Patents

Literature

50results about How to "Not easy to cool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

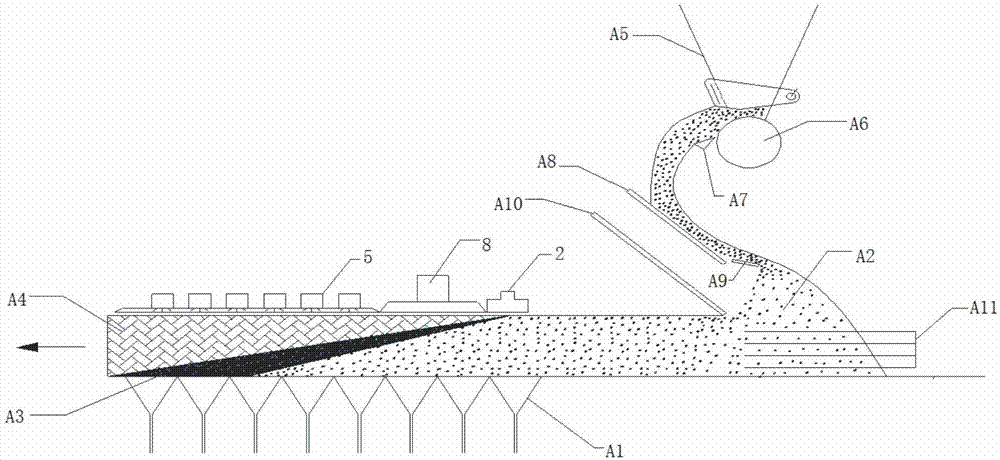

Soaking sintering process based on combustible gas blowing

The invention discloses a soaking sintering process based on combustible gas blowing. The soaking sintering process comprises the following steps: (1) batching; (2) charging; (3) igniting; (4) sintering; (5) performing heat preservation and heat supplementation: when agglomerate is formed on the surface layer of a sintering mix materiel after ignition, blowing a sintering flue gas or ring cooling machine hot gas to the surface of the sintering mix materiel by arranging a heat preservation and heat supplementation device on the sintering mix materiel; (6) performing soaking sintering based on combustible gas blowing: blowing a combustible gas to the part above the surface layer of the sintering mix materiel to enable the combustible gas to be combusted in the combustion layer of the sintering bed; and (7) completing sintering, and discharging. The invention provides a gas feeding method and device for uniform sintering, and aims to solve the problems of reducing the solid fuel consumption on the premise of improving the sintered ore quality and further reducing the carbon dioxide emission of the blast furnace.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

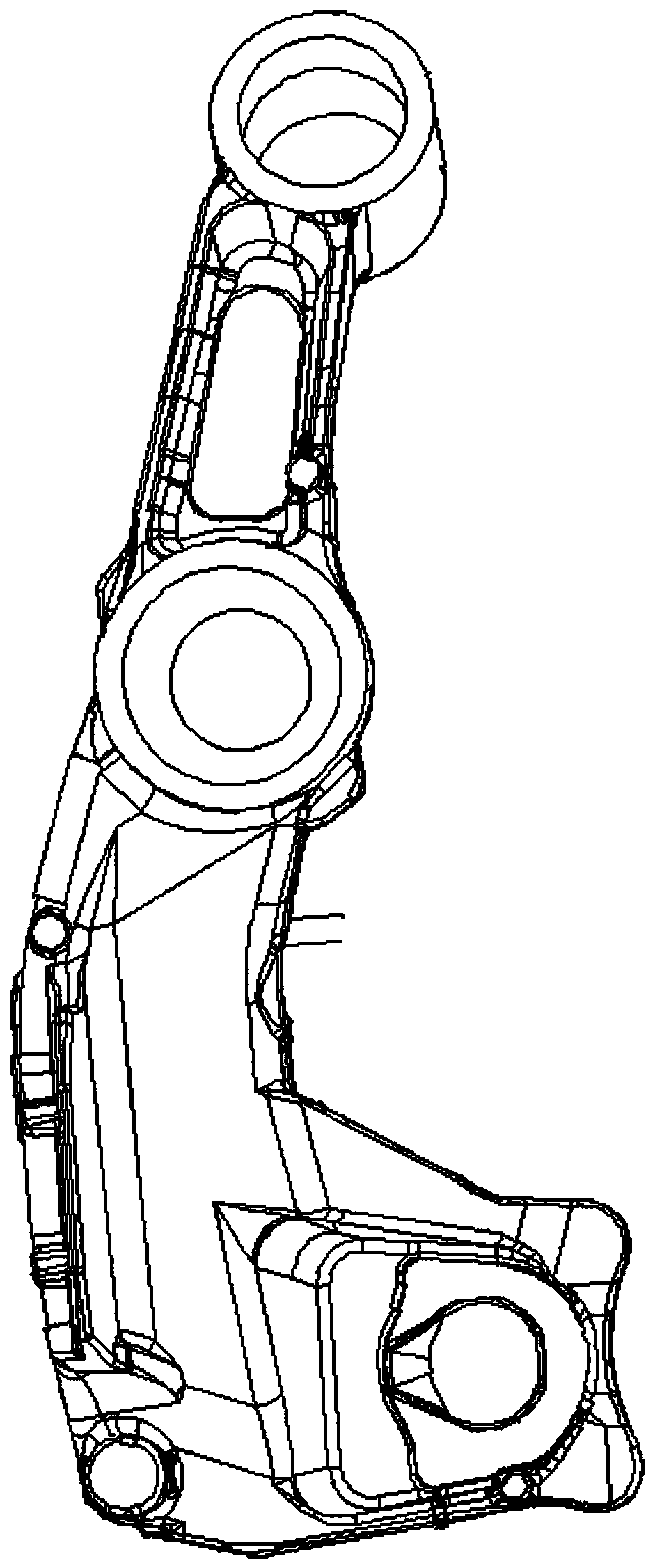

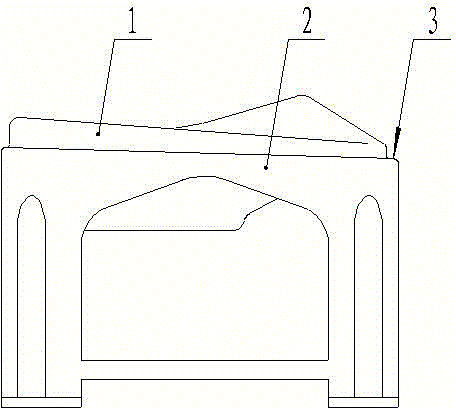

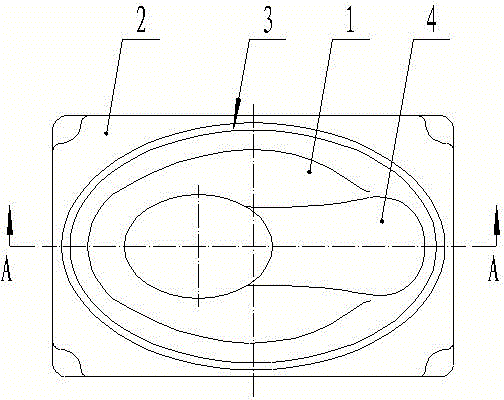

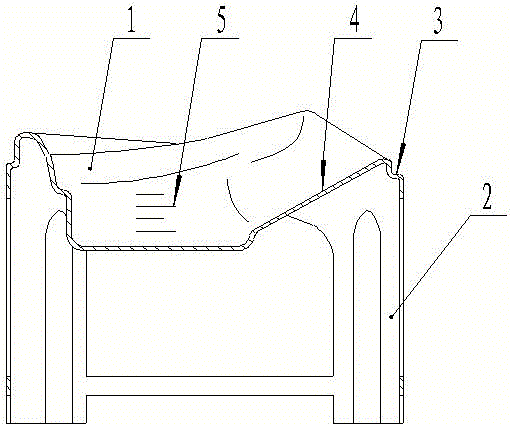

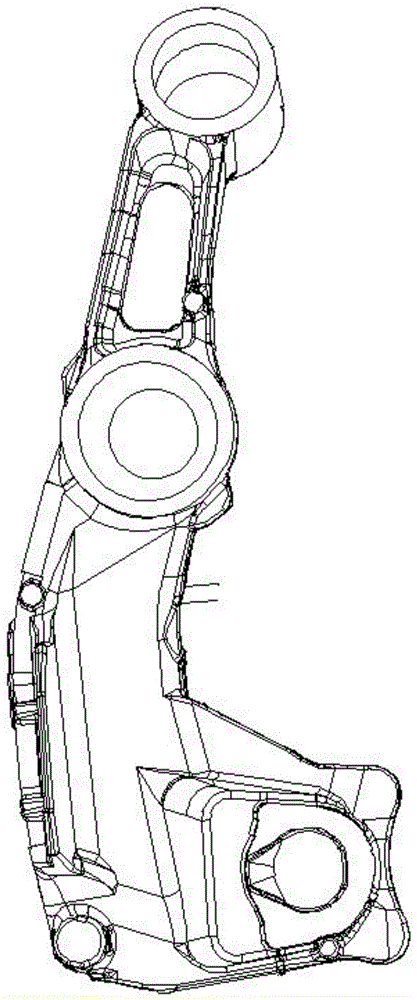

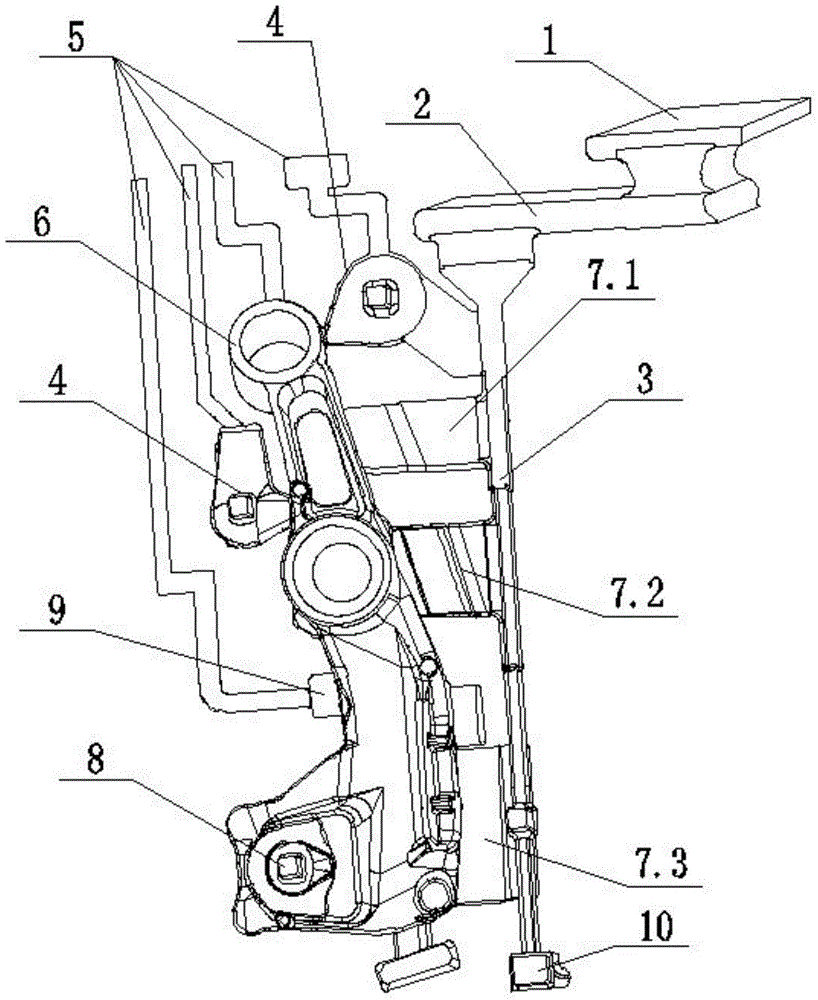

Casting method of steering knuckle of nodular cast iron

ActiveCN103846392AShort stayImprove cooling effectFoundry mouldsFoundry coresDuctile ironRejection rate

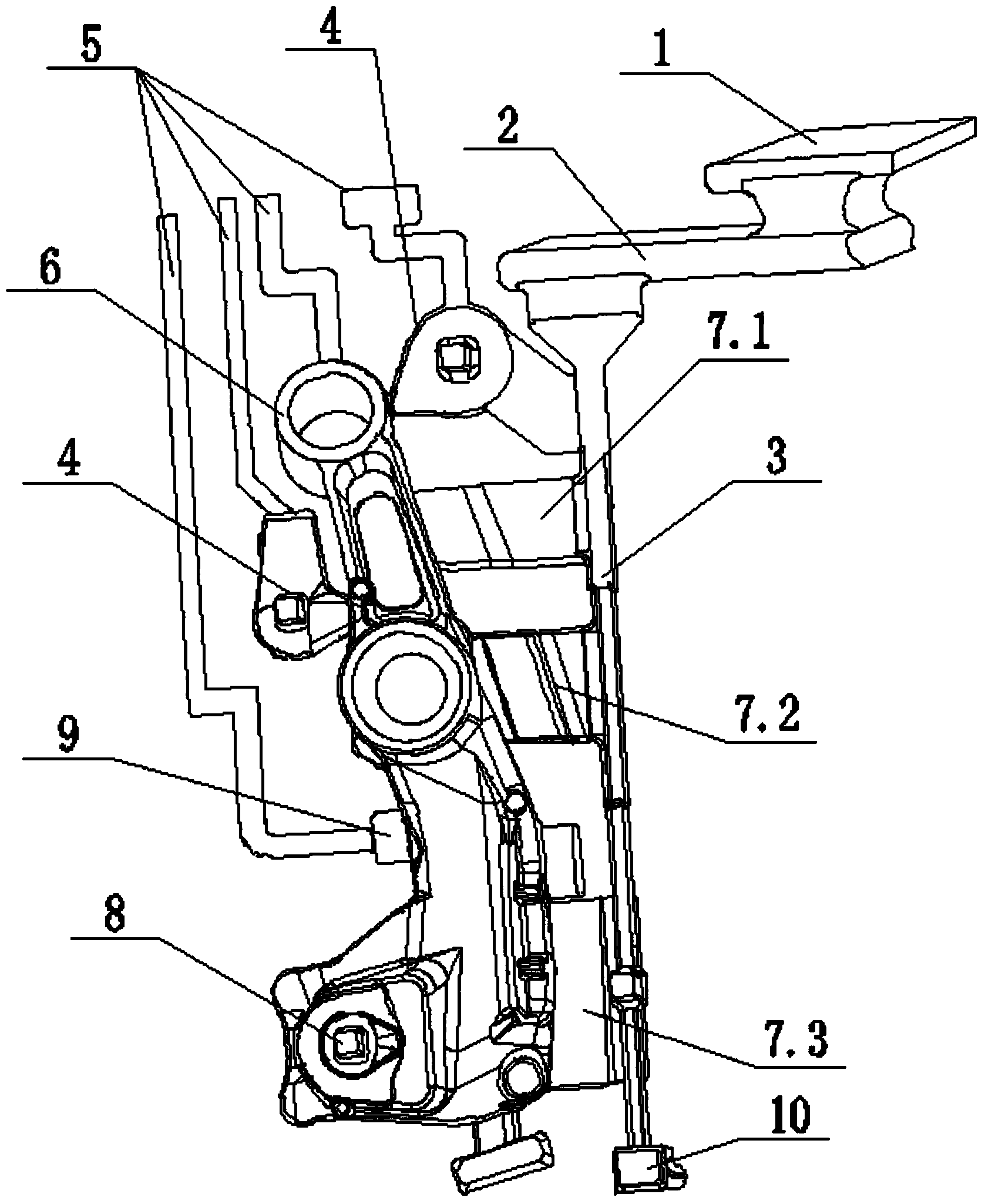

The invention discloses a casting method of a steering knuckle of nodular cast iron. The casting method comprises a mold manufacturing step, a sand mold manufacturing step and a pouring molding step, wherein the steering knuckle is vertically arranged, a thick part of a steering knuckle casting is arranged at the upper part, a thin-walled part of the steering knuckle casting is arranged at the lower part; a pouring system of the steering knuckle casting is divided into a pouring cup, a cross pouring gate and a straight pouring gate, the cross pouring gate is connected to the lower part of the pouring cup, the straight pouring gate is connected to the lower part of the cross pouring gate, and a scum riser is arranged at the bottom end of the straight pouring gate; the side wall of the straight pouring gate is connected with a first inner pouring gate, a second inner pouring gate and a third inner pouring gate from top to bottom; the steering knuckle casting is further provided with a hot riser, a cold riser and exhausting pieces; the sectional area ratio of each component of the casting is that F(straight pouring gate):F(cross pouring gate):F(inner pouring gates) is equal to 1:(1.2-1.4):(1.35-1.5); the casting is obtained by controlling the pouring temperature at 1370-1410 DEG C and carrying out pouring for 5-10 seconds. The casting method has the advantages that pouring speed is high, the defects such as shrinkage porosity, shrinkage cavity and the like cannot easily occur, and the casting is high in production efficiency, low in rejection rate and excellent in mechanical property.

