Aluminum profile for motor train unit running in high and cold regions and preparation method thereof

A technology for EMUs and aluminum profiles, applied in the field of aluminum profiles, can solve the problem of not being able to adapt to the environment in the cold area of the north, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

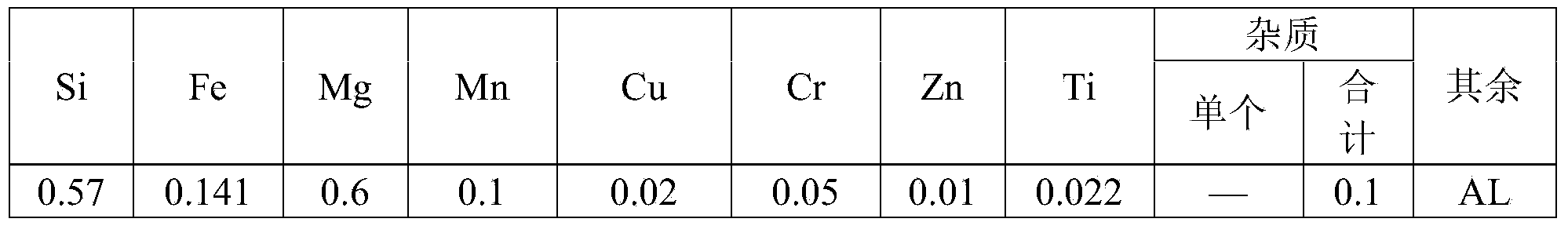

[0026] An aluminum profile for high-cold EMUs, containing metal substances in the following mass percentages:

[0027] Si0.4-0.7%, Fe≤0.20%, Mg0.5-0.75%, Mn0.01-0.2%, Cu≤0.05%, Cr≤0.1%, Zn≤0.08%, Ti0.02-0.04%, single impurity The amount of Al is ≤0.05%, the sum of impurities is ≤0.15%, and the rest is Al.

[0028] Explanation: Although there is no iron in the master alloy, the master alloy used in the present invention will introduce iron element more or less from some impurities, so the content of iron element needs to be controlled in the composition of the profile.

[0029] A preparation method of the aluminum profile for the high-cold multiple train set, which comprises the following steps:

[0030] (1) Removal of impurities in the furnace body: Before casting, the high temperature in the furnace must be 800°C to remove the dross on the furnace wall and bottom of the furnace, and use an iron rake to completely remove the remaining aluminum liquid from the furnace to remov...

Embodiment 2

[0040] A preparation method of the aluminum profile for the high-cold multiple train set, which comprises the following steps:

[0041] 1. Drain or cast the molten aluminum in the furnace completely before feeding, and then raise the temperature in the furnace to 800°C, sprinkle no less than 15kg of slag cleaning agent, keep it warm for 5 minutes, and then use a large shovel to clean the slag line and furnace Shovel off the dross on the wall and bottom of the furnace, and use an iron rake to remove the remaining molten aluminum completely out of the furnace.

[0042] 2. The aluminum ingots must be clean and dry before feeding. According to the production plan, weigh the aluminum ingots with a purity of 99.70% and above, and add them at the top of the scrap materials for the first time. Electrolytic aluminum liquid is not allowed, and weigh the intermediate alloys that need to be input. , the master alloy of aluminum-silicon alloy, aluminum-copper alloy, aluminum-chromium alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com