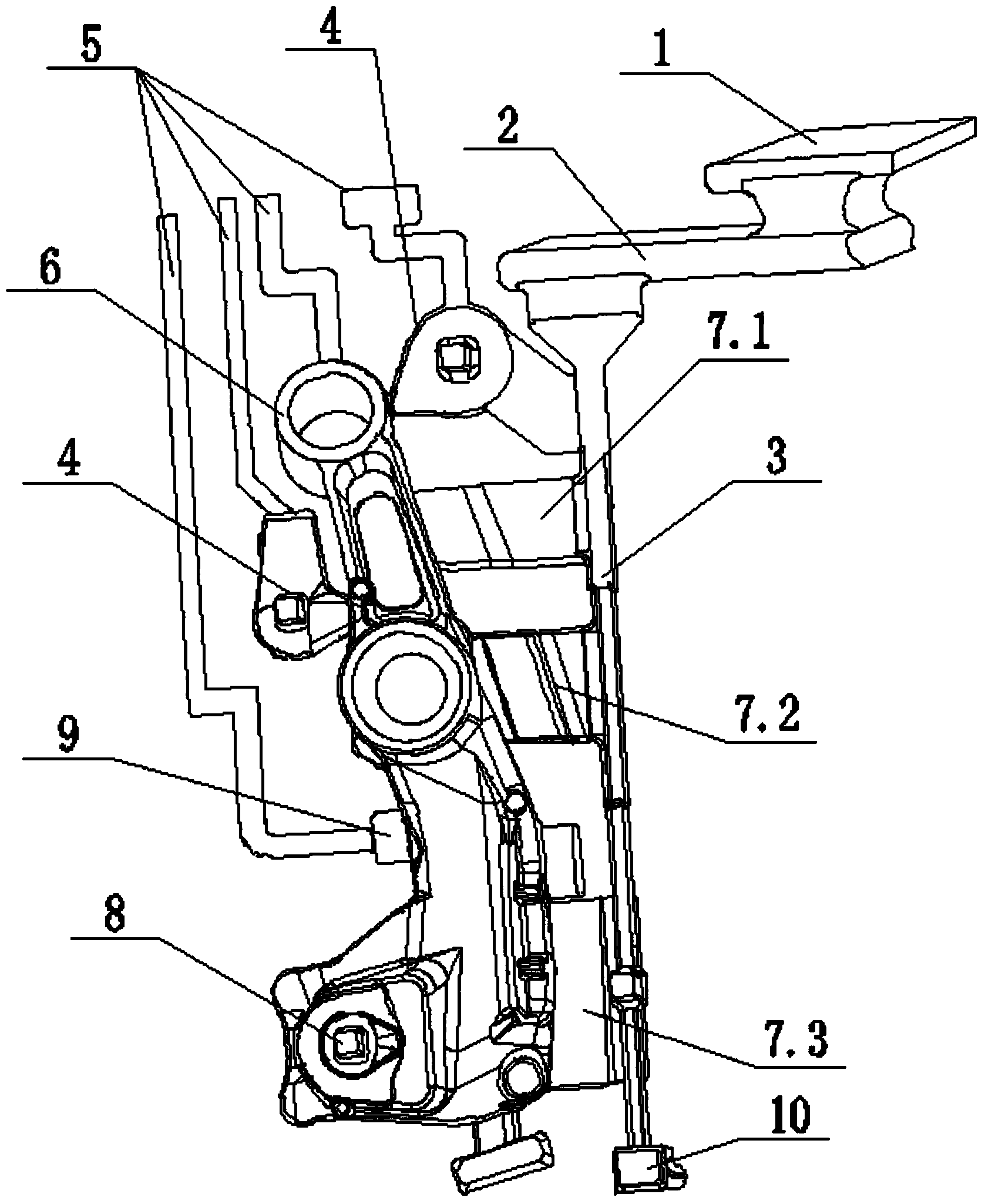

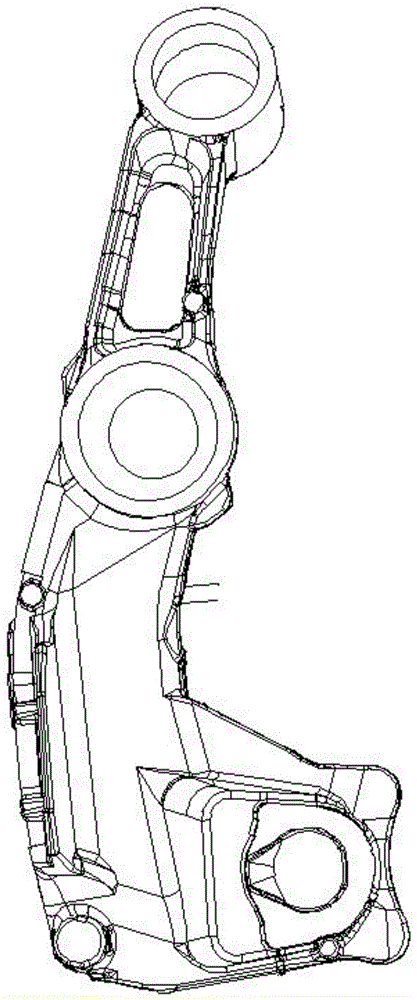

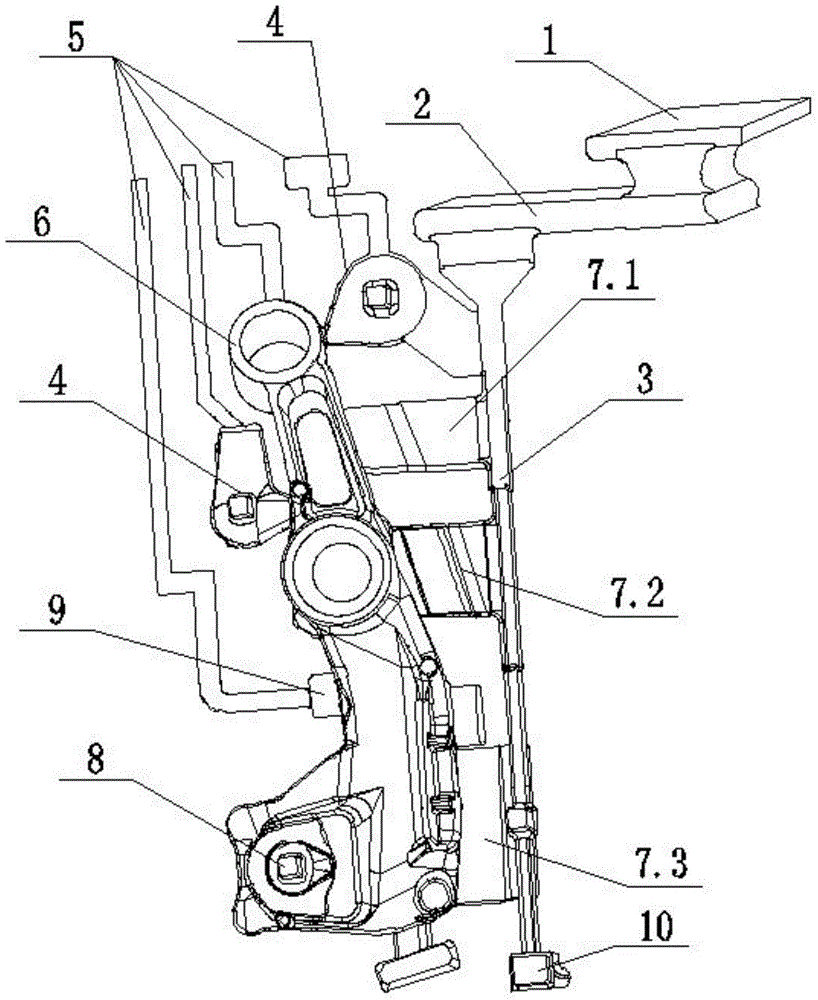

Casting method of steering knuckle of nodular cast iron

ActiveCN103846392AShort stayImprove cooling effectFoundry mouldsFoundry coresDuctile ironRejection rate

The invention discloses a casting method of a steering knuckle of nodular cast iron. The casting method comprises a mold manufacturing step, a sand mold manufacturing step and a pouring molding step, wherein the steering knuckle is vertically arranged, a thick part of a steering knuckle casting is arranged at the upper part, a thin-walled part of the steering knuckle casting is arranged at the lower part; a pouring system of the steering knuckle casting is divided into a pouring cup, a cross pouring gate and a straight pouring gate, the cross pouring gate is connected to the lower part of the pouring cup, the straight pouring gate is connected to the lower part of the cross pouring gate, and a scum riser is arranged at the bottom end of the straight pouring gate; the side wall of the straight pouring gate is connected with a first inner pouring gate, a second inner pouring gate and a third inner pouring gate from top to bottom; the steering knuckle casting is further provided with a hot riser, a cold riser and exhausting pieces; the sectional area ratio of each component of the casting is that F(straight pouring gate):F(cross pouring gate):F(inner pouring gates) is equal to 1:(1.2-1.4):(1.35-1.5); the casting is obtained by controlling the pouring temperature at 1370-1410 DEG C and carrying out pouring for 5-10 seconds. The casting method has the advantages that pouring speed is high, the defects such as shrinkage porosity, shrinkage cavity and the like cannot easily occur, and the casting is high in production efficiency, low in rejection rate and excellent in mechanical property.