Owner:宁波强盛机械模具有限公司

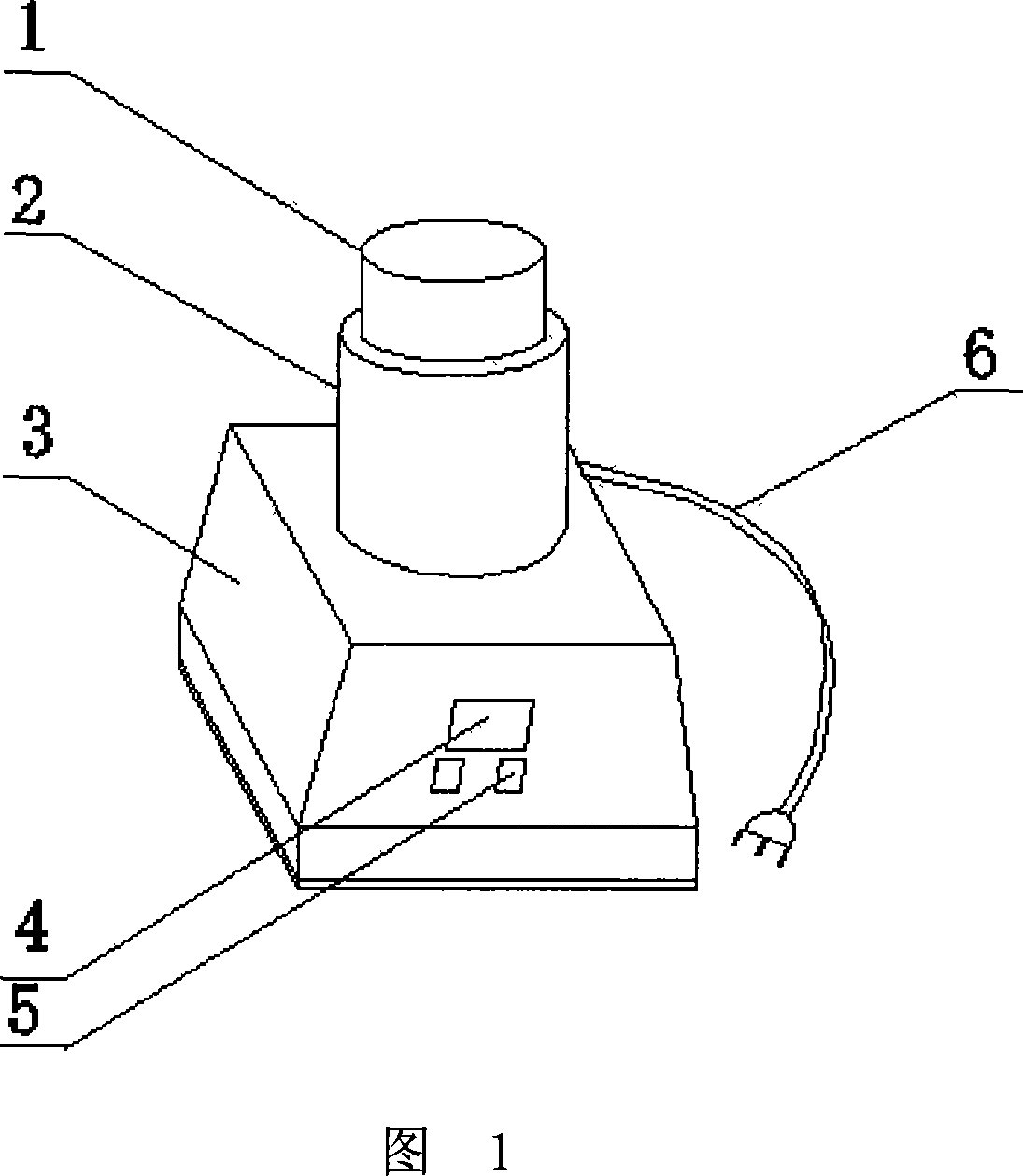

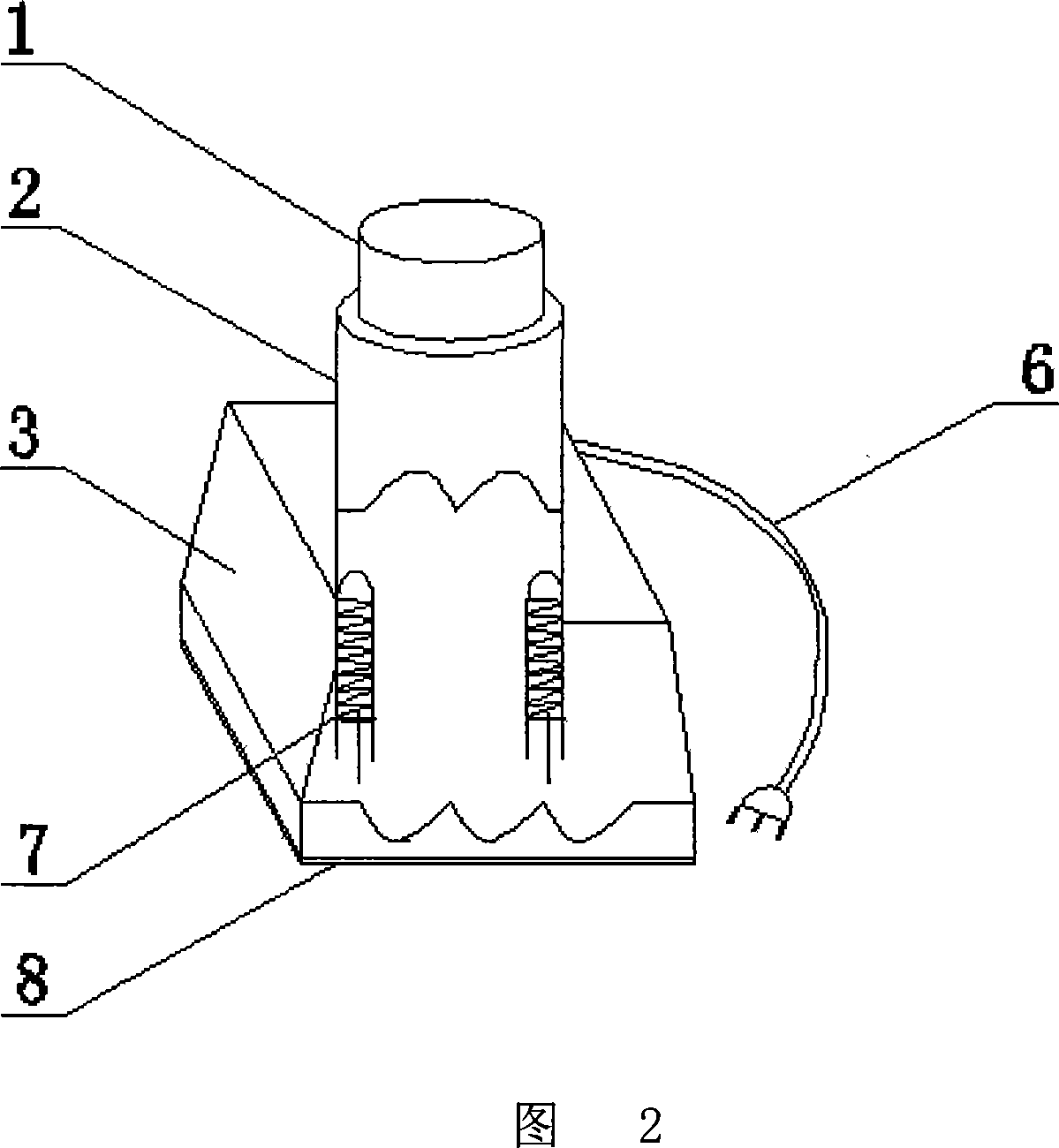

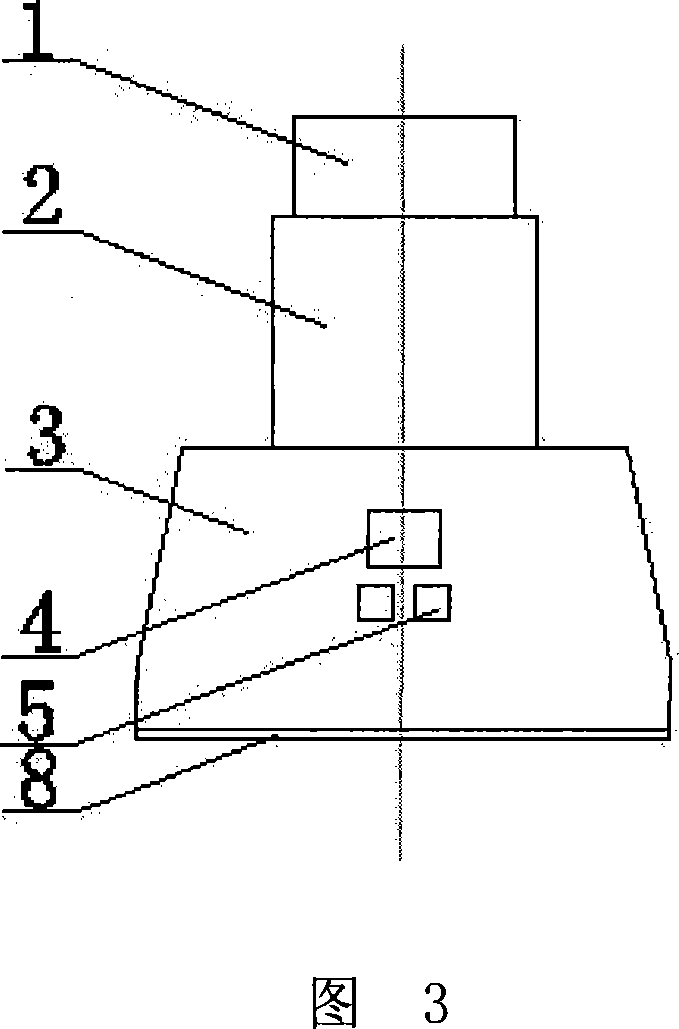

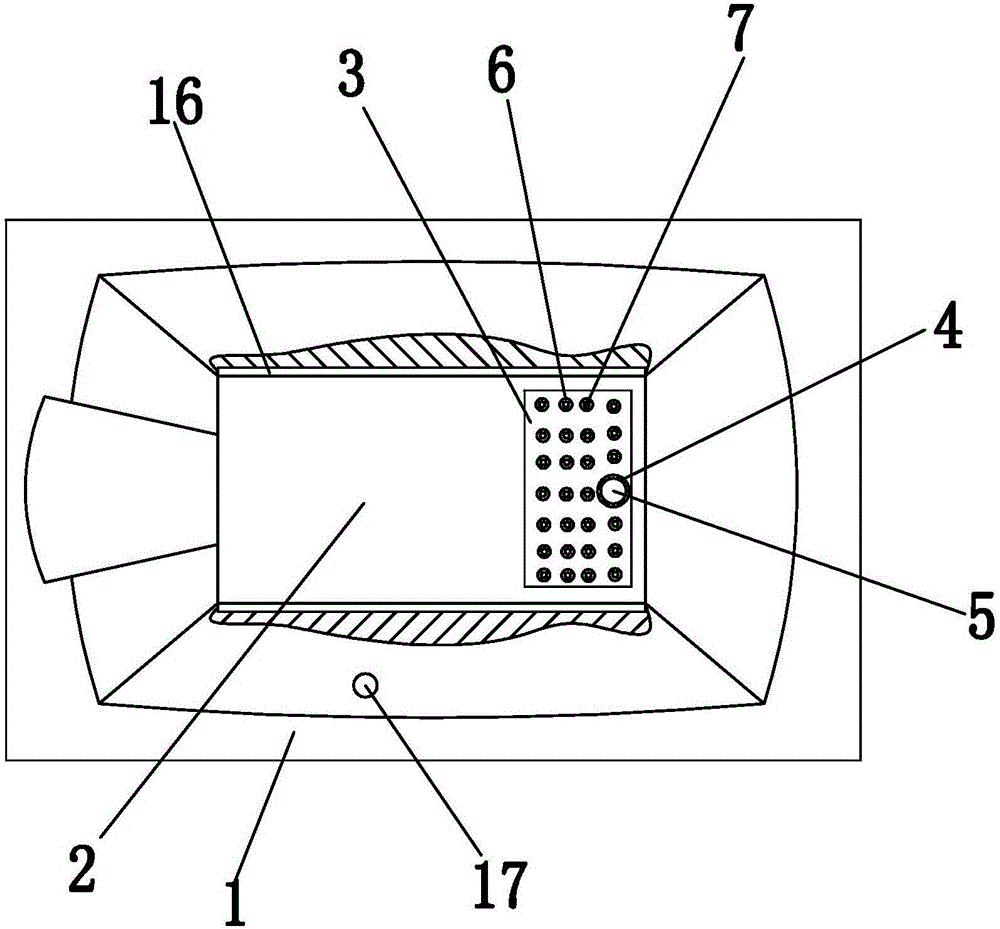

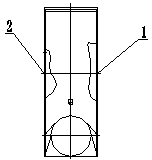

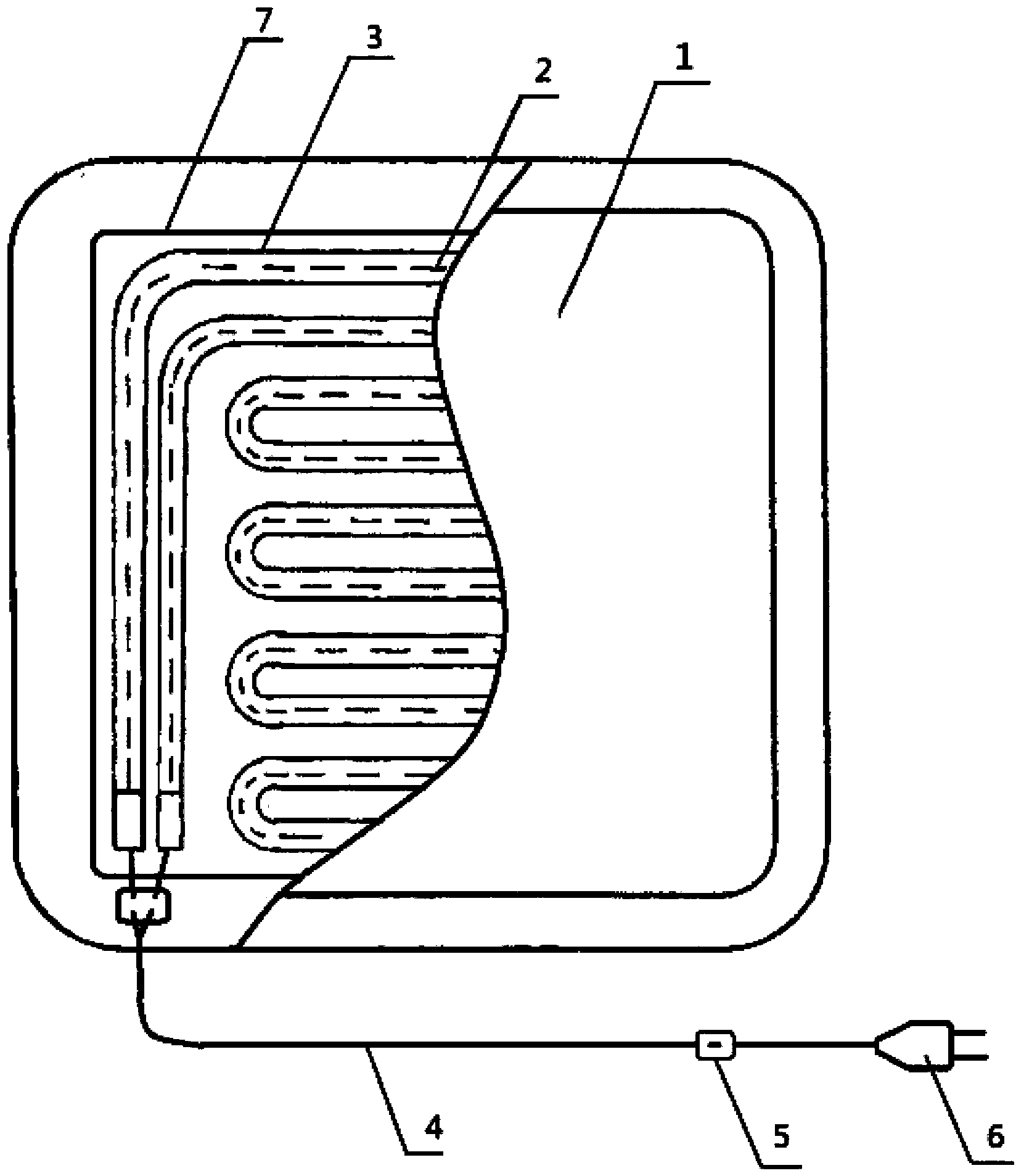

Ultrasound couplant constant temperature heating device and its testing method

InactiveCN101077304ADifficult to controlNot easy to coolUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsElectric heatingEngineering

The present invention discloses one kind of constant temperature ultrasonic couplant heating device and its measuring method. The ultrasonic couplant heating device is one double barrel structure, which has an inner barrel of heat conducting material, an outer barrel of heat insulating material, couplant set inside the inner barrel, an electric heating element around the inner barrel, temperature inducing and regulating unit in the middle part of the inner barrel. It heats by means of the heat conduction of the inner barrel and the couplant homogeneously without local overheat. The present invention is superior in that different constant temperatures may be set with functional switch, different duty ratios may be regulated to reach the aim of constant temperature heating, and the electric heating element may be set in the inner wall of the inner barrel.

Owner:FUZHOU GENERAL HOSPITAL OF NANJING MILITARY COMMAND P L A

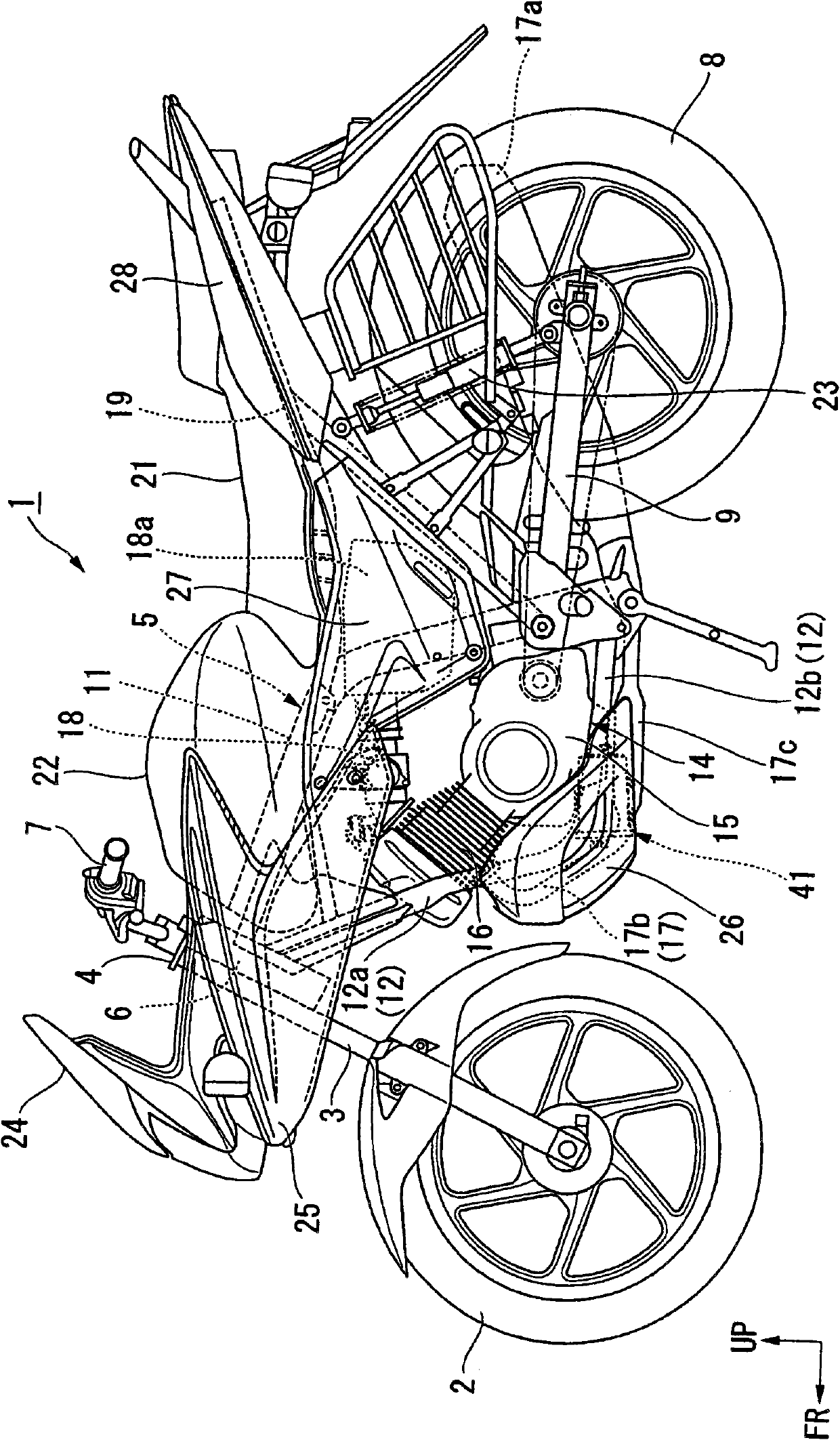

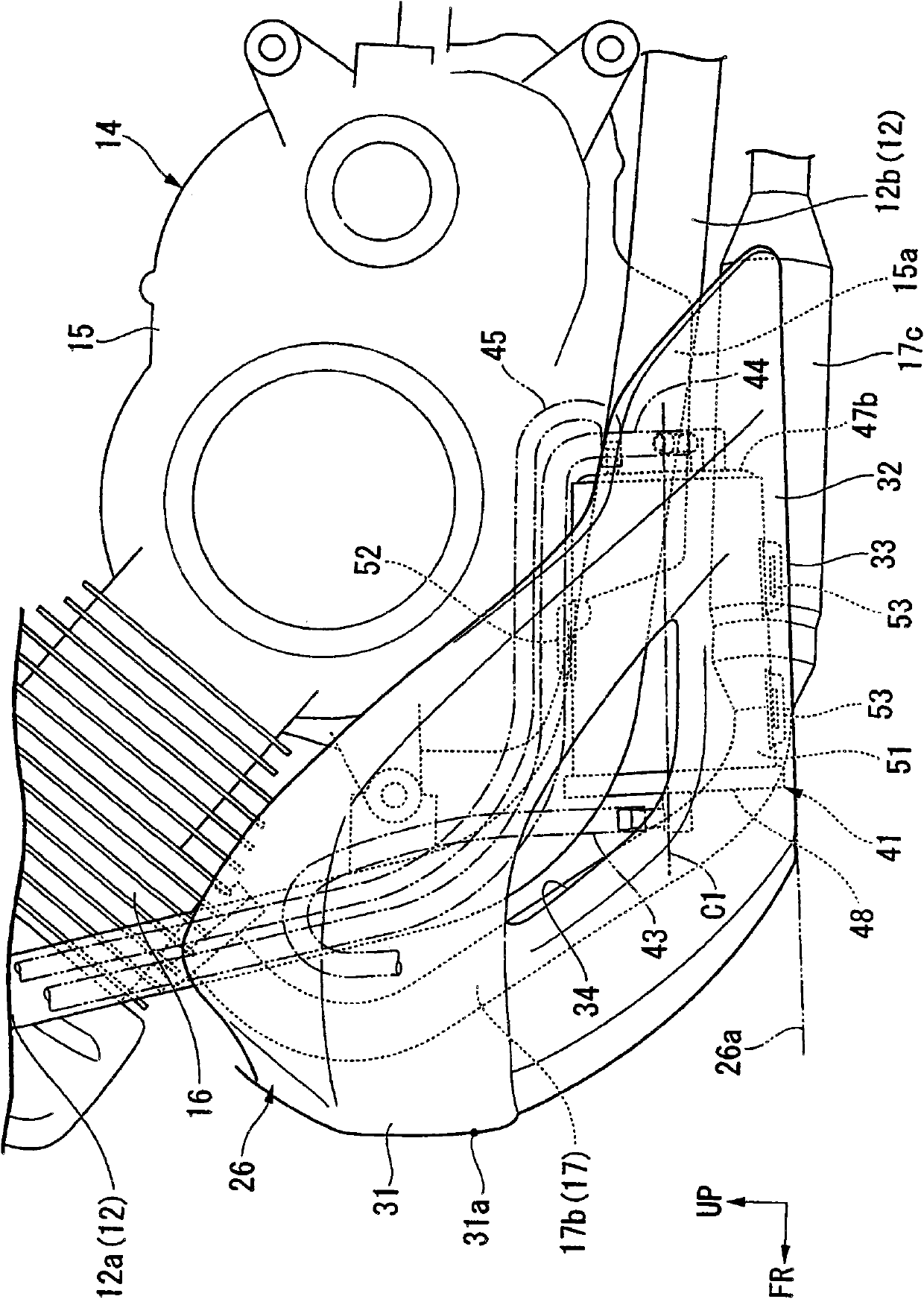

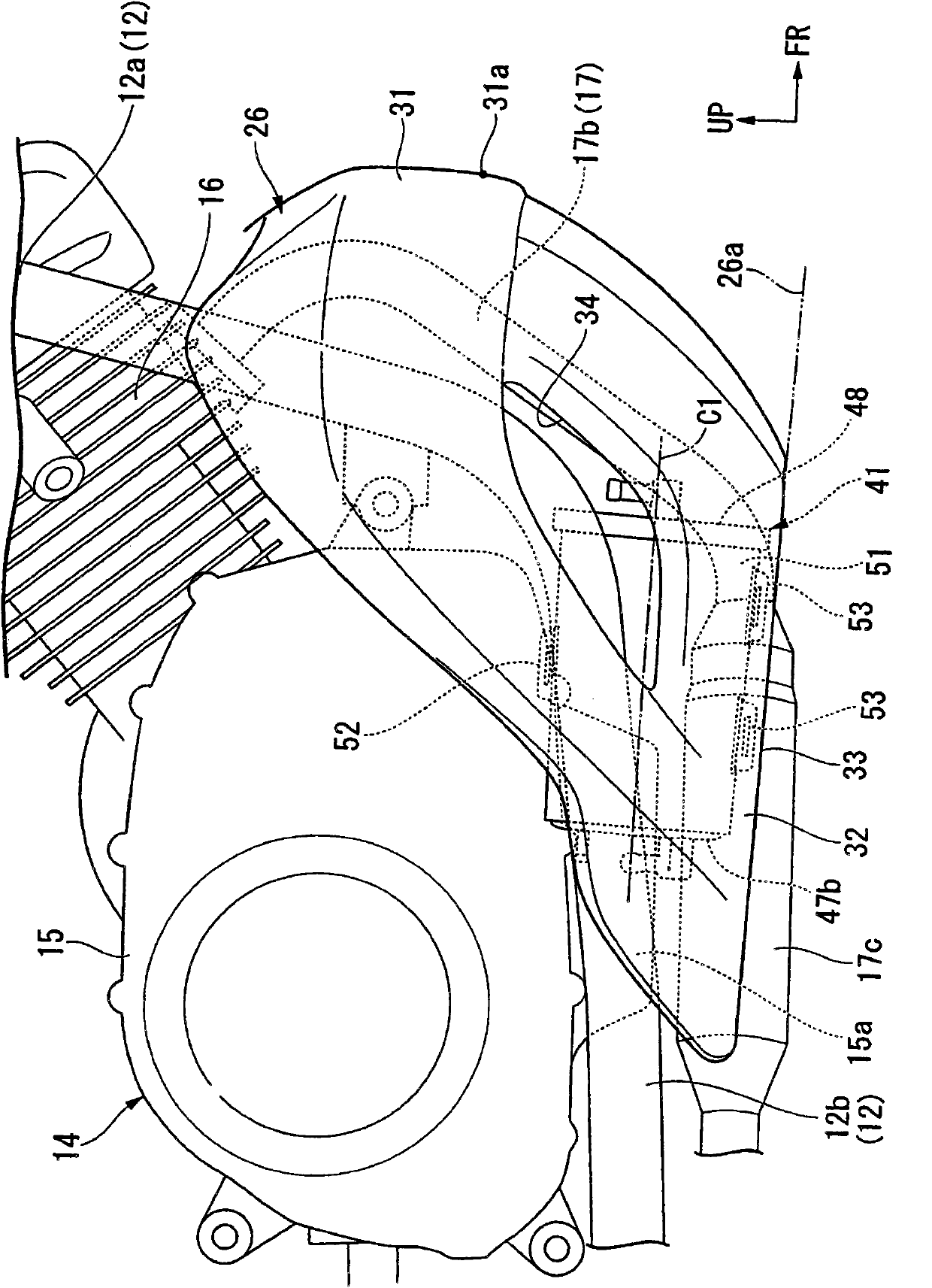

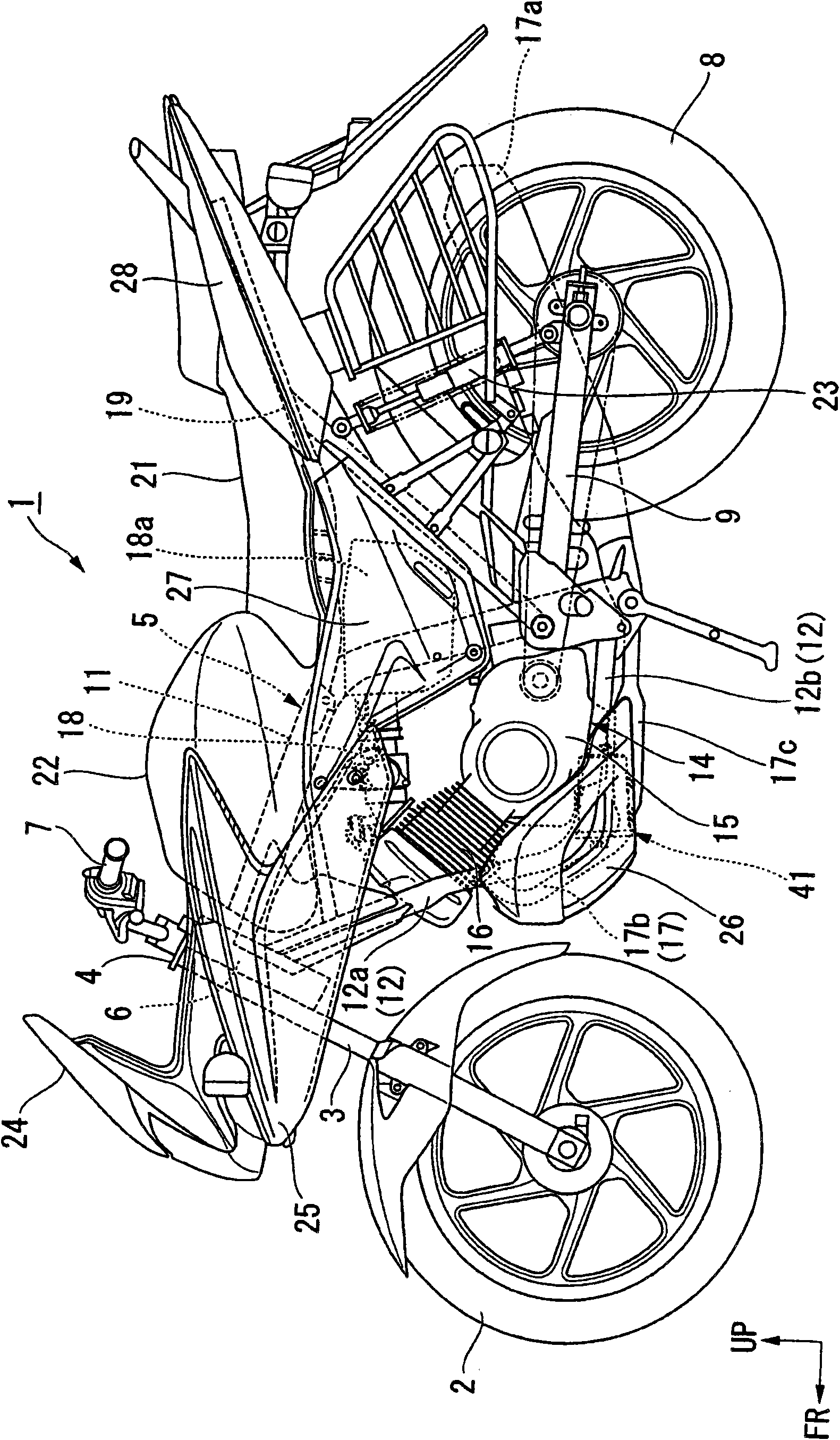

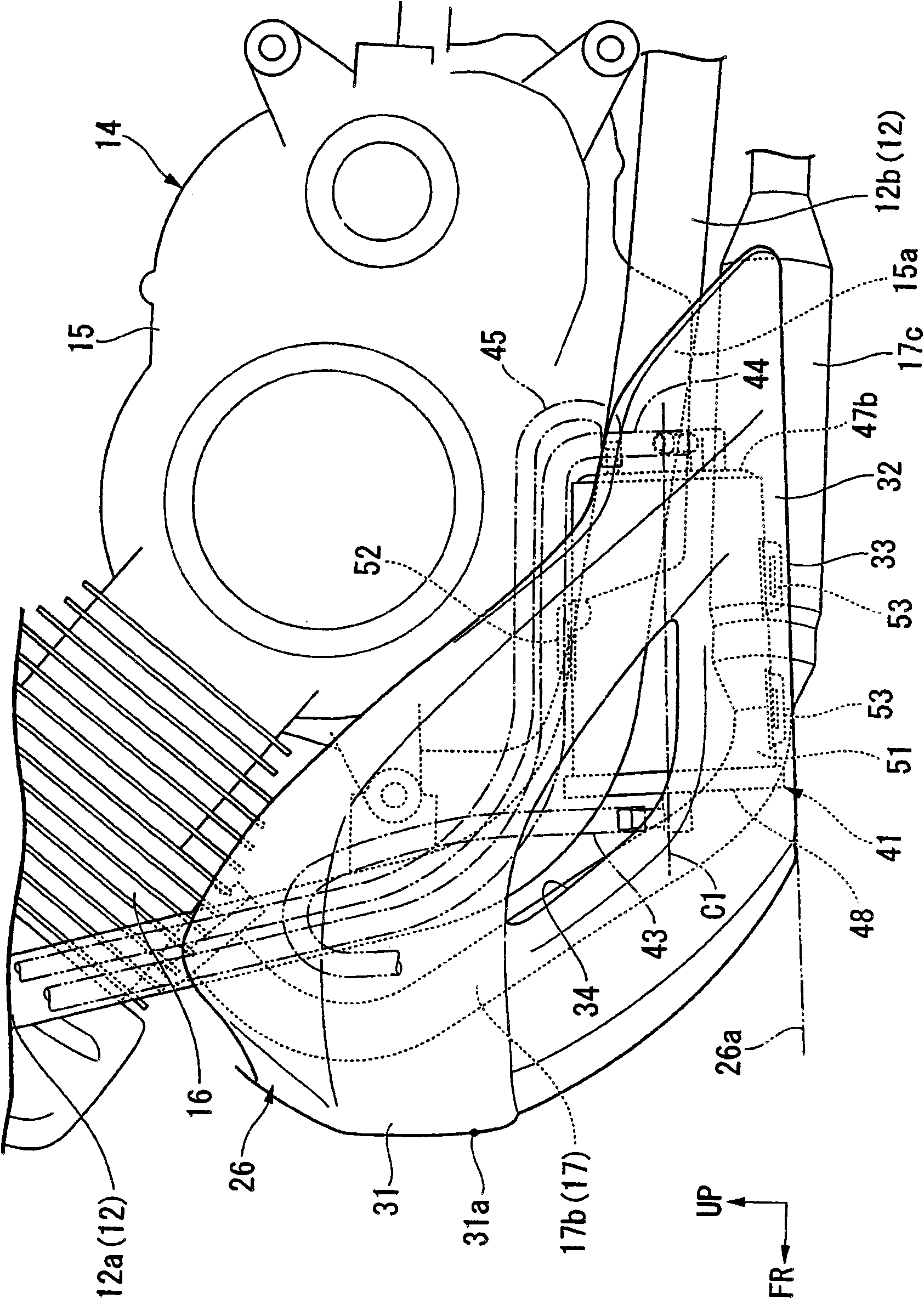

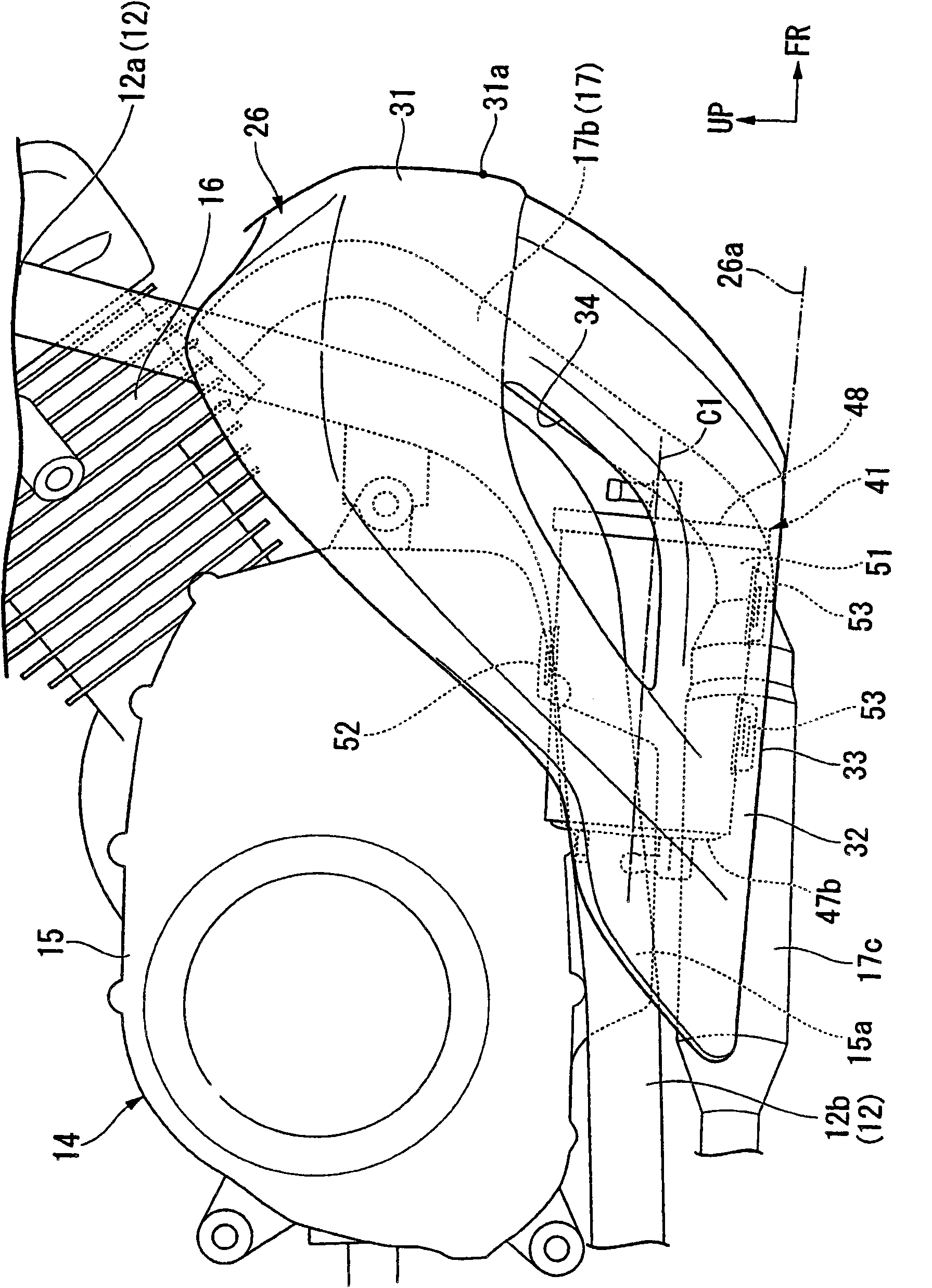

Arrangement structure of evaporated fuel treatment device of saddle-ride-type vehicle

ActiveCN102030059AImprove cooling effectCompact configurationNon-fuel substance addition to fuelMachines/enginesFuel treatmentEngineering

To enable mounting of a canister on a vehicle body in a compact manner while favorably ensuring the charge performance and the purge performance of the canister in the arrangement structure of an evaporated fuel treatment device of a saddle-ride-type vehicle. An under cowl (26) is provided at a front side of a lower portion of an engine (14), and a canister (41) is arranged below the engine (14) and inside the under cowl (26).

