Patents

Literature

234 results about "Glutamate fermentation" patented technology

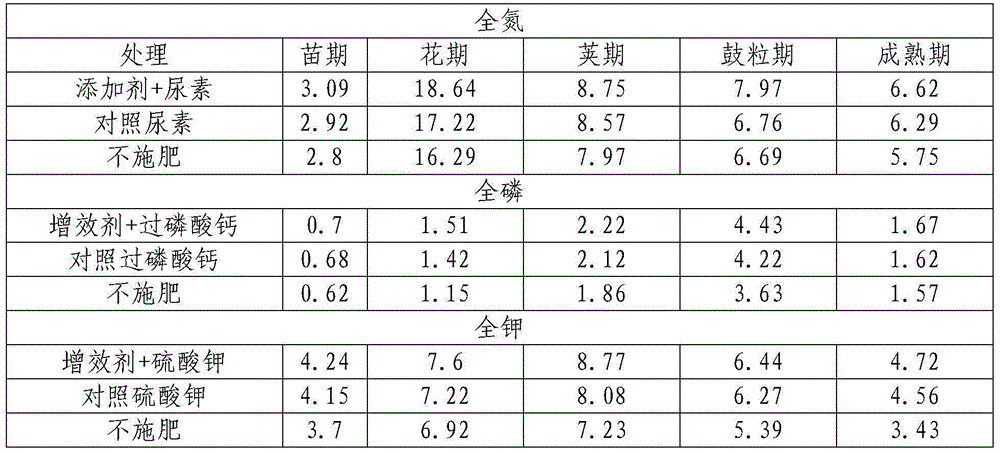

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two pathways are involved in the fermentation of glutamate to acetate, butyrate, carbon dioxide, and ammonia-the methylaspartate and the hydroxyglutarate pathways which are used by Clostridium tetanomorphum and Peptococcus aerogenes, respectively.

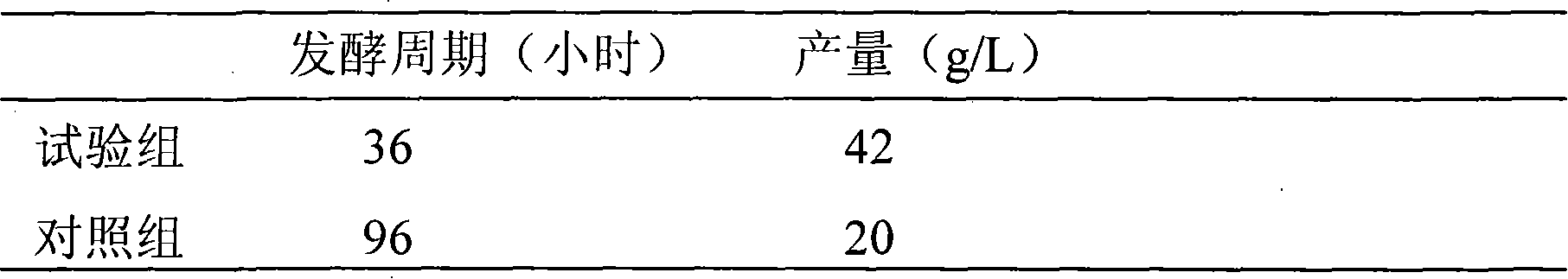

Bacillus licheniformis strain, application thereof and method for producing poly-gamma-glutamic acid thereby

InactiveCN101603015AShort fermentation cycleIncrease productivityBacteriaMicroorganism based processesBacillus licheniformisSubmerged fermentation

The invention discloses a bacillus licheniformis strain which is preserved as bacillus licheniformis WX-02 with the preserving number of NO: M208065 and the preserving date of April 24th, 2008 and the preserving unit of CCTCC. The invention also discloses an application of the bacillus licheniformis strain and a method for producing poly-gamma-glutamic acid by using the bacillus licheniformis strain. Poly-gamma-glutamic acid products are produced by processes of seed solution preparation and liquid submerged fermentation, and the strain has stable genetic performance of the strain, high production efficiency and low production cost. When the bacillus licheniformis strain of the invention and the fermentation method thereof are used for preparing 3000L of poly-gamma-glutamic acid, the yield of a fermentation tank can reach 35.05g / l.