Owner:宁波强盛机械模具有限公司

Heat treatment method for mold

InactiveCN106591543AShort cycleUniform spheroidizationSolid state diffusion coatingFurnace typesIonNitriding

The invention relates to a heat treatment method, in particular to a heat treatment method for an automobile mold. The method includes the following steps that firstly, isothermal spheroidizing annealing is performed; secondly, a mold subjected to air cooling is placed into a vacuum heating furnace again to be subjected to secondary step quenching; third, the mold subjected to secondary step quenching is subjected to high temperature tempering; fourthly, the mold subjected to tempering is placed in an ion nitriding furnace, a nitriding gas source is introduced to perform ion nitriding, after heat preservation is performed for 2-4 hours, the nitriding gas source is closed, and air is introduced to perform low pressure oxidation; and fifthly, the mold subjected to nitriding is subjected to low pressure slow cooling till room temperature is achieved. According to the method, methane and argon as are alternately used as the nitriding gas source, the production period can be effectively shortened, and the surface brittleness of the mold is lowered; and a low pressure oxidation process integrates traditional nitriding and oxidization processes, the production process is simplified, and the treatment time is shortened.

Owner:LIUZHOU TONGWEI MACHINERY

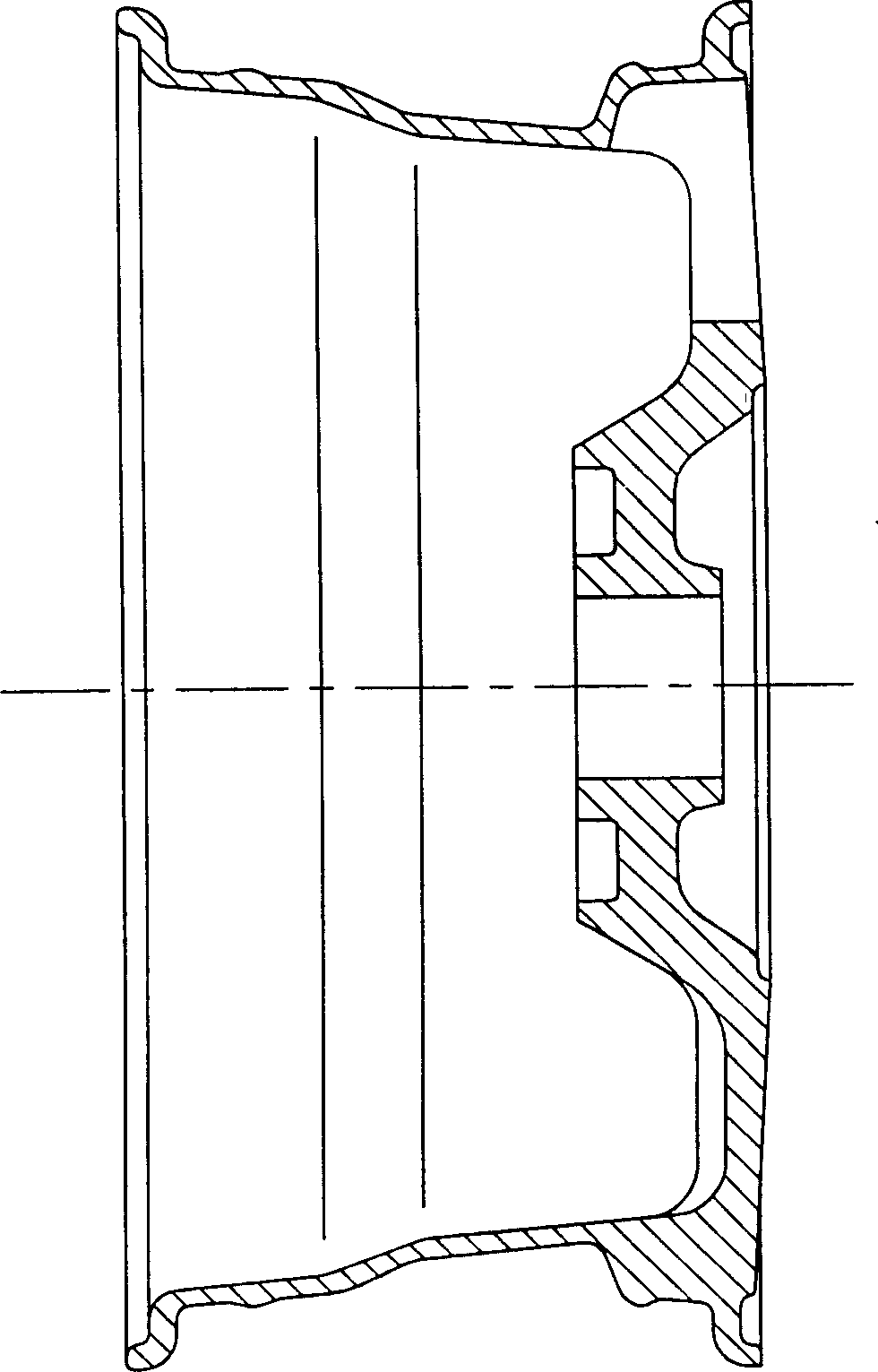

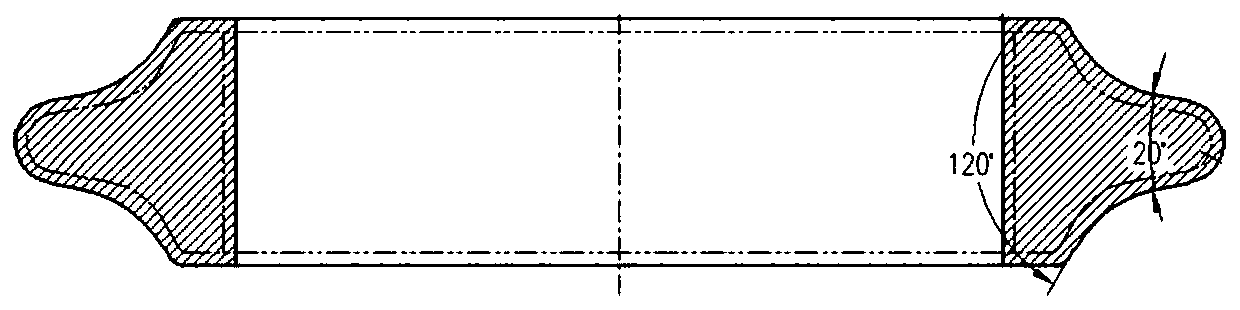

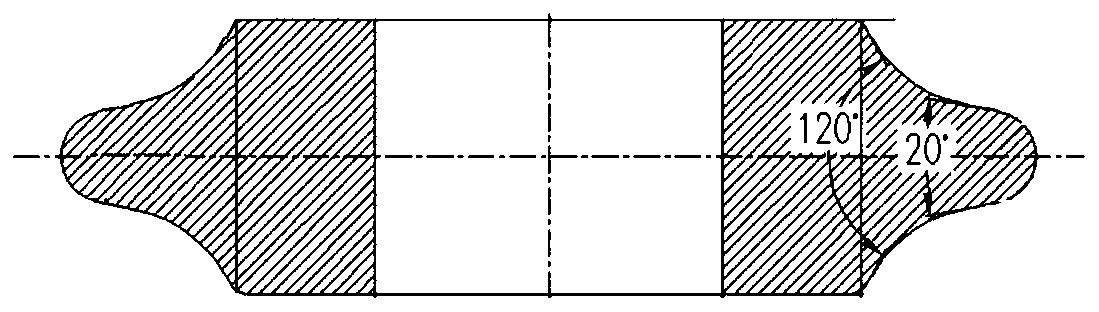

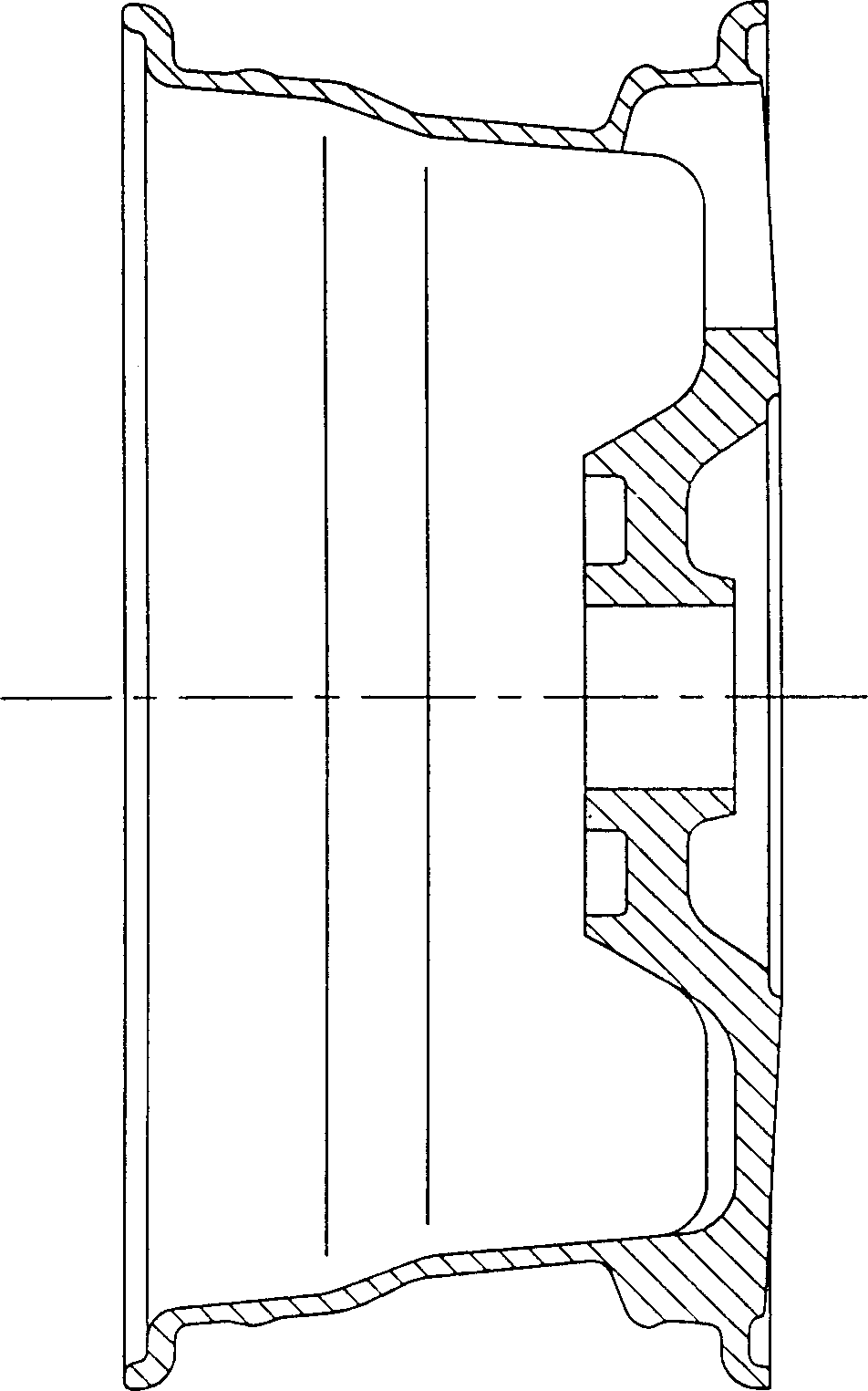

Rolling method for specially-shaped alloy steel ring part with section containing suddenly-changing curve