Owner:HONDA MOTOR CO LTD

Production method of rice flour

ActiveCN103478538AImprove cooling effectRapid coolingFood thermal treatmentMulti-step food processesSteam pressureToughness

The invention discloses a production method of rice flour. The production method comprises the steps of soaking and fermenting rice, grinding into thick liquid, piece steaming, extruding and forming, flour steaming, and cooling, in the grinding process, the particle size of the thick liquid is controlled to be 80-100 meshes, the water of the thick liquid accounts for 50-55% of the thick liquid in weight; in the piece steaming process, the steam pressure is controlled to be 0.1-0.18MPa, the piece steaming time is 50-80s, and the piece thickness is 1-2mm; the flour steaming operation comprises the steps of performing strip boiling and flour steaming to the extrusion-formed rice flour, wherein the strip boiling temperature is 95-100 DEG C and the strip boiling time is 8-12s, the flour steaming pressure is controlled to be 0.04-06MPa, and the flour steaming time is 120-160s; the cooling process refers to washing cooling, the washing time is 8-15 DEG C, and the used water is well water or mountain spring water. The rice flour produced by the production method has the advantages of difficulty in breakage, good toughness and the like.

Owner:贵州中裕华农粮油有限公司

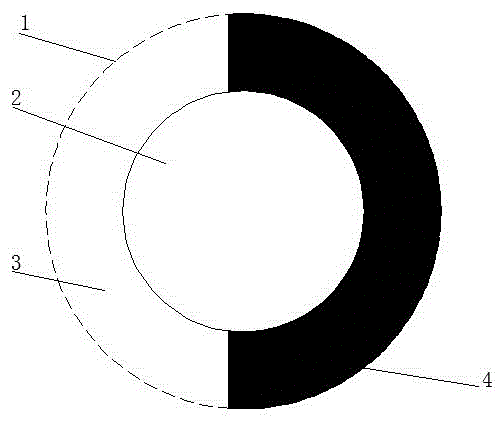

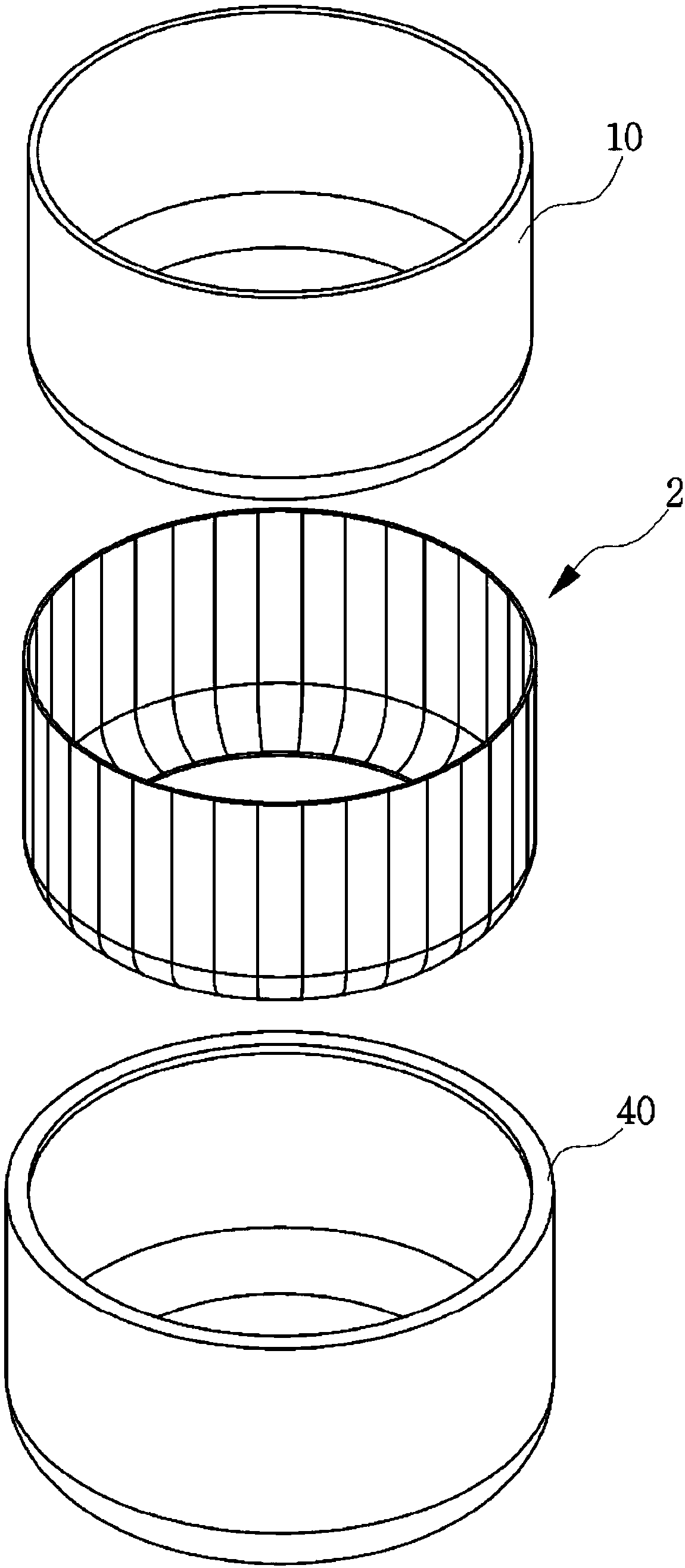

Novel heat-radiation and thermal-insulation integrated water cup

InactiveCN105029987ANot easy to coolHeat dissipation is slowDrinking vesselsContact formationThermal insulation

The invention discloses a novel heat-radiation and thermal-insulation integrated water cup and relates to a water cup; in order to overcome the difficulty that a heat-radiation cup having two layers and two rows of holes is incontrollable in heat-radiation degree, the invention designs a novel heat-radiation and thermal-insulation integrated water cup; the technical scheme is as follows: according to the novel heat-radiation and thermal-insulation integrated water cup, a cup body is divided into an inner layer and an outer layer, wherein foam is accommodated between the two layers of the cup body; the foam is divided in two parts, wherein one part of the foam is attached to the outer side of the inner layer of the cup body and the other part of the foam is stuck on the inner side of the outer layer of the cup body; on the part not stuck with the foam, the outer layer of the cup body is formed with heat-radiation holes; as the outer layer of the cup body is rotated, the two parts of foam can be partially or completely overlapped, so that some or all heat-radiation holes in the outer layer of the cup body are aligned with metals of the inner layer of the cup body; therefore, better heat radiation is guaranteed through air circulation between the two layers of metals; and when the outer layer of the cup body is rotated, the edges of the two parts of foam are mutually contacted in a vertical direction, so that a seal ring is formed. The integrated water cup disclosed by the invention has the beneficial effects that the integrated water cup can guarantee heat radiation and thermal insulation.

Owner:SICHUAN UNIV

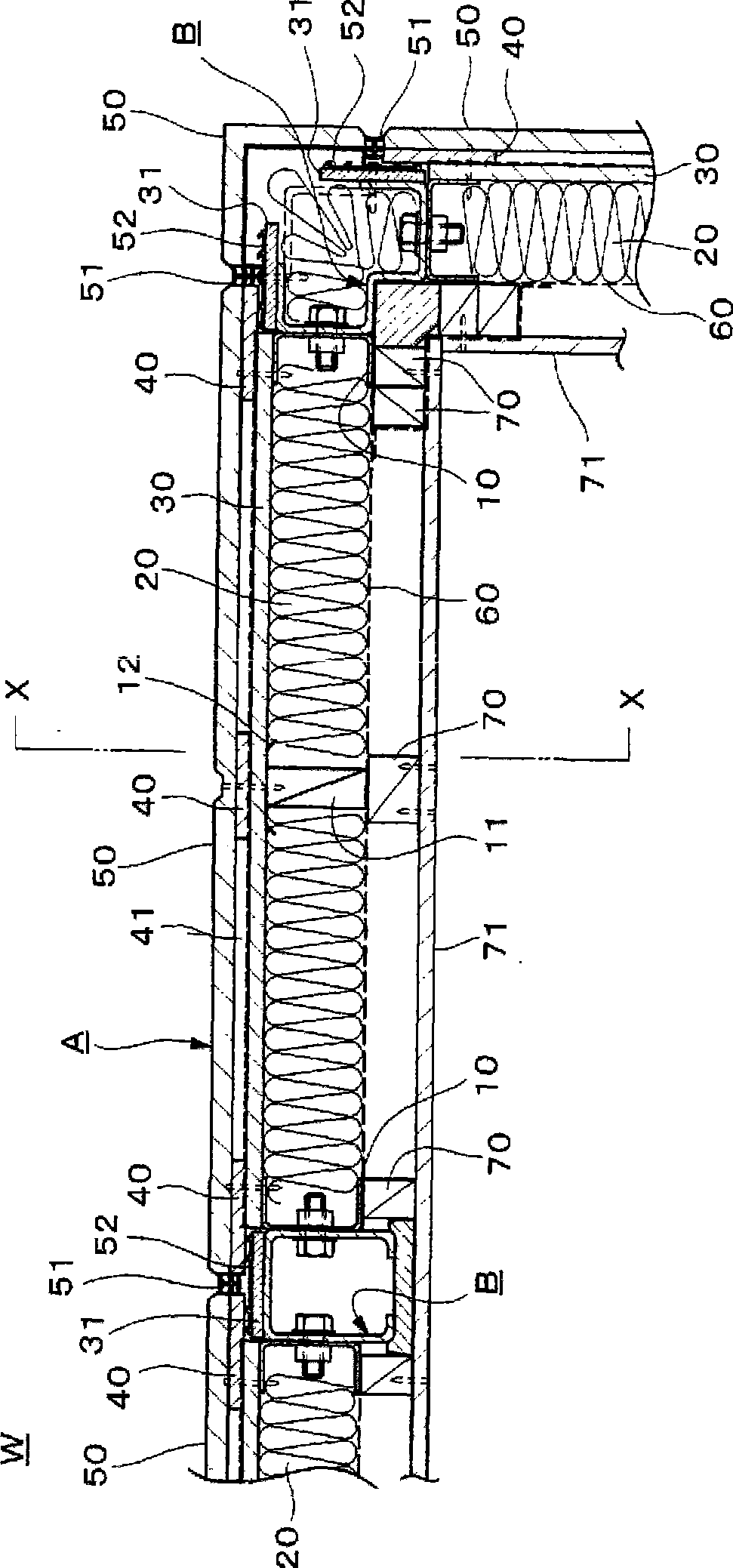

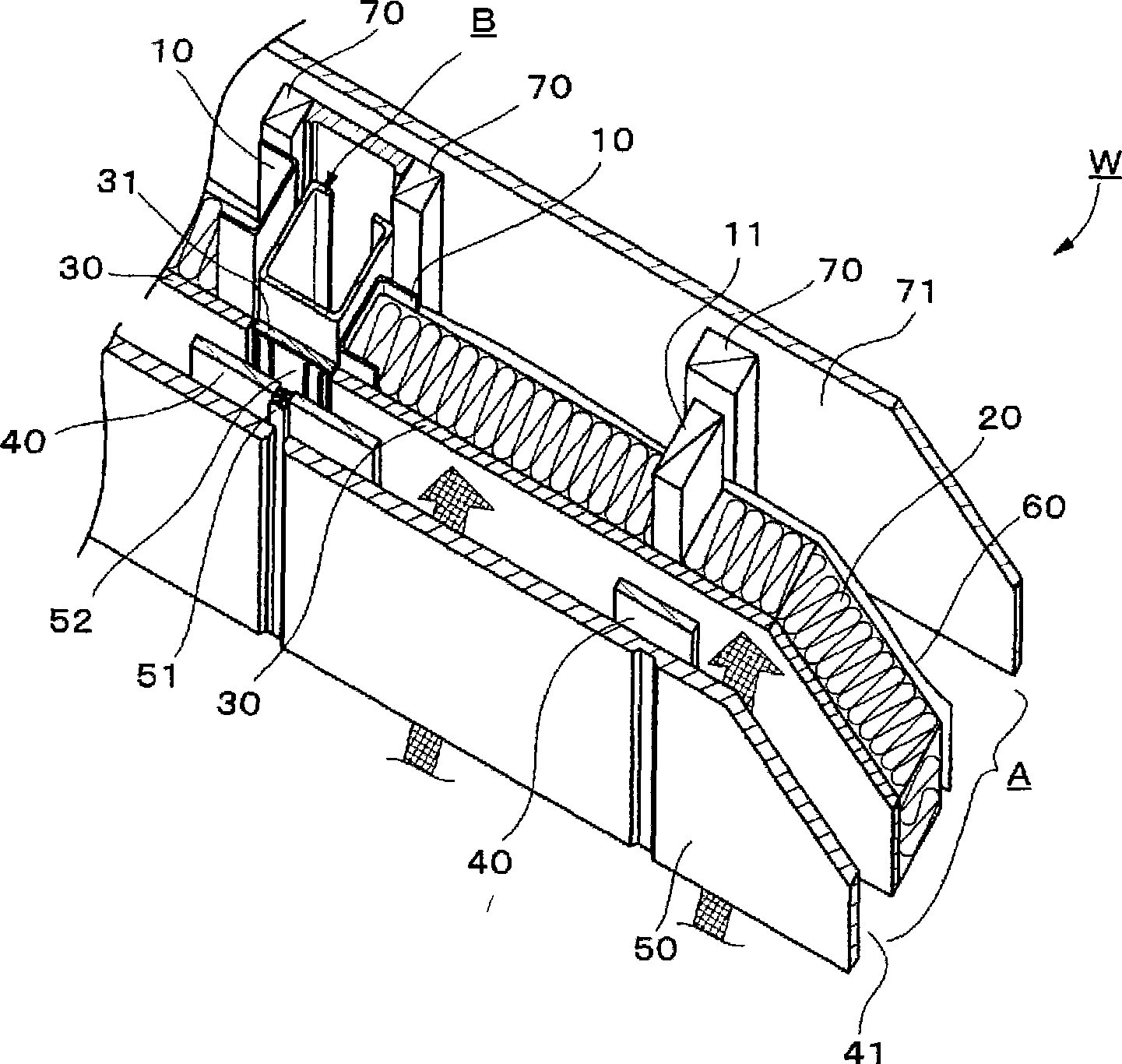

Exterior wall body

An exterior wall (W) formed by joining exterior wall panels (A) to both sides of steel beam columns (B). Each exterior wall panel (A) has a heat insulating board (30) as an exterior heat insulating material bonded to a panel frame (10) on its surface on the exterior side, and also has ventilation furring strips (40) fixed to the heat insulating board (30) on its surface on the exterior side. The ventilation furring strips (40) provide a ventilation layer (41) between an exterior wall surface material (50) and the heat insulating board (30). A joint of the heat insulating board (30) is located on a steel beam column (B) on its exterior side. A heat insulating material (31) for the joint is applied to the steel beam column (B) on its exterior side, and this prevents the joint from functioning as a heat bridge. Because of the presence of the ventilation layer (41), moisture entering from the outside can be efficiently discharged. Dew condensation is less likely to occur on the surface of a structure body and as a result the durability of the structure body is enhanced.

Owner:DAIWA HOUSE IND

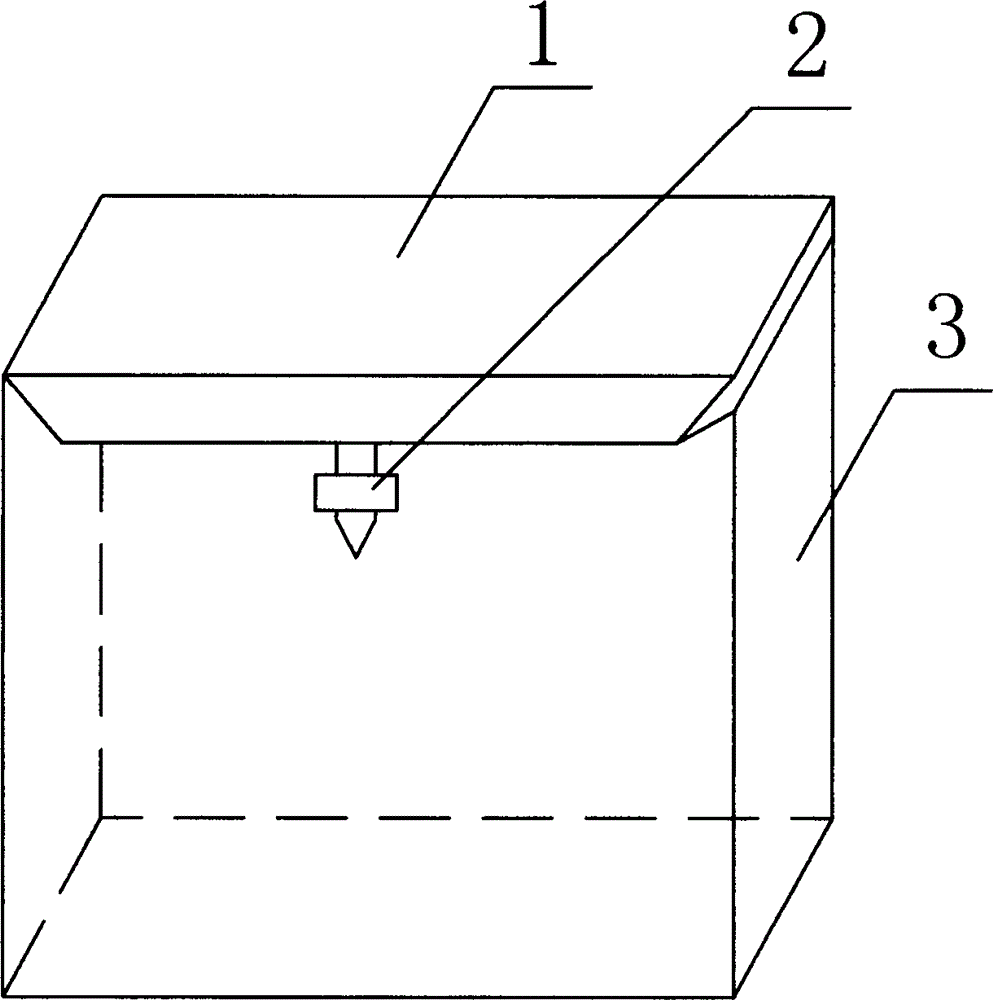

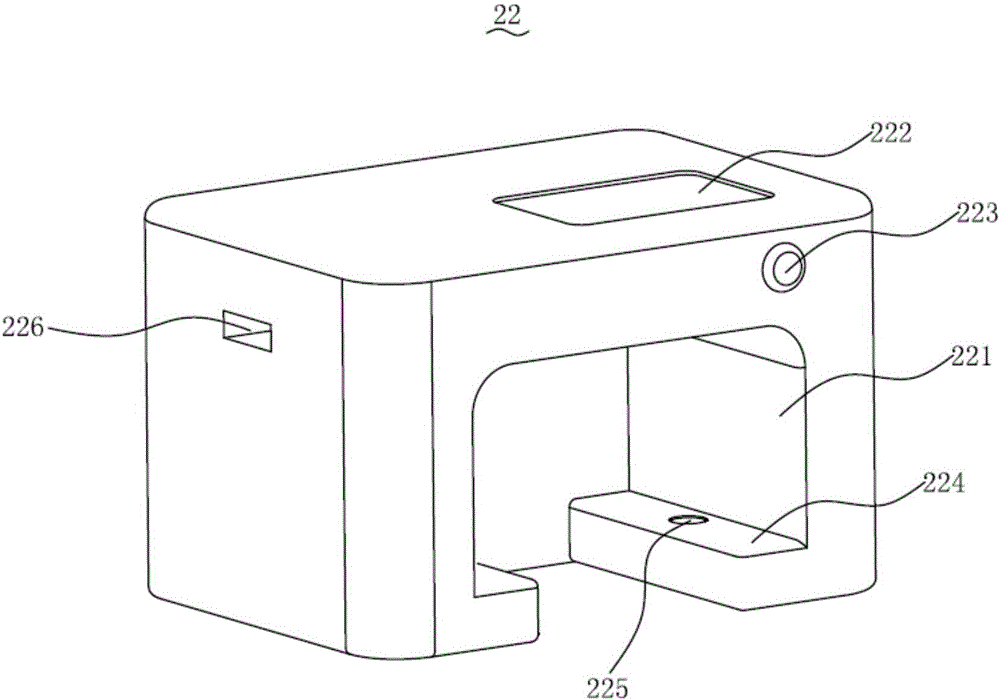

Warming take-out box

InactiveCN105883220ANot easy to coolAchieve insulation effectDomestic cooling apparatusLighting and heating apparatusEngineering

The invention belongs to the field of life, and particularly relates to a warming take-out box. During delivery, the temperature of the inner part of the take-out box can be maintained through heating, and then a warming effect can be achieved, and take-out food cannot get cold; and during delivery, a shake-proof sponge is arranged on the bottom of the take-out box, and in this way, the take-out food will not disperse due to overturning on a delivery way.

Owner:QINZHOU ZHUOPU TECH DEV CO LTD

Production technology and device of galvanized welded steel pipe

ActiveCN111945090AEasy to operateEasy to handleHot-dipping/immersion processesProcess efficiency improvementPipeIndustrial engineering

The invention relates to the technical field of galvanized steel pipe production, in particular to a production technology and device of a galvanized welded steel pipe. The production technology comprises the following steps: S1, horizontal suspension: horizontally suspending a steel pipe on a rotary hanging bracket; S2, acid pickling: adopting a hanging machine to place the hanging bracket in a pickling bath; S3, acid liquor removing, suspending a rotary crane on the top of the pickling bath through the suspension machine, and starting the rotary hanging bracket to enable the steel pipe to rotate in an aeration water tank; S4, water removing: suspending the rotary hanging bracket on the top of the aeration water tank through the suspension machine, and starting the rotary hanging bracketto enable residual water on the surface of the steel pipe to fall into the aeration water tank to prevent the residual water from diluting the galvanizing solution; galvanization, adopting a suspension frame to place the rotary hanging bracket in a hot galvanizing bath; and removing zinc liquid, and starting a zinc film remover. The galvanized steel pipe manufactured through the production technology is higher in quality and high in automation degree.

Owner:山东承泽金属科技有限公司

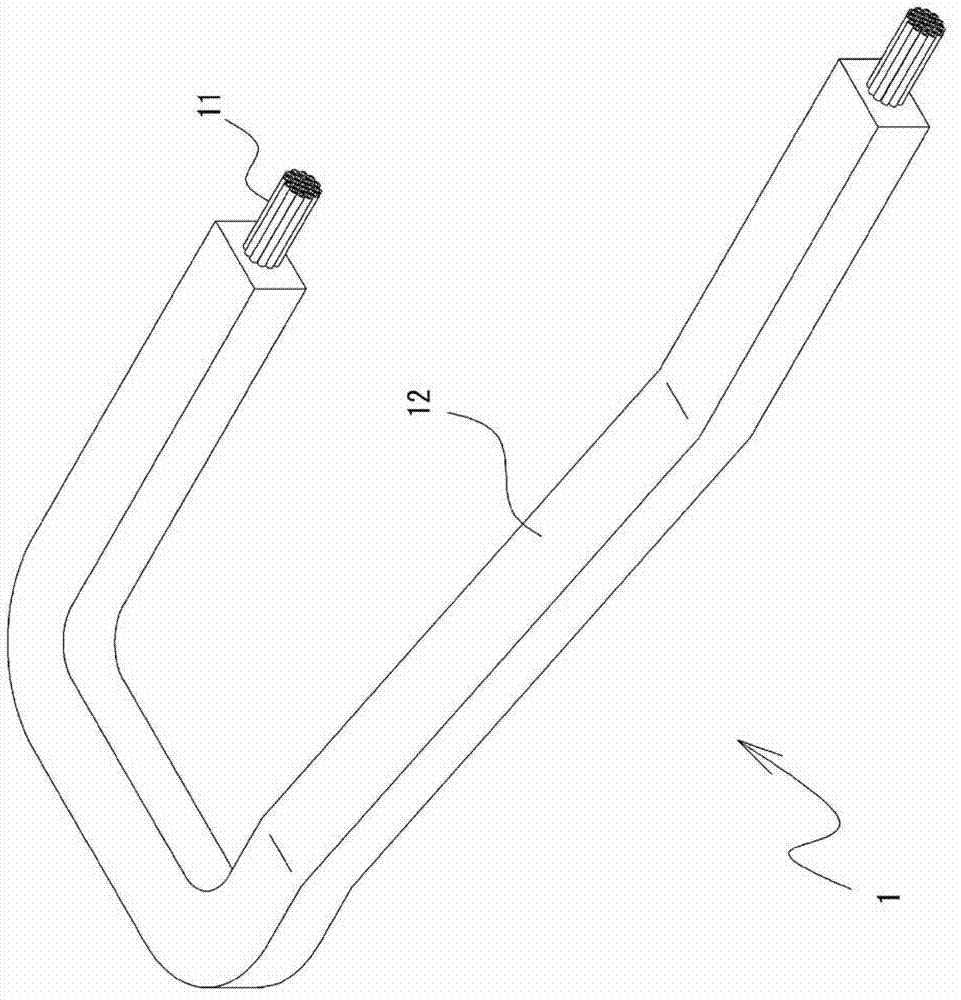

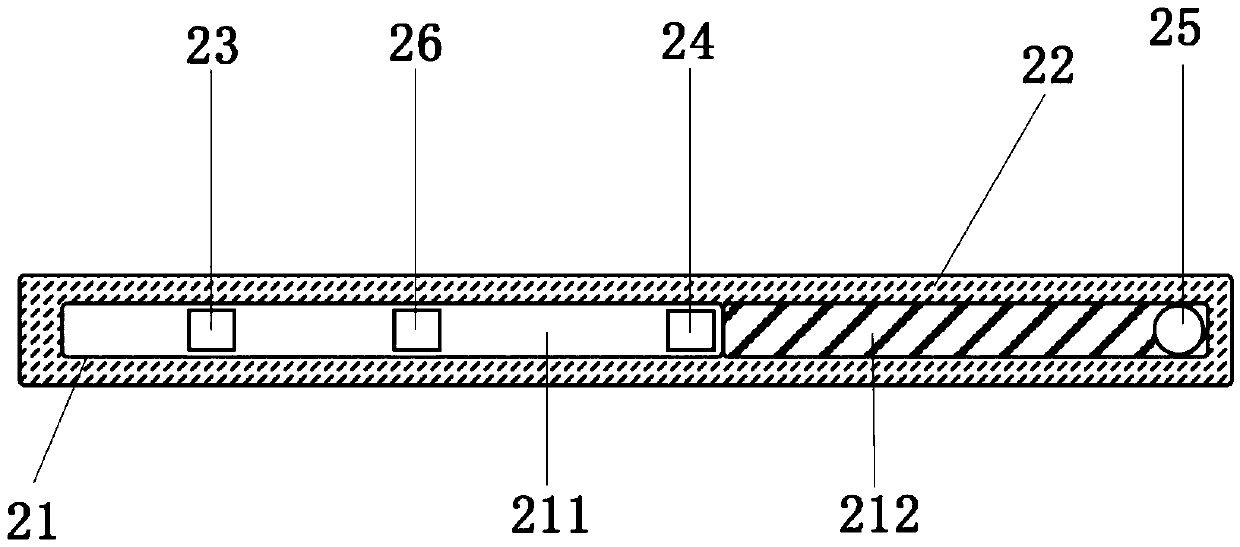

Manufacturing method for wire harness

InactiveCN102741946AReduce in quantityThe content of the process is simpleInsulated cablesManufacturing wire harnessesEngineeringElectric wire

Disclosed is a manufacturing method for a wire harness having a shape-retaining member and protector comprising a thermoplastic material, said manufacturing method enabling the easy formation of the axial shape of the shape-retaining member and protector into a predetermined shape during a manufacture process. The manufacturing method has: a first step, in which the periphery of an electrical wire is coated by a body (13) to be molded comprising a thermoplastic material, and in which the body (13) to be molded is formed into a predetermined cross-sectional shape and dimensions by applying pressure thereto while heating the body (13) to be molded at a temperature at which plastic deformation is possible because of the thermoplasticity; and a second step, after the first step, in which the body (13) to be molded is formed into a predetermined axial shape while at the temperature at which plastic deformation is possible because of the thermoplasticity, and is cooled after being formed into the predetermined axial shape. In the second step, the shape-retaining member (12) obtained through the first step is inlaid in a molding section (721) formed in a lower mold (72) of a second molding body (7), forming the axial shape of the shape-retaining member (12), which is then cooled.

