Sintering ore grate furnace cooling and waste heat utilization device and waste heat utilization method

A technology of sinter and grate furnace, which is applied in the fields of sinter grate furnace cooling, waste heat recovery device and waste heat utilization, which can solve the waste of waste gas and waste heat resources, reduce energy consumption, avoid air leakage, and increase air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

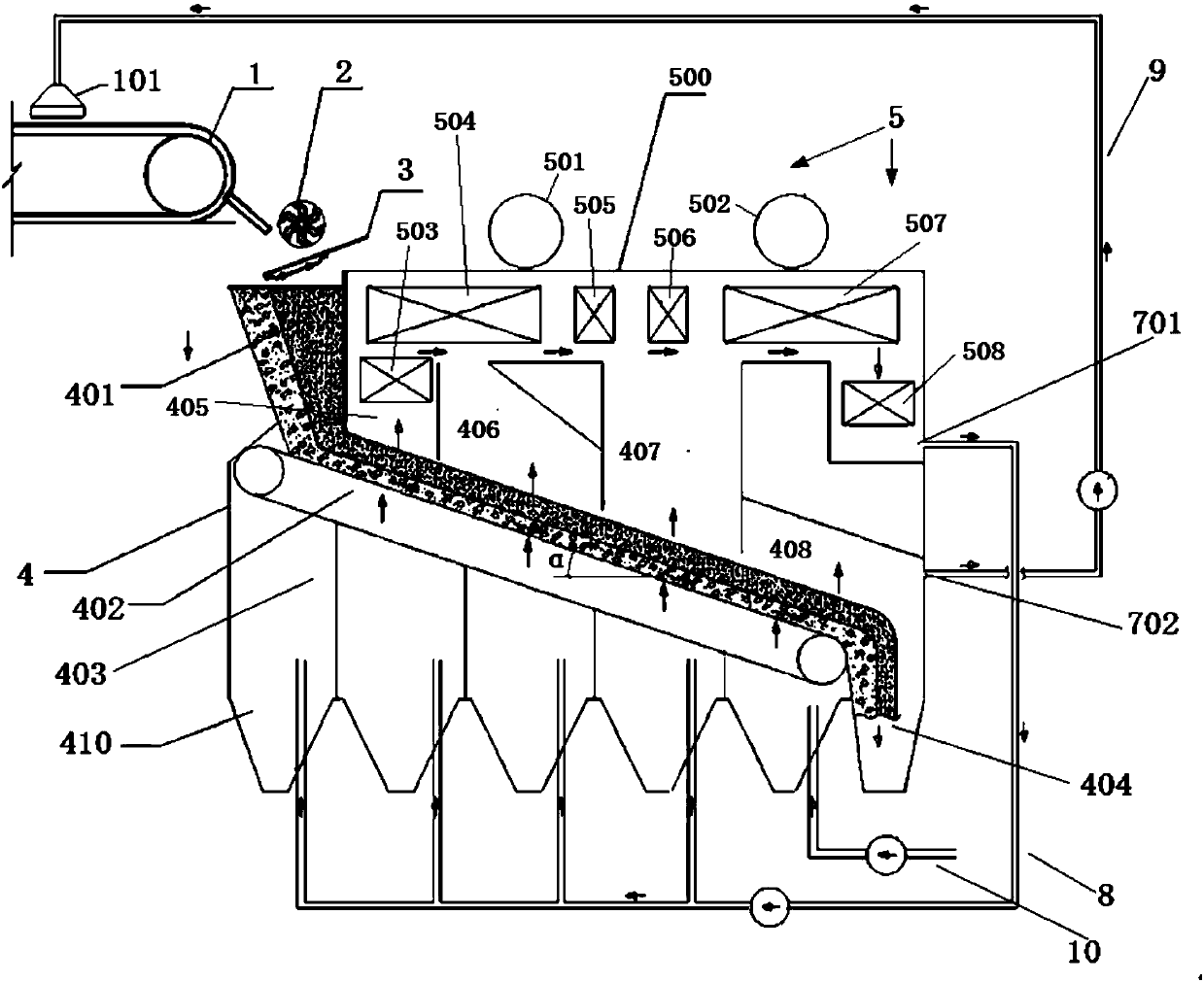

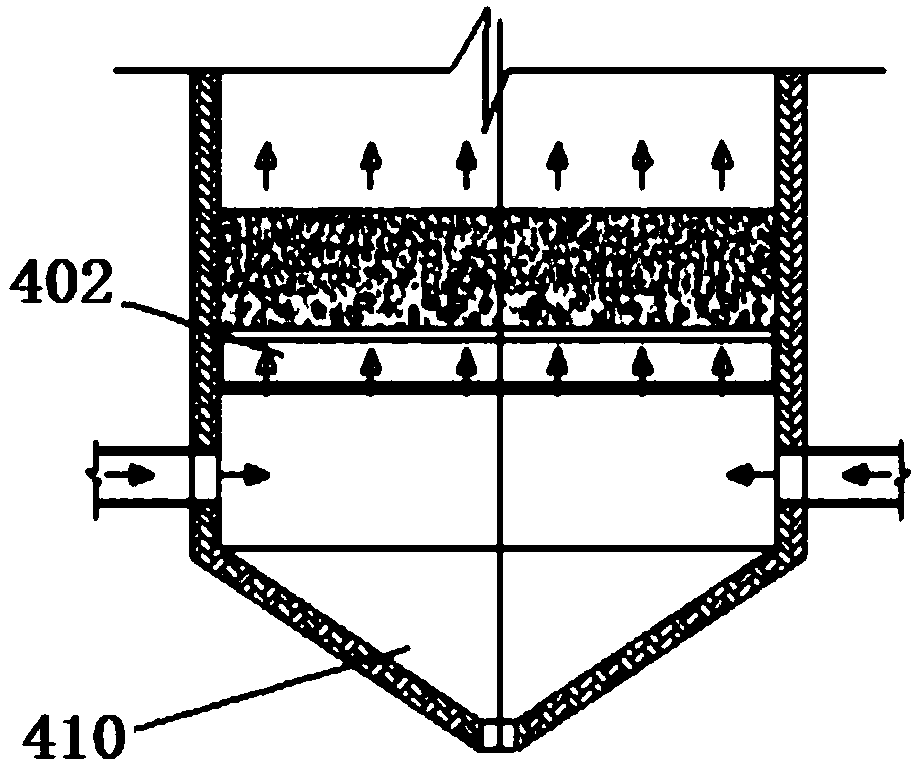

[0079] A sinter grate furnace cooling and waste heat utilization device, the device is sequentially provided with a sintering machine 1, a crusher 2, a hot screen 3, and a grate furnace 4. The grate furnace 4 includes a feed port 401 , a fire grate 402 , an air inlet chamber 403 , and a discharge port 404 . Wherein, the front end of the fire grate 402 is provided with a feed port 401 , and the feed port 401 is connected and communicated with the fire grate 402 . The end of the fire grate 402 is provided with a discharge port 404 , and the discharge port 404 is connected and communicated with the fire grate 402 . The bottom of the fire grate 402 is provided with an air inlet cavity 403 ; the top of the fire grate 402 is provided with a waste heat utilization device 5 . Crusher 2 is a single roll crusher. The grate 402 is a chain grate.

[0080] The top of the grate 402 is divided into four cavities. Along the running direction of the grate, there are first cavity 405 , seco...

Embodiment 2

[0084] Embodiment 1 is repeated, except that a dust collector 6 is provided below the low-parameter economizer 508, and the dust collector 6 is a gravity dust collector.