ActiveCN110666081AFine internal organizationIncrease profitEngine componentsMetal rollingFiberUltimate tensile strength

The invention discloses a rolling method for a specially-shaped alloy steel ring part with a section containing a suddenly-changing curve. The rolling method for the specially-shaped alloy steel ringpart with the section containing the suddenly-changing curve comprises the following steps: blanking to obtain an initial blank; preparing a ring rolling blank from the initial blank which reaches a forging temperature requirement; and placing the ring rolling blank in a ring rolling machine, and carrying out ring rolling forming to obtain a forged ring part with the specially-shaped section. Therolling method for the specially-shaped alloy steel ring part with the section containing the suddenly-changing curve is capable of realizing rolling for the specially-shaped ring part with the section containing the suddenly-changing curve; the deformation force needed by the specially-shaped ring rolling is greatly reduced, and the production cost is lowered; the rolling achieves high internal quality and close internal structure, crystalline grains are fine, fibers are arrayed in the circumferential direction, the mechanical strength and the wear resistance are obviously improved, and the fatigue life is obviously prolonged; high product accuracy, a low machining amount and a high material utilization rate are achieved; high production efficiency and a high rolling speed are achieved; the defects of incomplete filling, fishtail pits, dimension deviation and the like in the ring rolling process are solved; and the method is capable of realizing the most economic and efficient batch production as one-process rolling forming.

Owner:BEIJING NORTH VEHICLE GROUP CORP

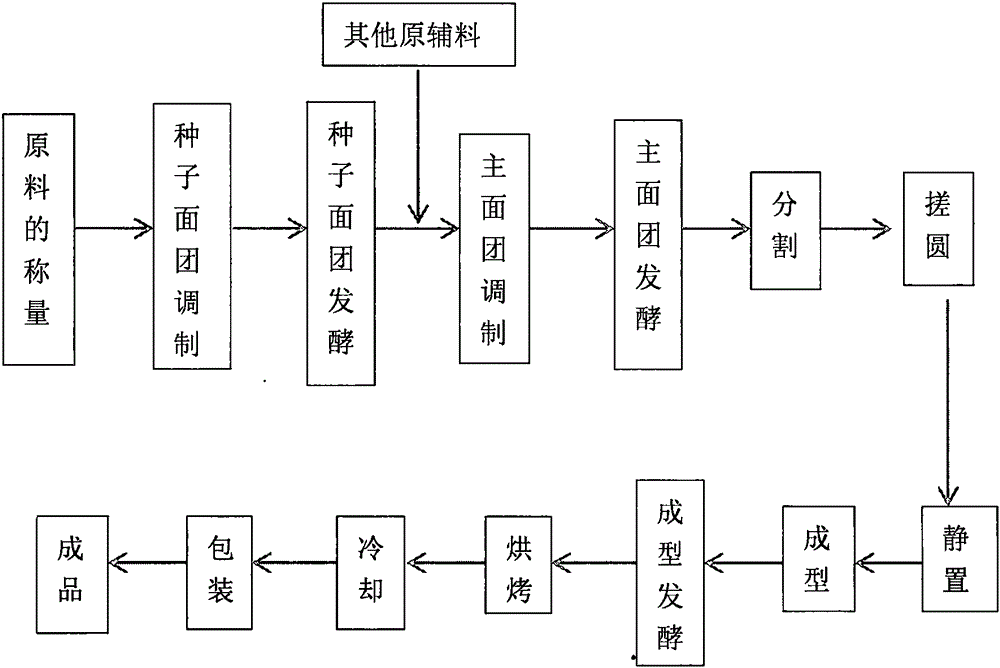

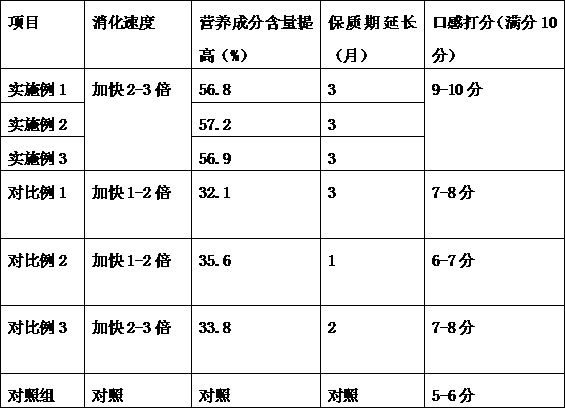

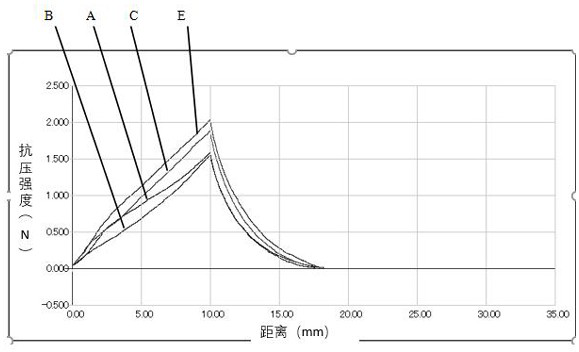

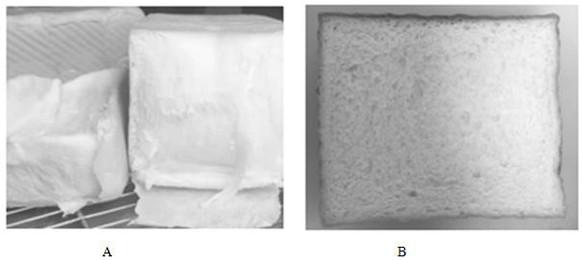

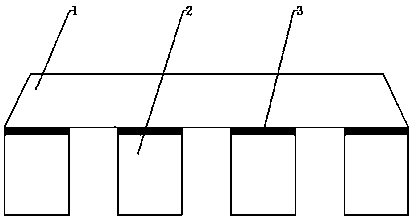

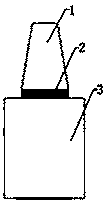

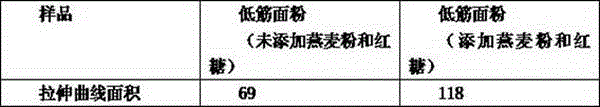

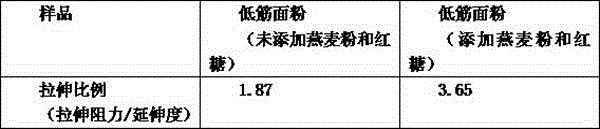

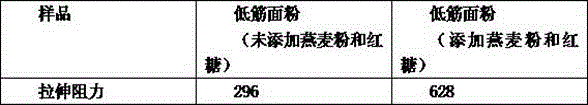

Technology adopting secondary fermentation method for making bread

InactiveCN105028568AComplete formPlumpPre-baking dough treatmentBakery productsDough fermentationRaw material

The invention discloses a technology adopting a secondary fermentation method for making bread, and relates to the technical field of bread making. The technology mainly comprises the steps that raw materials are prepared and weighed, seed dough is made through mixing and fermented, main dough is made through mixing and fermented, the dough is divided and rubbed to be round and stands, formed dough is fermented and baked, and then a baked product is taken out of an oven to be placed on an airing frame, cooled at indoor temperature and then packaged. The defects in the prior art can be overcome, the technology for making the bread is simple, by the adoption of the secondary fermentation method, the made bread is complete in form, plump, free of black foams or obvious burned dots, even and normal in surface color and luster, fine, smooth and elastic in internal tissue, even in pore, clear in grain, slow in aging, softer and more agreeable to the taste, and is in a sponge shape, and a stuffing membrane is thin.

