Rolling reduction control method under large liquid core pressure

A control method and reduction technology, applied in the direction of rolling force/roll gap control, etc., to improve the quality of the slab, refine the internal structure, and achieve the effect of easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

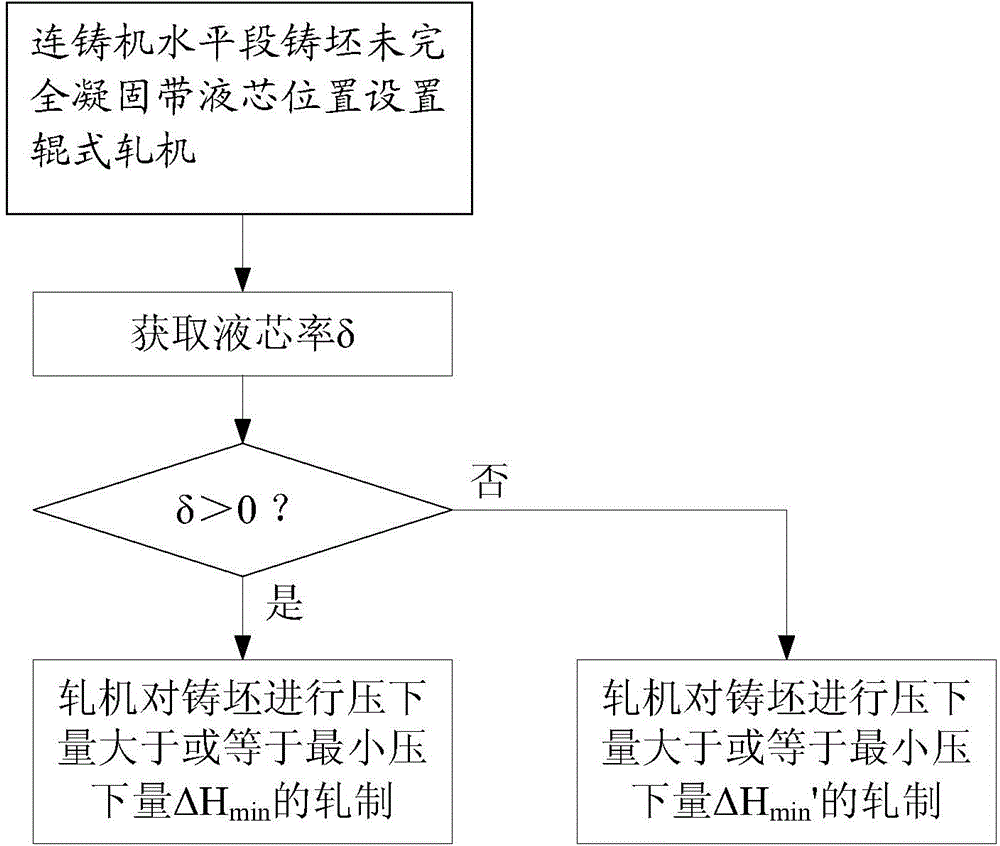

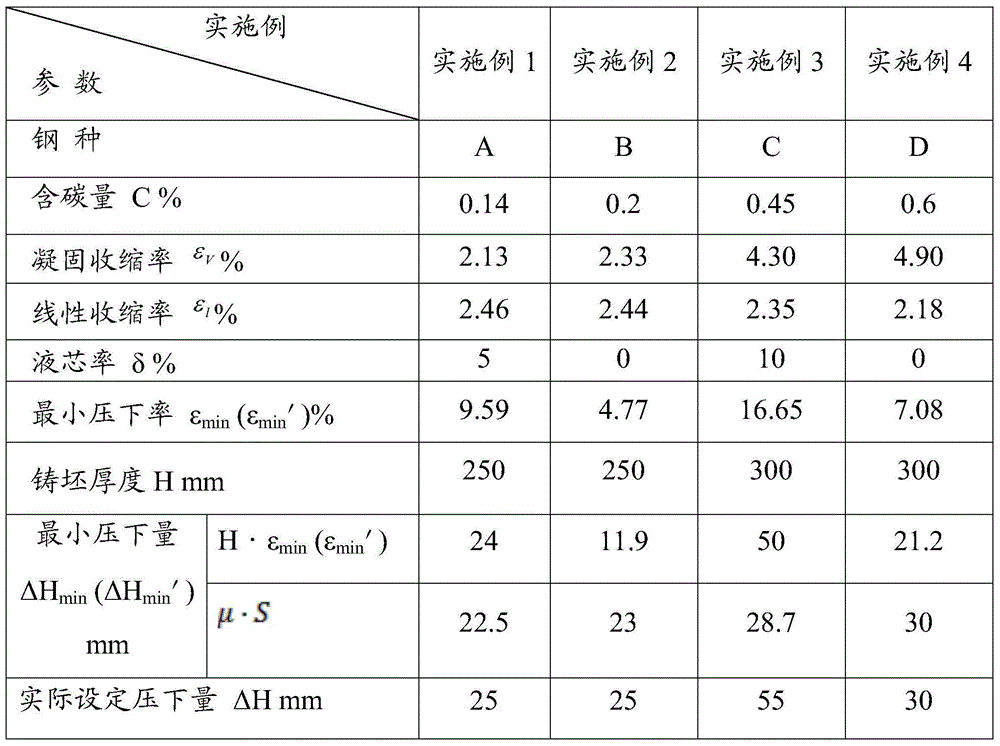

[0013] The liquid core big reduction rolling reduction control method of the present invention is as follows: figure 1 As shown, a roll mill is installed at the position where the slab is not completely solidified with a liquid core in the horizontal section of the continuous casting machine, and the percentage of the maximum liquid core thickness at the position of the rolling mill to the thickness of the slab before rolling is the percentage of the liquid core rate δ, and the liquid core rate is obtained δ and judge whether it is greater than 0, if the liquid core rate δ is greater than 0, the reduction of the casting slab by the rolling mill is greater than or equal to the minimum reduction ΔH min The liquid core is rolled with a large reduction, where the minimum reduction ΔH min =max[H·(ε v +ε l +δ), μ·S].

[0014] In the above formula, H is the thickness of the slab before rolling, in mm; ε V is the solidification shrinkage rate, unit %; ε l is the linear shrinkage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com