Gas-blowing and slag-removing device and slag-removing method

A technology of air blowing mechanism and slag removal machine, which is applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of poor slag removal effect and difficulty in on-site implementation, and achieve good slag removal effect, force balance, Avoid the effect of operating dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

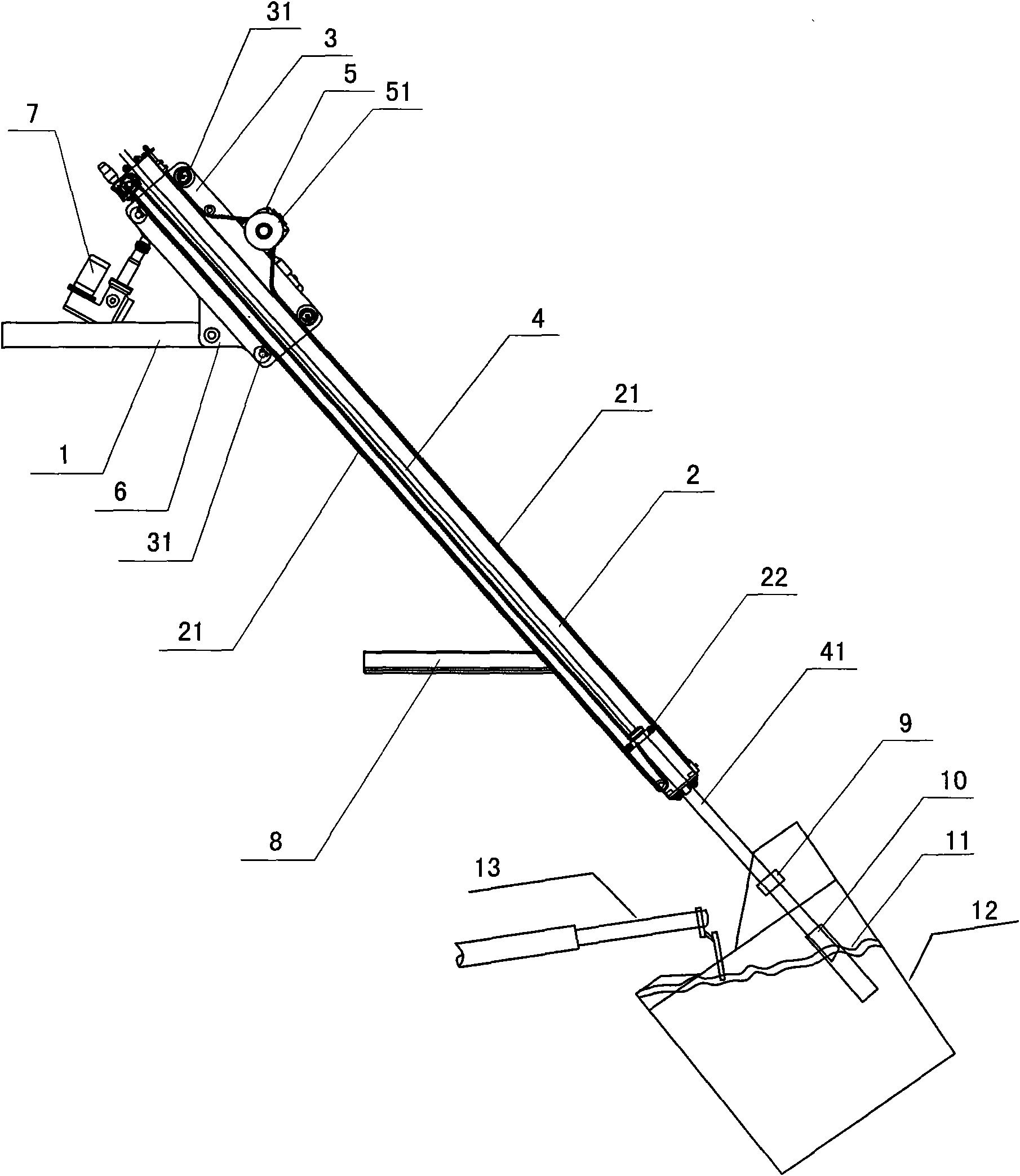

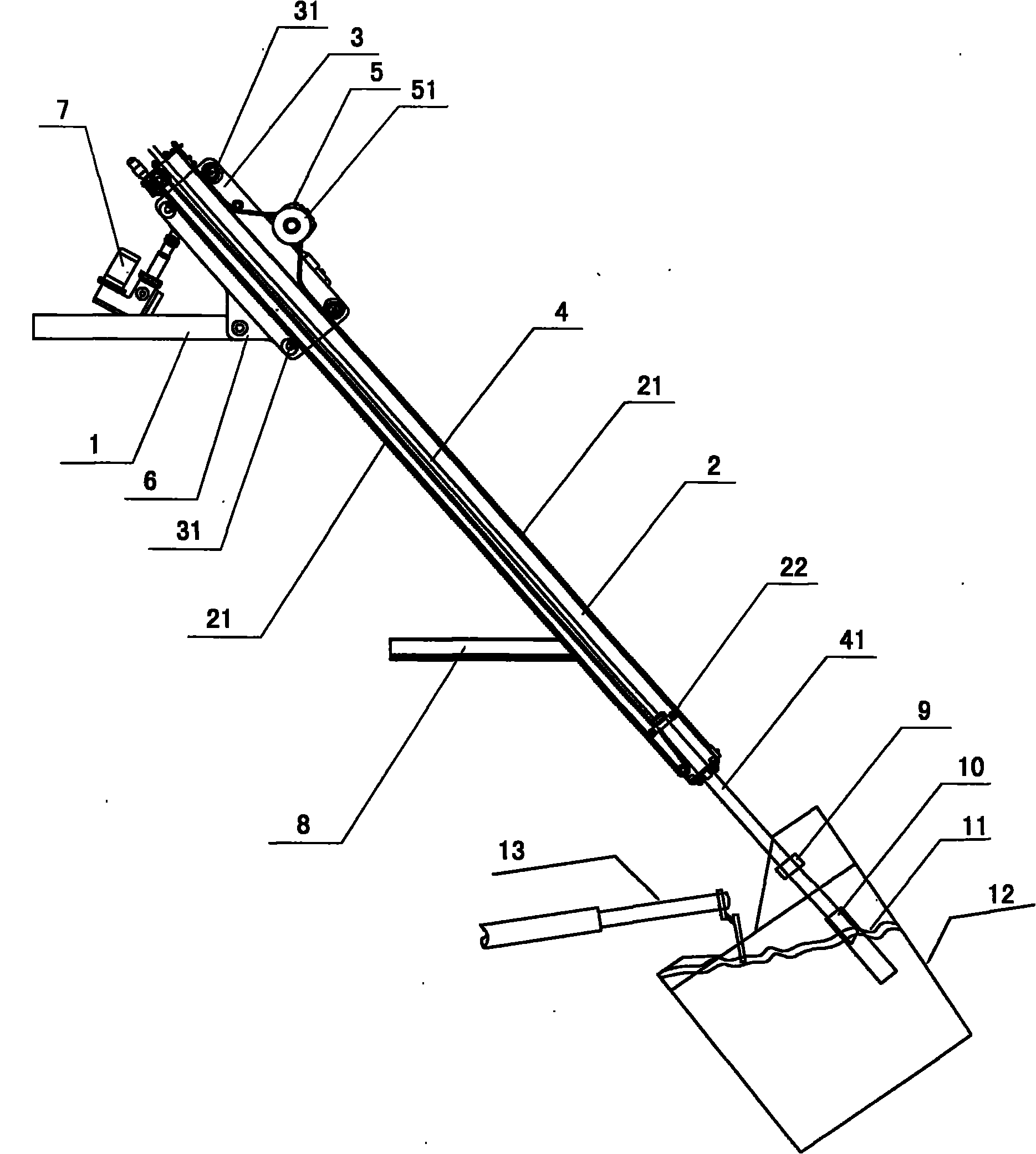

[0015] The basic structure of the air blowing slag removal device is as follows: figure 1 As shown, an air blowing and slag removal device includes an air blowing mechanism, a ladle 12 and a slag remover 13. The air blowing mechanism is fixed on one side of the support platform 1 through a hinge base 6. The air blowing mechanism includes an inclined track Frame 2, described track frame is provided with track chain 21; Also comprises a support that is flush with the upper surface of described track frame, on which speed changer 5 is arranged, and the output shaft of described speed changer is provided with described track The first sprocket wheel 51 that chain 21 matches; Described track frame is also provided with the clamping vehicle 3 that forms mobile pair with track frame, and described clamping vehicle 3 is provided with the second chain that is fixed together with track chain 21 Wheel 31, the middle part of the clamping car 3 clamps and fixes a connecting rod 4 located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com