Owner:金怀蕊

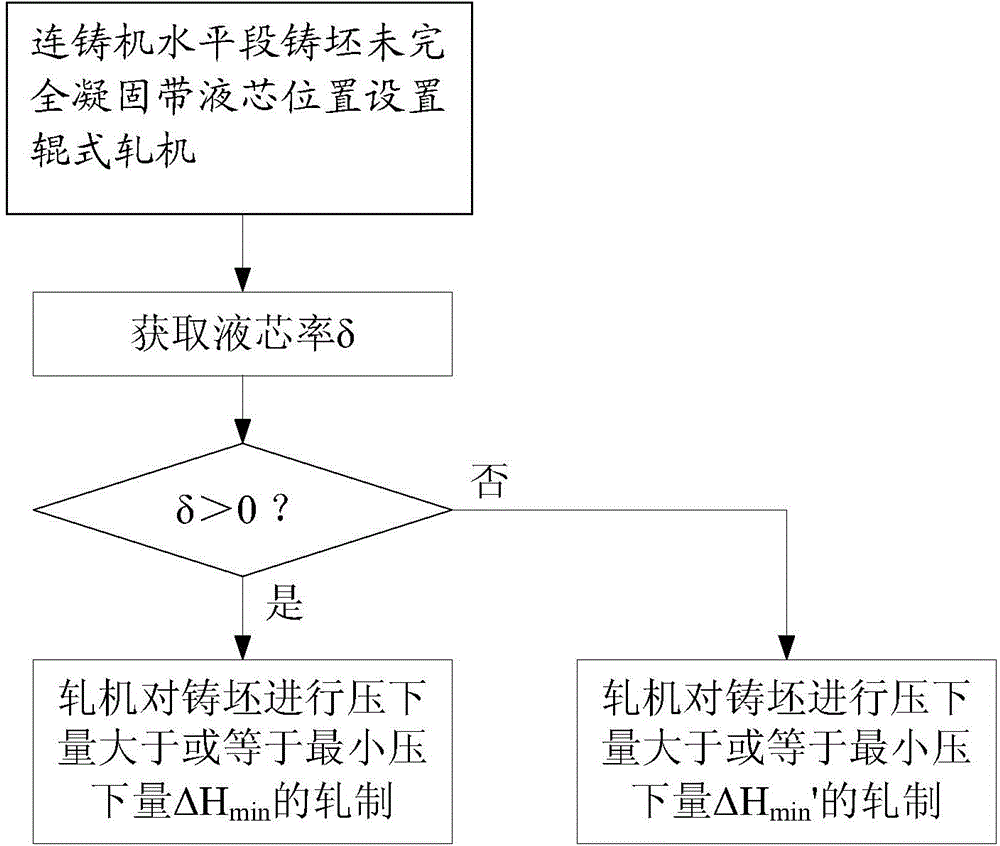

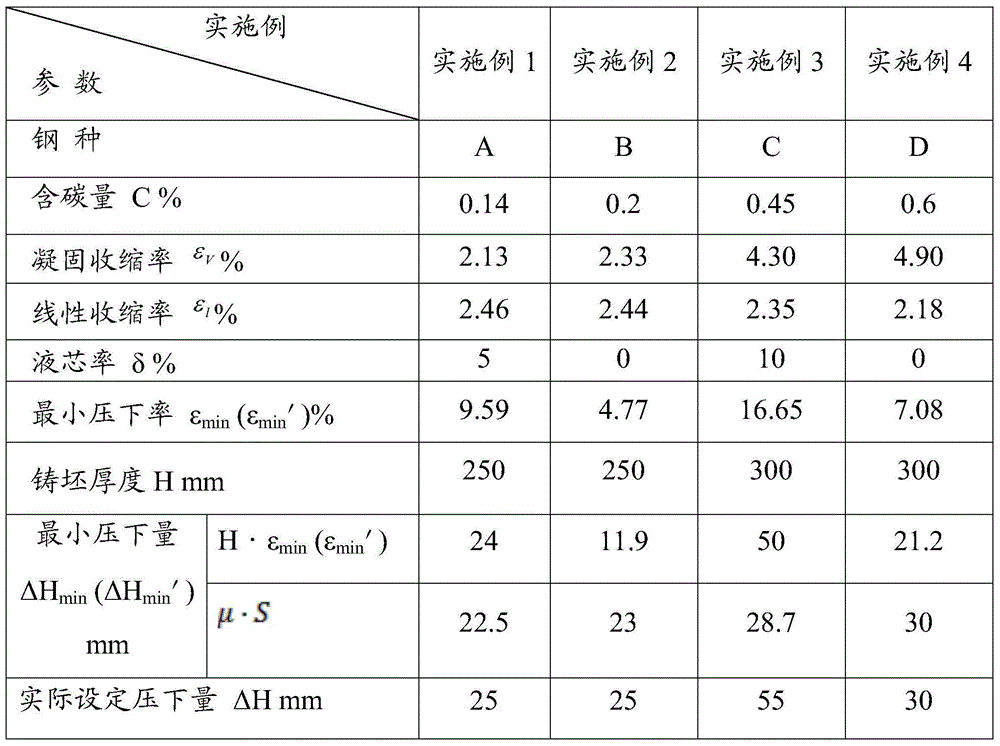

Rolling reduction control method under large liquid core pressure

ActiveCN104084429AImprove billet qualityRefine internal organizationRoll force/gap control devicePorosityModel control

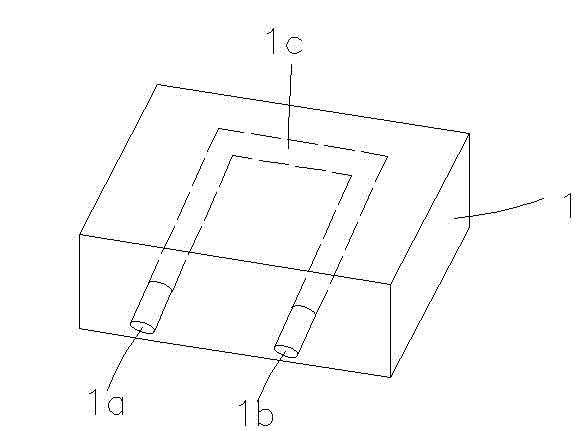

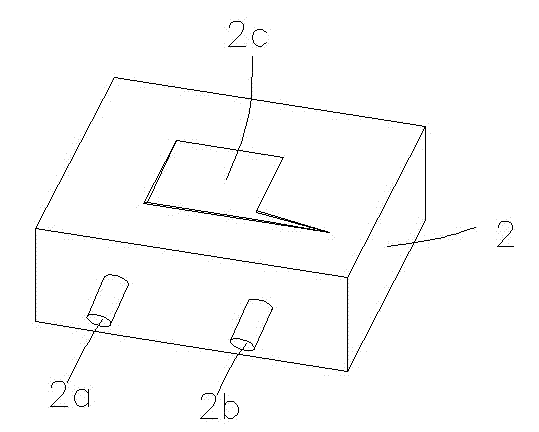

The invention discloses a rolling reduction control method under large liquid core pressure. A roller-type rolling mill is arranged at the position, with a liquid core, of the horizontal segment of a continuous casting machine, wherein a casting blank is not completely solidified at the position. The liquid core rate delta is obtained at the position of the rolling mill, and whether the liquid core rate delta is larger than 0 or not is judged. If the liquid core rate delta is larger than 0, the rolling mill conducts rolling under the large liquid core pressure on the casting blank, wherein the rolling reduction of the rolling under the large liquid core pressure is larger than or equal to the minimum rolling reduction delta H min, and the minimum rolling reduction meets the equation that delta H min=max [H*(epsilon v + epsilon l + delta), mu*S]. According to the rolling reduction control method, center porosity, segregation, internal cracks and the like of the casting blank can be removed, the quality of the casting blank is improved, and internal organization is refined; the internal quality of the rolled casting blank is remarkably improved, the density of the casting blank is improved, the linear shrinkage percentage of cooling from high temperature to room temperature is at least reduced by 1.5%, the model control is easy, and the rolling reduction control method is easy to implement.

Owner:BERIS ENG & RES CORP

Final forming technique of kitchen knife blank

InactiveCN102921893AHigh strengthFine internal organizationFoundry mouldsFoundry coresWear resistantAtmospheric pressure

The invention discloses a final forming technique of a kitchen knife blank. The final forming technique of the kitchen knife blank comprises the following steps: manufacturing a casting mould which consists of an upper steel mould and a lower steel mould; filling cooling water to the casting mould; heating steel materials to molten steel; casting; and moving the upper steel mould downwards to be buckled with the lower steel mould under the action of a hydraulic drive system or a pneumatic drive system, cooling and the like. The formed kitchen knife blank has a smooth surface, is free from any pore, attractive in appearance and high in knife blank quality; the knife blank materials have stable compositions and are wear resistant and long in service life; no raw material wastes during forming, the material utilization ratio reaches 100%, and the manufacturing cost is saved; and the technique is simple in procedure, easy to implement, and small in labor intensity of workers, and the manufacturing cost is reduced.

Owner:黄维明

Nutritive soft glutinous fermentation type rice cakes

The invention relates to the technical field of food processing, and discloses nutritive soft glutinous fermentation type rice cakes. After fermentation treatment, the content of ash content large particles in raw materials is notably reduced, the content of free fatty acids is notably increased, and the content of amino acids is increased, so that utilization of starch in the raw materials is greatly promoted, products are soft in texture, the mouth feel of the products is notably improved, and the digestion and absorption rate is also increased. According to the nutritive soft glutinous fermentation type rice cakes disclosed by the invention, the nutrition, the mouth feel, the flavor, the digestibility and the texture characteristics are improved, so that the rice cakes which are fine and smooth in internal texture, small and uniform in air holes, fine and smooth in mouth feel, light and soft and good in flexibility can be made, and the obtained fermentation type rice cakes are unique in flavor, rich in nutrition, easy to digest and wide in application crowds, wherein riboside, nucleotide, aminobutyric acid and some bioactive peptides have the effects of resisting oxidation, restraining the activity of angiotensin converting enzymes, preventing blood vessel ends from being contracted and reducing blood pressure; and therefore, the products are especially suitable for old people to eat.

