Gluten-free brown rice cake and production method thereof

A technology without additives and cakes, which is applied in dough preparation, pre-baked dough processing, baked food, etc. It can solve the problems of brown rice cakes with large specific volume, small foaming and instability, etc., and achieve good appearance, convenient eating, The effect of moderate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

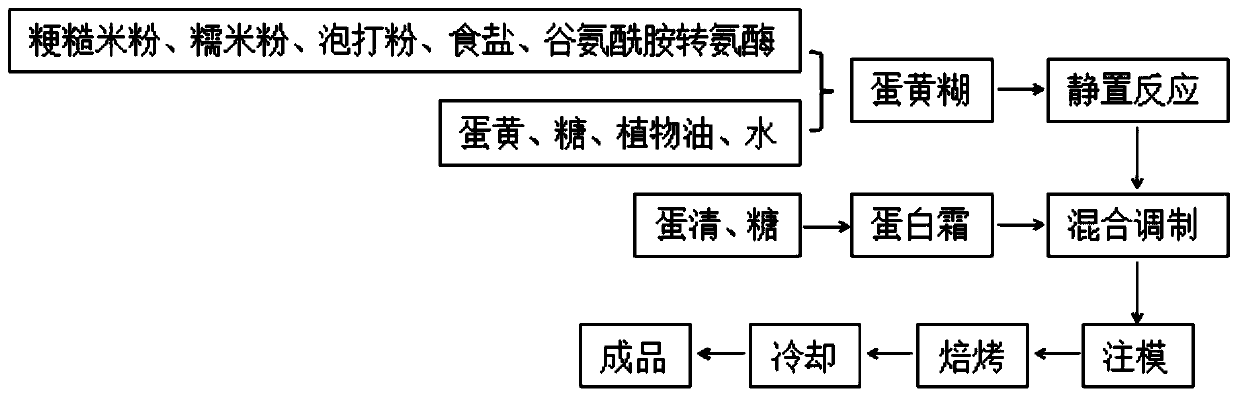

Method used

Image

Examples

Embodiment 1

[0028] (1) First, commercially available japonica brown rice grains are cleaned to remove impurities and surface dust, and then pulverized with a high-speed universal grinder, and all the pulverized japonica brown rice flours are passed through a sieve with an aperture of 0.150 mm for subsequent use.

[0029] (2) Weigh 85g brown rice raw material powder, 15g glutinous rice flour, 0.8g TGase, 2g baking powder and 1g salt, mix them evenly and pass through a 0.150mm sieve for later use to obtain mixed powder.

[0030] (3) Weigh 50g egg yolk, add 20g powdered sugar, beat evenly, then add 20g soybean oil and 80g purified water in 3 to 4 times, beat until the egg yolk paste liquid is uniform and thick, and there is no separation of oil and water . Add the sifted mixture and mix gently with a rubber spatula. The egg yolk paste that has been mixed is left to stand and react for 30 minutes at 50°C in the proofer.

[0031] (4) Weigh 150g of egg white, add 40g of powdered sugar in thre...

Embodiment 2

[0036] (1) First, commercially available japonica brown rice grains are cleaned to remove impurities and surface dust, and then pulverized with a high-speed universal grinder, and all the pulverized japonica brown rice flours are passed through a sieve with an aperture of 0.150 mm for subsequent use.

[0037] (2) Weigh 85g brown rice raw material powder, 15g glutinous rice flour, 1.6g TGase, 2g baking powder and 1g salt, mix them evenly and pass through a 0.150mm sieve for later use to obtain mixed powder.

[0038] (3) Weigh 50g egg yolk, add 20g powdered sugar, beat evenly, then add 20g soybean oil and 80g purified water in 3 to 4 times, beat until the egg yolk paste liquid is uniform and thick, and there is no separation of oil and water . Add the sifted mixture and mix gently with a rubber spatula. The egg yolk paste that has been mixed is left to stand and react for 30 minutes at 50°C in the proofer.

[0039] (4) Weigh 150g of egg white, add 40g of powdered sugar in thre...

Embodiment 3

[0044] (1) First, commercially available japonica brown rice grains are cleaned to remove impurities and surface dust, and then pulverized with a high-speed universal grinder, and all the pulverized japonica brown rice flours are passed through a sieve with an aperture of 0.150 mm for subsequent use.

[0045](2) Weigh 85g brown rice raw material powder, 15g glutinous rice flour, 2.4g TGase, 2g baking powder and 1g salt, mix them evenly and pass through a 0.150mm sieve for later use to obtain mixed powder.

[0046] (3) Weigh 50g egg yolk, add 20g powdered sugar, beat evenly, then add 20g soybean oil and 80g purified water in 3 to 4 times, beat until the egg yolk paste liquid is uniform and thick, and there is no separation of oil and water . Add the sifted mixture and mix gently with a rubber spatula. The egg yolk paste that has been mixed is left to stand and react for 30 minutes at 50°C in the proofer.

[0047] (4) Weigh 150g of egg white, add 40g of powdered sugar in three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com