Method for measuring surface temperature of high-temperature casting billet within water fog medium

A surface temperature and measurement method technology, applied in the field of temperature measurement, can solve the problems of immature slab surface temperature, constraints, and insufficient cooling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with embodiment to further understand this method.

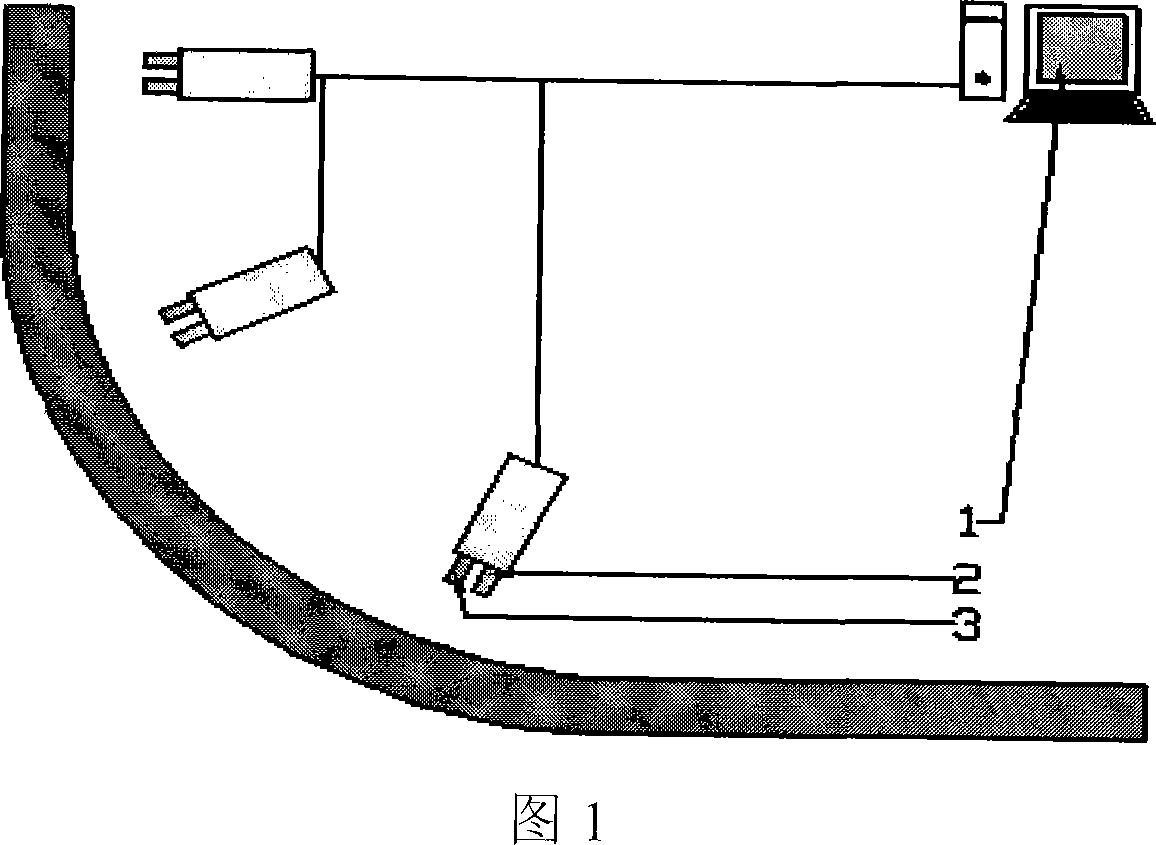

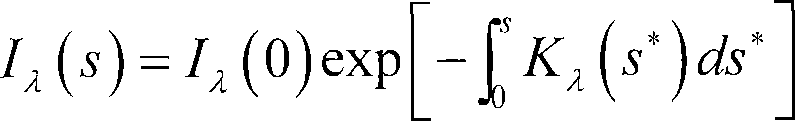

[0026] The absorption of radiant energy by the water mist medium on the surface of the slab is the most restrictive link affecting the temperature measurement accuracy of the non-contact thermometer invented based on the theory of photoelectric effect or thermal radiation; at the same time, the emissivity of the slab surface is also the most restrictive link. An important factor affecting the accuracy of radiation temperature measurement. Therefore, according to the purpose and requirements of the patent of the present invention, two problems need to be solved: 1. Find out the attenuation coefficient K when the radiant energy passes through the water mist medium λ ; 2. Determine the emissivity ε of the oxide film on the surface of the slab at different temperatures. After these two parameters are obtained, the temperature measured by the non-contact th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com