Final molding process of agricultural steel hoe blank

A forming process and hoe technology, which is applied in the field of the ultimate forming process of agricultural hoes, can solve the problems of complex processing process, low utilization rate of raw materials, time-consuming and labor-intensive, etc., and achieves simple process steps, low labor intensity of workers, and reduced manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] A final forming process of a steel agricultural hoe blank, comprising the following steps:

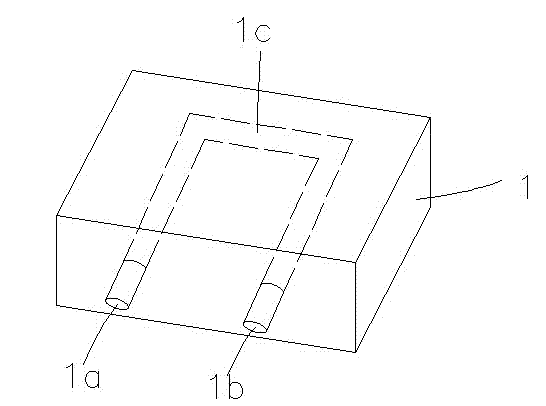

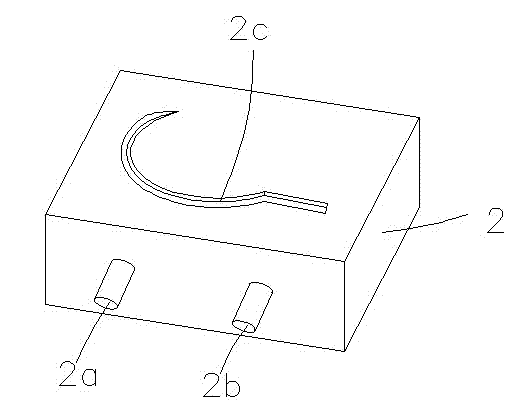

[0023] Step 1, making the pouring mold; combining figure 1 , figure 2 As shown, the pouring mold is used for forming the sickle, and consists of a steel upper mold 1 and a steel lower mold 2. The lower surface of the steel upper mold 1 is a plane, the steel upper mold 1 is provided with an upper mold cooling water channel 1c, the steel upper mold 1 is provided with an upper mold water inlet pipe 1a and an upper mold outlet pipe 1b, and the upper mold enters The water pipe 1a, the upper mold cooling water channel 1c and the upper mold outlet pipe 1b are connected in sequence to cool down the steel upper mold 1 and facilitate rapid cooling of the molten steel in the pouring mold. The upper surface of the steel lower mold 2 is provided with a cavity 2c matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com