Exothermic agent for converter molten iron with low heating value

A low calorific value, exothermic agent technology, applied in the manufacture of converters, etc., can solve the problems of unsuitable supplementary heat source, unfavorable converter slag and dephosphorization, high slag alkalinity, etc., achieve good heating effect, increase specific gravity, and cheap price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] After the converter is loaded with steel scrap and molten iron, it is added from the furnace top hopper before ignition and blowing, and the temperature of the molten iron is used to melt the silicon carbon balls as soon as possible.

[0045] Embodiment composition is referring to table 2:

[0046] Table 2

[0047] Example

Silicon material

carbonaceous material

Iron pellets, iron filings

binder

1

47.5

31.3

6.0

7.3

7.9

2

35.0

43.5

10.3

7.2

4.0

3

36.8

32.5

14.0

10.0

6.7

4

43.2

38.3

8.3

4.0

6.2

5

41.5

37.5

10.0

7.0

4.0

6

40.5

41.0

7.5

5.5

5.5

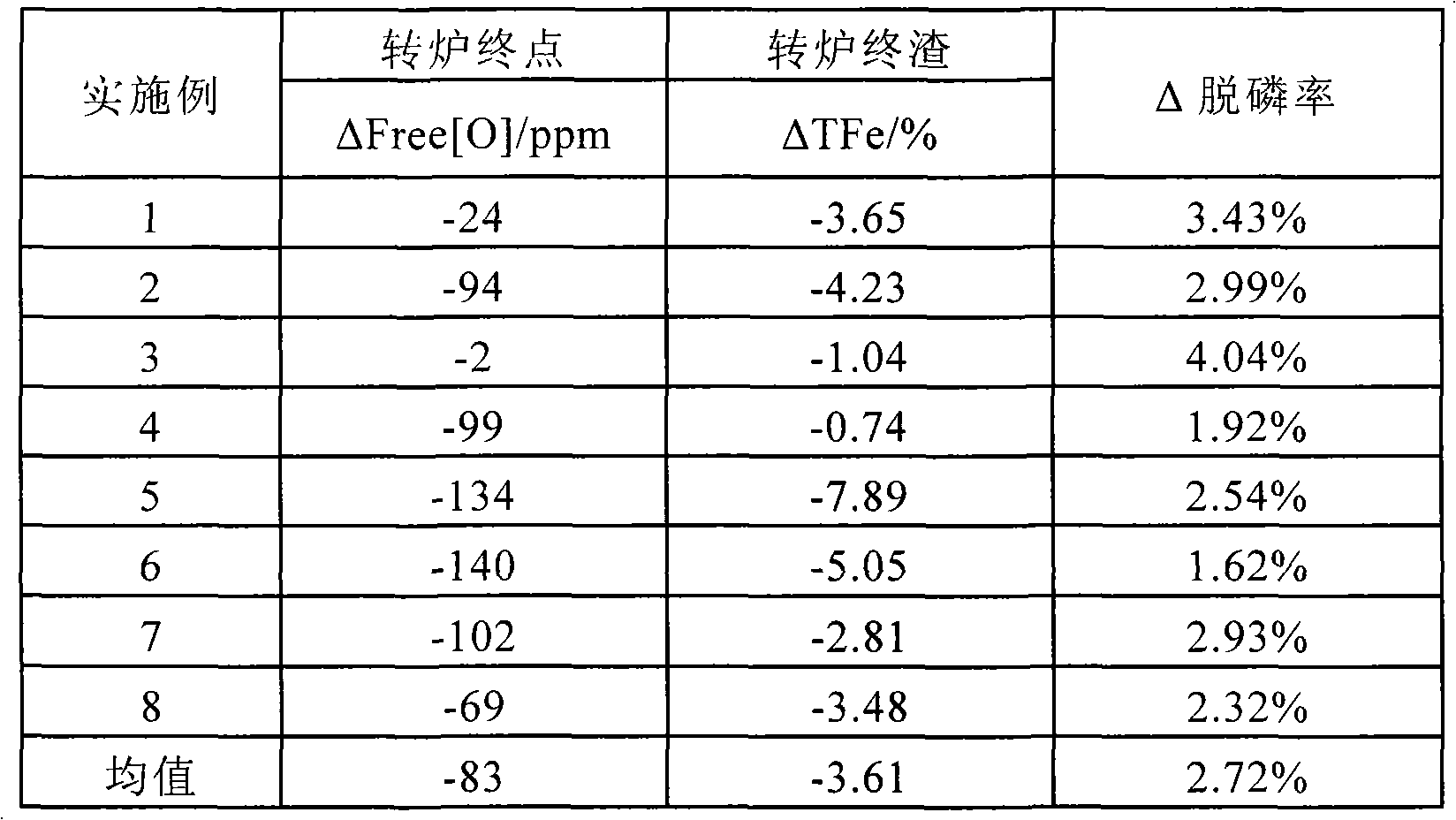

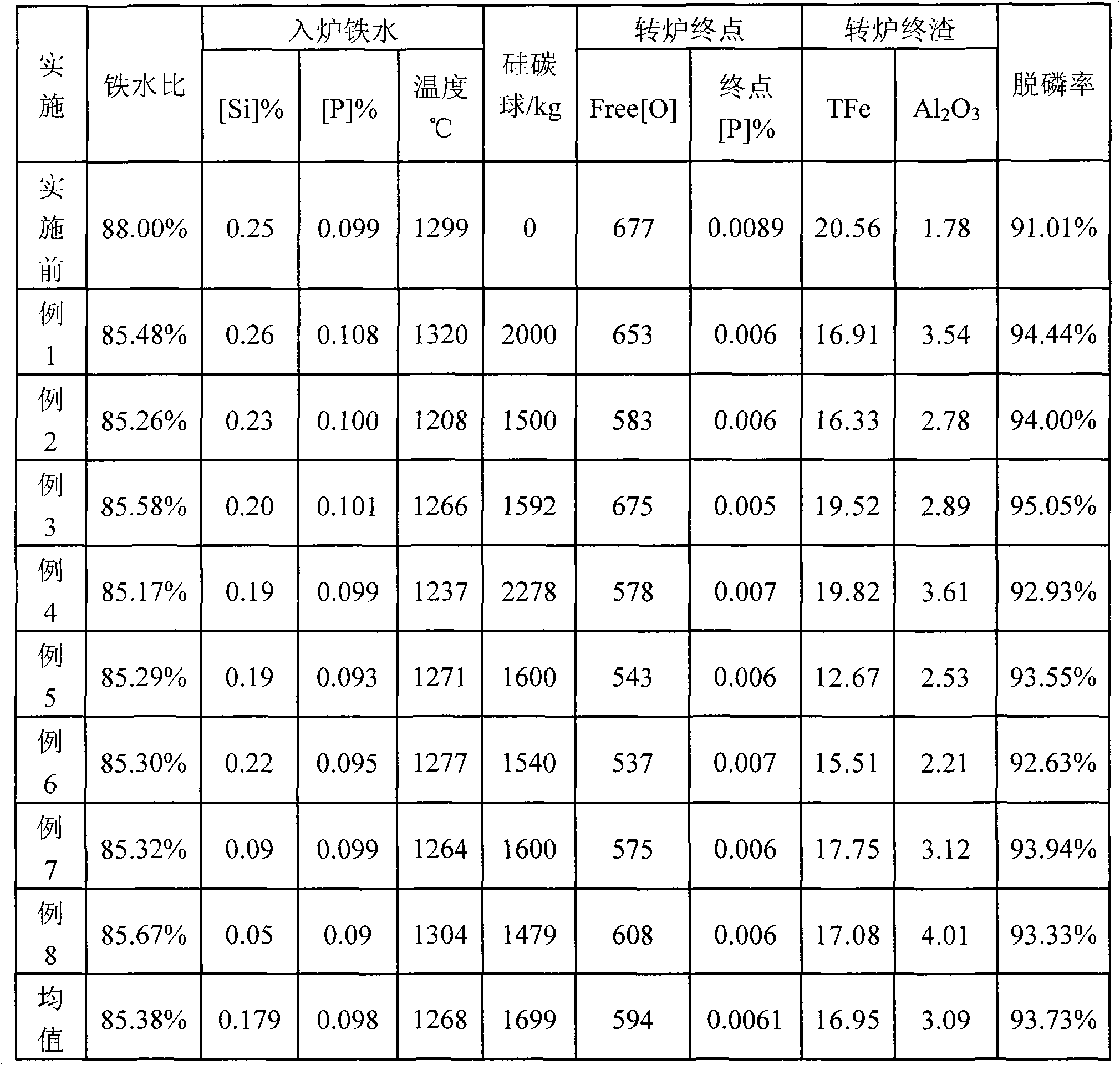

[0048] Implementation result shows (see table 3, table 4), in the molten iron of low calorific value that the Si average value of entering furnace molten iron in converter is 0.179%, temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com