Centrifuge for casting steel tube by heated mould method

A thermal molding method and centrifuge technology, applied in the field of centrifuges, can solve the problems of unguaranteed quality, low material utilization rate, complex equipment, etc., and achieve the effect of ensuring tissue performance and comprehensive quality, accurate size, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

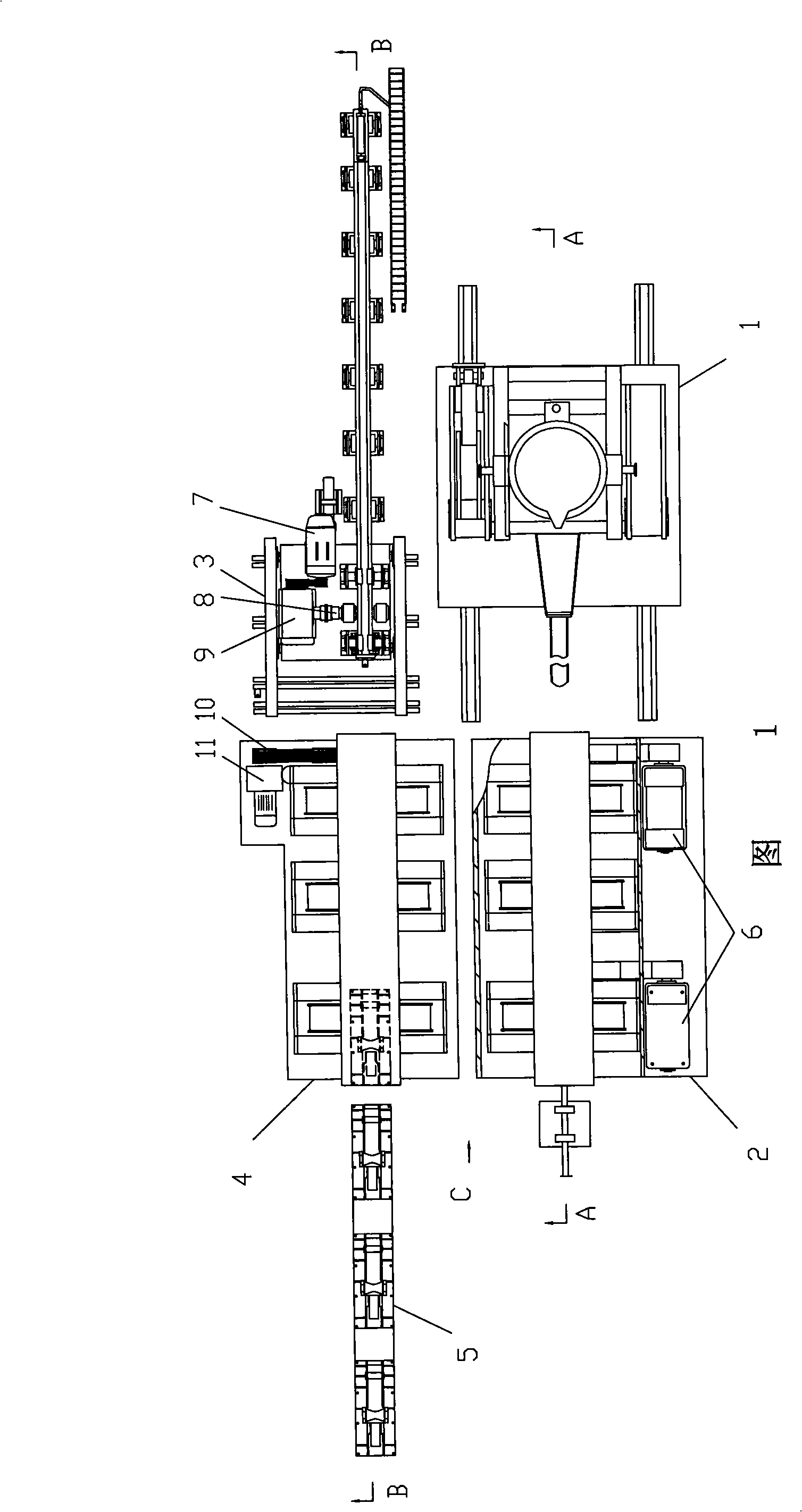

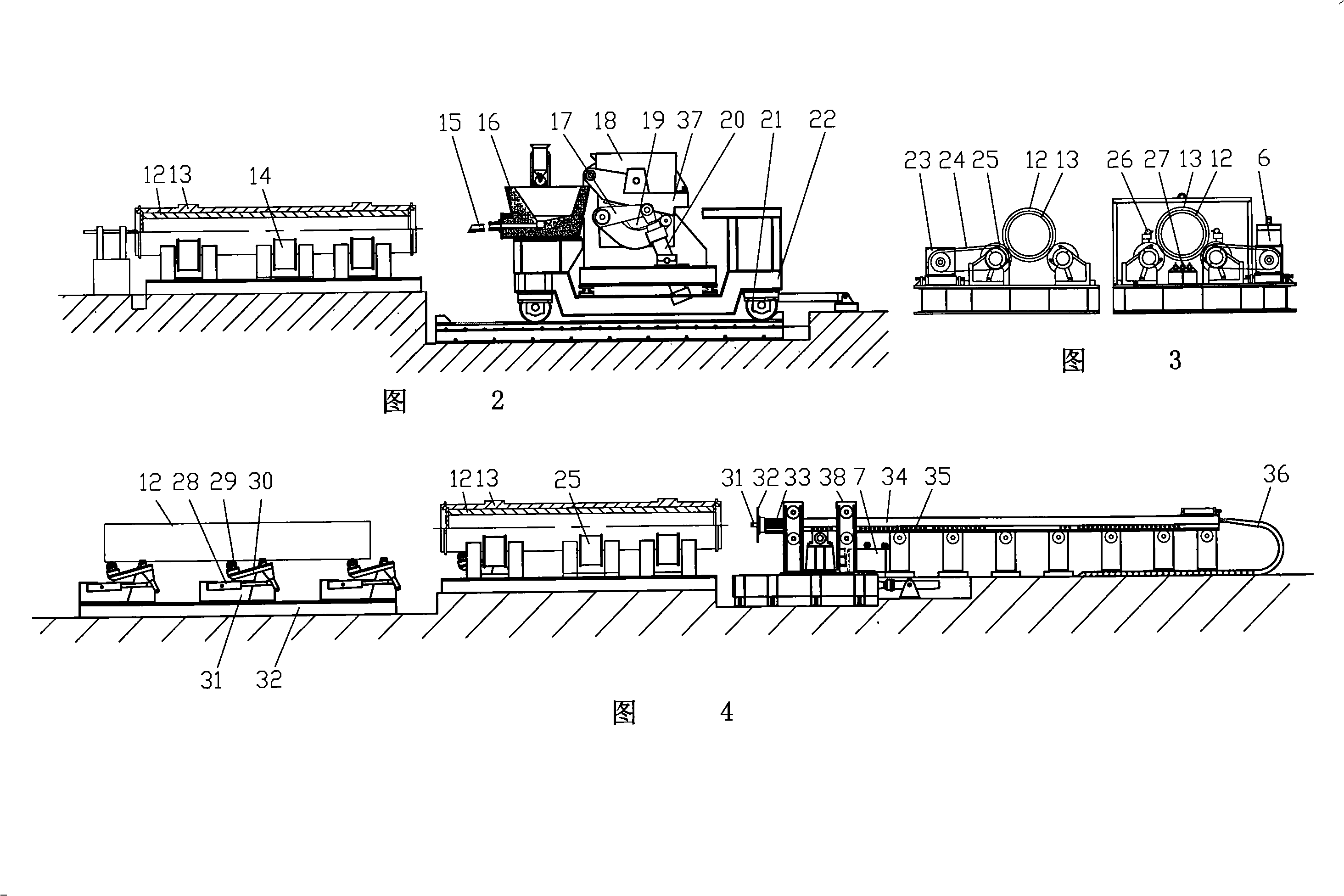

[0013] As shown in FIG. 1 , the present invention includes an equal pouring device 1 , a centrifugal host 2 , a tube pushing device 3 , a tube supporting device 4 and a connecting device 5 . As shown in Figure 2, the vehicle frame 22 of the said equivalent pouring device 1 is fixed with a running wheel 21 by a bearing, and the running wheel 21 sits on a guide rail fixed on the ground, and the driving wheel 21 is driven by a motor fixed on the vehicle frame 22 . The oil cylinder 20 is hinged on the vehicle frame 22, the piston of the oil cylinder 20 is hinged with one end of the turning mechanism 17, the other end of the turning mechanism 17 is close to the constant velocity plate 19, the constant velocity plate 19 is fixed with the ladle fixing frame 37, and the ladle is fixed Frame 37 is hinged with vehicle frame 22, and ladle fixed frame 37 can fix ladle 18 fast. The ladle 16 is fixed on the vehicle frame 22 on the tapping nozzle side of the ladle 18, and the long sprue 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com