Owner:BENGBU LAOWANTONG FOOD FACTORY

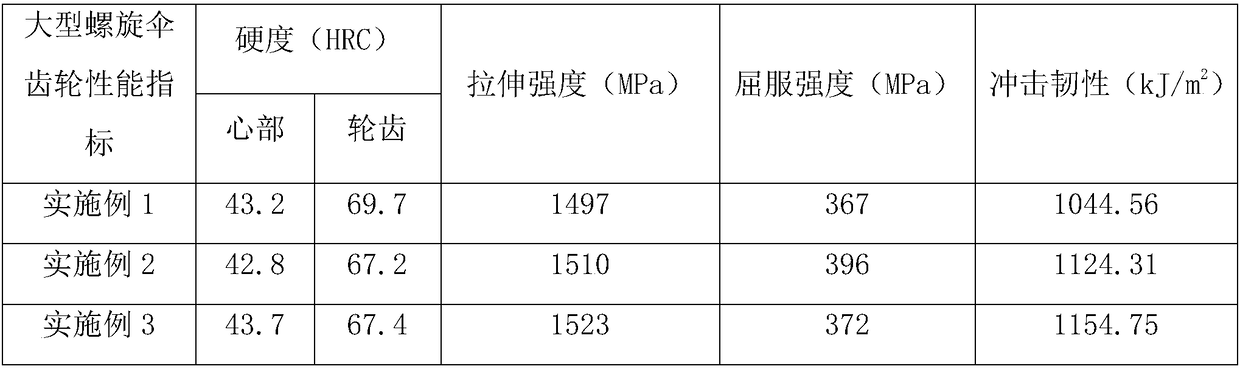

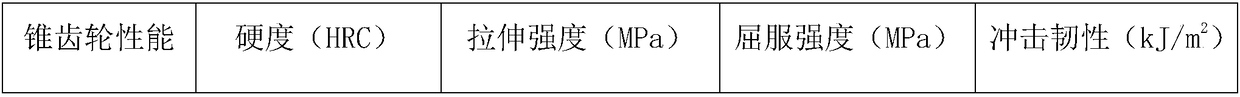

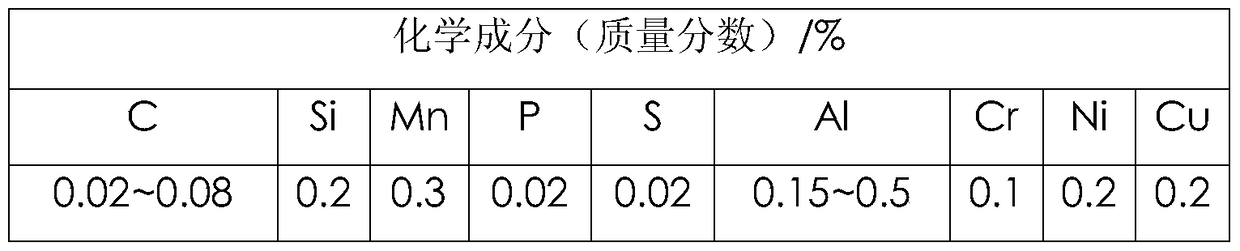

Heat treatment technology of 30CrMnTi steel large-scale spiral bevel gear

InactiveCN108823502AFine internal organizationHigh hardnessSolid state diffusion coatingFurnace typesThermal insulationHigh intensity

The invention provides a heat treatment technology of a 30CrMnTi steel large-scale spiral bevel gear. The spiral bevel gear comprises the following chemical elements (by weight): 0.24-0.32% of C, 0.17-0.37% of Si, 0.8-1.3% of Mn, 1.0-1.3% of Cr, 0.04-0.12% of Ti, P being less than 0.035%, S being less than 0.035% and the balance iron. Through anticarburizing treatment, carburization, thermal insulation, two-stage quenching, normalization and tempering and then through machining, a 30CrMnTi steel passive skew / spiral bevel gear with high strength, high impact toughness and high tensile propertyis prepared.

Owner:HUBEI WEINENGDA TRANSMISSION CO LTD

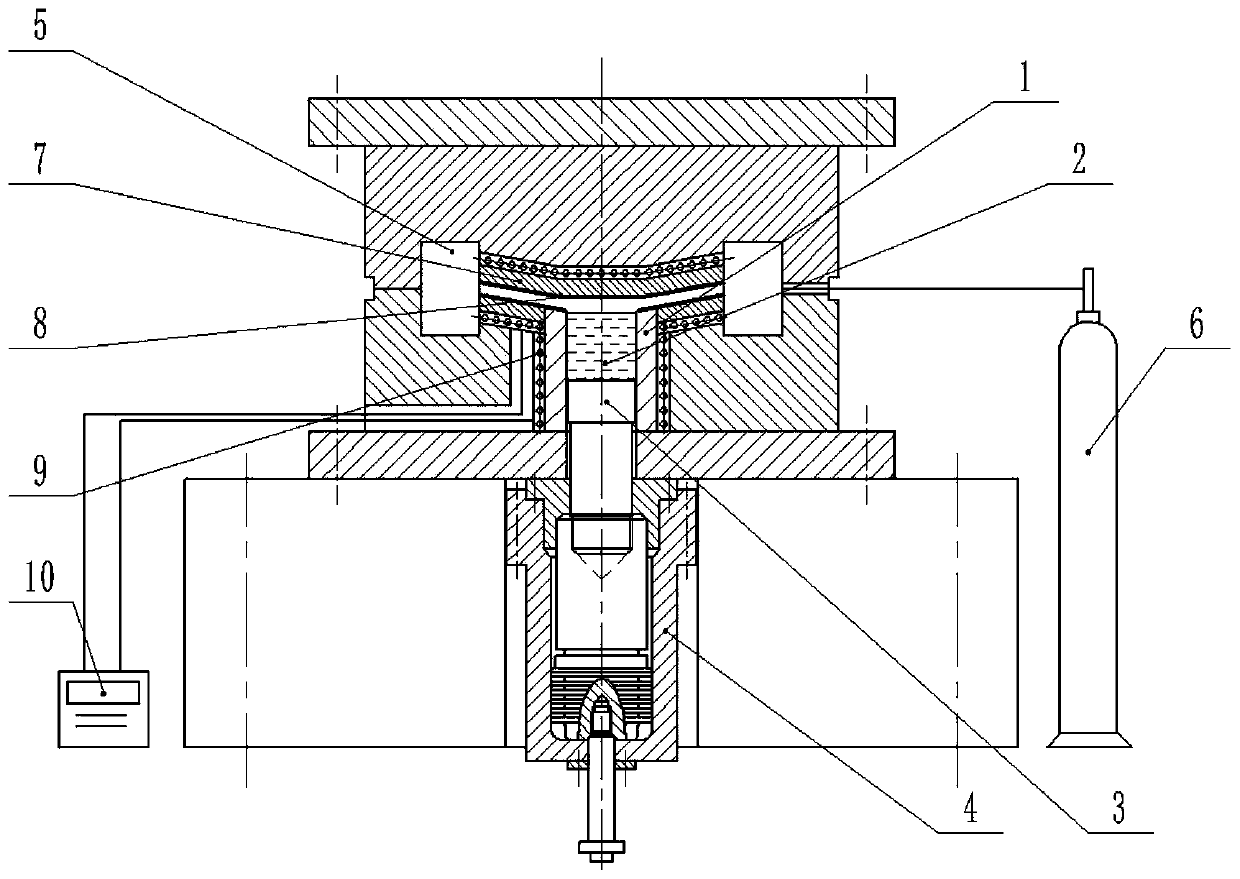

Flow-following semi-solid forming method and device

The invention discloses a flow-following semi-solid forming device. The device comprises a charging barrel, a pressure head, a flow passage and a temperature control system, wherein the charging barrel is a barrel-shaped cavity; one end of the charging barrel is connected with a mold; the pressure head is a cylinder; the diameter of the pressure head is smaller than the inner diameter of the charging barrel by 0.2-1.0 mm; the length of the pressure head is 50-120 mm; one end of the pressure head is connected with a piston rod of a pressurizing oil cylinder through a connecting rod, and the other end of the pressure head extends into the charging barrel and can freely move in the charging barrel; one end of the flow passage communicates with the charging barrel, and the end of the flow passage and the axis of the charging barrel form an included angle of 20-90 degrees; the other end of the flow passage communicates with mold cavities; the temperature control system comprises heating elements and a temperature control instrument of the heating elements; the temperature control precision is + / -1 DEG C; and the heating elements are matched with the shape of the flow passage and wound around the outsides of the flow passage and the charging barrel.

Owner:BEIJING JIAOTONG UNIV

Rice-made sponge cake and processing method thereof

ActiveCN103222494BFine internal organizationFine tissueDough treatmentBakery productsFlavorVegetable oil

The invention provides a rice-made sponge cake and a processing method thereof. The rice-made sponge cake comprises the following ingredients in parts by weight: 100-180 parts of whole eggs, 60-70 parts of granulated sugar, 100 parts of rice flours, 1-1.5 parts of salt, 6-9 parts of vital gluten, o.5-2 parts of baking powders, 3-5 parts of cake oil, 10-15 parts of vegetable oil, and 20-35 parts of water. The rice-made sponge cake provided by the utility model has fine and smooth internal tissues, uniform air holes, spongy appearance, and no sour flavor, and is soft and elastic, and not easy to age.

Owner:长沙味味食品有限公司

Final molding process of agricultural steel hoe blank

InactiveCN102921894AFine internal organizationNice appearanceFoundry mouldsFoundry coresMolten steelAtmospheric pressure

The invention discloses a final molding process of an agricultural steel hoe blank. The final molding process comprises the following steps: manufacturing a casting die comprising an upper steel die and a lower steel die; filling cooling water into the casting die; heating steel materials to form molten steel; casting; enabling the upper steel die to move downwards under the action of a hydraulic drive system or a pneumatic drive system until the upper steel die is buckled with the lower steel die; cooling the molded die, and the like. The molded agricultural hoe has a smooth surface and a, beautiful appearance without any air pore, so that the quality of the hoe is high. The hoe is made of raw materials with stable and abrasion-proof performance, so that the hoe has a long service life. In addition, the raw material waste is avoided during the molding process, and the material utilization ratio reaches 100%, so that the manufacturing cost is saved. The molding process has the advantages of simplicity in molding, easiness in implementation and small labor intensity, thereby lowering the manufacturing cost further.

