Hollow granular bait

A hollow particle and bait technology, applied in the field of hollow particle bait, can solve the problems that the hard core part cannot achieve the fishing effect, the bait hangs laboriously and time-consumingly, wastes resources and other problems, and achieves the effect of good fishing effect, saving resources and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

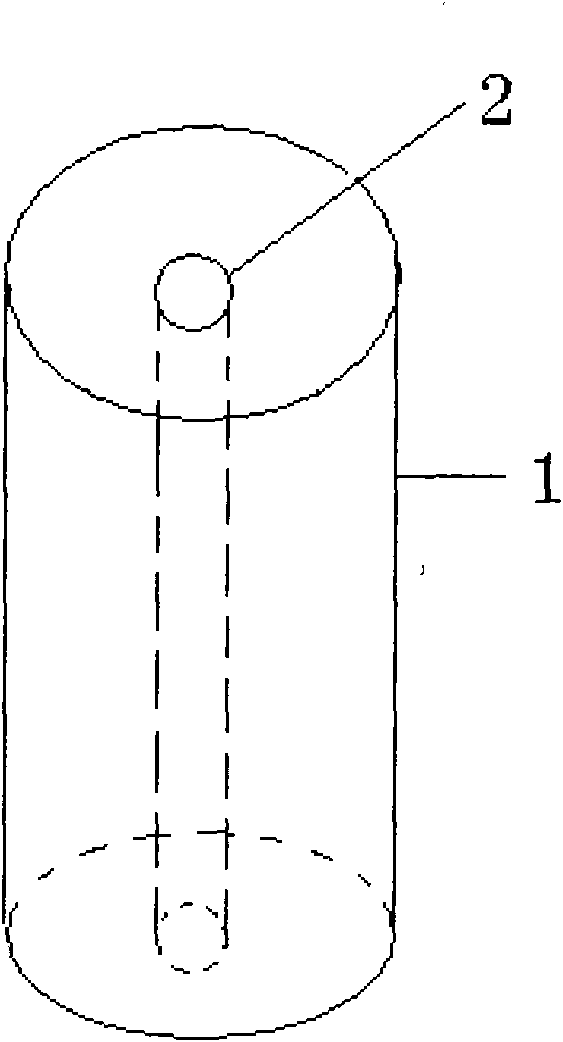

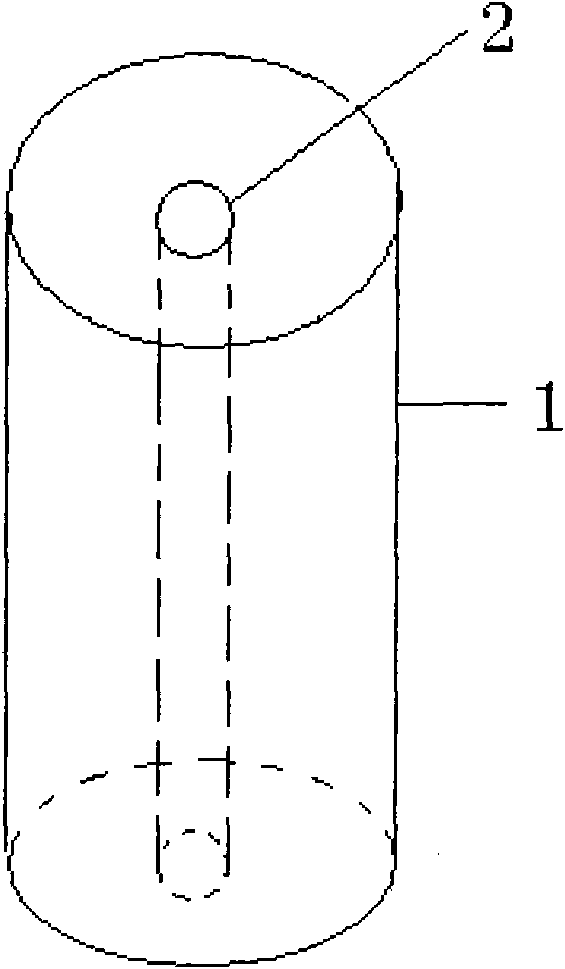

[0011] A hollow particle fishing bait in this embodiment includes a fishing bait body 1 , and a hole 2 that runs through the whole fishing bait body 1 is provided in the center of the fishing bait body 1 .

[0012] Production method: 1. Cleaning and removing sundries from raw materials; 2. Ripening and crushing treatment; 3. Premixing according to the formula ratio; 4. Adding water and fully stirring; 5. Perforating and pressing; 6. Drying; 7. Packaging; 9. Storage. The powdery bait composed of different formulas is processed into dry hollow granular bait with different colors, different flavors and different shapes by means of mechanical processing and molding.

[0013] The difference between the hollow granular bait of this embodiment and the common fish pellet feed is that the processed granular bait is hollow, absorbs water and swells rapidly after encountering water, it not only takes a short time for rehydration, but also bubbles inside and outside the bait. The water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com