Embodiment 3

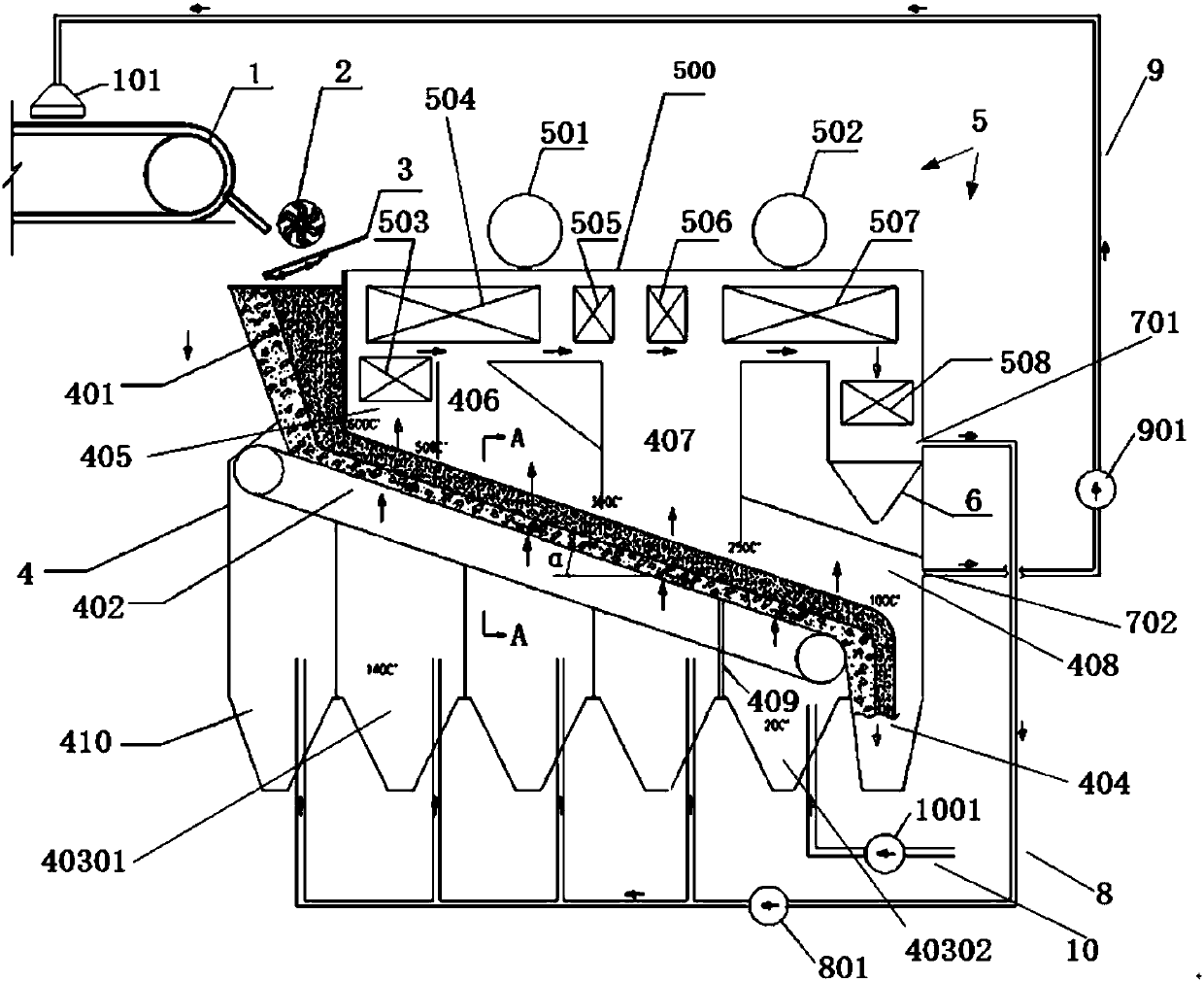

[0086] Embodiment 2 is repeated, except that a partition 409 is provided in the air inlet cavity 403 . The partition 409 divides the air inlet cavity 403 into an exhaust gas inlet 40301 and an air inlet 40302 . The width of the waste gas inlet 40301 accounts for 70% of the entire air inlet cavity 403 .

[0087] The inlet of the first waste gas pipeline 8 is connected to the first high-temperature waste gas outlet 701 . The outlet of the first exhaust gas pipeline 8 is connected to the exhaust gas inlet 40301 . A circulating fan 801 is provided on the first waste gas pipeline 8 . The device also includes a second exhaust gas duct 9 . A second high-temperature exhaust gas outlet 702 is provided in the fourth cavity 408 . A wind cover 101 is provided above the sintering machine 1 . The inlet of the second waste gas pipeline 9 is connected to the second high-temperature waste gas outlet 702 in the fourth cavity. The outlet of the second waste gas pipe 9 is connected to the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com