Owner:AUTONETWORKS TECH LTD +2

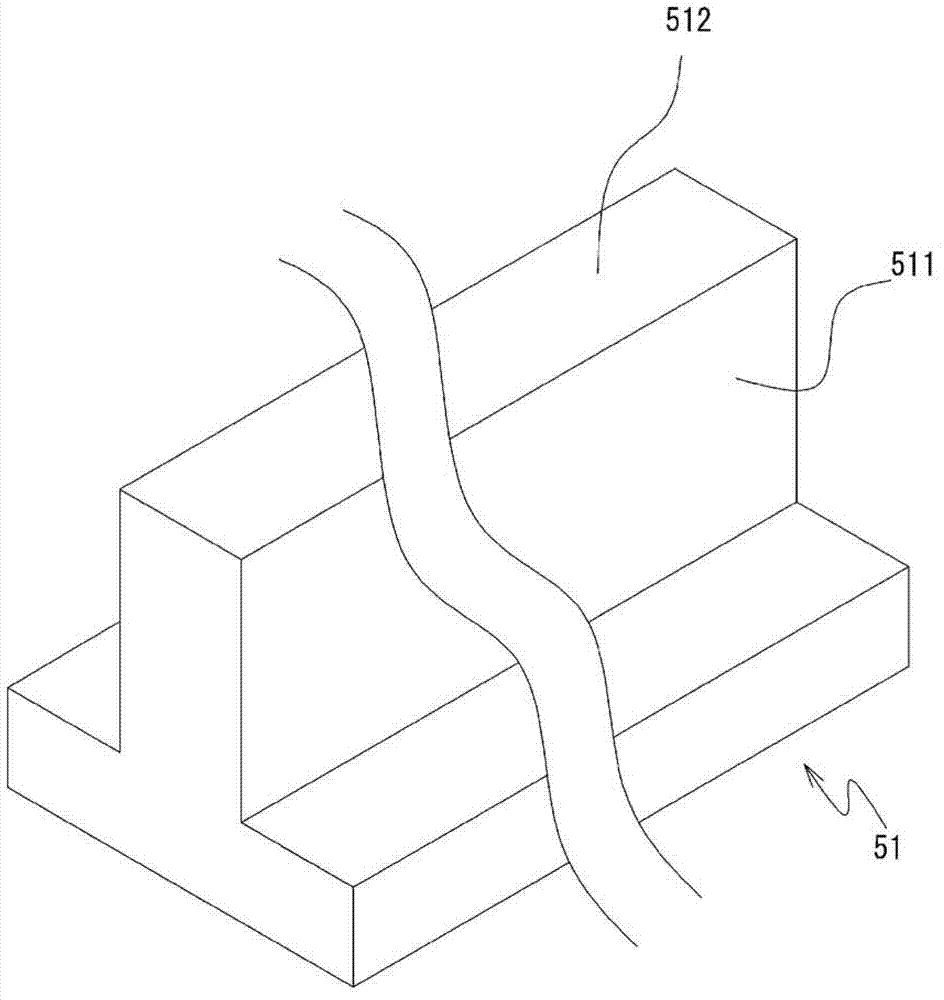

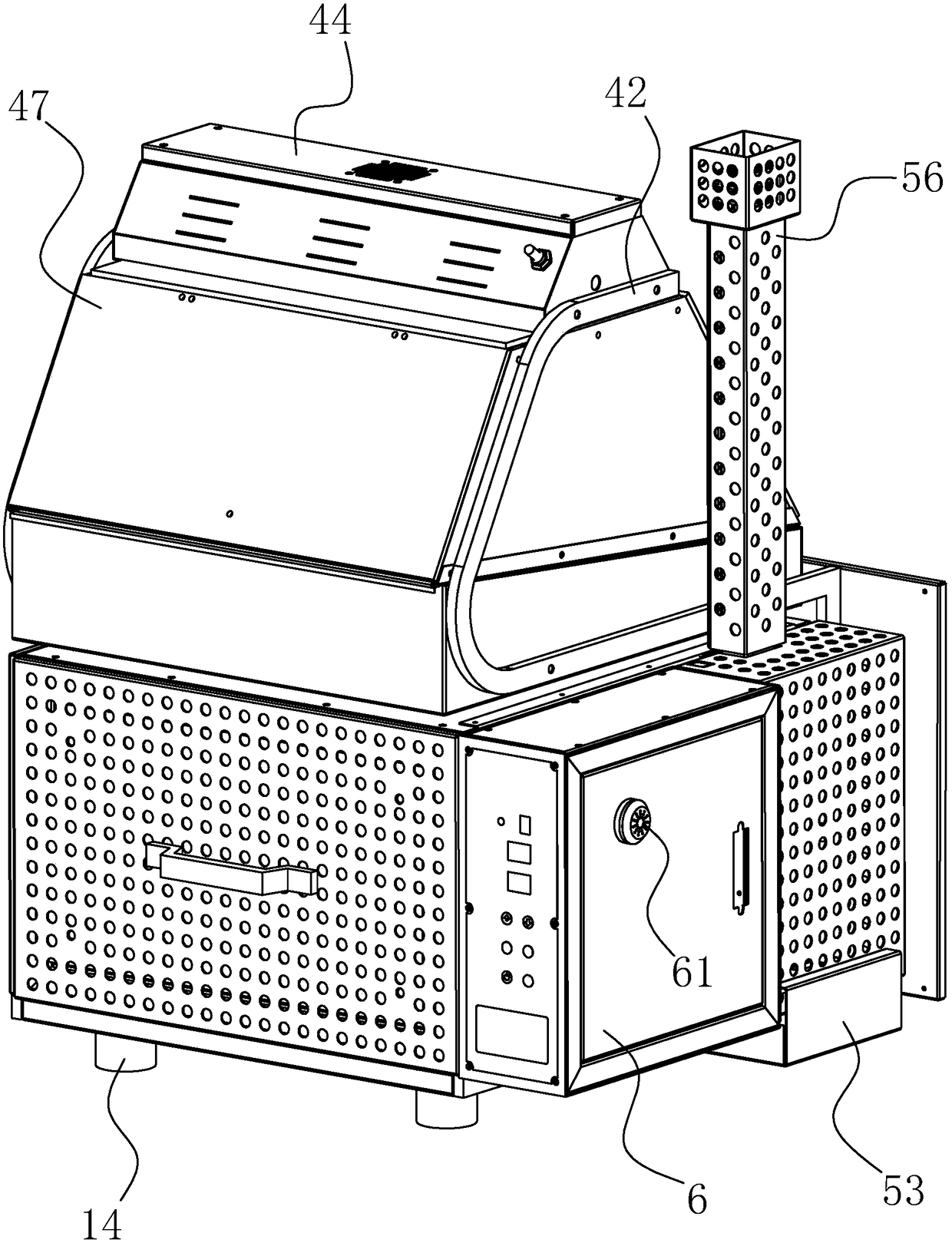

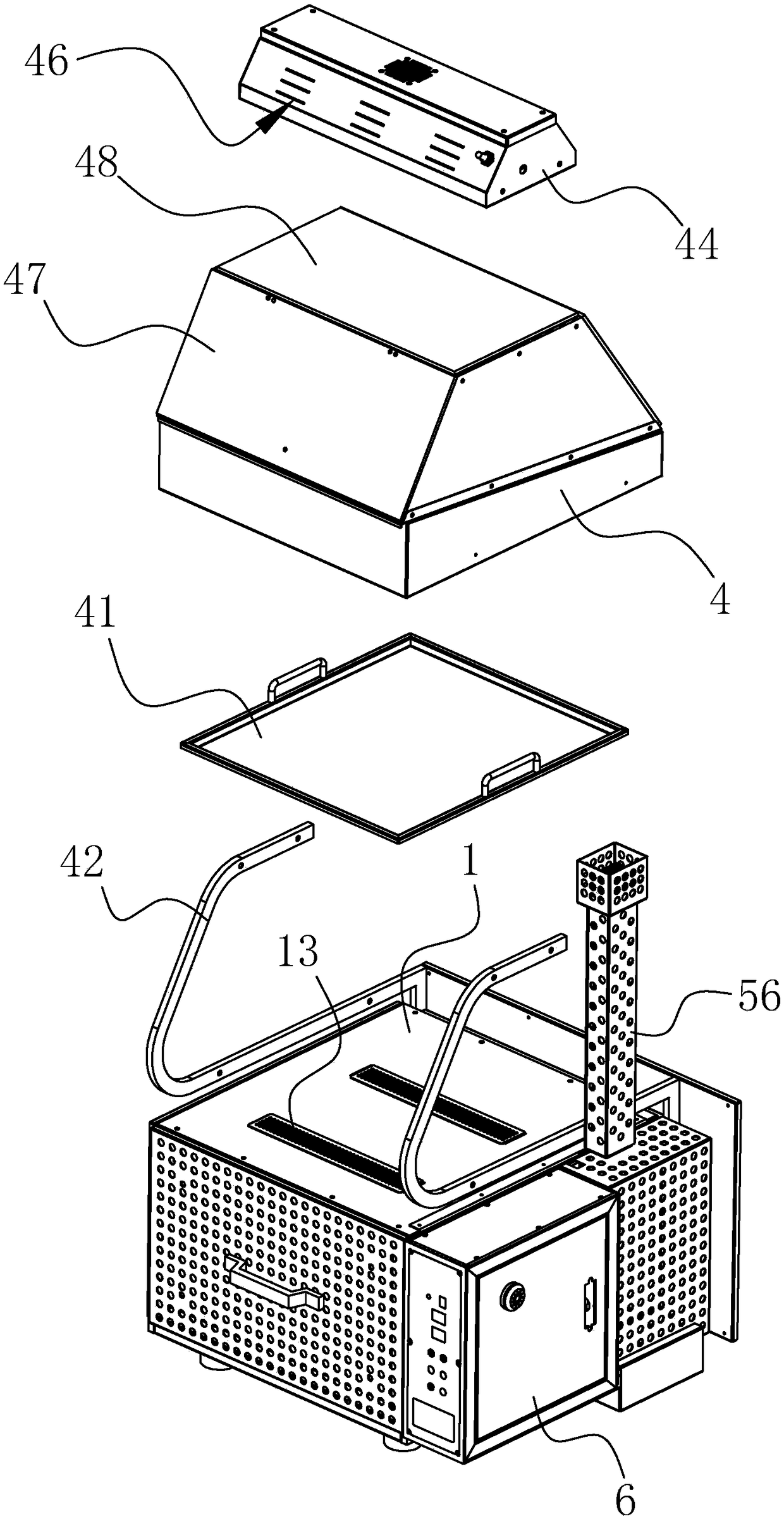

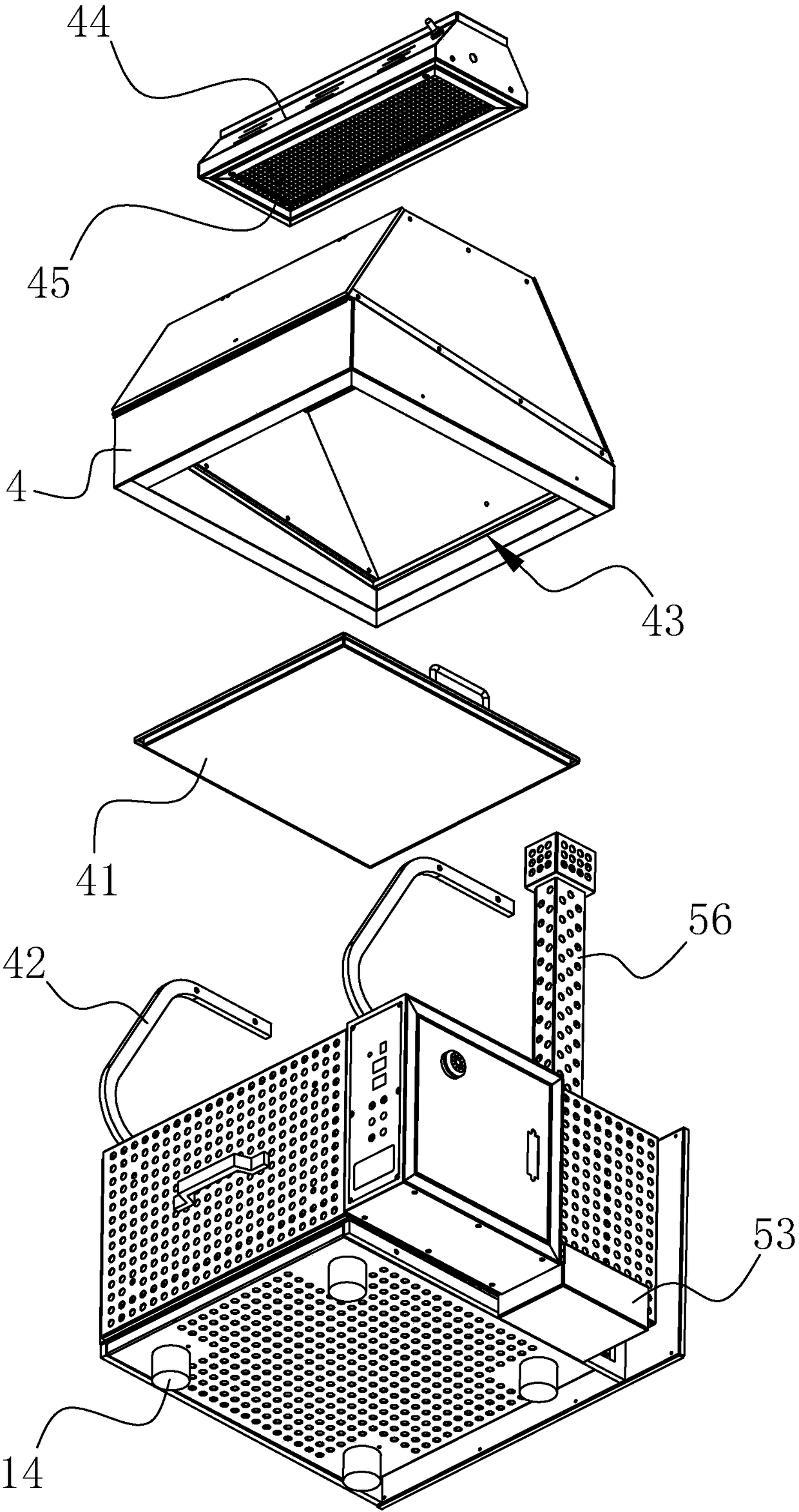

Baking oven

PendingCN108478033AHigh speedImprove cooling effectRoasters/grillsCooking & bakingProcess engineering

The invention relates to a baking oven. The baking oven comprises an electric heating baking part, a heat-preservation part and a fume discharging chimney (5) which is communicated with the electric heating baking part and can discharge fumes in the electric heating baking part out to the outer world, the heat-preservation part is located on the top of the electric heating baking part, the fume discharging chimney (5) is located on the side portion of the heat-preservation part, and a circuit controller capable of adjusting and controlling the baking temperature of the electric heating bakingpart is further arranged on the baking oven. The baking oven has the advantages that hot fume generated by heating in the baking oven can be smoothly discharged out from the fume discharging chimney to improve the baking peed of foods, the baking efficiency is high, a wind power system is not needed to discharge the fumes, the baking cost is lower, the fumes are concentrated and discharged out from the chimney, and therefore the baking is cleaner and more hygienic; long-term heat preservation of baked foods can be achieved in a heat-preservation box, the baked foods do not easy to get cold, the freshness of the baked food can be maintained for a long time, the advantage of not losing taste is achieved, and it is hygienic and environmental-friendly to place the baked foods in a sealed heat-preservation box.

Owner:宁波智恒自动化科技有限公司

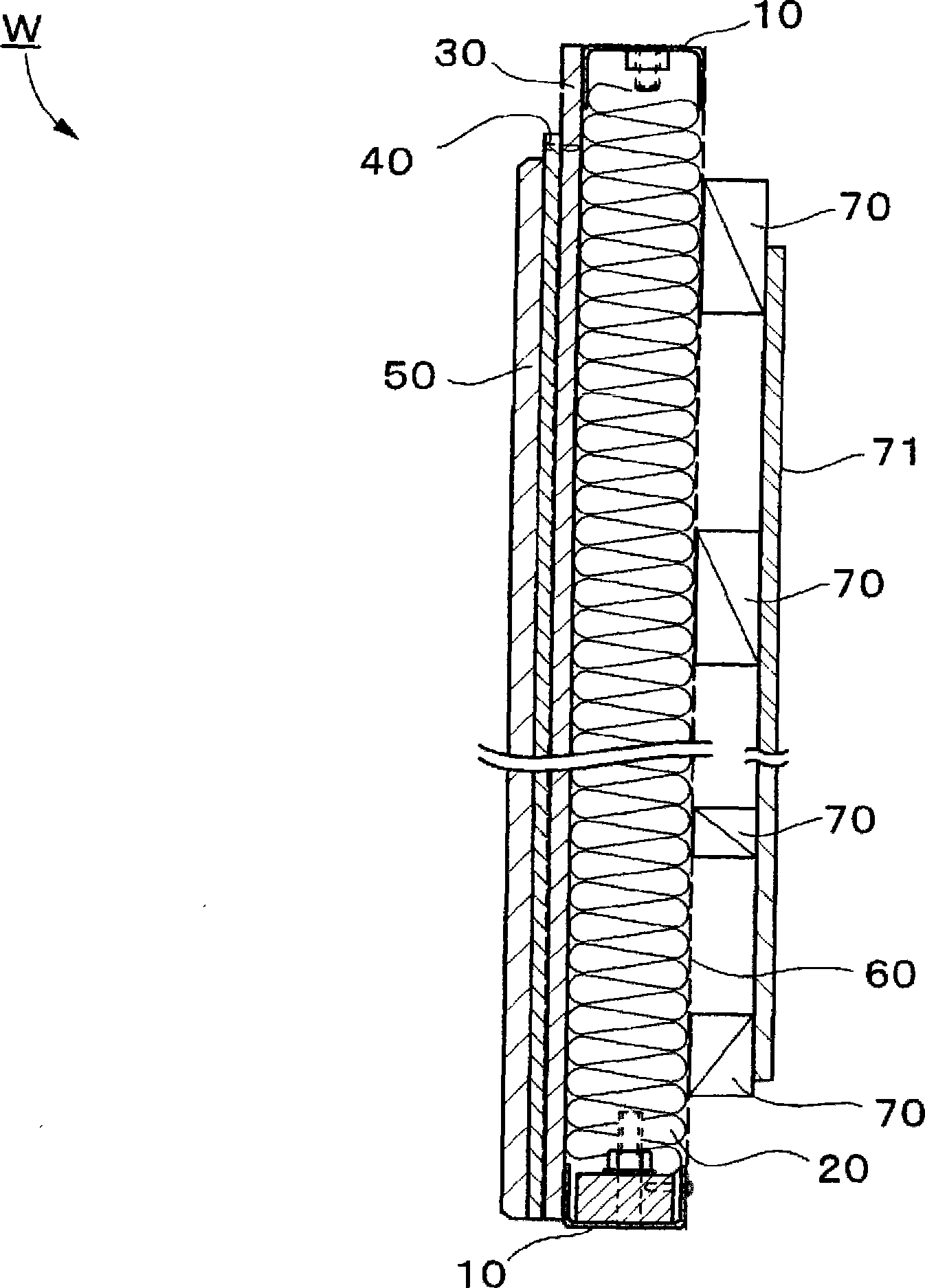

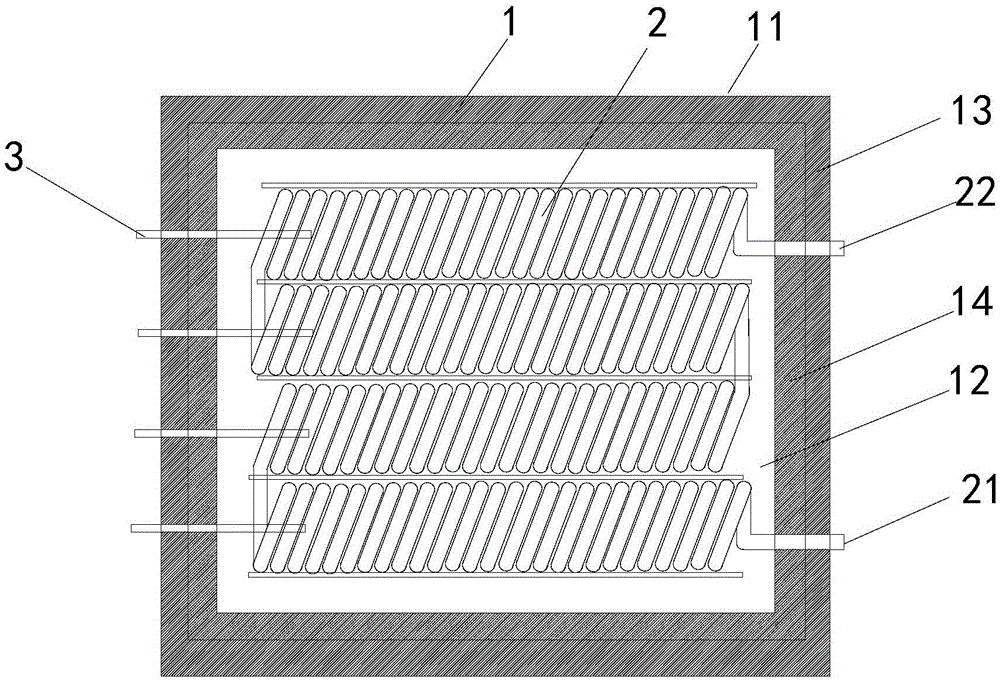

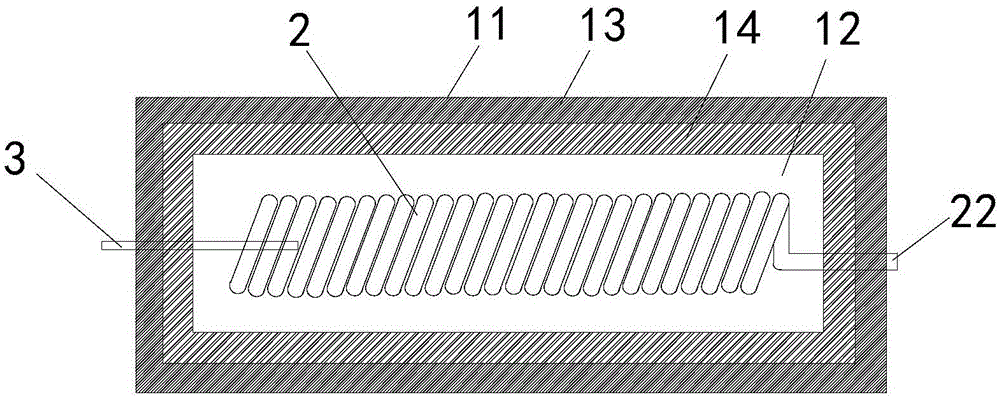

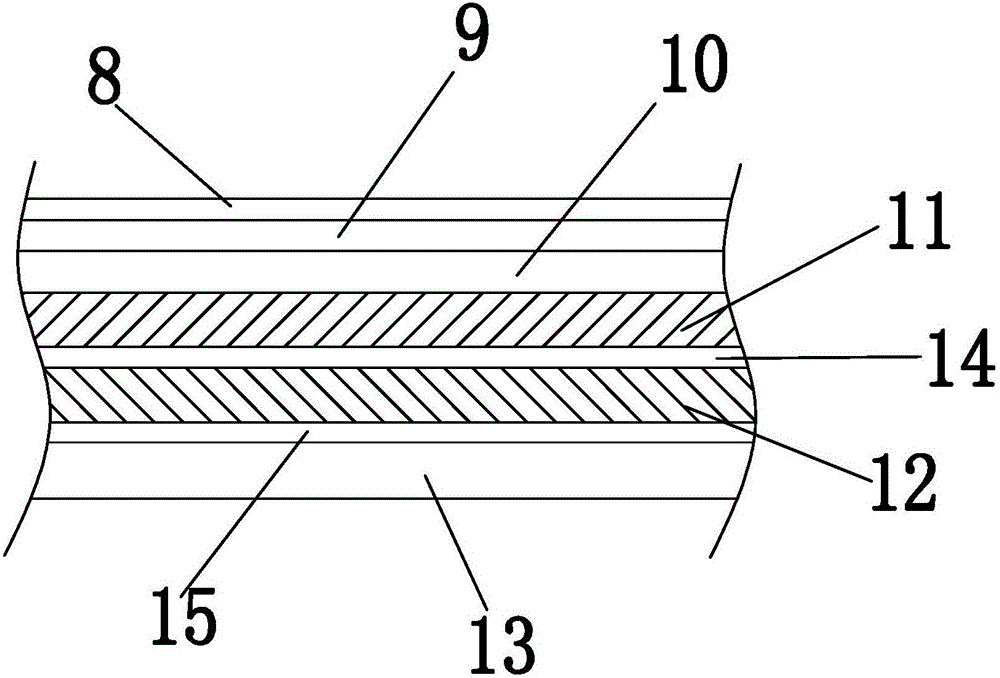

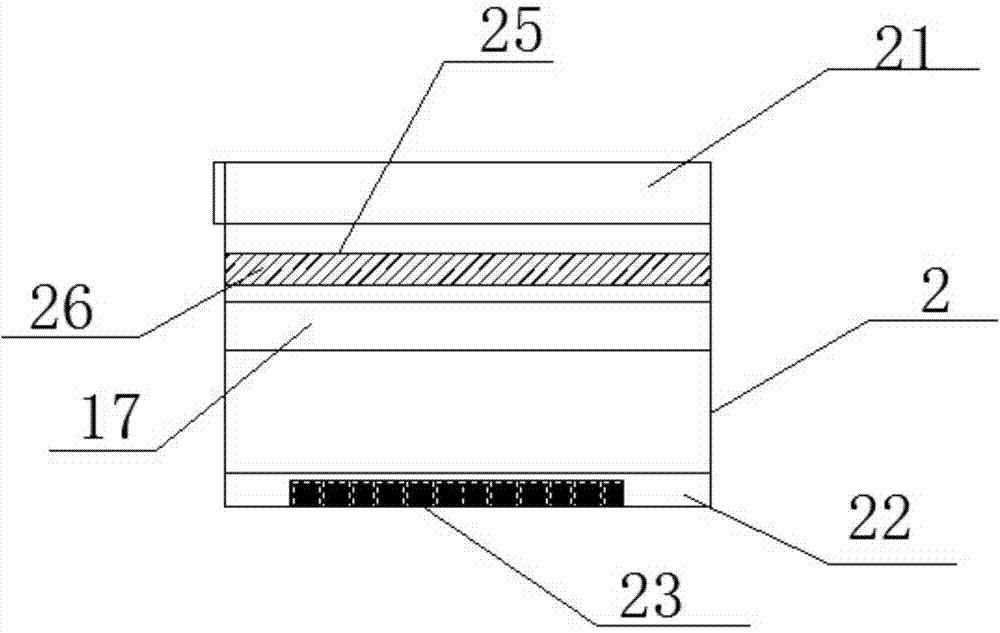

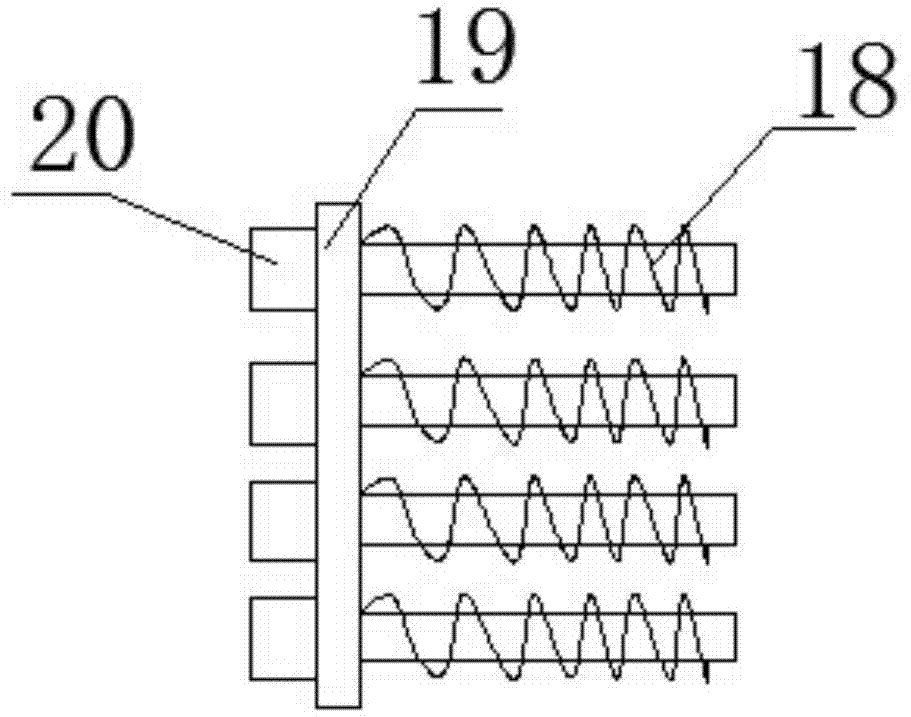

Phase change energy storage electric water heater

InactiveCN105003950AIncrease the heat exchange areaFast heat transferHeat storage plantsCentral heating systemEngineeringWater cooling

The invention provides a phase change energy storage electric water heater, which comprises a water tank and a heat exchange coil and electric heating rods arranged in the water tank. The heat exchange coil is a multilayer horizontal spring coil, and the electric heating rods are arranged in a layering manner corresponding to the multilayer horizontal spring coil. The water tank comprises a shell and a liner, a heat preservation layer and a phase change material energy storage layer are arranged between the shell and the liner sequentially from outside to inside, the heat exchange coil is arranged in the liner, and the liner is filled with a heat aid. The phase change energy storage electric water heater is good in heat exchanging effect, high in heat exchanging speed, slow in water cooling, capable of saving energy and water, capable of realizing heating in a layering manner, and capable of making into water heaters in different sizes and with different usages.

