A high conductivity prebaked anode steel claw

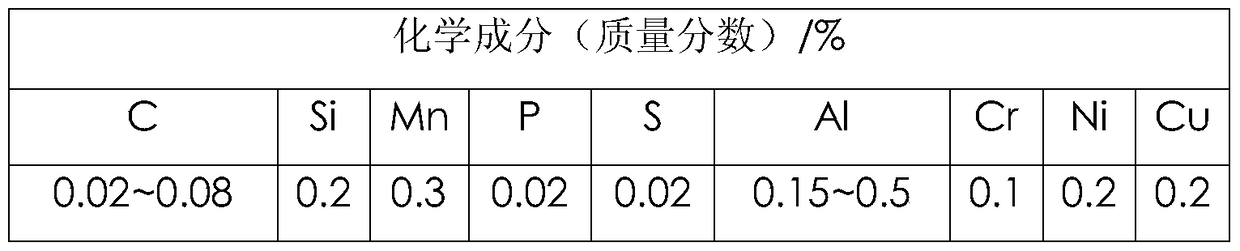

A prebaked anode and high conductivity technology, which is applied in the field of aluminum electrolytic prebaked anode steel claws, can solve the problems of reducing the anode voltage drop steel claw corrosion resistance, welding deformation can not be effectively controlled, and the electrical conductivity of steel claws cannot be improved. , to achieve good mechanical properties, low content of alloying elements, and improve welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

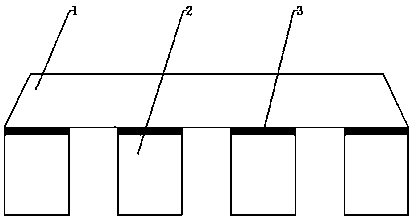

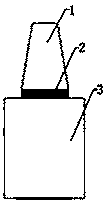

[0024] A kind of high-conductivity anode steel claw, its manufacturing plan is: (1) adopt the cold-rolled non-oriented electrical steel such as DT4 or DT4A or DT4E or DT4C processed and formed as the material of beam 1 and claw head 2, wherein claw head 2 is long 220mm, a cylinder with a diameter of 170-190mm; (2) using a molten electrode mixture gas (80% Ar+20% CO 2 ) Protected welding: Weld the claw head 2 equidistantly on the beam 1; (3) Adopt a narrow gap I-type groove, the groove width is about 12-16mm, single-layer single-pass, multi-layer surfacing arc welding technology.

Embodiment 2

[0026] A kind of high-conductivity anode steel claw, and its manufacture scheme is: (1) adopt the YT01 charge pure iron of processing molding as crossbeam 1 and claw head 2 materials, wherein claw head 2 is long 220mm, the cylinder of diameter 170-190mm; (2) Using molten electrode mixture gas (80% Ar+20% CO 2 ) Protected welding: Weld the claw heads 2 equidistantly on the beam 1; (3) Adopt a narrow gap I-shaped groove with a groove width of 12-16mm, single-layer single-pass, multi-layer surfacing arc welding technology.

[0027] The following is a comparative test of the pressure drop test using the anode steel claw of Example 1 of the present invention and the traditional cast steel claw. Since the current passing through each group of anodes may be different, the actual voltage drop needs to be weighted and corrected according to the passing anode current data to ensure that the voltage drop data is comparable. We selected two groups of electrolyzers for the test, punched h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com