Diamond cutting pick and machining method thereof

A processing method and diamond technology, applied in the field of coal shearer, diamond pick and its processing, and roadway boring machine, can solve the problems affecting the internal structure of cemented carbide, reducing the service life of the pick, reducing the strength of the alloy tooth, etc. Achieve the effects of avoiding adverse effects, enhancing welding strength, high impact resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

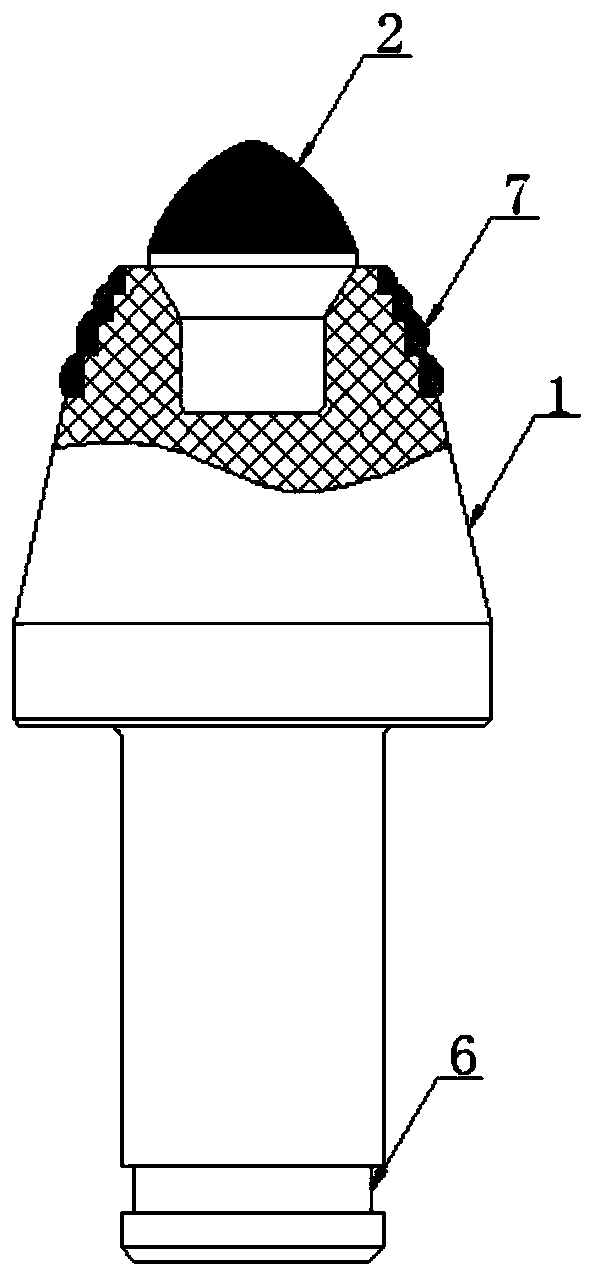

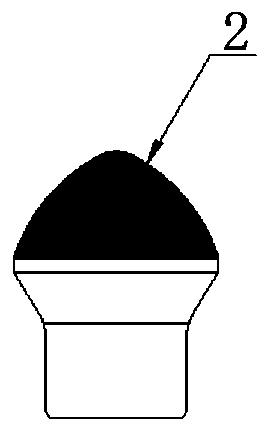

[0038] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure of a diamond pick according to the present invention. The present invention provides a diamond pick, which is a mushroom-shaped diamond composite tooth (not marked) welded in the mosaic hole of the pick base 1, and the mushroom-shaped diamond composite tooth The cutting teeth on the upper part of the tooth are covered with a layer of diamond composite material to increase the strength of the tooth surface and the impact resistance and wear resistance. At the same time, a wear-resistant layer 7 is arranged on the easy-wear area on the top of the pick base body, and the wear-resistant layer 7 is covered on the wear-resistant area on the top of the pick base body 1. seat connection.

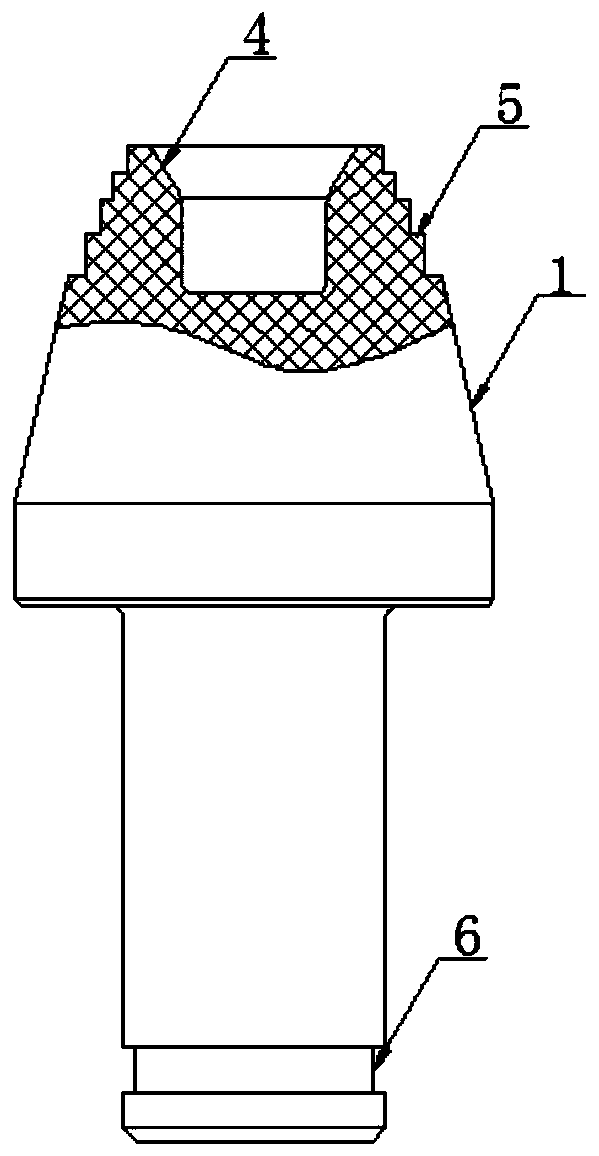

[0039] Such as figure 2 as shown, figure 2 It is a schematic structural view of the pick base 1 provided by the embodiment of the present invention. The upper part of the pick base 1 is provided with an inla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com