Owner:许求鑫

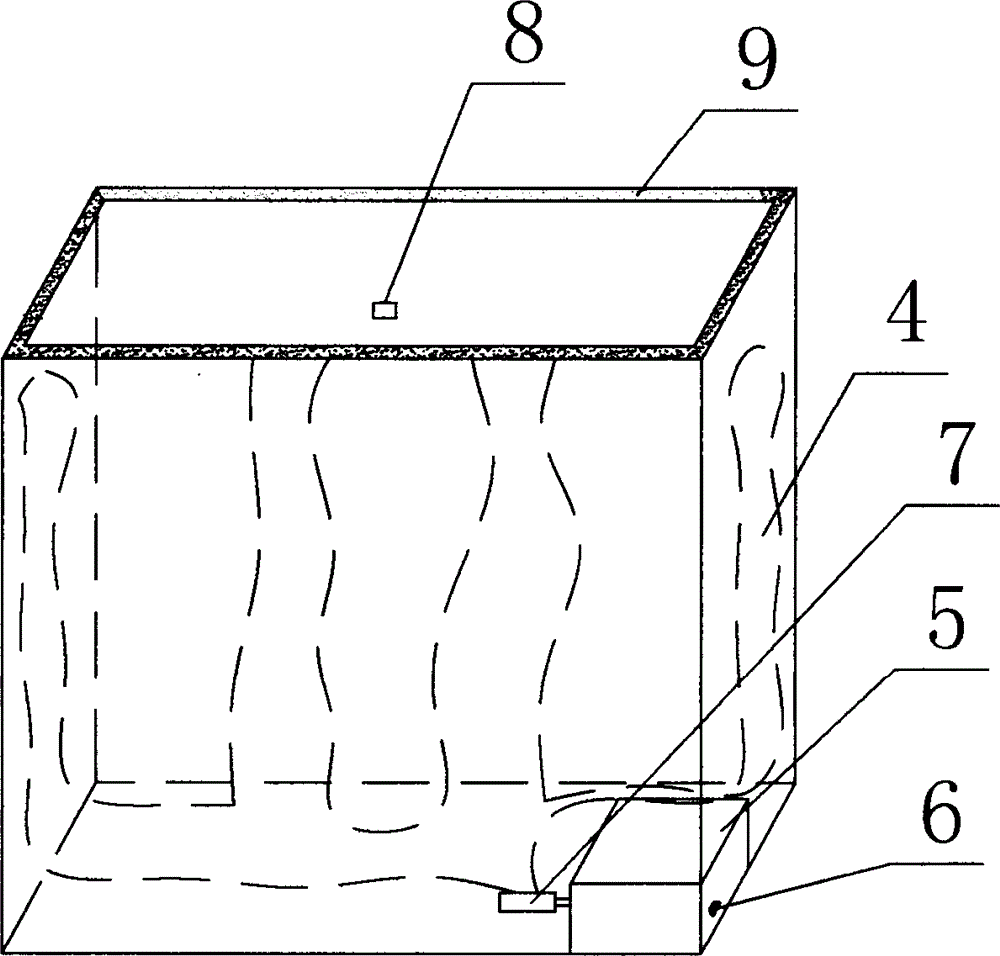

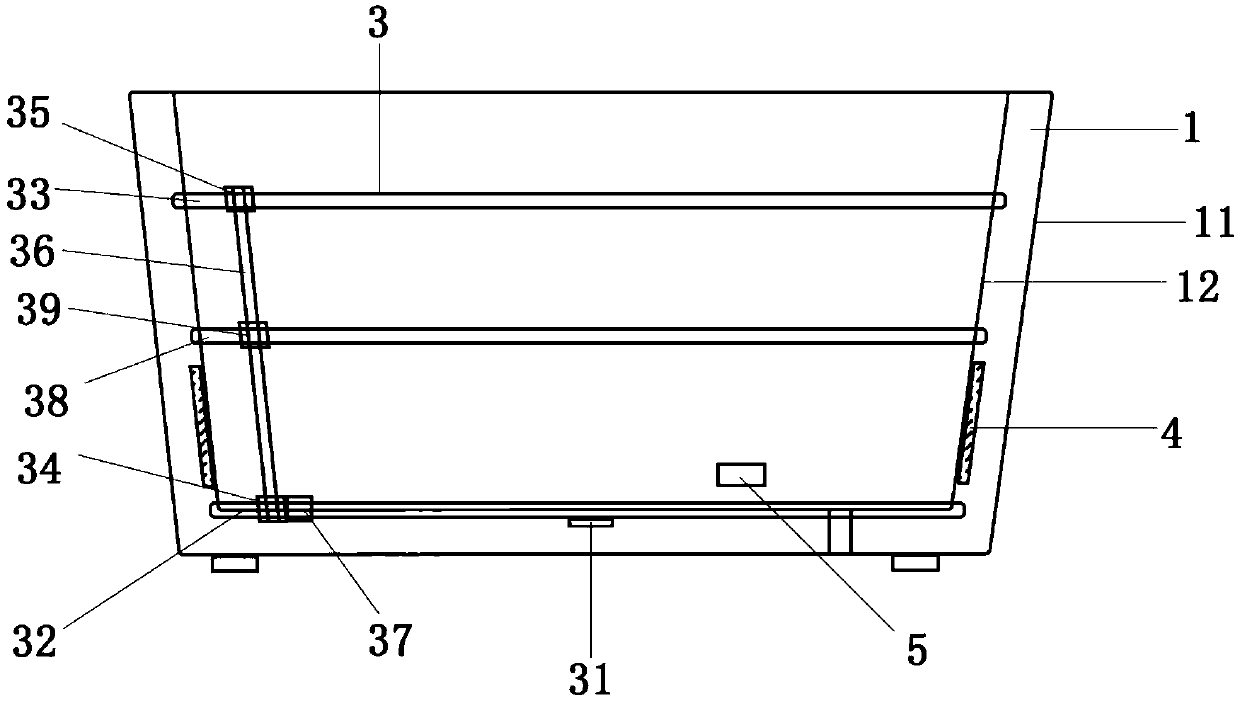

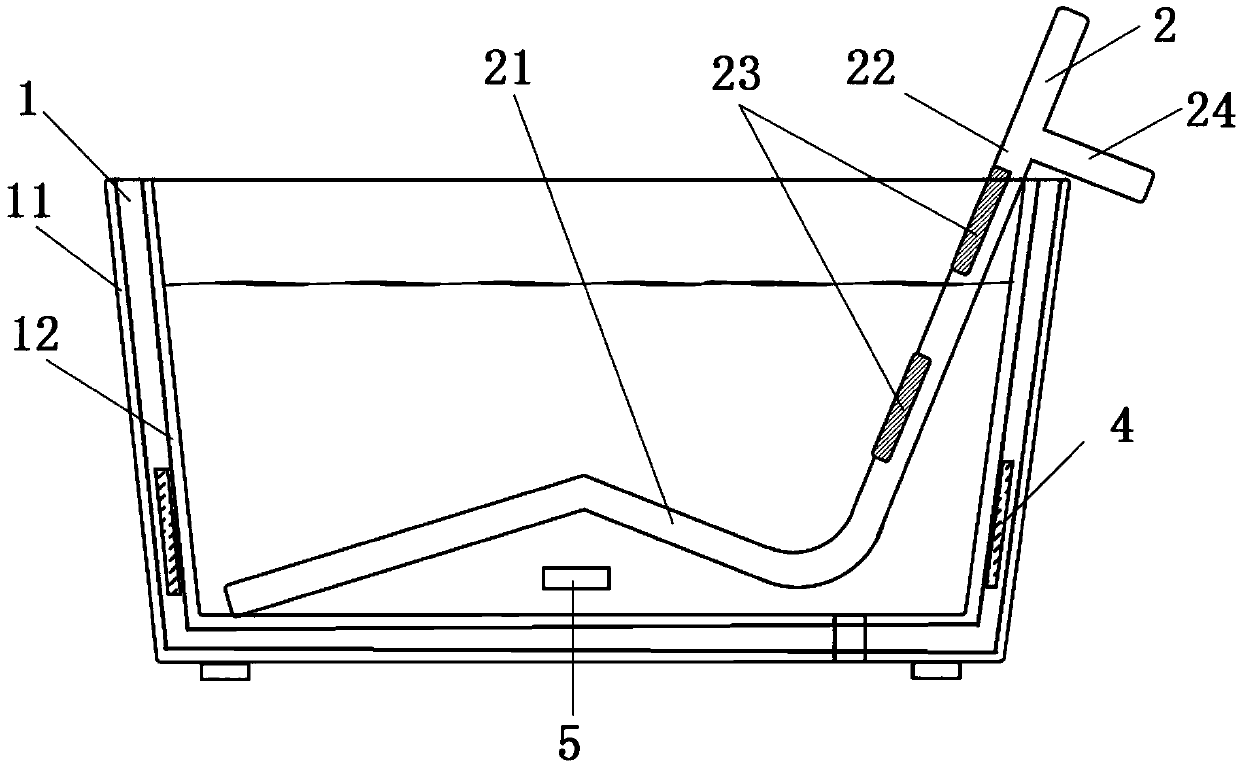

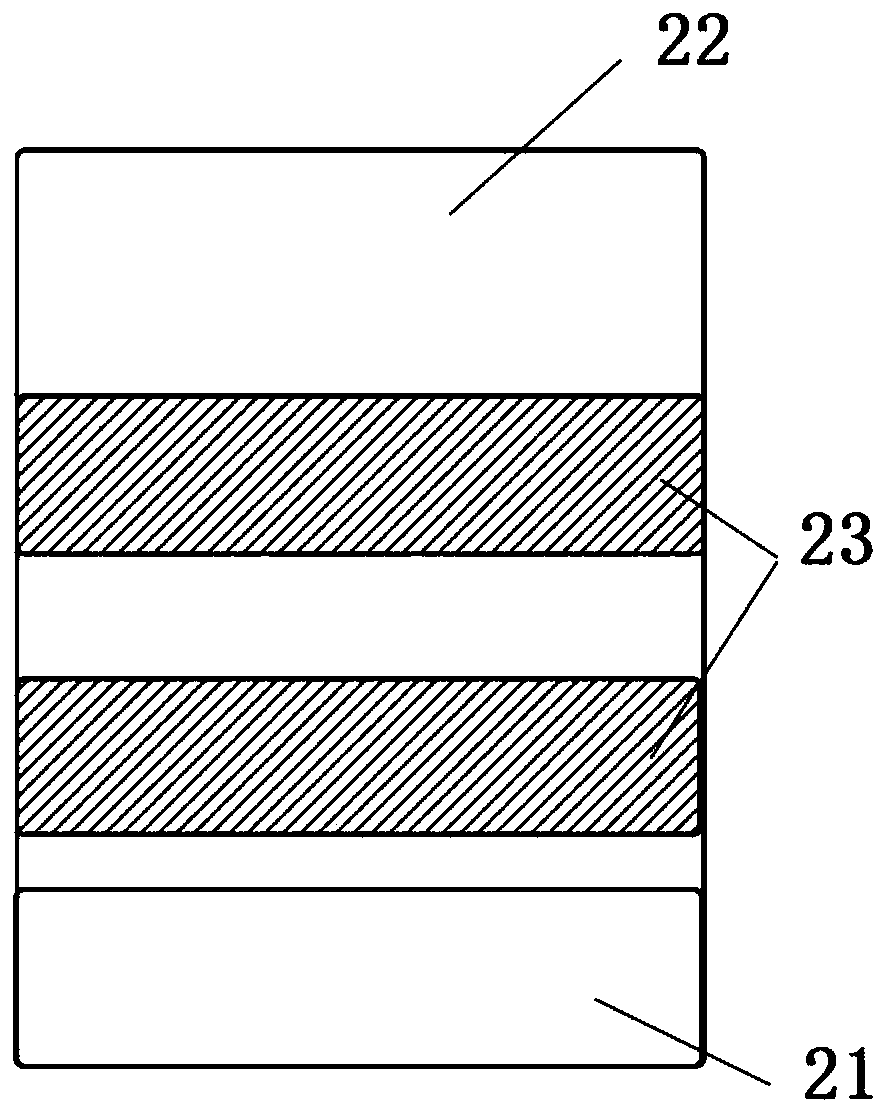

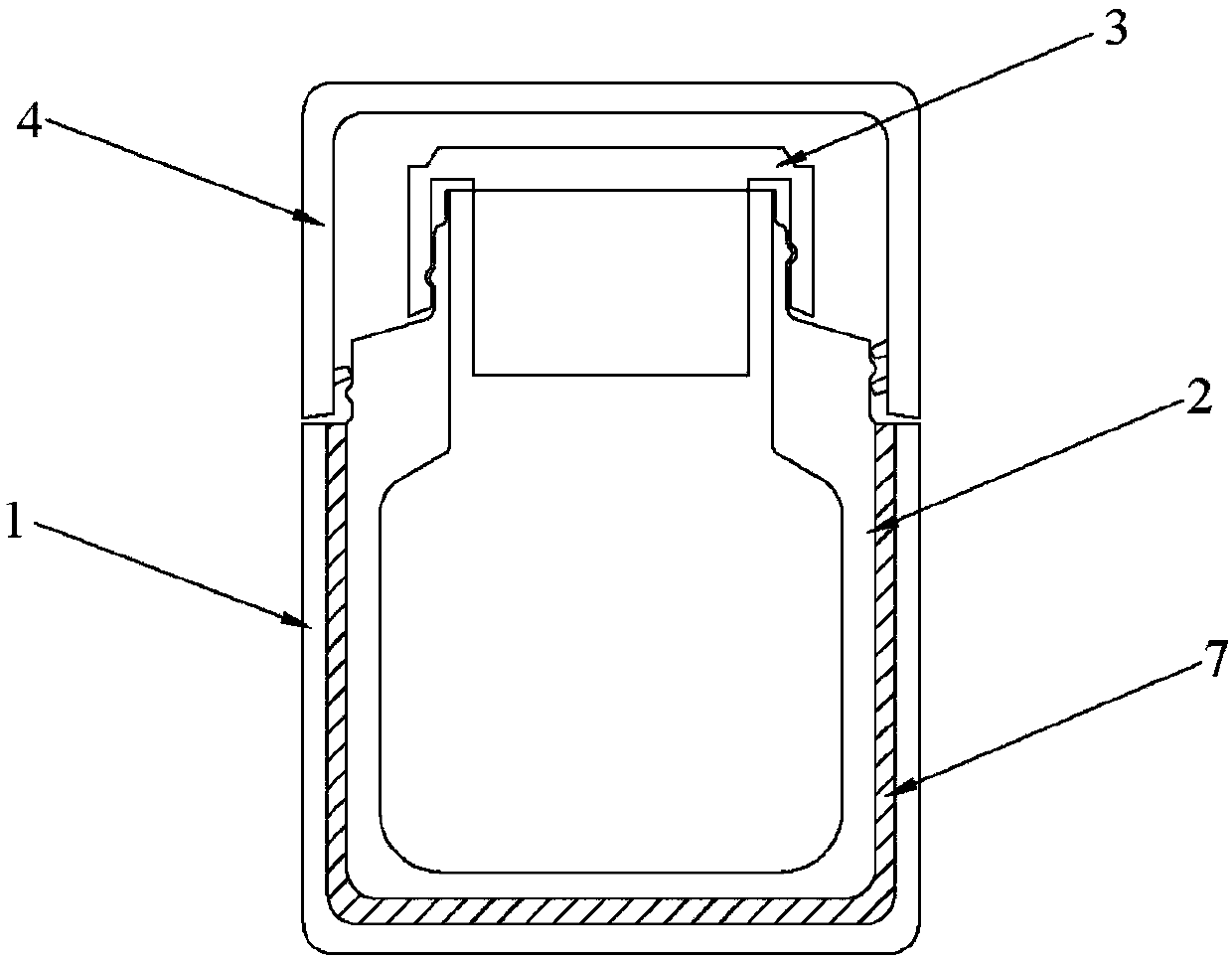

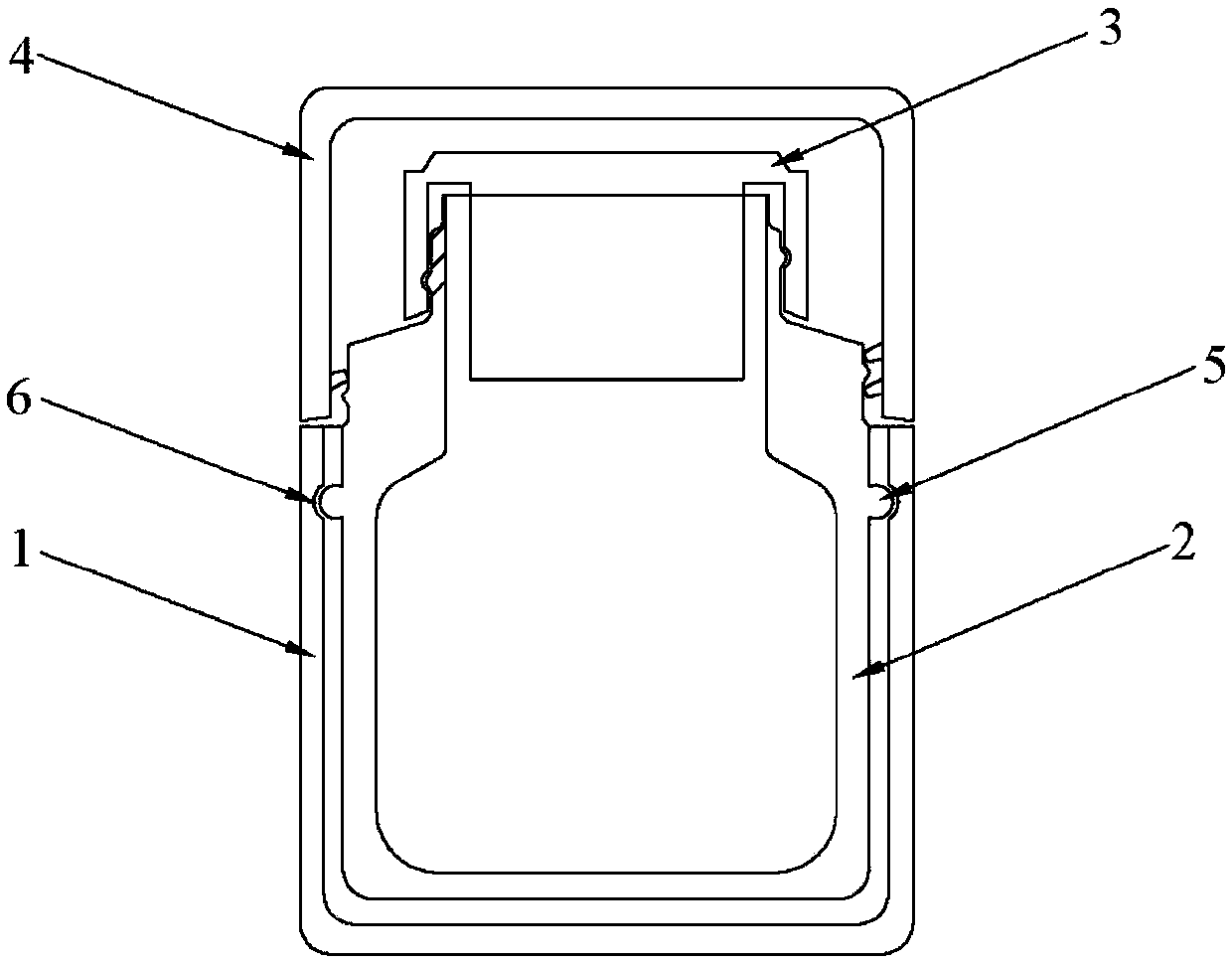

Bathtub

InactiveCN106580156AGood insulation effectLong holding timeDevices for pressing relfex pointsBathsPerliteBathtub

The invention relates to a bathtub. The bathtub comprises a bathtub body, wherein the bottom inside the bathtub body is arranged in an inclined manner at an inclined angle of 3-5 degrees, a foot massage area is arranged at the bottom of the inclined bottom, and is lower than the bottom inside the bathtub body; a water outlet is formed in the foot massage area, and is provided with a water retaining cover; except the water outlet, a plurality of round grooves are uniformly formed in other positions of the foot massage area, and elastic rubber bulges having a semispherical structure are arranged in the round grooves; the bathtub body is sequentially provided with an inner shell resin environment-friendly plate, a decorating layer, an epoxy resin layer, a perlite heat insulation layer, a foam polyurethane material layer and an outer shell substrate from inside to outside; two electric heating devices having a strip structure are arranged between the epoxy resin layer and the perlite heat insulation layer; and the electric heat devices are connected with an external power supply. Compared with the prior art, the bathtub has a constant temperature function, and has the advantages of steady structure, good insulation effect, high safety, abrasion resistance, hanging tolerance, environmental friendliness and the like.

Owner:平湖市欧迪雅厨卫设备有限公司

Heat preservation bathtub

InactiveCN110881878AImprove insulation effectImprove cooling effectMechanical apparatusBathsEpoxyThermodynamics

A heat preservation bathtub comprises a bathtub body, and the bathtub body is of a double-layer closed structure composed of an inner layer and an outer layer. The inner layer is composed of a resin environment-friendly plate arranged on the inner side and an epoxy resin layer arranged on the outer side. The outer layer is composed of a perlite heat preservation layer arranged on the inner side and a polyurethane foaming heat preservation layer arranged on the outer side. The electric heating device is tightly attached to the outer portion of the inner layer and surrounds the bottom of the inner layer. A temperature sensor is arranged in the inner layer, and the electric heating device is electrically connected with the temperature sensor and an external power source. The bathtub body is of a double-layer closed structure composed of the outer layer and the inner layer. The outer layer is composed of the perlite heat preservation layer with the heat preservation function and the polyurethane foaming heat preservation layer, the bathtub body can have a good heat preservation effect due to double heat preservation, and the electric heating device is arranged outside the inner layer and can heat water in the bathtub body to enable the water in the bathtub body to be kept at the constant temperature.

Owner:覃婷

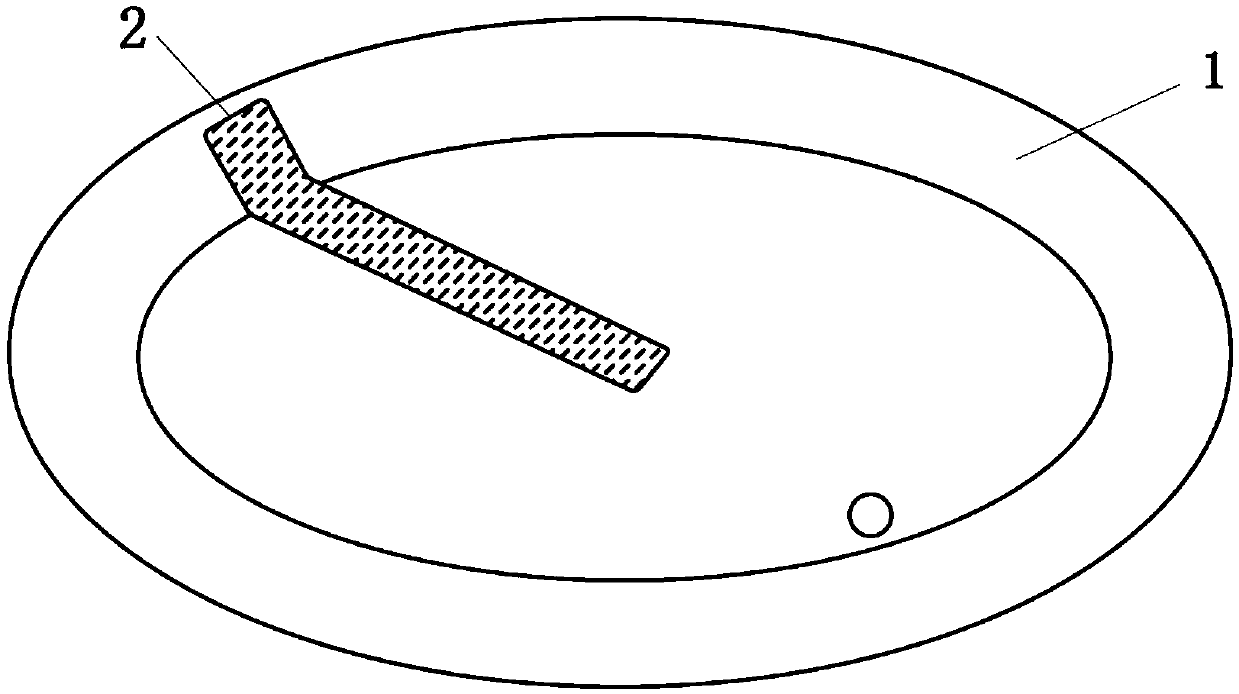

Fuming and washing basin for hemorrhoidal or gynecological diseases

The invention discloses a fuming and washing basin for hemorrhoidal or gynecological diseases, belongs to medical instruments and aims at providing a fuming and washing basin good in sealing performance, labor saving and convenient to use and capable of allowing soaking and washing at the same time. The fuming and washing basin comprises a basin body (1), the basin body (1) is fixed on a stool (2) and integrated with the same, a basin opening of the basin body (1) is of a toilet seat structure, and a washing sink (4) inclining downwards is arranged at the front end of the basin opening. The fuming and washing basin has the advantages of simple structure, labor saving and comfortability in use, good sealing performance, convenience in washing and operating, accurate computation and the like and is used as a special fuming and washing basin for curing the hemorrhoidal or gynecological diseases.

