Ultrasound couplant constant temperature heating device and its testing method

An ultrasonic couplant and constant temperature heating technology, which is applied in ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, infrasonic diagnosis, etc., can solve the problems of small amount of heating couplant, high price of heating device, and insufficient scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

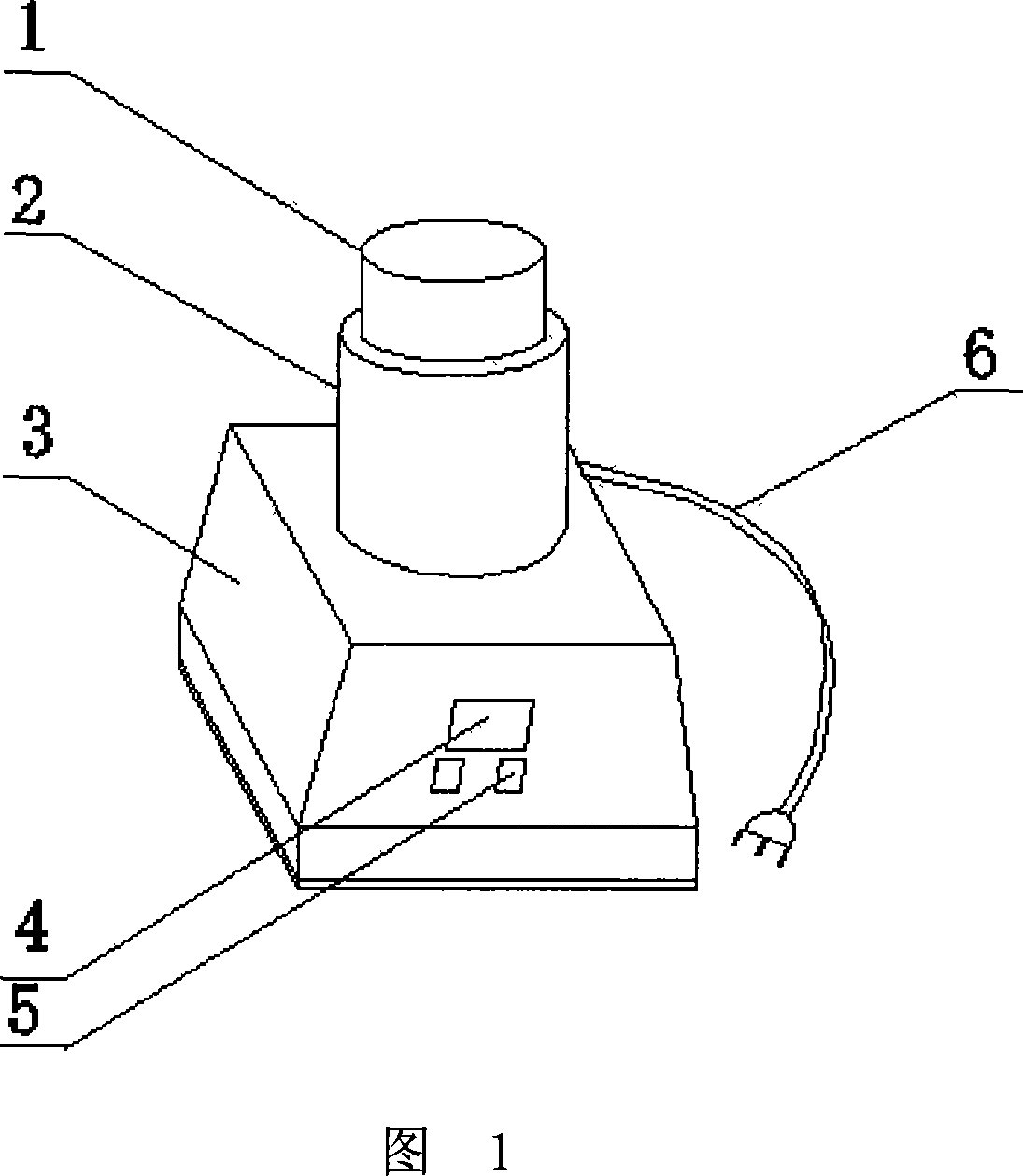

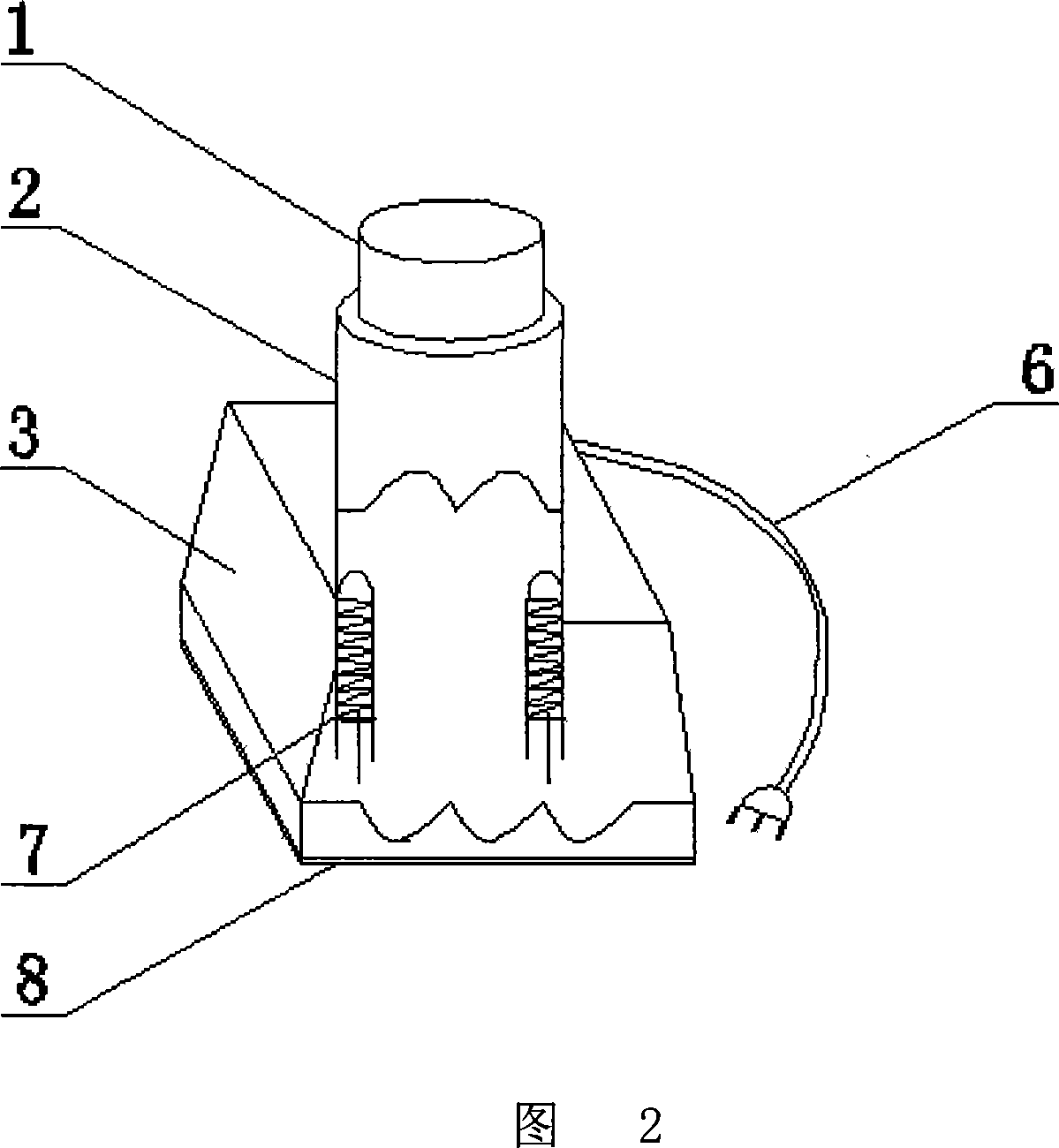

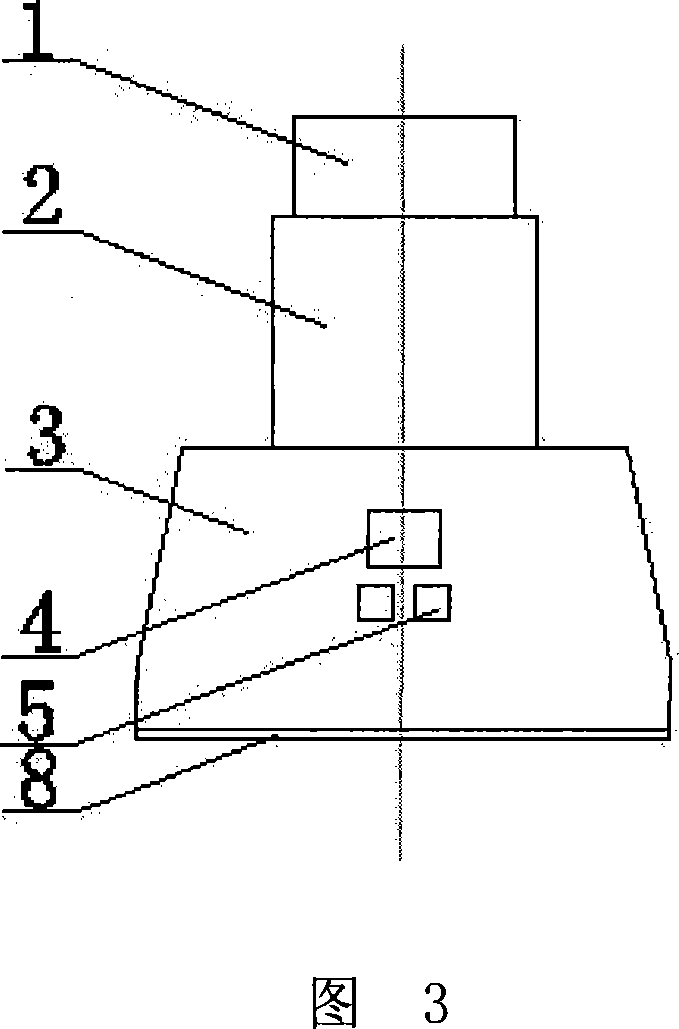

[0033] This heating device adopts a double-cylinder structure, the inner cylinder 1 is a heating conductive material, the outer cylinder 2 is a heat preservation material, the couplant is placed in the inner cylinder 1, and the heat conduction between the inner cylinder 1 and the couplant is used for heating, and the electric heating element 7 is installed. Around the inner cylinder. The electric heating element 7 is placed in the inner wall of the inner cylinder 1, and there are four electric heating elements 7, and the temperature collection is directly applied to the temperature sensor DS18B20 with A / D conversion. The inner cylinder 1 is made of aluminum alloy material.

[0034] Experimental method: Pulse-Width Modulation (PWM) is used for heating. The temperature is directly collected by the temperature sensor DS18B20, processed by the PIC16F877 microprocessor, and controls the four heating elements that have been installed on the inner wall of the thermostatic tank in advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com