Owner:黄维明

Casting extruding compound shaping method of magnesium alloy automobile hub

InactiveCN1253269CFine internal organizationDense internal organizationDisc wheelsGraphiteMechanical property

Owner:ZHONGBEI UNIV

Bean dreg bread

InactiveCN108112657ARetain nutrientsPreserve health benefitsDough treatmentModified nutritive productsBiotechnologyPorosity

The invention belongs to the field of foods, and particularly relates to bean dreg bread. The bean dreg bread is made from the following raw materials in parts by weight of 100 parts of flour, 80-120parts of bean dregs, 0.8-1.4 parts of yeast, 15-20 parts of sugar, 15-20 parts of eggs, 0.5-1.5 parts of table salt, 2-8 parts of milk powder, 0.6-1.2 parts of a bread modifier and an appropriate amount of water. The raw materials of the bean dreg bread contain the bean dregs, the formula is simple, and the made bread is soft and loose, fine and smooth in internal structures, uniform in porosity and free from sour taste, has light bean dreg fragrance, and reserves nutrient components and health-care efficacy of the bean dregs. The making method of the bean dreg bread is simple to operate, andeasy to produce.

Owner:RONGCHANG COUNTY PANLONG TOWN HEXIN FOOD FACTORY

Preparation method for high-hardness friction block for brake pad

The invention discloses a preparation method for a high-hardness friction block for a brake pad. The preparation method comprises the following steps of raising the temperature of raw materials in the argon atmosphere until a molten state, and then carrying out vacuum heat preservation to obtain a material a; discharging the material a, pouring, cooling to 400-500 DEG C, and carrying out surface machining to obtain a material b; raising the temperature of the material b to T1 DEG C, austenitizing, then carrying out heat preservation for 3-4h, taking out, putting in a nitrate bath with the temperature to be 220-230 DEG C, raising the temperature to T2 DEG C, and carrying out heat preservation for 4-5h to obtain the high-hardness friction block for the brake pad, wherein T1=1100+K1x240x110x(nC+nW+nZr) / 28.7, T2=345+K2x100x(nC+nW+nZr), a value of K1 is 5-8, a value of K2 is 28-30, and nC, nW and nZr express the weight percentages of carbon element, tungsten element and zirconium element occupied in the material a respectively.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

After-forging heat treatment technique of CrMn steel

ActiveCN104152654AImprove performanceIncrease the degree of diffusionHeat treatment process controlCarbideHardness

The invention discloses an after-forging heat treatment technique of CrMn steel, which comprises the following steps: (1) heating to 1050-1060 DEG C to perform solid solution treatment, keeping the temperature for 1-1.5 hours, taking out, carrying out oil quenching, and cooling; (2) heating to 150-180 DEG C, keeping the temperature for 2-3 hours, heating to 770-780 DEG C, keeping the temperature for 0.5-1 hour, carrying out furnace cooling to 650-660 DEG C, and keeping the temperature for 0.5-1 hour; (3) heating to 770-780 DEG C, keeping the temperature for 0.5-1 hour, carrying out furnace cooling to 650-660 DEG C, and keeping the temperature for 1-1.5 hours; (4) taking out, and cooling in air; and (5) heating to 980-1000 DEG C, keeping the temperature for 0.5-1 hour, taking out, carrying out oil quenching, heating to 150-160 DEG C at the speed of 100-120 DEG C / hour, keeping the temperature for 2-4 hours, taking out and cooling in air. The multiplex heat treatment is utilized to improve the properties of the CrMn steel, so that the internal structure is dense and uniform and has high carbide dispersion degree on the premise of keeping high hardness and high wear resistance, and thus, the internal stress and brittleness are lowered, thereby avoiding cracking or early failure when the CrMn steel is in use; and the CrMn steel has favorable strength and toughness.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

Casting Method of Ductile Iron Steering Knuckle

The invention discloses a casting method of a steering knuckle of nodular cast iron. The casting method comprises a mold manufacturing step, a sand mold manufacturing step and a pouring molding step, wherein the steering knuckle is vertically arranged, a thick part of a steering knuckle casting is arranged at the upper part, a thin-walled part of the steering knuckle casting is arranged at the lower part; a pouring system of the steering knuckle casting is divided into a pouring cup, a cross pouring gate and a straight pouring gate, the cross pouring gate is connected to the lower part of the pouring cup, the straight pouring gate is connected to the lower part of the cross pouring gate, and a scum riser is arranged at the bottom end of the straight pouring gate; the side wall of the straight pouring gate is connected with a first inner pouring gate, a second inner pouring gate and a third inner pouring gate from top to bottom; the steering knuckle casting is further provided with a hot riser, a cold riser and exhausting pieces; the sectional area ratio of each component of the casting is that F(straight pouring gate):F(cross pouring gate):F(inner pouring gates) is equal to 1:(1.2-1.4):(1.35-1.5); the casting is obtained by controlling the pouring temperature at 1370-1410 DEG C and carrying out pouring for 5-10 seconds. The casting method has the advantages that pouring speed is high, the defects such as shrinkage porosity, shrinkage cavity and the like cannot easily occur, and the casting is high in production efficiency, low in rejection rate and excellent in mechanical property.

Owner:宁波强盛机械模具有限公司

Thermal treatment process for 20CrMnMoA steel bevel gear

InactiveCN108866311AHigh hardnessHigh strengthSolid state diffusion coatingFurnace typesChemical elementHigh intensity

The invention provides a thermal treatment process for a 20CrMnMoA steel bevel gear. The bevel gear comprises chemical element ingredients in percentage by mass: 0.17% to 0.23% of C, 0.17% to 0.37% ofSi, 0.8% to 1.3% of Mn, 1.0% to 1.3% of Cr, 0.04% to 0.12% of Ti, 0.20% to 0.30% of Mo, smaller than 0.03% of Ni, smaller than 0.03% of Cu, smaller than 0.035% of P, smaller than 0.035% of S and thebalance of iron. The high-intensity high-impact-toughness high-tensile-property 20CrMnMoA steel bevel gear is prepared by machining after carburization prevention treatment, carburization, heat preservation, two stages of quenching, normalization and tempering.