Owner:贵州拜特制药有限公司

Asphalt stirring apparatus

InactiveCN104841315AEasy to stirEasy to coolRotary stirring mixersMixer accessoriesAsphaltBevel gear

The invention discloses an asphalt stirring apparatus, and relates to the field of road and bridge construction apparatuses. The apparatus comprises a workbench, the workbench is provided with a stirring box, one side of the stirring box is provided with a driving device, the driving device comprises a motor, a first bevel gear, a second bevel gear, a bevel gear and a fourth bevel gear, the workbench is provided with a first fixing rack, the first fixing rack is provided with a connecting shaft, the third bevel gear and the fourth bevel gear are respectively arranged at two ends of the connecting shaft, the second bevel gear is arranged on the connecting shaft, the first bevel gear is arranged on the main shaft of the motor, two sides of the stirring box are respectively provided with second fixing racks, a first leading screw and a second leading screw are respectively arranged between the second fixing racks, one ends of the first leading screw and the second leading screw are respectively provided with a fifth bevel gear and a sixth bevel gear, the first leading screw and the second leading screw are respectively provided with leading screw nuts, a slide bar is arranged between the leading screw nuts, two sidewalls of the stirring box are respectively rectangular holes, and the lower end of the slide bar is provided with a stirring shaft. The apparatus adopting the above design has the advantages of convenient operation and uniform stirring.

Owner:甘肃路航道路材料有限公司

Medicated bath bathtub

InactiveCN110882149AImprove insulation effectPromote absorptionMechanical apparatusBathing devicesEpoxyPharmacy medicine

The invention relates to a medicated bath bathtub, which comprises a bathtub body and further comprises a chair arranged in the bathtub body, and the chair comprises a seat plate, a backrest, a medicine bag and a buckling piece; the upper end of the backrest is fixedly connected with the buckling piece, the lower end of the backrest is connected with one end of the seat plate, a groove used for containing the medicine bag is formed in the front side of the backrest, and the buckling piece is buckled with the upper edge of the bathtub body in a matched mode; the bathtub body is of a double-layer closed structure composed of an inner layer and an outer layer. The inner layer is composed of a resin environment-friendly plate arranged on the inner side and an epoxy resin layer arranged on theouter side. The outer layer is composed of a perlite heat-preservation layer arranged on the inner side and a polyurethane foaming heat preservation layer arranged on the outer side. The bathtub is good in heat preservation effect and can effectively promote absorption of medicated bath medicine by a human body.

Owner:覃婷

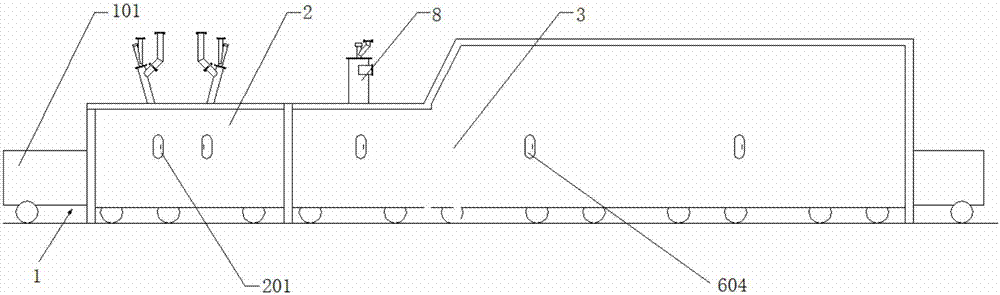

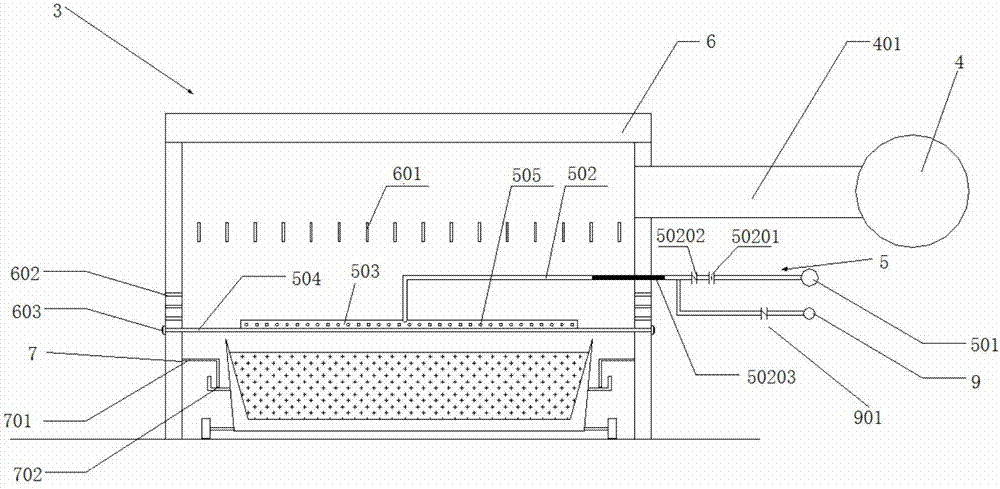

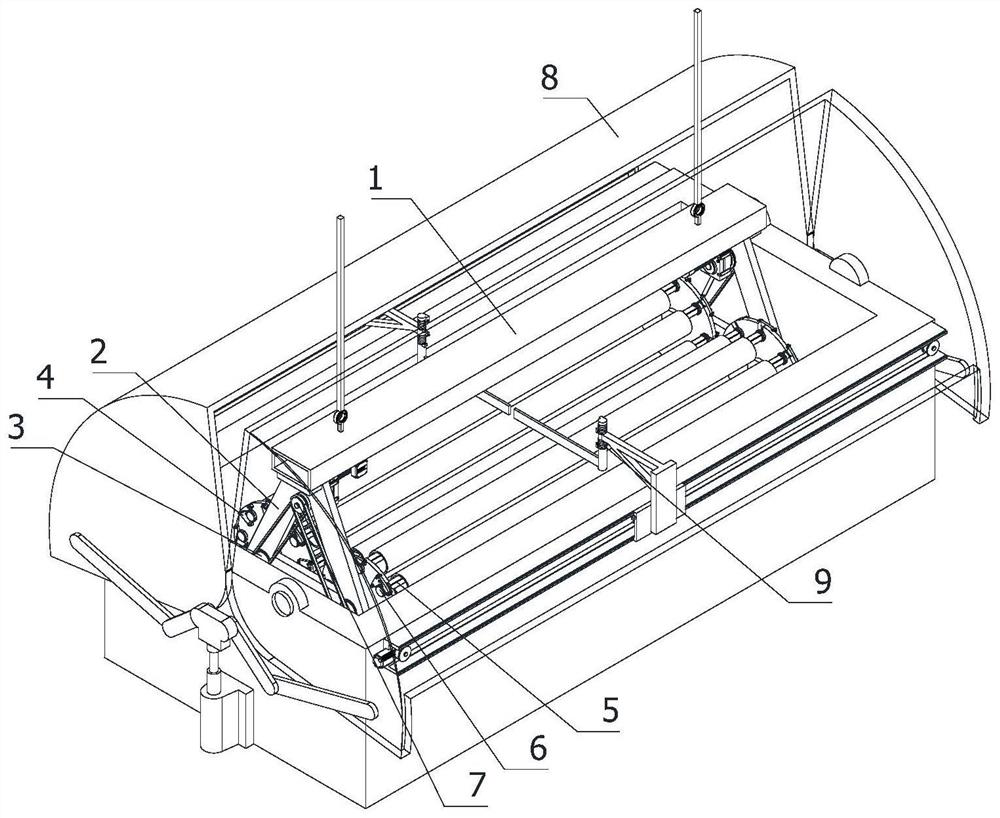

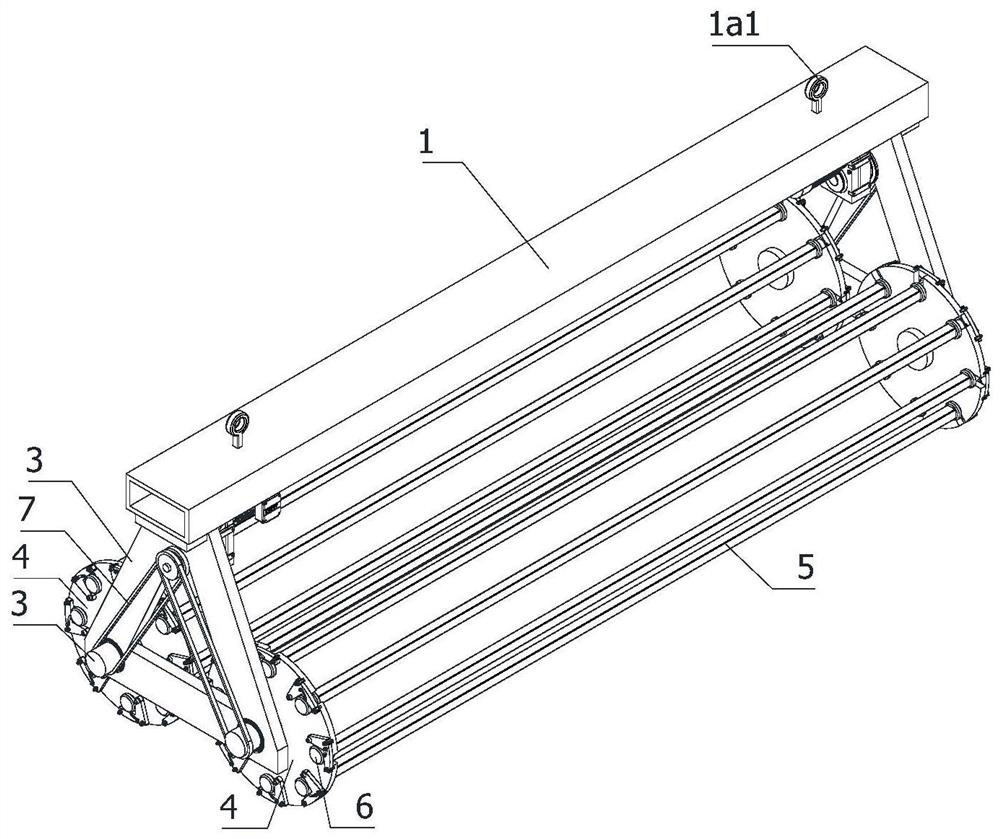

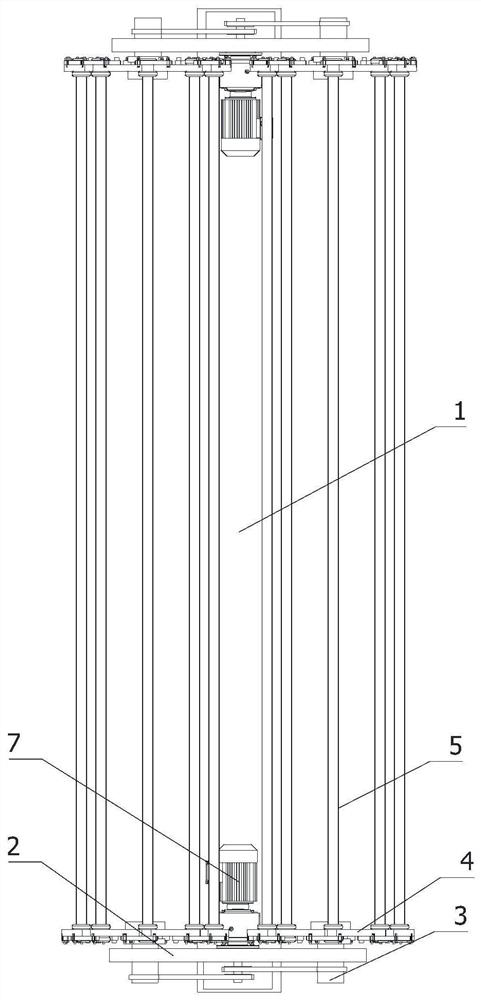

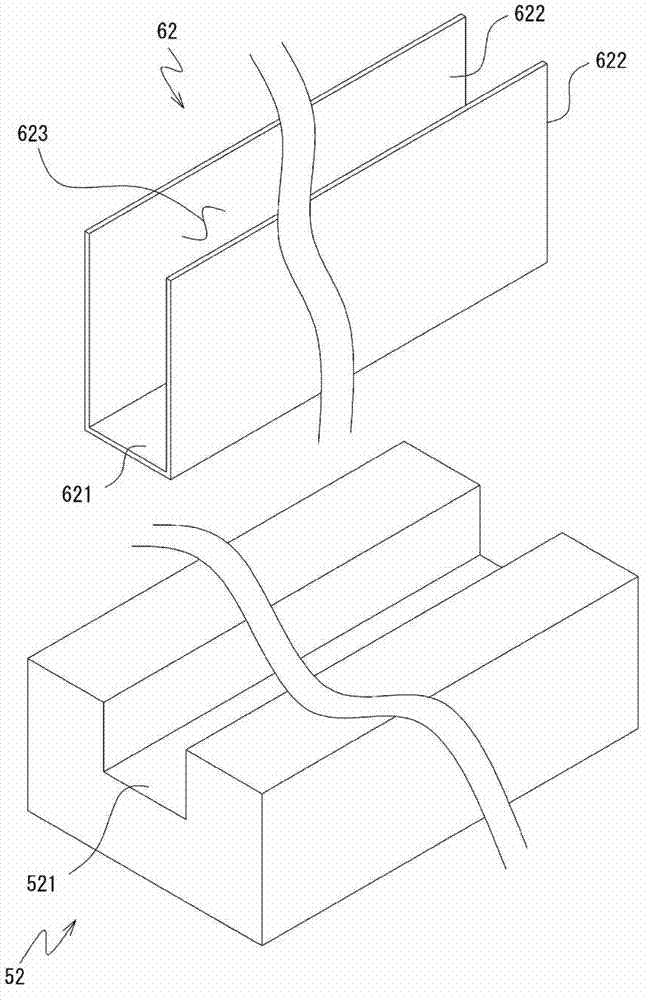

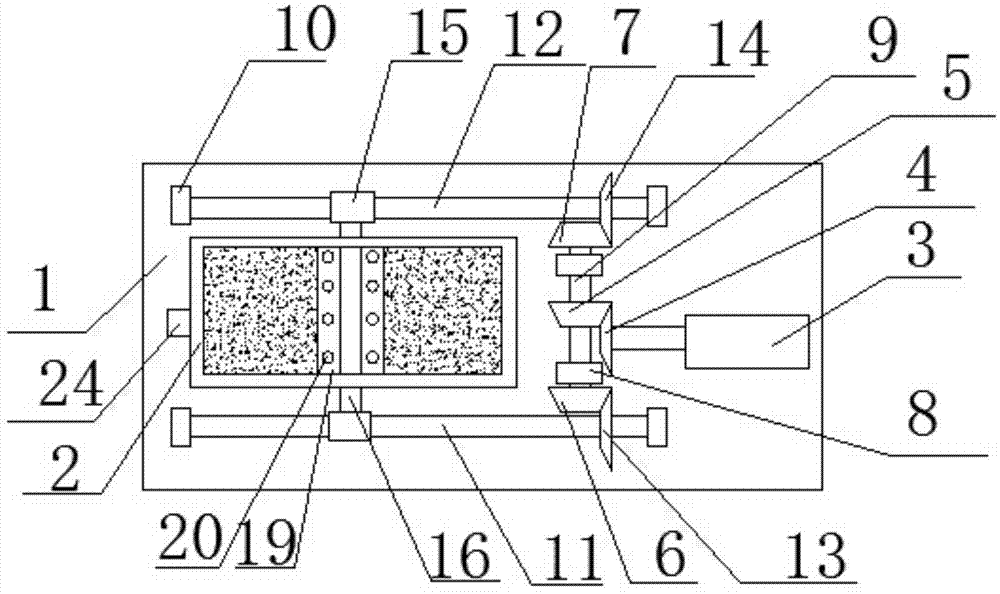

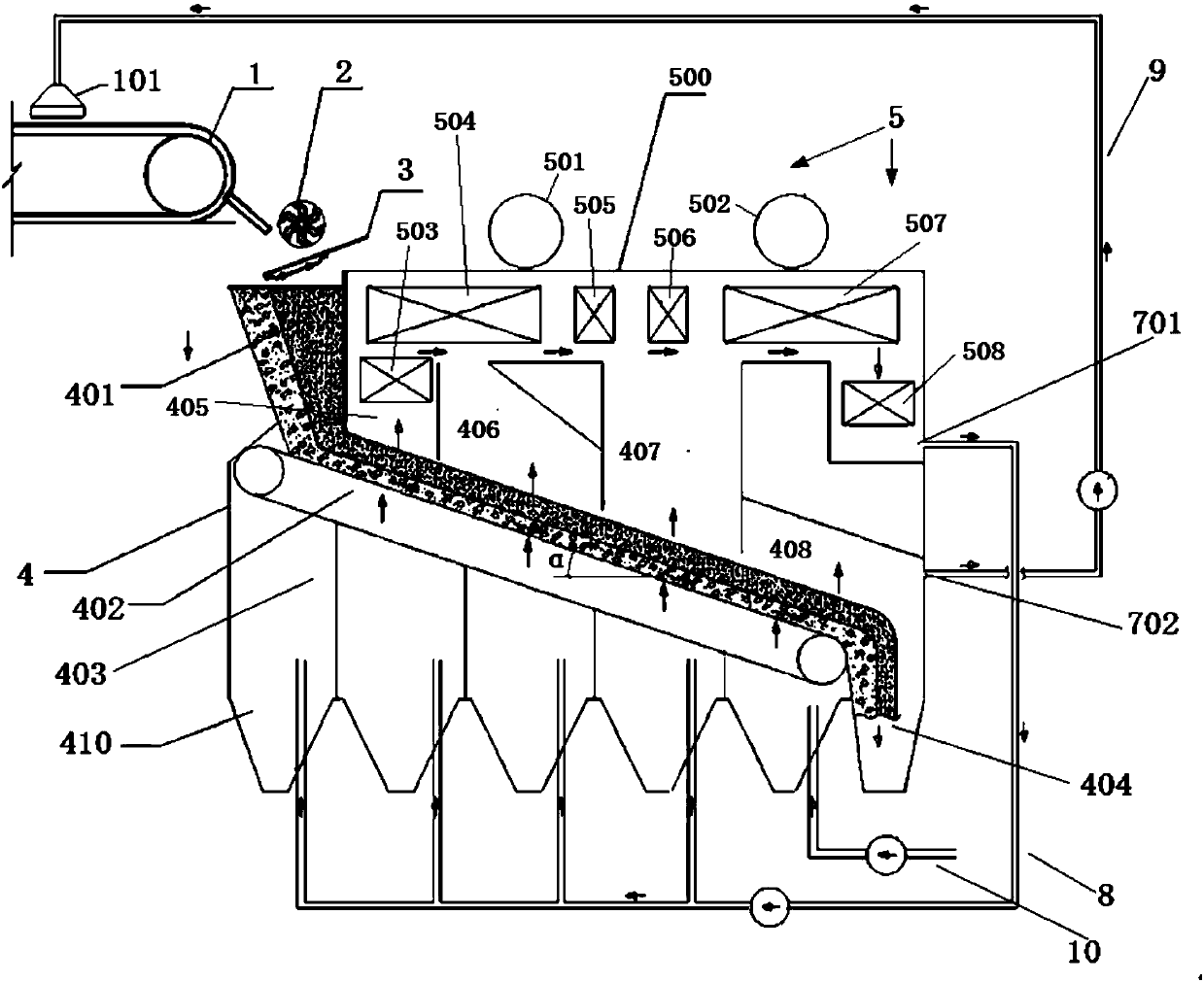

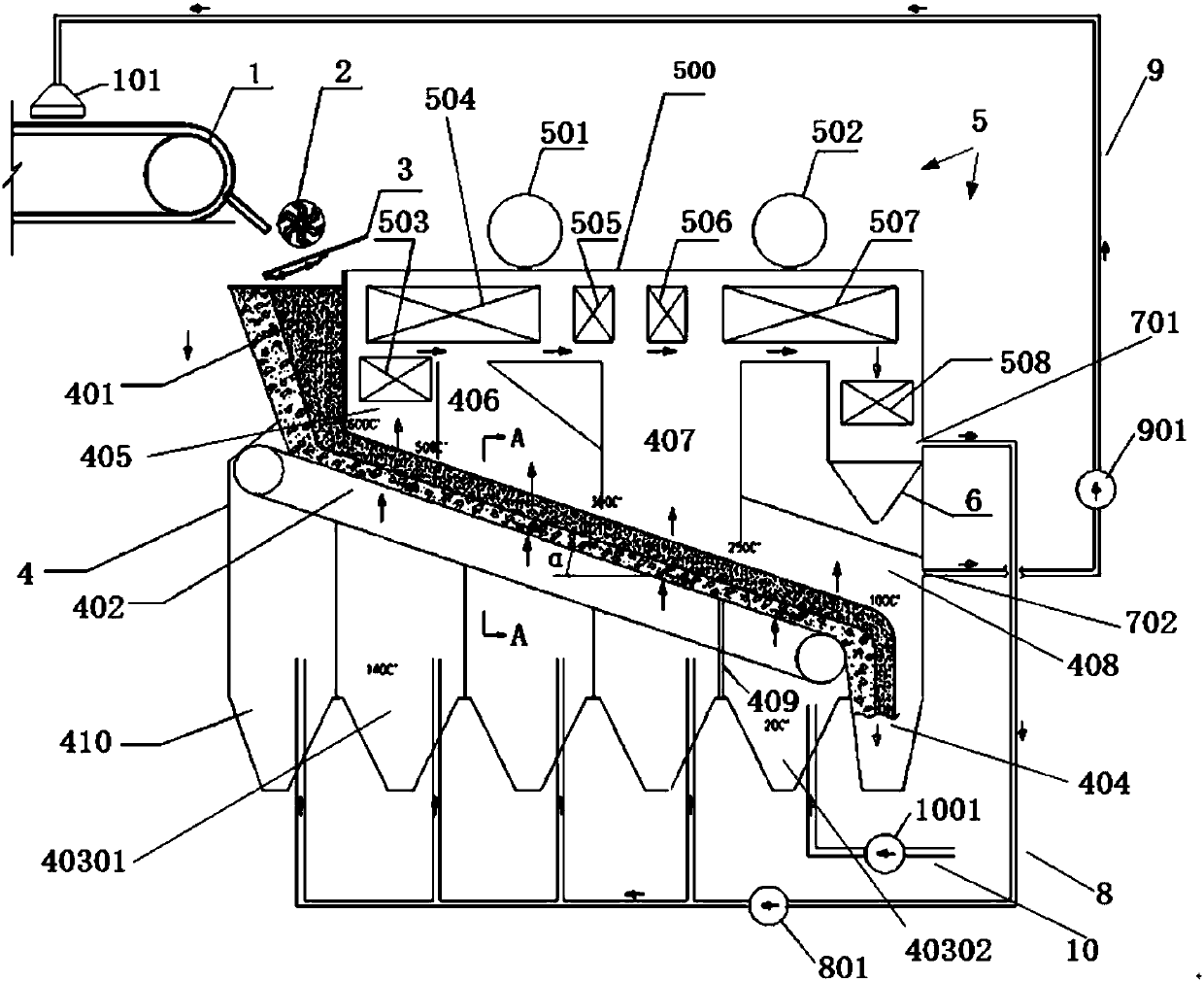

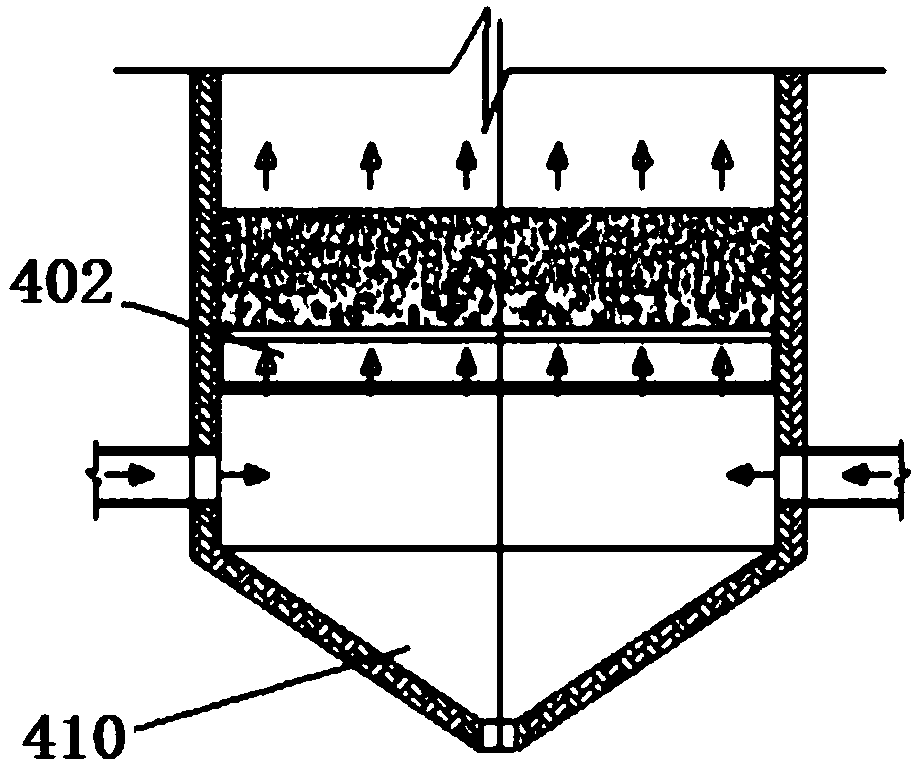

Sintering ore grate furnace cooling and waste heat utilization device and waste heat utilization method

PendingCN107796226ANo pollution in the processOvercome congenital deficienciesHandling discharged materialWaste heat treatmentEngineeringAir blower

The invention relates to a sintering ore grate furnace cooling and waste heat utilization device and waste heat utilization method. The device is sequentially provided with a sintering machine (1), acrusher (2), a hot screen (3) and a grate furnace (4). The grate furnace (4) comprises a feeding opening (401), a fire grate (402), air inlet cavities (403) and a discharging opening (404). High-temperature waste gas above the fire grate is recycled to be utilized through the waste heat utilization device, the utilized waste gas enters the air inlet cavities below the fire grate or an air cover ofthe sintering machine, and a cycle is formed. According to the device and waste heat utilization method, the problems of cooling machine air leaking, waste gas waste heat resource waste and environment pollution in the prior art can be solved, the problem of high power consumption of a vertical tank type cooling air blower can be reduced, and total utilization of sintering ore waste gas waste heat resources can be achieved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Casting Method of Ductile Iron Steering Knuckle

The invention discloses a casting method of a steering knuckle of nodular cast iron. The casting method comprises a mold manufacturing step, a sand mold manufacturing step and a pouring molding step, wherein the steering knuckle is vertically arranged, a thick part of a steering knuckle casting is arranged at the upper part, a thin-walled part of the steering knuckle casting is arranged at the lower part; a pouring system of the steering knuckle casting is divided into a pouring cup, a cross pouring gate and a straight pouring gate, the cross pouring gate is connected to the lower part of the pouring cup, the straight pouring gate is connected to the lower part of the cross pouring gate, and a scum riser is arranged at the bottom end of the straight pouring gate; the side wall of the straight pouring gate is connected with a first inner pouring gate, a second inner pouring gate and a third inner pouring gate from top to bottom; the steering knuckle casting is further provided with a hot riser, a cold riser and exhausting pieces; the sectional area ratio of each component of the casting is that F(straight pouring gate):F(cross pouring gate):F(inner pouring gates) is equal to 1:(1.2-1.4):(1.35-1.5); the casting is obtained by controlling the pouring temperature at 1370-1410 DEG C and carrying out pouring for 5-10 seconds. The casting method has the advantages that pouring speed is high, the defects such as shrinkage porosity, shrinkage cavity and the like cannot easily occur, and the casting is high in production efficiency, low in rejection rate and excellent in mechanical property.

