Heat treatment method of low-coercivity miniature soft magnetic ring

A heat treatment method and low coercivity technology, applied in the field of material processing, can solve the problems of long annealing time, long process time and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

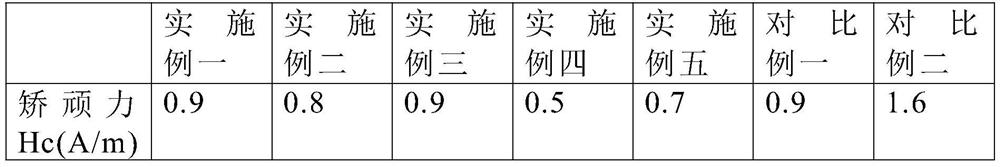

Examples

Embodiment 1

[0032] A heat treatment method for a miniature soft magnetic magnetic ring with low coercive force, using an amorphous alloy magnetic ring with a composition of Fe63Co21Si2B14, placing the magnetic ring in a vacuum annealing furnace filled with argon, and the vacuum degree is 4×10 -3 Pa, carry out segmental heating up, and segmental heating up comprises the following steps:

[0033] 1) The first heating step

[0034] From room temperature, the temperature was raised to 330°C in the first stage of 20 minutes, and kept for 15 minutes.

[0035] 2) The second heating step

[0036] From 330°C to 480°C in the second period of 30 minutes, and keep the temperature for 20 minutes.

[0037] 3) The third heating step

[0038] From 480°C to 530°C in the third stage, which takes 15 minutes, and is kept for 20 minutes.

[0039] 4) cooling step

[0040] The magnetic ring is cooled from 530°C to 270°C with the furnace through air cooling for 100 minutes, the cooling time is 30 minutes, a...

Embodiment 2

[0042] A heat treatment method for a miniature soft magnetic magnetic ring with low coercive force, using an amorphous alloy magnetic ring with a composition of Fe63Co21Si2B14, placing the magnetic ring in a vacuum annealing furnace filled with argon, and the vacuum degree is 4×10 -3 Pa, carry out segmental heating up, and segmental heating up comprises the following steps:

[0043] 1) The first heating step

[0044] From room temperature to 380°C in the first period of 30 minutes, and keep warm for 20 minutes.

[0045] 2) The second heating step

[0046] From 380°C to 500°C in the second stage with a duration of 40 minutes, and keep the temperature for 10 minutes.

[0047] 3) The third heating step

[0048] From 500°C to 545°C in the third stage of 20 minutes, and keep it warm for 40 minutes.

[0049] 4) cooling step

[0050] The magnetic ring is cooled from 545°C to 280°C with the furnace through air cooling for 120 minutes, the cooling time is 40 minutes, and then natu...

Embodiment 3

[0052] A heat treatment method for a miniature soft magnetic magnetic ring with low coercive force, using an amorphous alloy magnetic ring with a composition of Fe63Co21Si2B14, placing the magnetic ring in a vacuum annealing furnace filled with argon, and the vacuum degree is 4×10 -3 Pa, carry out segmental heating up, and segmental heating up comprises the following steps:

[0053] 1) The first heating step

[0054] From room temperature, the temperature was raised to 340°C in the first period of 40 minutes, and kept for 25 minutes.

[0055] 2) The second heating step

[0056] From 340°C to 510°C in the second period of 50 minutes, and keep the temperature for 5 minutes.

[0057] 3) The third heating step

[0058] From 510°C to 540°C in the third stage of 25min, and keep it warm for 50min.

[0059] 4) cooling step

[0060]The magnetic ring is cooled from 540°C to 280°C with the furnace through air cooling for 110 minutes, the cooling time is 35 minutes, and then naturall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com