Fluoride-free refined flux slagging agent and preparation method and application method thereof

A technology of slag agent and tailing slag, which is applied in the field of iron and steel metallurgy, can solve the problems of high production cost and complicated preparation process of fluoride-free slag agent, and achieve the effect of low cost, simple production process and good effect of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the above-mentioned fluorine-free refining auxiliary melting slag agent, which comprises the following steps:

[0031] a. Stir and mix 40-60% of continuous casting slag and tailings, 20-40% of ferro-vanadium smelting corundum slag, and 8-20% of industrial barium carbonate for 5-7 minutes. Add auxiliary material forming binder, stir and mix for 3-5 minutes. Prepare a dry blend;

[0032] b. The dry mixture is pressed by a powerful ball press to obtain pellets, and the pellets with a particle size ≥ 5mm are screened out, which are fluorine-free refining auxiliary melting slag agent pellets.

[0033] Wherein, in the method for preparing the fluorine-free refining auxiliary melting slag agent, the size of the pellet in step b is 20 to 35 mm.

[0034] Wherein, in the preparation method of the above-mentioned fluorine-free refining auxiliary melting slag agent, the control pressure during ball pressing in step b is 8-12 MPa. ...

Embodiment 1

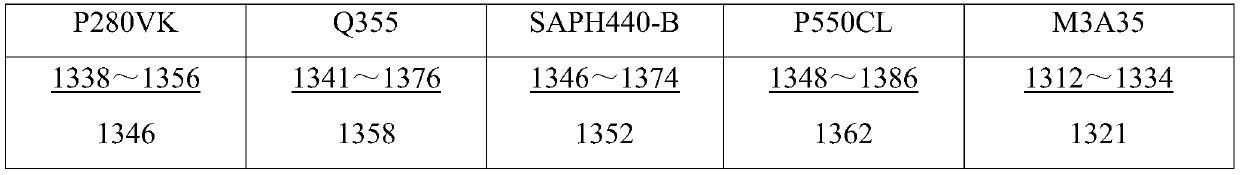

[0039] Example 1 Using the fluorine-free refining auxiliary melting slag agent of the present invention to slag M3A35 steel

[0040] To prepare pellets, the specific operations are as follows:

[0041] a. Stir and mix 500kg of continuous casting slag and tailings, 300kg of ferro-vanadium smelting corundum slag, and 160kg of industrial barium carbonate for 7min, add auxiliary material forming binder (16kg of bentonite and 24kg of cement), stir and mix for 4min to obtain a dry mixture ;

[0042] b. Use a powerful ball press to press the dry mixture into pellets with a pressure of 8 MPa to obtain pellets with a size of 30 mm; the pellets with a particle size ≥ 5 mm are screened out for use.

[0043] The above pellets were added according to 15% of the added lime during washing of the converter tapping slag. After addition, the small platform was stirred with atmospheric argon for 2 minutes; the heating process of LF was added at 10% of the added lime.

[0044] The slag-forming time of Exa...

Embodiment 2

[0045] Example 2 Using the fluorine-free refining auxiliary melting slag agent of the present invention to slag SAPH440-B steel

[0046] To prepare pellets, the specific operations are as follows:

[0047] a. Stir and mix 500kg of continuous casting slag tailings, 300kg of ferro-vanadium smelting corundum slag, and 160kg of industrial barium carbonate for 7 minutes, add auxiliary material forming binder (16kg of bentonite and 24kg of cement), stir and mix for 3 minutes to obtain a dry mixture ;

[0048] b. Use a powerful ball press to press the dry mixture with a pressure of 10 MPa to obtain pellets with a size of 20 mm; the pellets with a particle size ≥ 5 mm are screened out for use.

[0049] The above pellets were added at 10% of the added lime when washing the converter tapping slag. After adding, the small platform was stirred with atmospheric argon for 3 minutes; the heating process of LF was added at 10% of the added lime.

[0050] The slag-forming time of Example 2 is 3 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com