Owner:宁波强盛机械模具有限公司

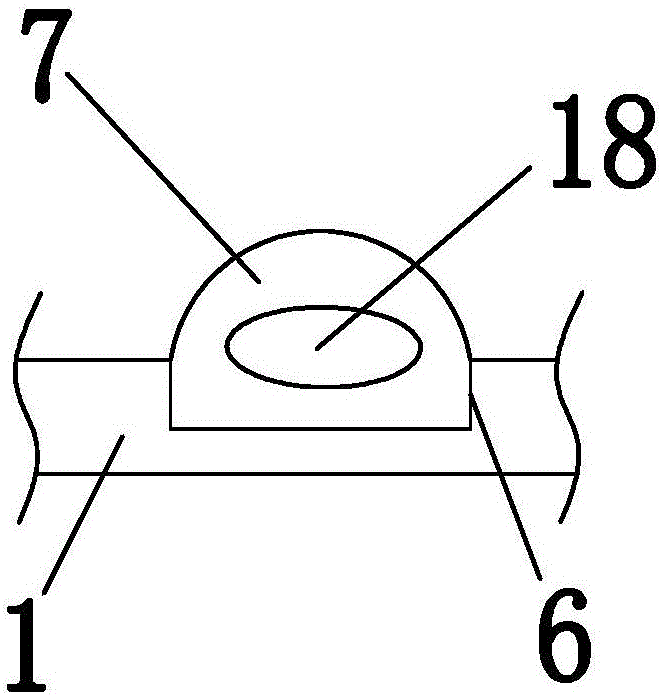

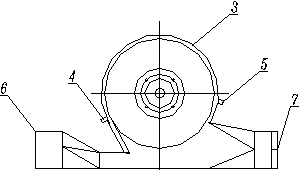

Counter-blowing type hot-cutting hood with cooling effect

The invention discloses a counter-blowing type hot-cutting hood with a cooling effect and relates to the technical field of mechanical equipment. A first round rabbet (1) is formed in one side of a hood body (3); a second round rabbet (2) is formed in the other side of the hood body (3); water inlet pipe joint (4) and a water outlet pipe joint (5) are arranged on two sides of the periphery of the hood body (3); a high-pressure fan blowing-in joint pipe (6) is arranged at one end of the lower part of the hood body (3); a discharging pipeline (7) is arranged at the other end of the lower part of the hood body (3); the high-pressure fan blowing-in joint pipe (6) is communicated with the discharging pipeline (7). The counter-blowing type hot-cutting hood has the beneficial effects that a material bonding problem is solved, and an inner cavity of the hot-cutting hood is not prone to block; the hot-cutting hood is simple in structure, convenient to use and operate and easy to air and cool, the time-saving and labor-saving effects are achieved, and the production efficiency is improved.

Owner:江苏鸿云翔橡塑机械有限公司

Thermal insulation table cover

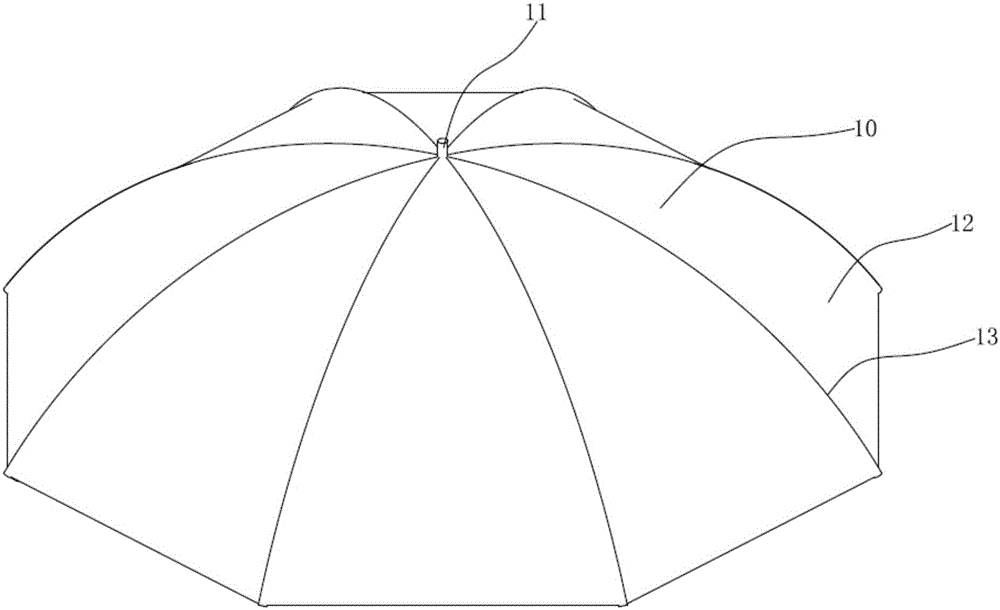

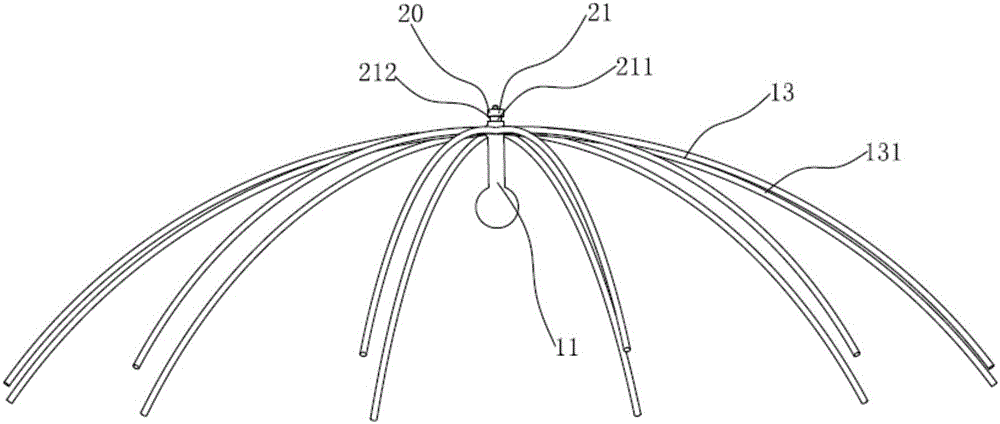

InactiveCN105662081AGood insulation environmentNot easy to coolTable equipmentsElectricityLife quality

The invention discloses a thermal insulation table cover, which comprises an umbrella-shaped cover and a temperature regulation control system, wherein the cover can be unfolded and folded; the temperature regulation control system is arranged on the cover; the cover comprises cover cloth, a bone bracket and a central column, wherein the bone bracket is used for supporting the cover cloth; the central column passes through the cover cloth and the bone bracket to be arranged at the center to extend to two sides; the cover cloth covers the bone bracket; the temperature regulation control system arranged on the central column is electrically connected with the cover cloth; the temperature regulation control system controls the cover cloth to generate heat. Since the cover cloth which can generate heat is adopted to cause the whole cover cloth to evenly heat and inwards transmit heat, when the cover covers a table, a cavity under the whole cover has an even and good thermal insulation environment, meals under the cover are unlikely to become cold, the life demands of people are met, and the quality of life is improved.

Owner:XIAMEN UNIV OF TECH

Novel electric heat table top structure

InactiveCN103504794AImprove cooling effectEasy to implement and popularizeServing tablesFeetElectrical resistance and conductancePower switching

The invention provides a novel electric heat table top structure. An insulation inner container provided with evenly-arranged heating unit resistance wires is arranged under a table top. The resistance wires are wrapped by complete insulation sleeves. The two ends of each resistance wire are respectively connected with a power switch and a plug through wires, and accordingly the plug is connected to a power source, the power switch is turned on and the heating unit resistance wires under the table top can emit heat. The novel electric heat table top structure has the advantages that even in severe cold winter, cooked food placed on the warm table top is not prone to cooling, and accordingly the warm cooked food eaten by people in the cold winter is beneficial to health; the novel electric heat table top structure is simple in structure, good in use effect and quite easy to implement and popularize and is a good product convenient to use.

Owner:XUZHOU CONTENT TRANSMISSION TECH

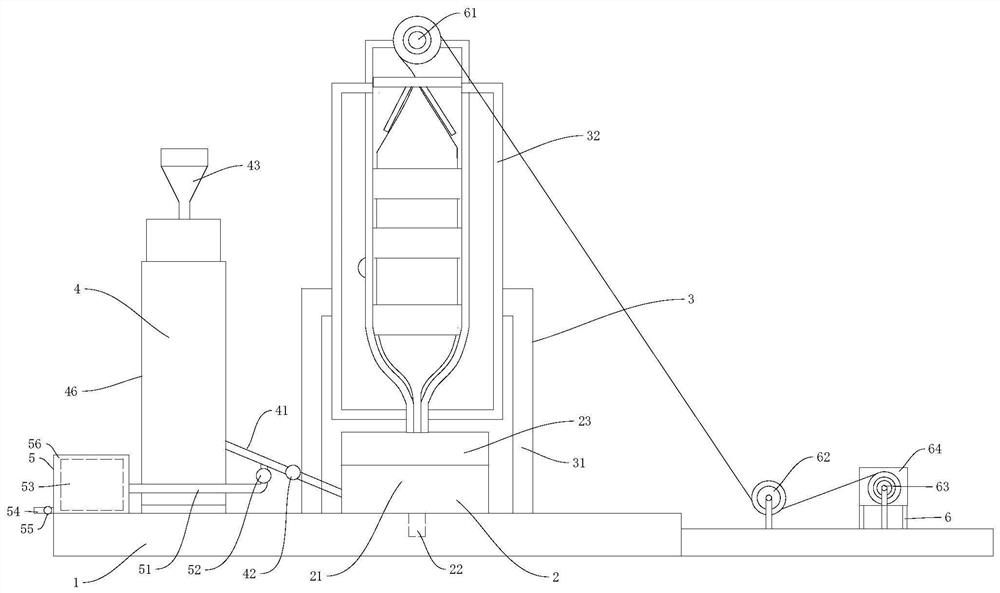

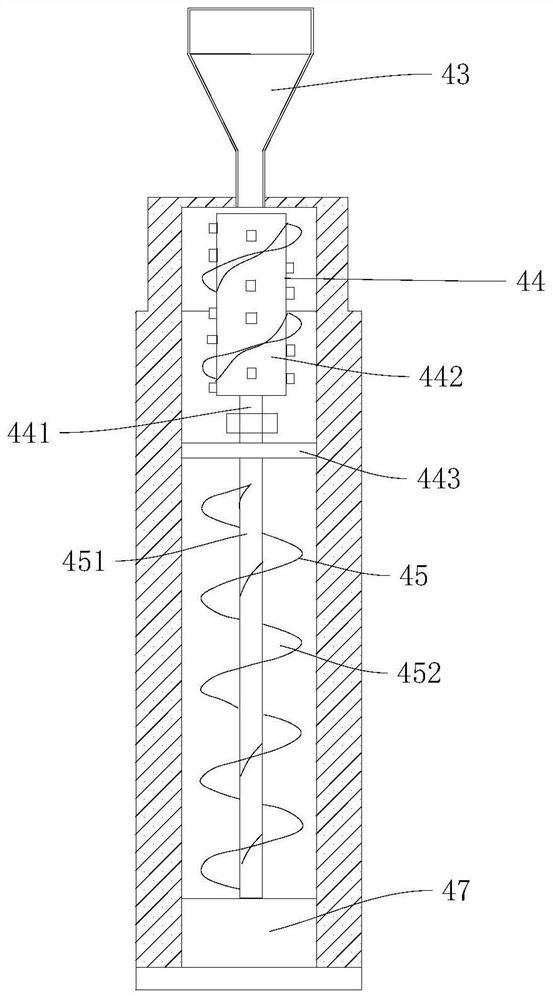

Degradable environment-friendly PE film blowing equipment for shoe and clothing packaging

The invention discloses degradable environment-friendly PE (polyethylene) film blowing equipment for shoe and clothing packaging. The equipment comprises a base, a box body arranged on the base, a support frame arranged on the base, an extruder arranged on the base, a recycling box connected with the extruder and a film rolling mechanism, a film blowing machine head, an air inlet end and a cooling air ring are arranged on the box body, and the support frame is arranged on the outer side of the box body. The extruder is provided with a conveying pipe connected with the extruder and the film blowing machine head, the recycling box is provided with a recycling pipe connected to a conveying pipe, the film rolling mechanism comprises a first film rolling roller, a second film rolling roller, a third film rolling roller and a first driving device, the first film rolling roller is arranged on the top of the supporting frame, and the second film rolling roller and the third film rolling roller are arranged on one side of the base. The third film rolling roller is connected with a first driving device. According to the invention, the recycling box is arranged, so that the extruded materials of the extruder can be recycled through the recycling box when production is required to be stopped or changed, waste of plastic raw materials is avoided, and the extruded materials in the extruder can be prevented from blocking the extruder after shutdown.

Owner:BOA SHEN PAPER & PLASTIC PROD

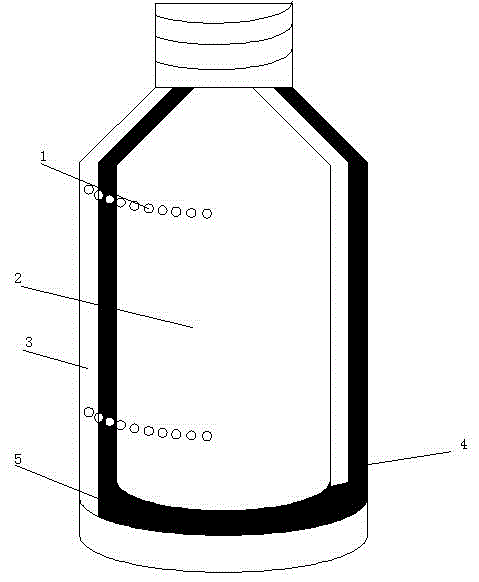

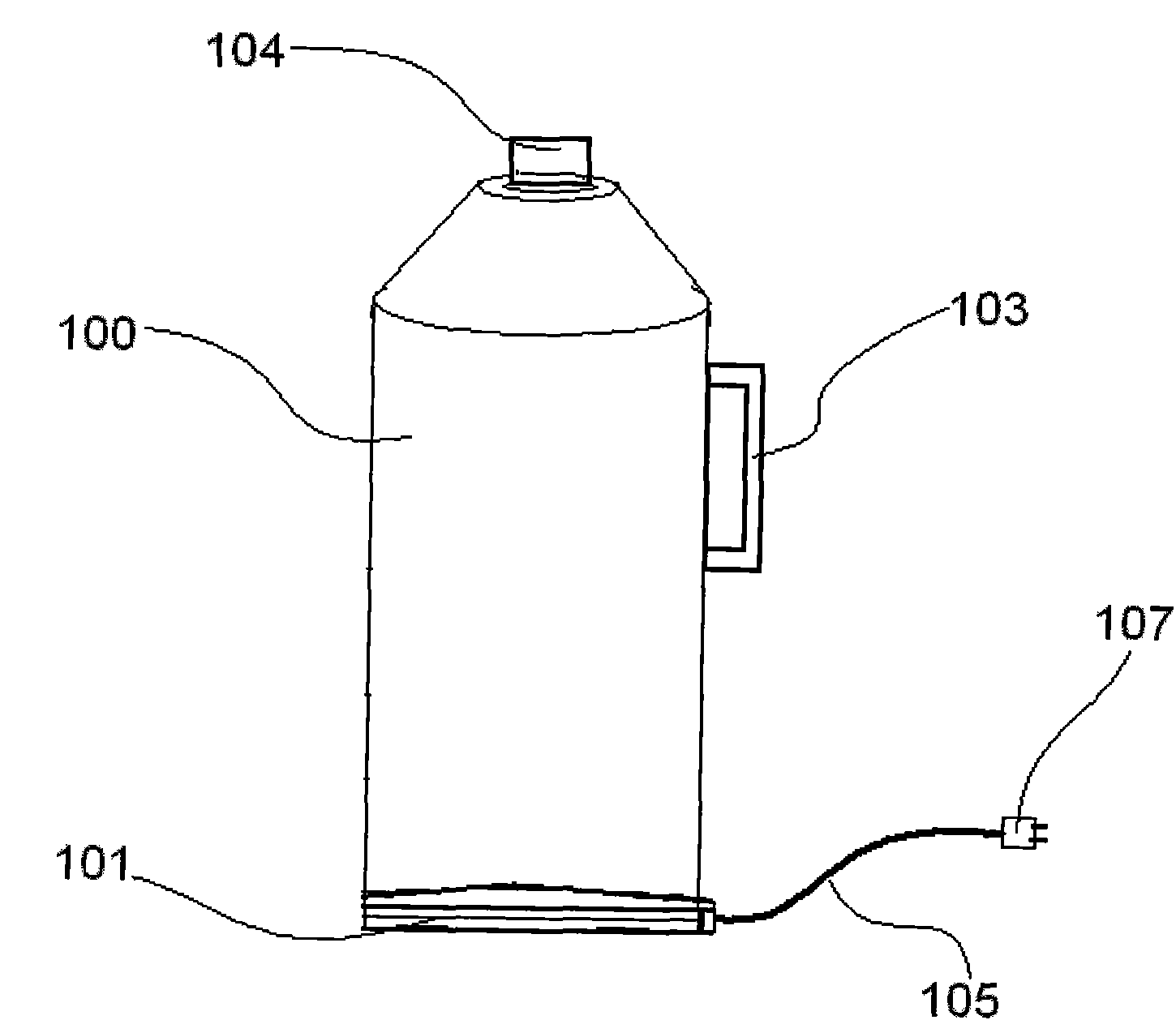

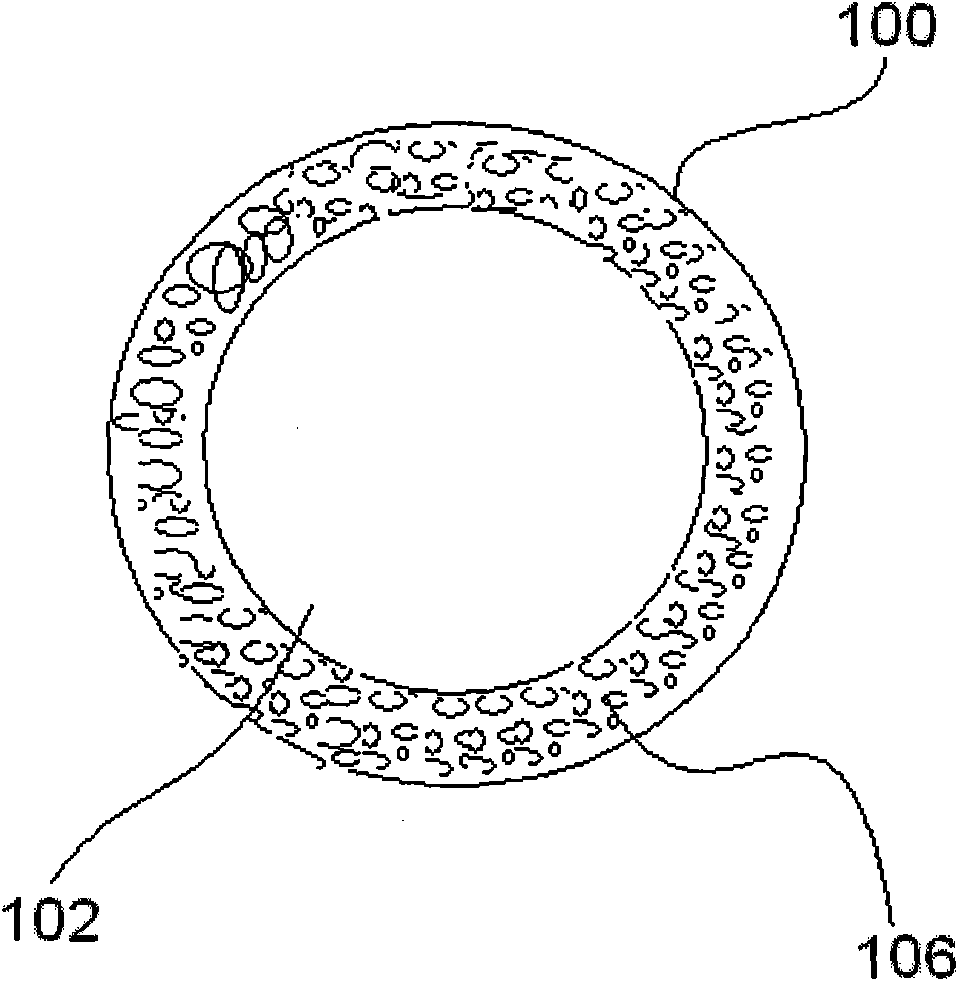

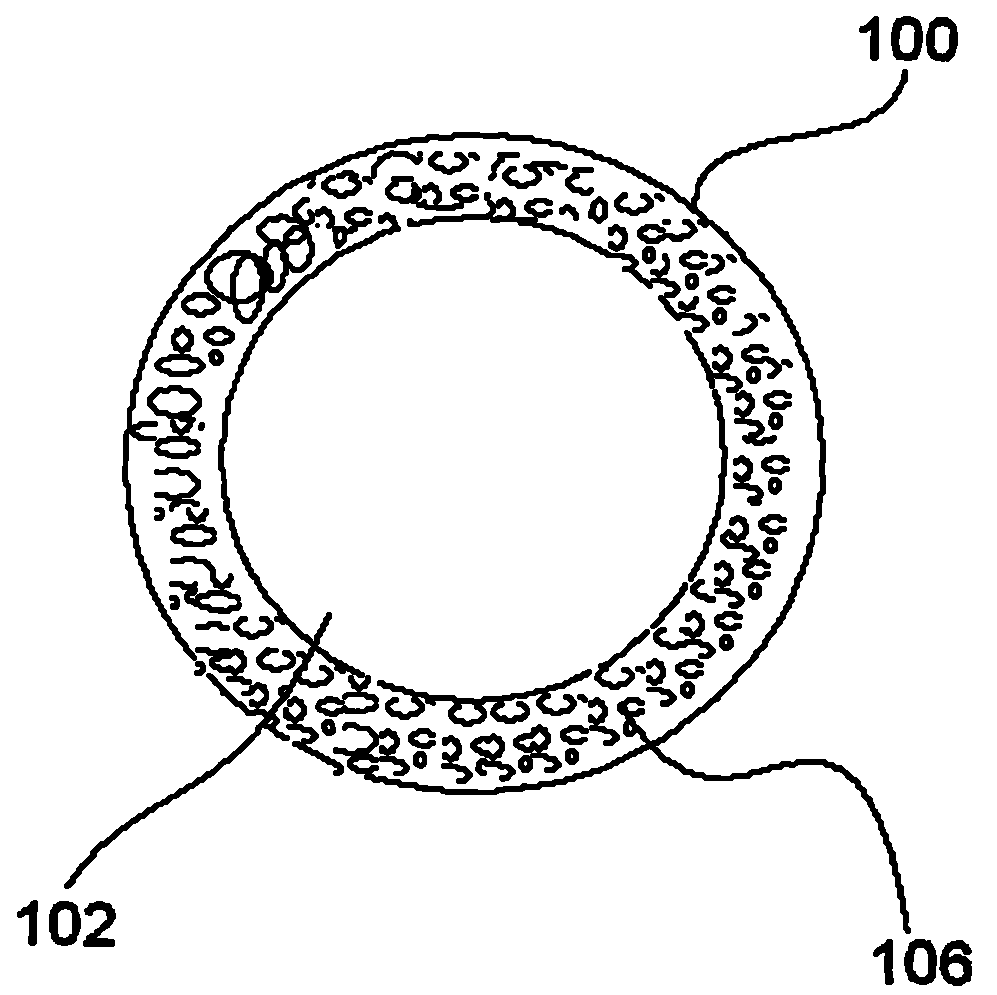

Electric heating bottle with thermal insulation layer

InactiveCN102113820ALow thermal conductivityImprove cooling effectWater-boiling vesselsThermally-insulated vesselsElectricityThermal insulation

The invention discloses an electric heating bottle with a thermal insulation function. The electric heating bottle comprises a bottle body, a heating base and a water storage bladder, wherein a bottle handle and a bottle cover are arranged on the bottle body; the water storage bladder is arranged inside the bottle body; a power line connected with a power supply is arranged on the heating base; the electric heating bottle also comprises a foamed thermal insulation layer; and the foamed thermal insulation layer is arranged between the bottle body and the water storage bladder. Because an interlayer of the electric heating bottle body, which is formed between the bottle body and the water storage bladder is filled with an expandable polystyrene foam material which forms a great quantity of independent hermetic bubbles, the heat conduction property of air is small and the air is sealed in the bubbles and cannot form convection, therefore, the electric heating bottle with the thermal insulation function, provided by the invention, has excellent heat insulation property and higher electric heating speed is higher, ensures that boiled water is not easy to cool, and is beneficial to saving electricity and energy.

