Casting Method of Ductile Iron Steering Knuckle

A technology of nodular cast iron and steering knuckles, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. It can solve the problems of low production efficiency casting waste rate, and achieve the effects of reducing production costs, not being easy to cool quickly, and increasing pouring speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] First of all, what needs to be explained and explained is that the casting process of the so-called rapid vertical pouring of the nodular cast iron steering knuckle includes the pouring system and the mold should be in the corresponding production line, and the pouring time can be improved by controlling the cross-sectional size of each part of the pouring system to meet the requirements. Fast production tempo (the highest production tempo is 400 boxes per hour), and at the same time eliminate casting defects such as cold shut and insufficient pouring that may occur in rapid pouring. In this way, the whole process is controlled as a fast vertical pouring casting process.

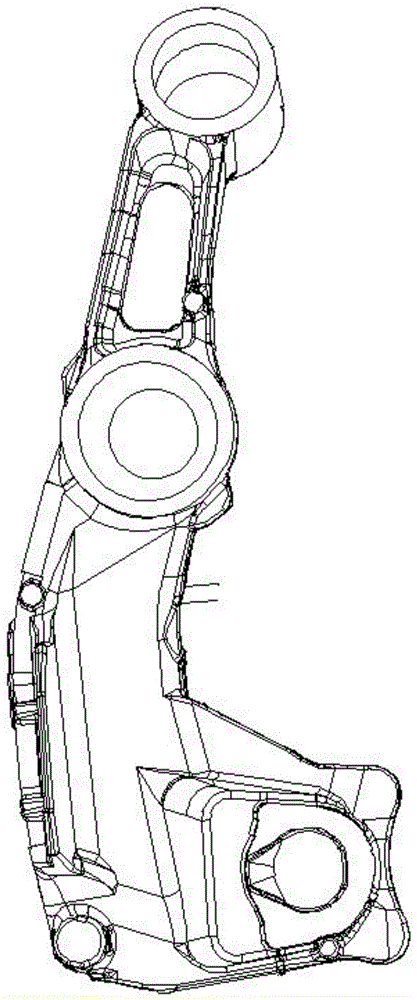

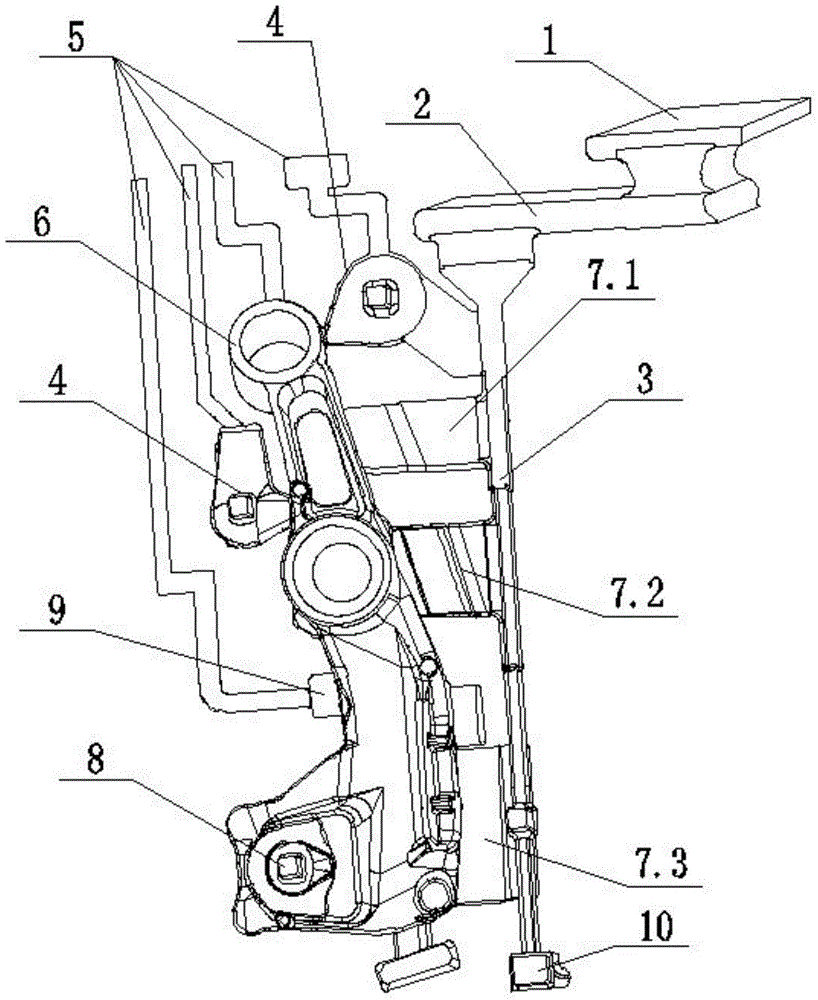

[0020] Combine below Figure 1-2 The present invention is described in detail, and its main technical measures include the following:

[0021] (1) Mold production: According to figure 1 The structure of the steering knuckle casting is shown, and molds are made by conventional mold making processes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com