Production method of brocade-ball-shaped steamed bun foods stuffed with bean paste

A production method, the technology of bean paste buns, which is applied in food science and other fields, can solve the problems of excessive steam and product cracking, and achieve the effects of promoting cell growth, beautiful appearance and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described in detail below in conjunction with the examples.

[0021] In the following specific embodiments of the present invention, each raw material can be obtained commercially, and the proportioning of each raw material is such as flour, egg white, milk powder, oatmeal, non-dairy creamer, white sugar, oil, etc., unless otherwise specified , all can be configured according to the technical scheme proportioning of prior art, and so-called egg white is the albumen after removing egg yolk. The flour used in the embodiment is low-gluten flour. The devices used in the present invention to prepare pasta, such as stirring devices, are commercially available; low-gluten wheat flour is low-gluten flour, and wheat flour is flour.

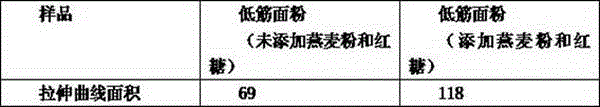

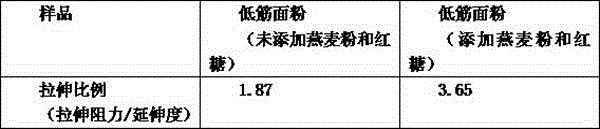

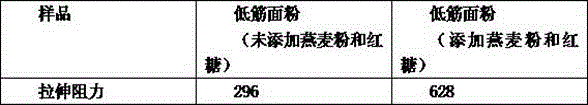

[0022] The technical indexes of using raw material low-gluten flour in the embodiment of the present invention are shown in Table 1:

[0023] Table 1. Physica...

Embodiment 1

[0053] The preparation method of the present invention will be described in detail below with the product whose specifications and models are 300g hydrangea red bean paste buns; the dough raw material is prepared, and the addition of the oat flour is controlled to be 2.5wt% of the quality of low-gluten flour; the addition of brown sugar is controlled to be low-gluten 4Wt% of flour mass.

[0054] 1. The production process of bean paste filling:

[0055] Required raw materials: red beans, oranges, bean paste, white sugar, oil. The oil used can be selected from pure natural vegetable oil such as salad oil, blended oil or pure animal oil such as lard, etc., and prepared according to the specified ratio;

[0056] Required equipment and utensils: B60 mixer, stainless steel knife, food turnover basket, electronic scale with a division value of 1g;

[0057] Handling of oranges: Remove the roots, wash the oranges 3 times until the surface is clean and shiny; use a chopper to cut the o...

Embodiment 2

[0086] All the other processing methods are identical with embodiment 1 except following explanation,

[0087] The dough raw materials are prepared, and the addition of the oat flour is controlled to be 3.0 wt% of the mass of the low-gluten flour; the addition of brown sugar is controlled to be 5 wt% of the mass of the low-gluten flour.

[0088] The wake-up steaming process, proofing requirements and steps, the proofing room is hygienic and clean, free of sundries, and no water on the ground; close the front and rear doors of the proofing room 30 minutes in advance, turn on the power switch, and set the temperature of the thermometer to 38±2°C. The relative humidity of the proofing room is 75±5%. Slowly open the steam valve. After the temperature and humidity of the proofing room rise to the specified range, the semi-finished products can be pushed in for proofing. Note that the steamer cannot be placed under the fan.

[0089] Judgment of the termination of proofing: the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com