Owner:THE SECOND FOREIGN LANGUAGE SCHOOL AFFILIATED TO SHANGHAI NORMAL UNIV

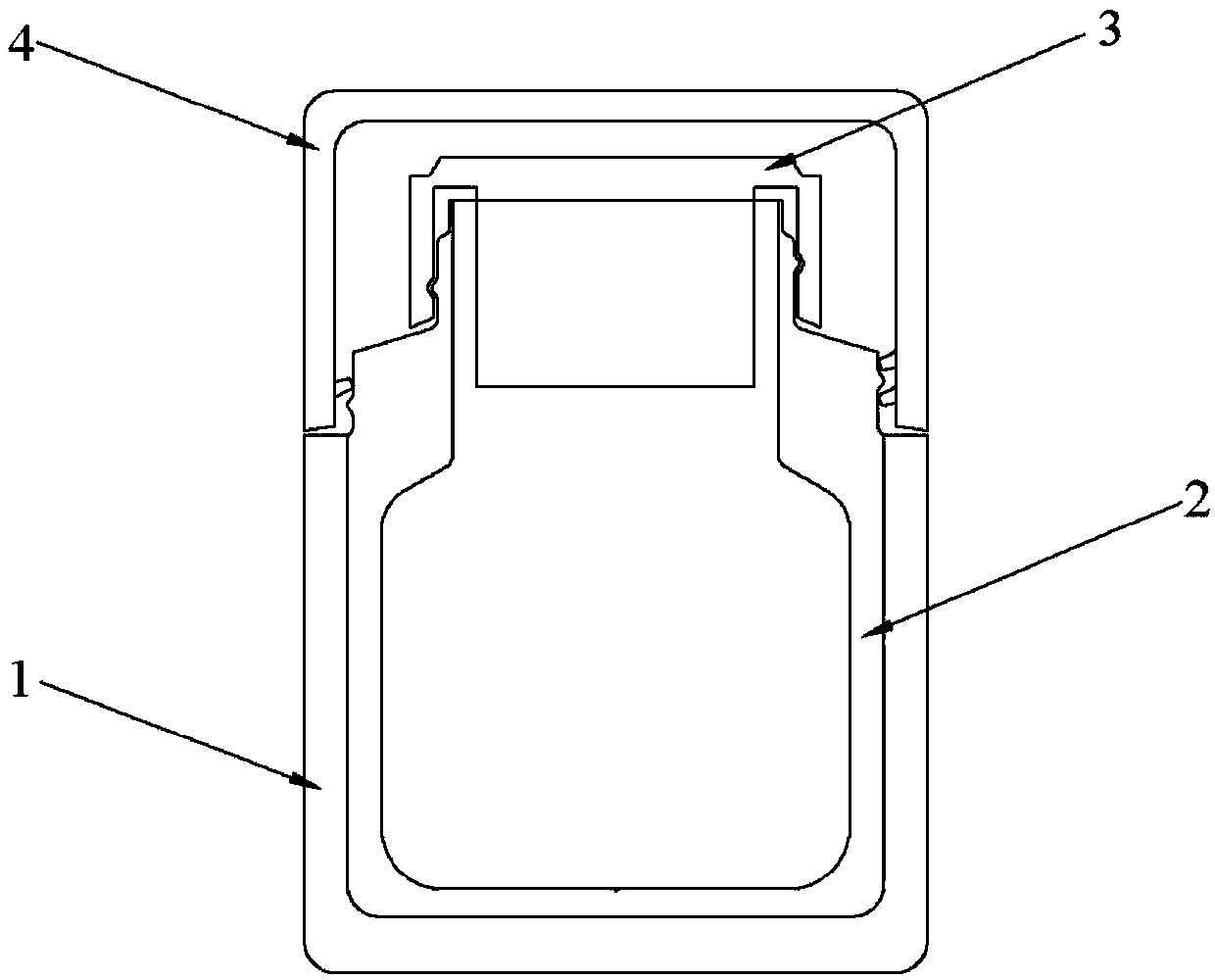

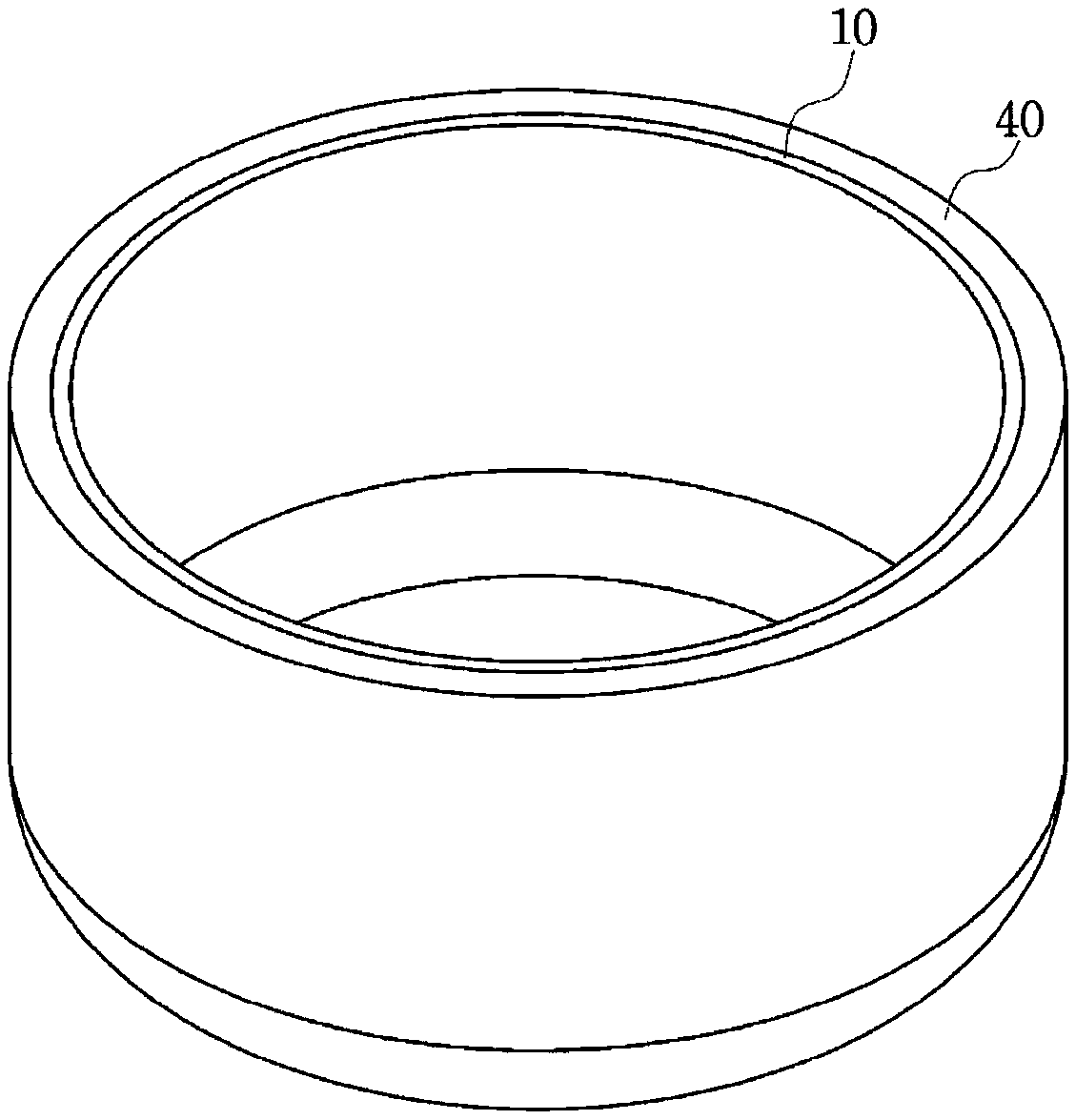

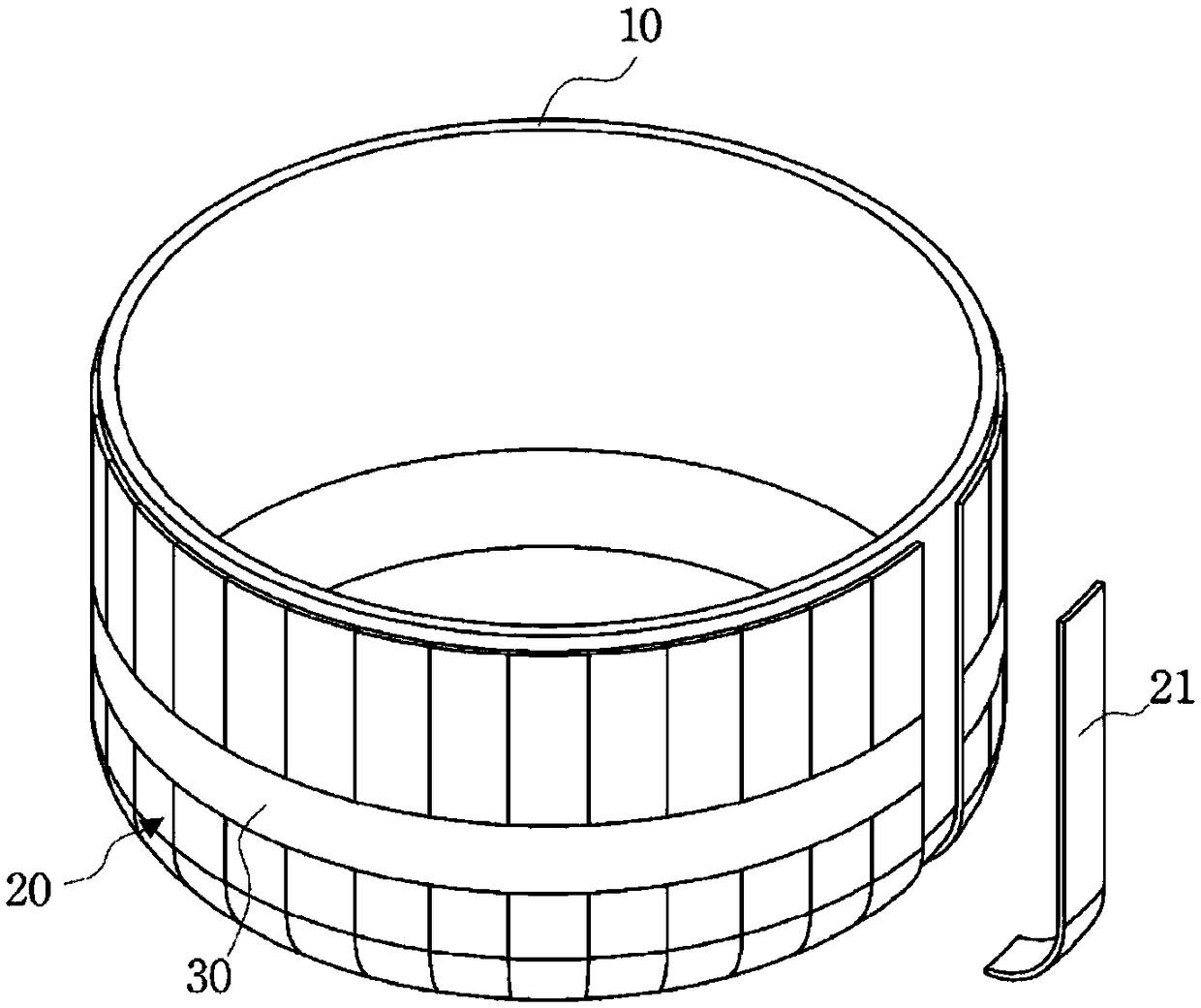

Novel double-layer vacuum cup

InactiveCN110150932AImprove cooling effectImprove insulation effectDomestic vesselsDrinking vesselsWhole bodyEngineering

The invention discloses a novel double-layer vacuum cup. The novel double-layer vacuum cup comprises a cup body constituted by cup walls, and a cup lid constituted by lid walls; the cup body comprisesan outer cup body (1) with the corresponding cup wall being vacuum in the whole body and an inner cup body (2) with the corresponding cup wall being vacuum in the whole body, and the cup wall constituting the outer cup body is made of a phase-change material; the inner cup body is enveloped in the outer cup body through a lower section of the inner cup body; the cup lid comprises an inner cup lidbody (3), and an outer cup lid body (4) with the corresponding lid wall being vacuum in the whole body; and the inner cup lid body is buckled and fastened on a cup rabbet of the inner cup body, and the outer cup lid body is fastened on an upper section of a cup main body of the inner cup body in an interference mode. Compared with the prior art, an interior and exterior separated structure is adopted, the heat insulation effect is good, and the service life is long.

Owner:浙江朗骏工贸有限公司 +1

Outdoor cookware using heat pipes

The present invention relates to outdoor cookware, using heat pipes, comprising: an inner receptacle for accommodating contents; heat pipes which are attached to the outer lateral side of the inner receptacle; and an external receptacle which is attached to the outer lateral side of the heat pipes and of which the center part of the lower side is raised and attached to the bottom side of the innerreceptacle. Therefore, since the heat from a burner flame is quickly transmitted to the lateral side of the inner receptacle by means of the heat pipes, the floor side and the lateral side of the outdoor cookware is evenly heated and the contents are evenly cooked.

Owner:에이테크주식회사

Arrangement structure of evaporated fuel treatment device of saddle-ride-type vehicle

ActiveCN102030059BNot easy to coolCompact configurationNon-fuel substance addition to fuelFuel tanksFuel treatmentAutomotive engineering

To enable mounting of a canister on a vehicle body in a compact manner while favorably ensuring the charge performance and the purge performance of the canister in the arrangement structure of an evaporated fuel treatment device of a saddle-ride-type vehicle. An under cowl (26) is provided at a front side of a lower portion of an engine (14), and a canister (41) is arranged below the engine (14) and inside the under cowl (26).

Owner:HONDA MOTOR CO LTD

Low-foam high-efficiency aluminum alloy wire-drawing liquid

ActiveCN104046454ANot easy to foamReduce lubricationLubricant compositionEpoxyEnvironmental resistance

The invention relates to a wire-drawing liquid and especially relates to a low-foam high-efficiency aluminum alloy wire-drawing liquid. The low-foam high-efficiency aluminum alloy wire-drawing liquid is prepared from 30-32 parts by weight of soybean oil, 10-12 parts by weight of epoxy fatty acid methyl ester, 8-10 parts by weight of neopentylene glycol, 1-2 parts by weight of dodecyl dimethyl benzyl ammonium chloride, 4-5 parts by weight of alkylphenol ethoxylate, 1-2 parts by weight of rosemary extract, 4-5 parts by weight of dimeric linoleic acid, 3-5 parts by weight of vulcanized cottonseed oil, 3-4 parts by weight of aluminum stearate, 1-3 parts by weight of mannitol, 4-5 parts by weight of an assistant and 800-1000 parts by weight of deionized water. The low-foam high-efficiency aluminum alloy wire-drawing liquid utilizes an aluminum stearate-mannitol mixture as an antifoaming agent. Compared with the conventional antifoaming agent, the aluminum stearate-mannitol mixture antifoaming agent has more excellent use performances. Through use of a soybean oil-epoxy fatty acid methyl ester mixture as base oil and the raw materials such as rosemary extract, dimeric linoleic acid and the assistant, the low-foam high-efficiency aluminum alloy wire-drawing liquid has excellent lubrication performances, does not foam easily, has stable emulsion performances, is not demulsified easily, is environmentally friendly, and has temperature resistance and high wire drawing efficiency.

Owner:ANHUI SHUOLI IND

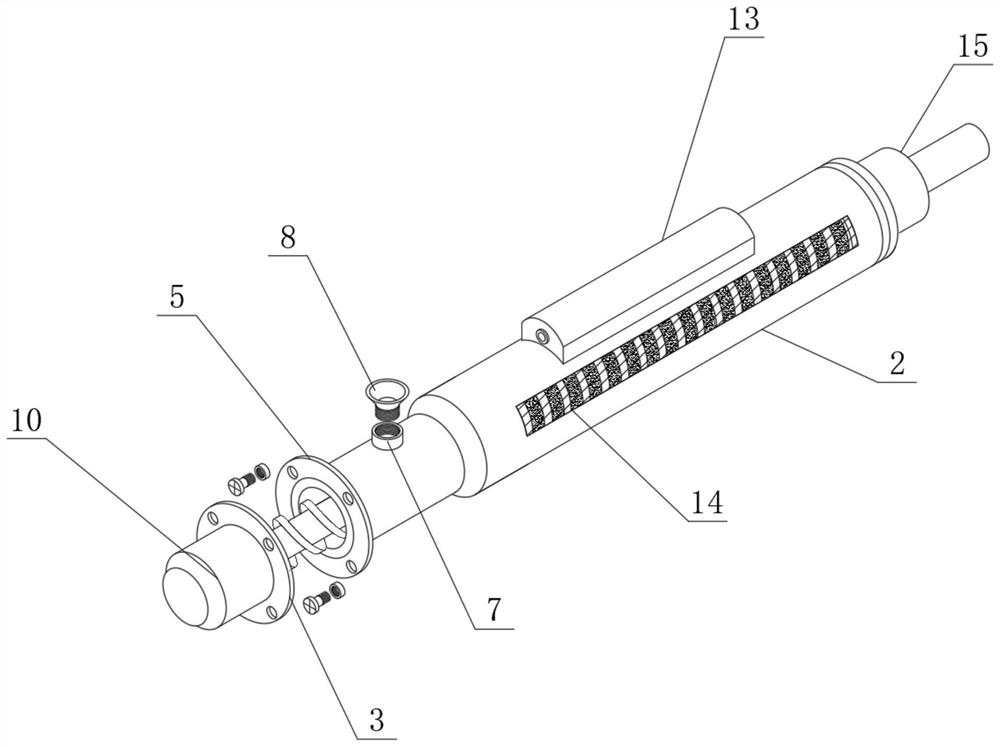

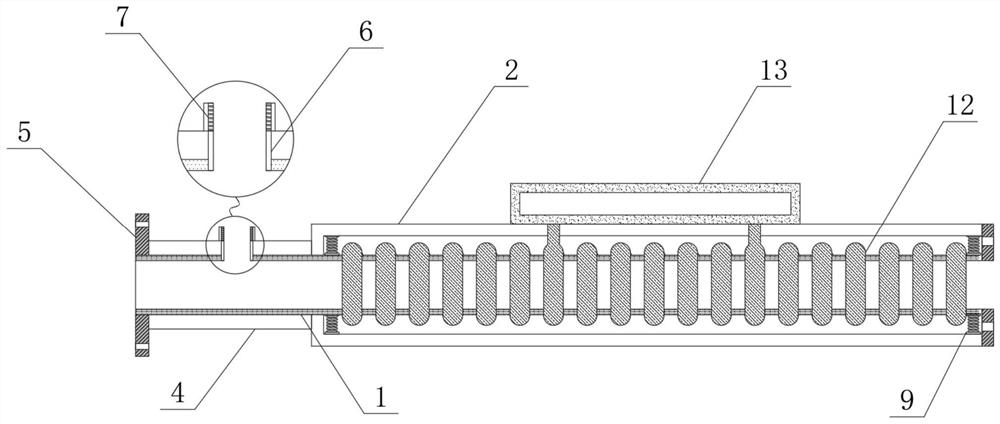

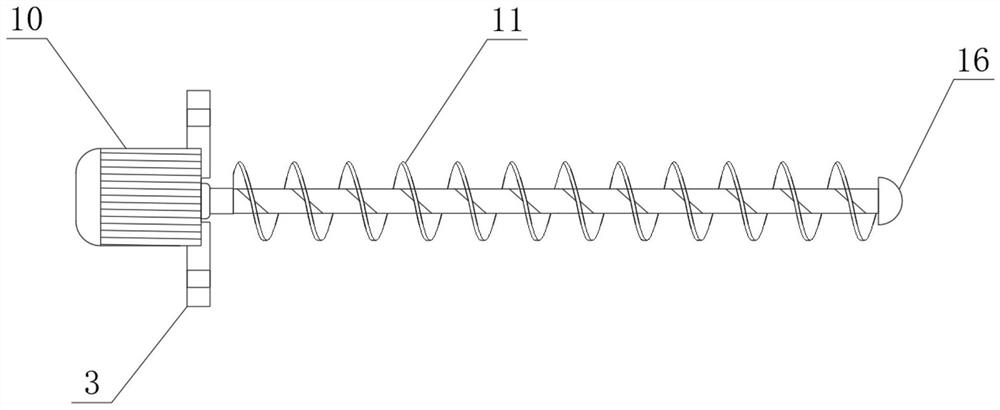

Die-casting machine charging barrel with heating device

The die-casting machine charging barrel with the heating device comprises a material conveying pipe, a sleeve and flanges, a protective pipe is installed on the outer surface of the material conveying pipe, connecting flanges are installed at the front end and the rear end of the material conveying pipe correspondingly, a feeding port is formed in the top end of the material conveying pipe, the feeding port is formed in the protective pipe, and a heating device is arranged in the sleeve. A threaded seat is installed at the top end of the feeding port, and a feeding pipe is installed in the threaded seat in a threaded mode. Through the arrangement of the material conveying pipe, the heating ring is wound on the material conveying pipe, the heating ring is driven to work to heat the material conveying pipe after being electrified through the arrangement of the power supply base, plastic can be injected into the material conveying pipe through the arrangement of the feeding pipe, and after the plastic is injected, through the arrangement of the driving motor and the alloy screw rod, the material conveying pipe is driven to heat the material conveying pipe. After the driving motor is powered on to work, the alloy screw is driven to rotate, and when the alloy screw rotates, friction and mutual movement can be generated between plastic and the inner wall of the machine barrel, the bottom face of the screw groove and the propelling face of the screw flight and between the plastic and the plastic.

Owner:上海胜桀精密机械科技有限公司

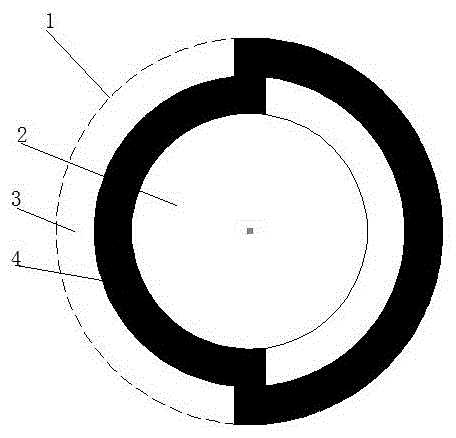

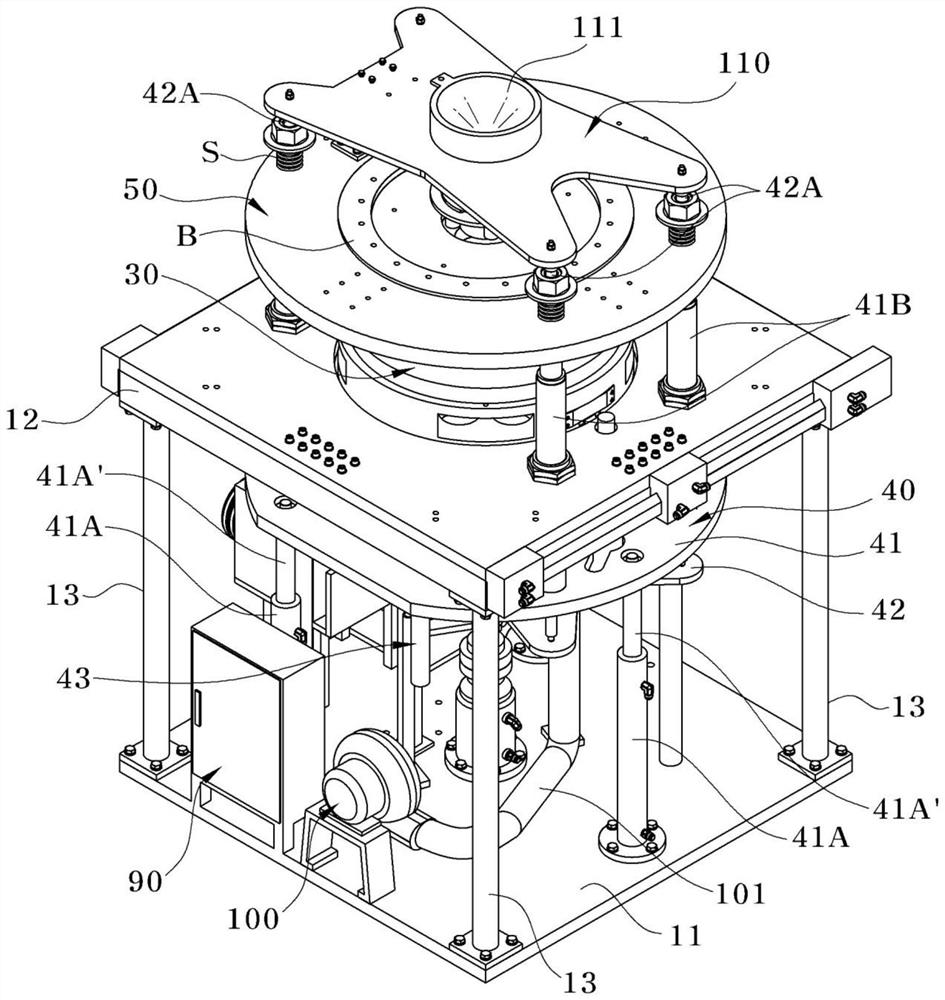

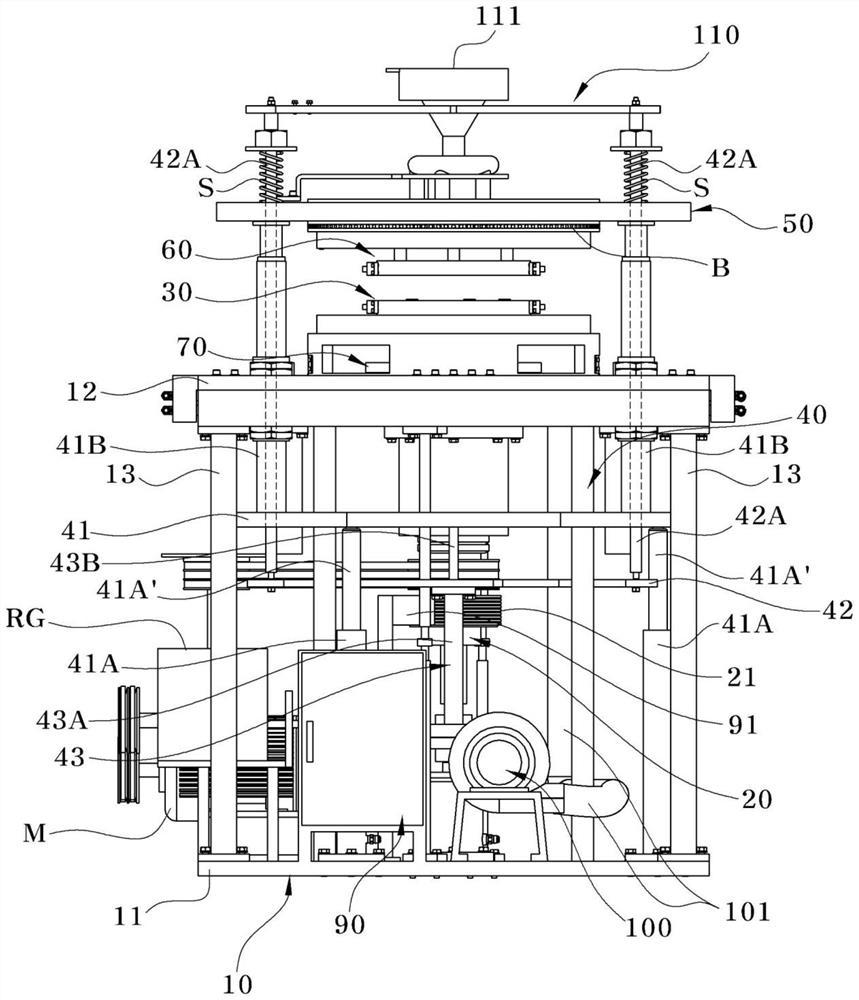

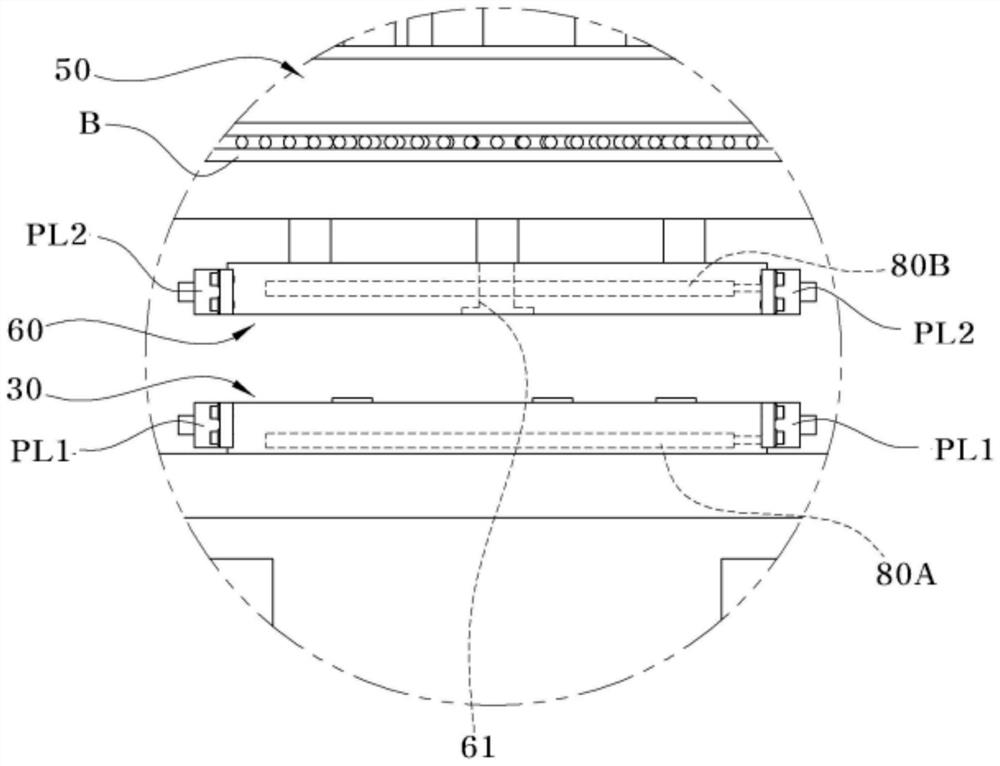

A centrifugal casting device

Owner:新荣株式会社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com