Owner:HUBEI WEINENGDA TRANSMISSION CO LTD

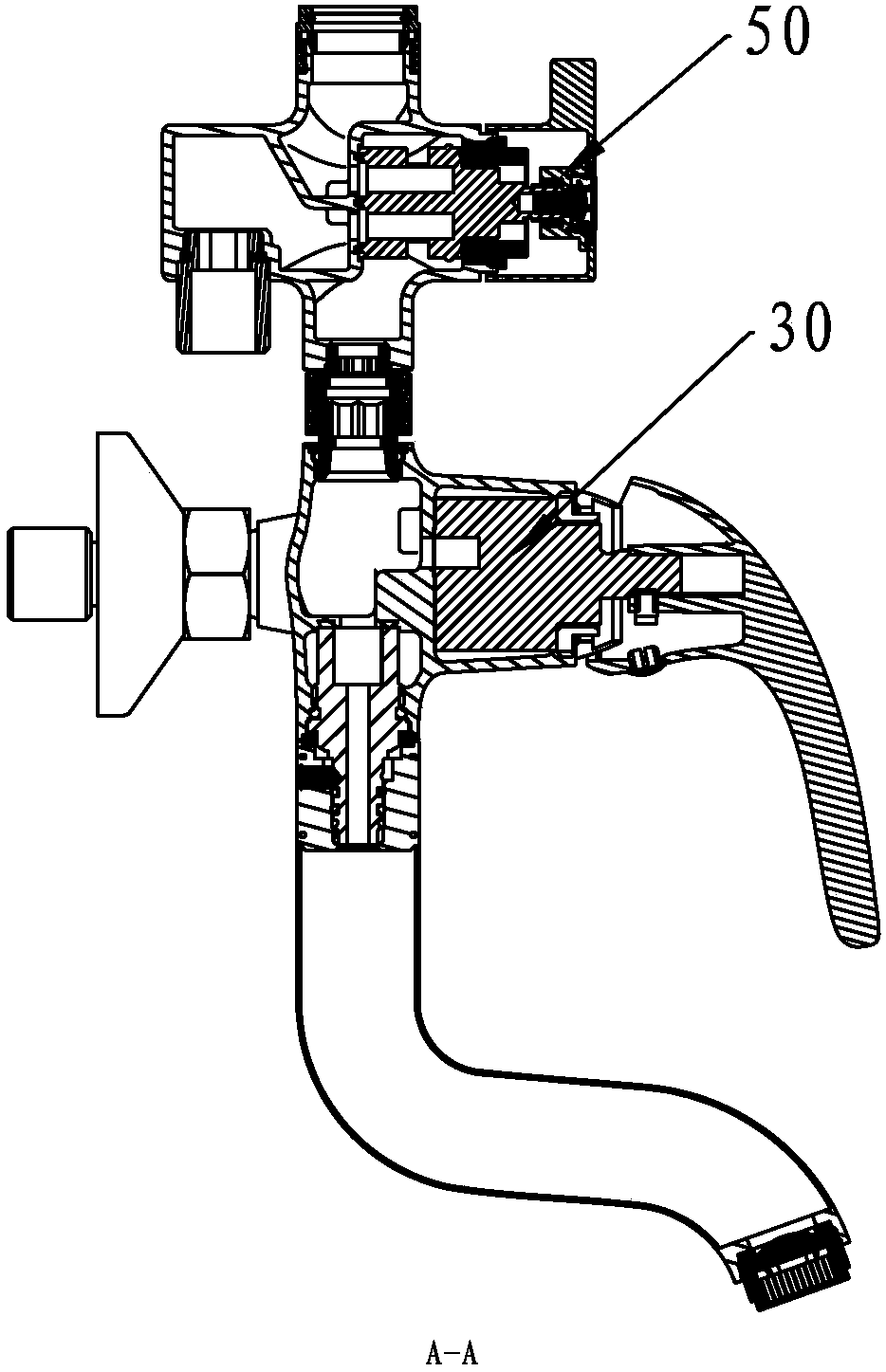

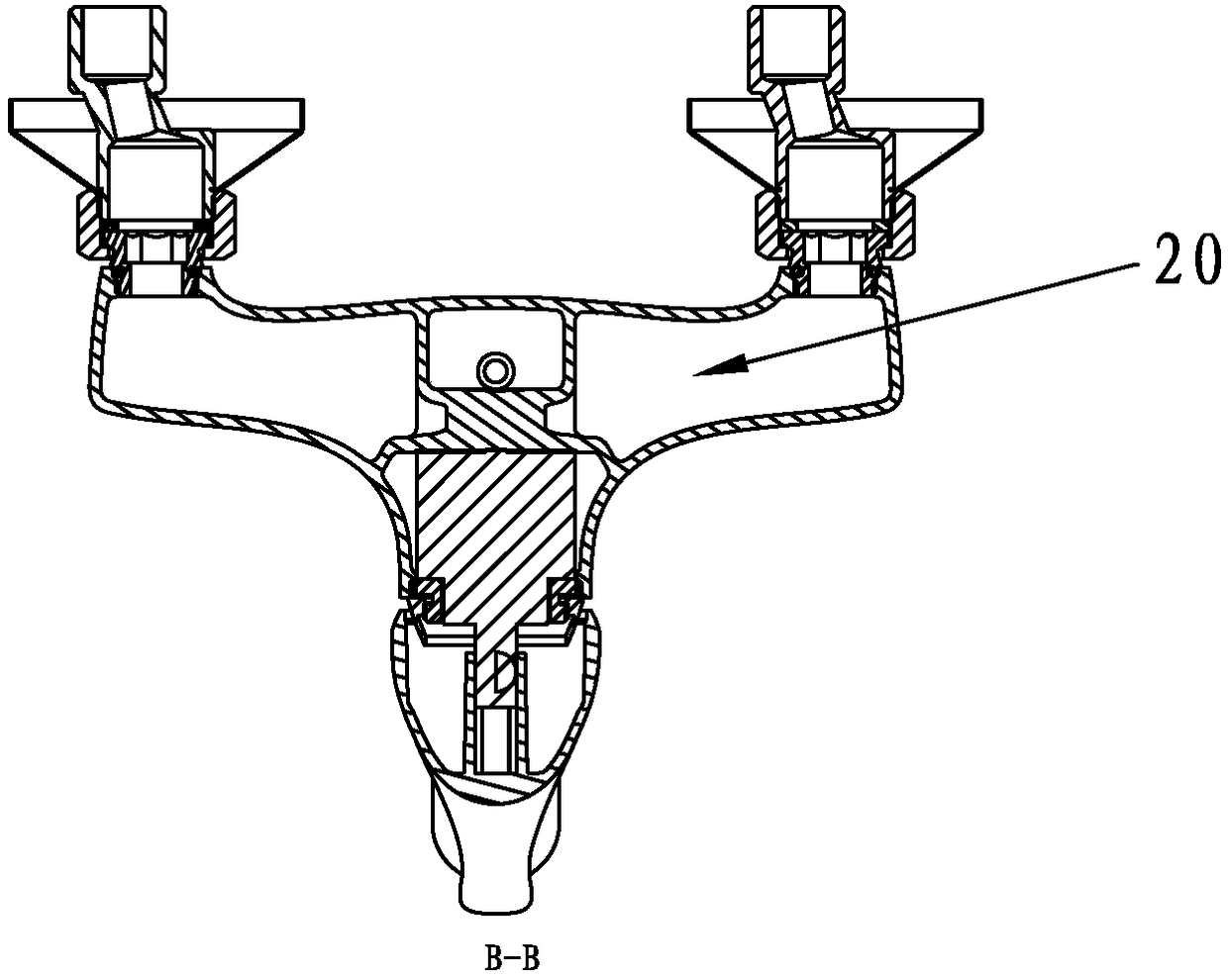

Control main body of shower system

PendingCN108087590AImprove mechanical propertiesFine internal organizationMultiple way valvesValve housingsWater flowEngineering

The invention relates to a control main body of a shower system. The control main body comprises a shell, wherein a valve body is arranged in the shell, a first water inlet flow path, a second water inlet flow path and a mixed water flow path are arranged in the valve body, a mixed water valve is arranged between the first water inlet flow path and the mixed water flow path, and between the secondwater inlet flow path and the mixed water flow path, a water distributing valve is arranged between the mixed water flow path and a water outlet terminal, and the valve body is formed by a forging process; and the first water inlet flow path, the second water inlet flow path and the mixed water flow path are formed by machining. According to the control main body of the shower system, firstly, the valve body is formed by the forging process, so that the internal tissue is fine, strength is high, the mechanical property of material is good, and the service life is longer than 10 years withoutdamage; and secondly, the internal structure of the control main body is simple, the function integration degree is high, operation is convenient, the appearance is simple, and the texture is strong.

Owner:福建省海标水暖洁具有限公司

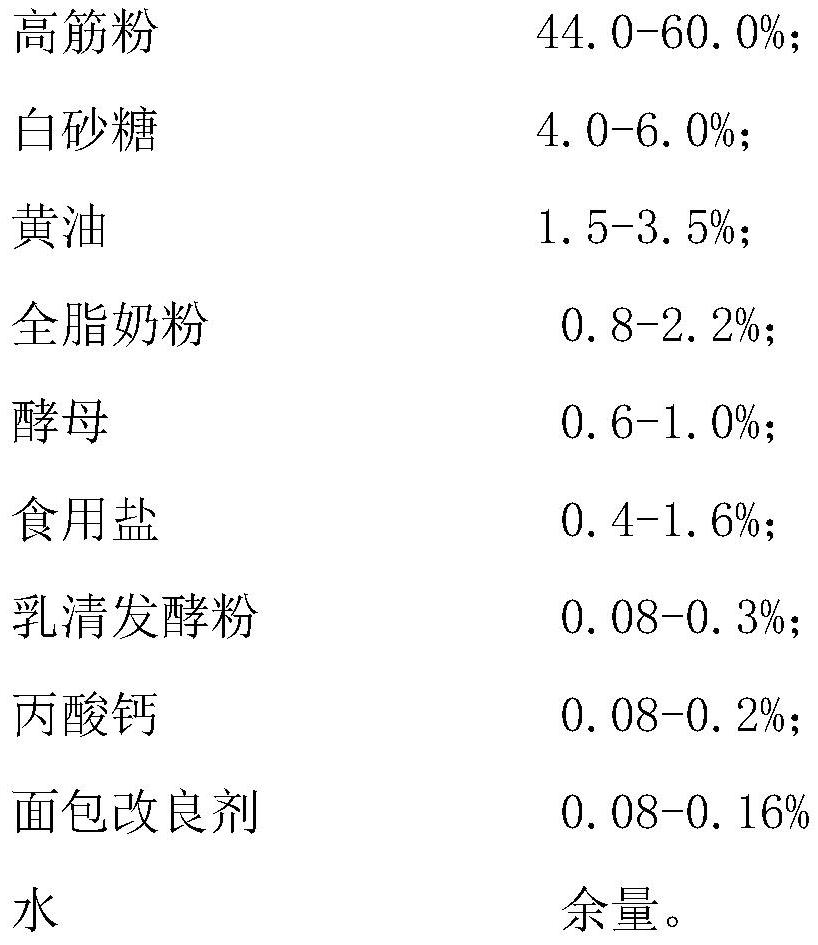

Frozen anti-aging toast slice with long shelf life

PendingCN113925075ASimple internal structureFine tissueDough/pre-mixesPre-baking dough treatmentBiotechnologyMilk Serum

The invention provides a frozen anti-aging toast slice with a long shelf life. The frozen anti-aging toast slice is prepared from high gluten flour, white granulated sugar, butter, whole milk powder, edible salt, yeast, edible salt, whey ferment powder, calcium propionate, a bread improver and the balance of water. The invention further provides a preparation method of the frozen anti-aging toast slice with the long shelf life. Through research on a formula, process steps and process conditions of the toast slice, the problem of long shelf life of the frozen toast slice is solved. The toast slice disclosed by the invention is still soft after being frozen for three months at the temperature of minus 18 DEGC or below and then unfrozen, and has the characteristics of good mouth melting property and fine and smooth internal tissues.

