Submersible sand-proof permanent magnet synchronous energy-saving motor

A permanent magnet synchronous motor technology, applied in the field of motors, can solve the problems of inability to separate sediment and waste resources, etc., and achieve obvious power saving effect, good sand control effect, and adjustable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

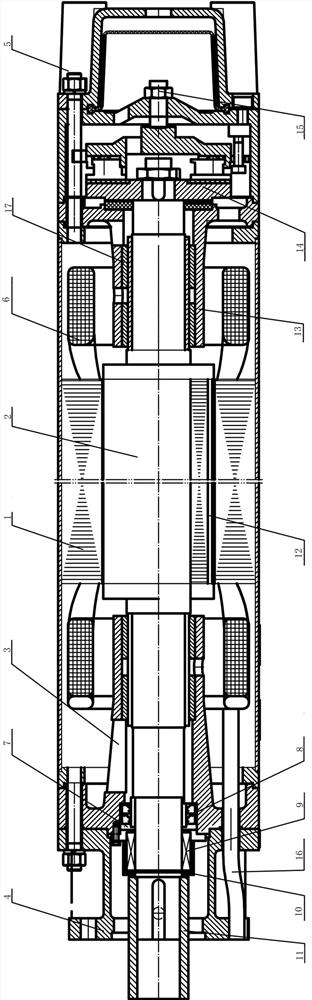

[0017] Such as figure 1 As shown, the submersible sand-proof permanent magnet synchronous energy-saving motor of this embodiment includes a permanent magnet rotor 2, a stator 1 is arranged on the circumference of the permanent magnet rotor 2, and a rotor permanent magnet guide bar 12 is arranged between the rotor 2 and the stator 1, and the permanent magnet The top of the magnetic rotor 2 is connected with a bearing, and the bottom is connected with a thrust sliding bearing 17. The bearing is located on the upper guide bearing seat 3, and the thrust sliding bearing 17 is located on the lower guide bearing seat 13. The upper guide bearing seat 3 and the lower guide bearing seat 13 Waterproof coils are provided on the outer sides of the outer parts respectively, the waterproof coils are connected with the stator 1, the top of the waterproof coils is connected with a lead wire 16, the top of the upper guide bearing seat 3 is provided with a coupling seat 4, and a coupling 11 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com