Rolling method for specially-shaped alloy steel ring part with section containing suddenly-changing curve

A technology of alloy steel and special-shaped rings, applied in the field of rolling processing, to achieve the effects of reduced production costs, less machining, and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

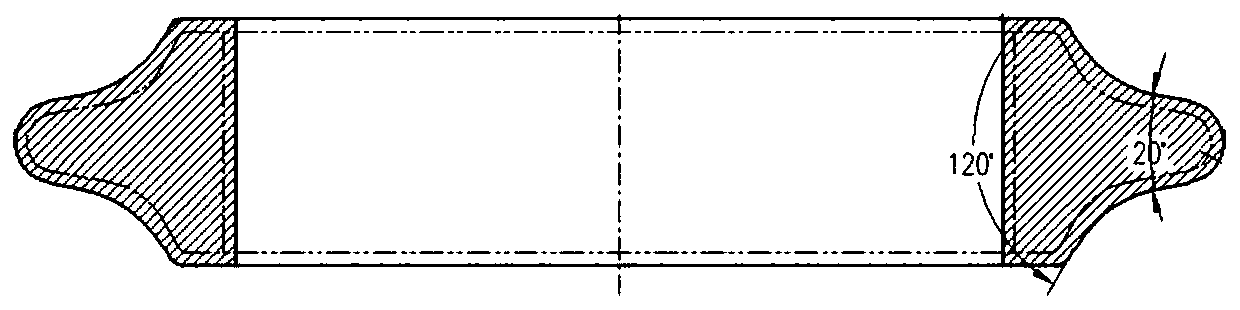

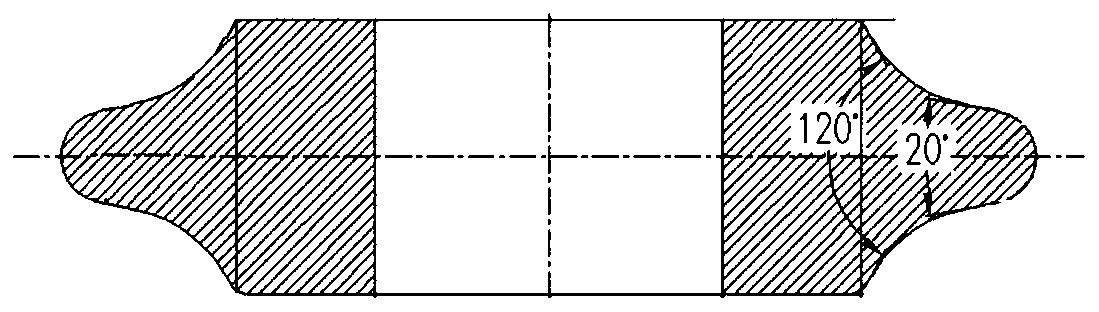

[0022] This embodiment proposes a method for rolling alloy steel special-shaped rings with abrupt curves in section, which is used for rolling such as figure 1 Sections shown contain profiled rings with abrupt curves. This rolling method specifically comprises the steps:

[0023] S1. Cutting: The initial blank is obtained by blanking with a sawing machine. The length and diameter of the initial blank are calculated by combining the parts drawing and forging drawing, considering factors such as material utilization rate and deformation steps;

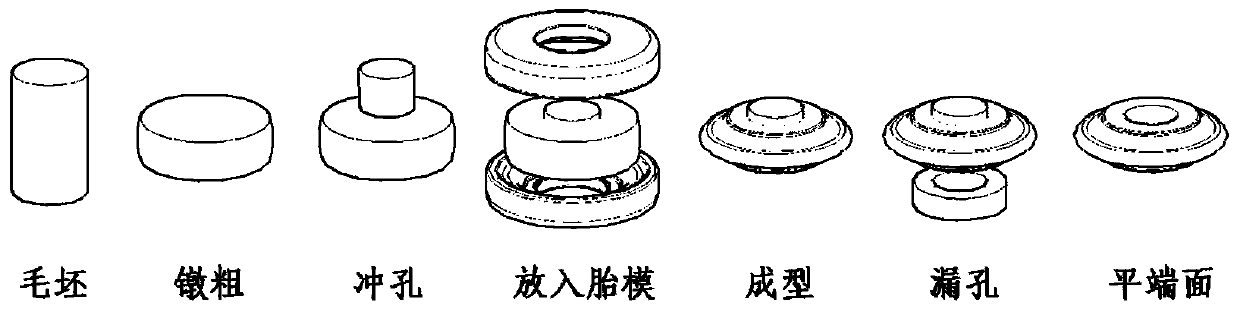

[0024] S2. Billet making: the initial blank that will reach the forging temperature requirement, after such figure 2 The processes of upsetting, punching, tire mold forming, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com