Owner:上海馥松食品有限公司

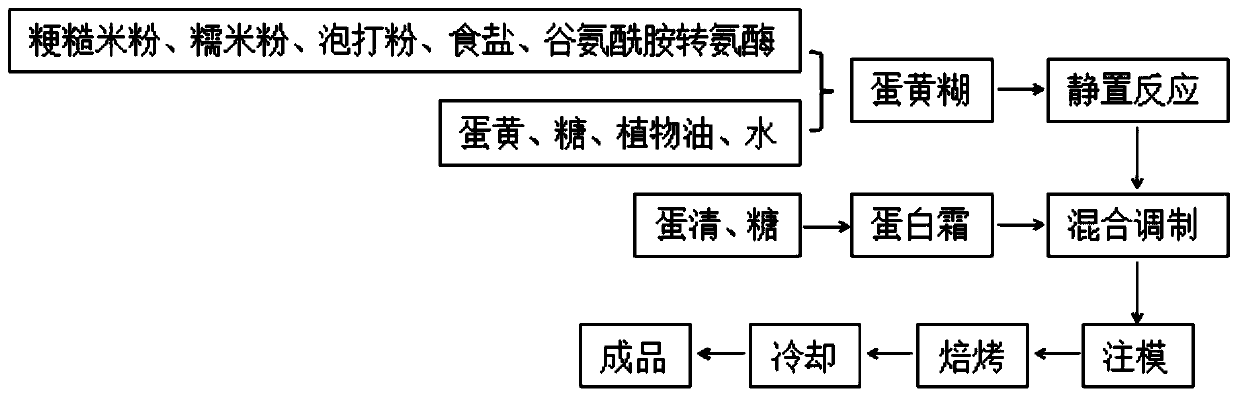

Gluten-free brown rice cake and production method thereof

ActiveCN110896979AHigh nutritional valueGood lookingPre-baking dough treatmentModified nutritive productsBiotechnologyVegetable oil

The invention discloses a gluten-free brown rice cake and a production method thereof. The brown rice cake is produced by adopting a formula comprising: a yolk paste including 80-90 g of brown rice powder, 10-20 g of glutinous rice flour, 1-3 g of baking powder, 0.5-2 g of table salt, 0.8-2.4 g of glutamine transaminase, 50-65 g of yolk, 15-25 g of sugar, 10-30 g of vegetable oil and 70-90 g of water; and meringue including 150-185 g of egg white and 30-50 g of sugar. The problems of small bubbles and instability in the brown rice cake making process are solved, and the purposes of large specific volume, proper hardness and good elasticity of the brown rice cake are achieved without adding gluten proteins.

Owner:JIANGNAN UNIV

Production method of multi-element aluminum alloy standard sample

ActiveCN101294875BHigh yieldImprove distribution uniformityPreparing sample for investigationColor/spectral properties measurementsChemical elementMulti element

The invention relates to a method for preparing a standard multi-element aluminum alloy sample. The method comprises the steps of proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and is characterized in that the standard sample contains the following 20 chemical elements in pure aluminum: Si, Fe, Cu, Mg, Mn, Zn, Sn, Pb, Ni, Ti, Cr, Sr, Ca, V, Ga, Zr, Cd, Be, B and P. The standard sample is manufactured sequentially through proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and finally, standard samples are prepared according to the requirements for the standard samples. By adopting the preparation method, the multi-element aluminum alloy sample with uniform composition and good stability can be obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

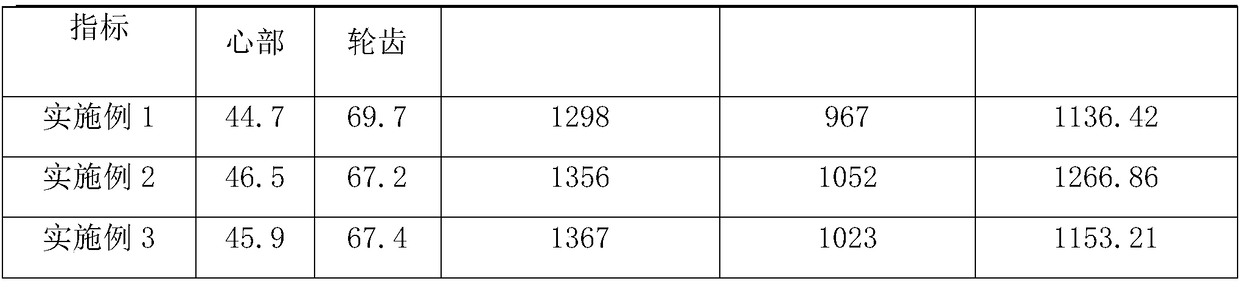

A high conductivity prebaked anode steel claw

The invention relates to an aluminum electrolysis prebaked anode steel claw and belongs to the technical field of electrolytic aluminum industry, and particularly provides a novel high-conductivity prebaked anode steel claw which is good in conductivity, low in cost, small in deformation and long in service life. The novel high-conductivity prebaked anode steel claw comprises a cross beam, a claw head and a welding line. The material of the cross beam or the claw head is low-carbon low-silicon non-oriented electrical steel or other high-conductivity steel, and the cross beam and a steel claw are connected by consumable electrode mixed gas arc welding. According to the invention, through optimal selection of the cross beam and the claw head and selection of a proper welding process, anode drop is remarkably reduced, the electrical conductivity and the flexural behavior of the steel claw are improved, and the life of the anode steel claw is effectively prolonged, and therefore, economic benefit is improved.

Owner:WUHAN UNIV

Production method of brocade-ball-shaped steamed bun foods stuffed with bean paste

The invention provides a production method of brocade-ball-shaped steamed bun foods stuffed with bean paste. The production method of the brocade-ball-shaped steamed bun foods stuffed with the bean paste comprises the following steps: preparing bean paste stuffing, preparing dough sheets, preparing raw brocade-ball-shaped steamed buns stuffed with the bean paste by adopting hand shaping, carrying out fermenting, carrying out steaming, and carrying out quick-freezing so as to prepare the quick-frozen brocade-ball-shaped steamed buns stuffed with the bean paste. The production method utilizes low-gluten flour as the raw material, and comprises the steps of preparing bean paste stuffing, preparing dough sheets, preparing raw brocade-ball-shaped steamed buns stuffed with the bean paste by adopting hand shaping, carrying out fermenting, carrying out steaming, and carrying out quick-freezing so as to prepare the quick-frozen brocade-ball-shaped steamed buns stuffed with the bean paste. The bean paste stuffing is prepared by the following steps: firstly, treating the raw materials used for preparing the bean paste stuffing, wherein the raw materials comprises oranges, red beans, fine bean mash, non-dairy cream, white sugar and oil; and the oranges are treated by the following steps: clearly washing the oranges, chopping the washed oranges until the chopped oranges are 0.8-1.2cm in sizes, and then, grinding the chopped oranges into orange paste. By changing and controlling the process and technical parameters adopted for preparing the brocade-ball-shaped steamed buns stuffed with the bean paste, the produced brocade-ball-shaped steamed buns stuffed with the bean paste are rich in product color, variety and nutrition, free of wrinkling or collapse, and free of bubbles on the product surfaces; moreover, the brocade-ball-shaped steamed buns stuffed with the bean paste are good in taste. The brocade-ball-shaped steamed buns stuffed with the bean paste and the production method thereof are great in economic and social benefits.

Owner:JIANGXI YIJIA FOOD

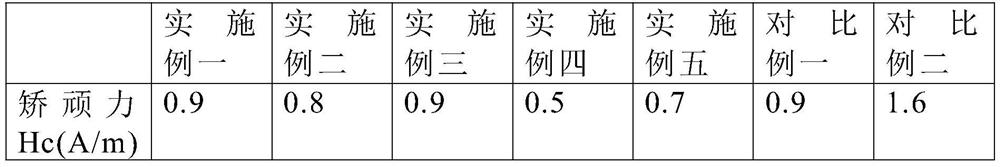

Heat treatment method of low-coercivity miniature soft magnetic ring

ActiveCN112695186ALow coercivityReduce heat upFurnace typesInductances/transformers/magnets manufactureShielding gasEngineering

The invention belongs to the technical field of material processing, and relates to a heat treatment method of a low-coercivity miniature soft magnetic ring. Segmented heating is carried out in an annealing furnace which contains a soft magnetic ring and is filled with protective gas. The segmented heating comprises the following steps: 1, raising the temperature to 330-390 DEG C in the first segment, and keeping the temperature for the time of t1; 2, raising the temperature to 480-520 DEG C in the second segment, and keeping the temperature for the time of t2; and 3, raising the temperature to 530-545 DEG C in the third segment, and keeping the temperature for the time of t3. According to the method, the design of the annealing process is carried out on the miniature magnetic ring with the outer diameter smaller than 10 mm, the heating and heat preservation time is effectively shortened, the production efficiency is greatly improved, the magnetic ring has low coercivity, and the production cost is reduced while the product quality is guaranteed.

Owner:浙江晶芯磁业有限公司

Aluminum profile for high-cold EMUs and preparation method thereof

ActiveCN104046852BMeet the standard requirements for low temperature fatigueHigh strengthImpurityMetal

The invention discloses an aluminum profile for a motor train unit running in high and cold regions. The aluminum profile comprises the following metal substances in percentage by weight: 0.4-0.7% of Si, less than or equal to 0.20% of Fe, 0.5-0.75% of Mg, 0.01-0.2% of Mn, less than or equal to 0.05% of Cu, less than or equal to 0.1% of Cr, less than or equal to 0.08% of Zn, 0.02-0.04% of Ti, less than or equal to 0.05% of single impurities, less than or equal to 0.15% of total impurities and the balance of Al. The invention further discloses a preparation method of the aluminum profile for the motor train unit running in high and cold regions. The aluminum profile for the motor train unit running in high and cold regions provided by the invention satisfies the standard requirements of low-temperature fatigue of the motor train unit running in high and cold regions. The application temperature of the common motor train unit ranges from 25 DEG C below zero to 40 DEG C. The aluminum profile disclosed by the invention is not broken in low-temperature fatigue test which is carried out for 107 cycles at 40 DEG C below zero.

Owner:龙口市丛林铝材有限公司

Panicum miliaceum L. bread and preparation method thereof

The invention relates to panicum miliaceum L. bread which comprises the following constituents in parts by weight: 15-50 parts of panicum miliaceum L. powder, 50-85 parts of wheatmeal, 1-3 parts of dried yeast, 7-10 parts of a sweetening agent, 0.5-1.5 parts of table salt, 5-7 parts of oil and 50-55 parts of water. Panicum miliaceum L. is added in the raw material of the panicum miliaceum L. bread, the formula is simple, the prepared bread is soft and tasty, fine and smooth in internal texture and uniform in pore, has light panicum miliaceum L flavor and retains the nutritional ingredient andhealth efficacy of panicum miliaceum L..

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com