Owner:HEBEI WELCOME PHARMACEUTICAL CO LTD +1

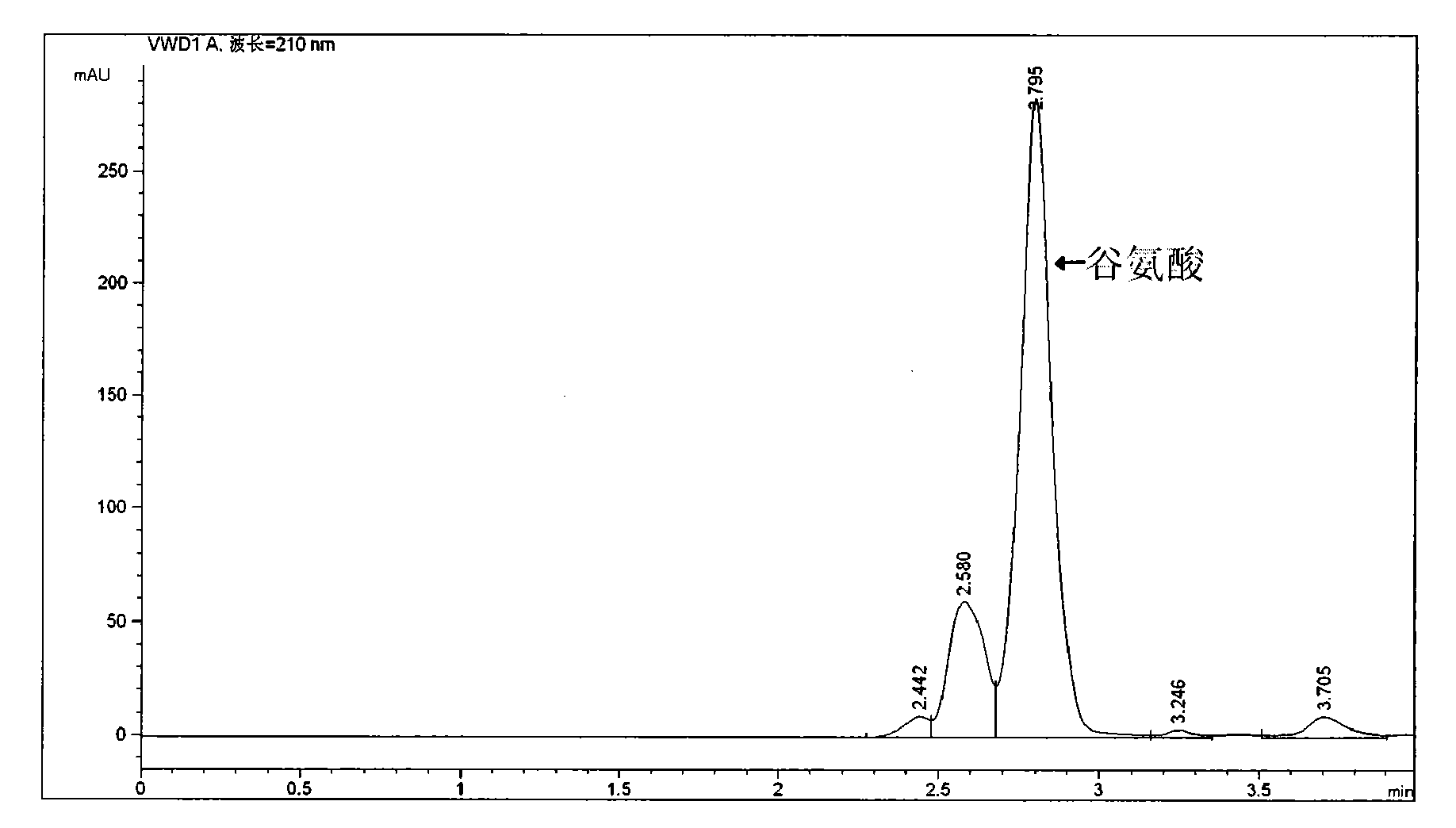

Novel production method for glutamic acid

ActiveCN102703537AReduce lossesLess waste waterOrganic compound preparationMicroorganism based processesHigh concentrationFluidized bed drying

The invention discloses a novel production method for glutamic acid, belonging to the technical field of the production of amino acid. The novel production method for the glutamic acid comprises the following steps of: removing thalli and insolubles by means of high-speed disc separation; evaporating and concentrating separated glutamic acid material liquid through a multi-effect plate type evaporator at low temperature, wherein the generated secondary steam condensed water is used for fermentation ingredients of the glutamic acid; performing continuous isoelectric extraction on the glutamic acid in the evaporated glutamic acid concentrated solution; absorbing the glutamic acid by making supernatant fluid pass through ion exchange columns; performing isoelectric reextraction on the analyzed glutamic acid; inputting high-concentration wastewater into a fertilizer workshop for producing fertilizer; squeezing heavy phase (mycoprotein) through a plate frame, and granulating; and drying through a fluid bed, and thus producing high-protein feed. The novel production method for the glutamic acid has the advantages of low unit consumption of liquid ammonia and sulfuric acid, high extraction yield of the glutamic acid, less ion exchange investment and the like; and meanwhile, the purity of the extracted glutamic acid is high, sodium glutamate can be produced without crystalloblast, resources are fully used in the whole process, the aims of energy conservation and consumption reduction are achieved, and the novel production method for the glutamic acid has a wide application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Process of preparing gamma-polyglutamic acid by bacillus subtilis and glutamic acid bacillus mixed cultivating system

InactiveCN100999756AGood hygroscopicityGood moisturizing effectMicroorganism based processesFermentationBiotinCulture mediums

Owner:ZHEJIANG UNIV

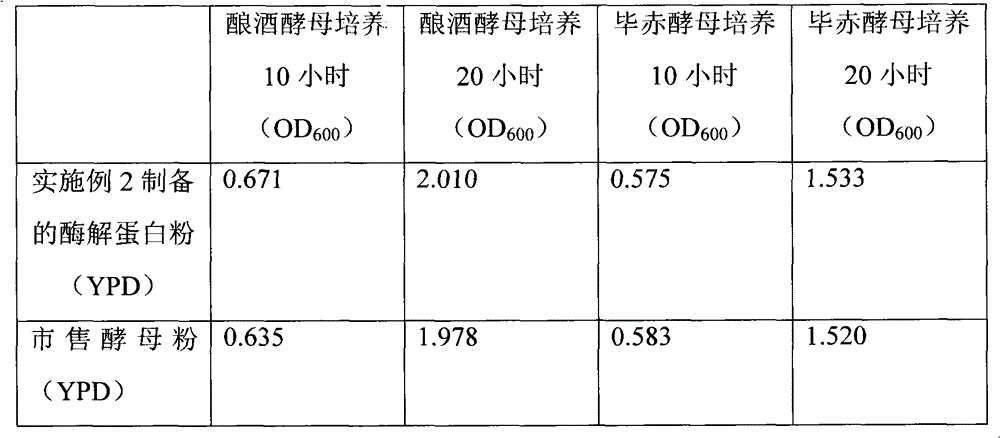

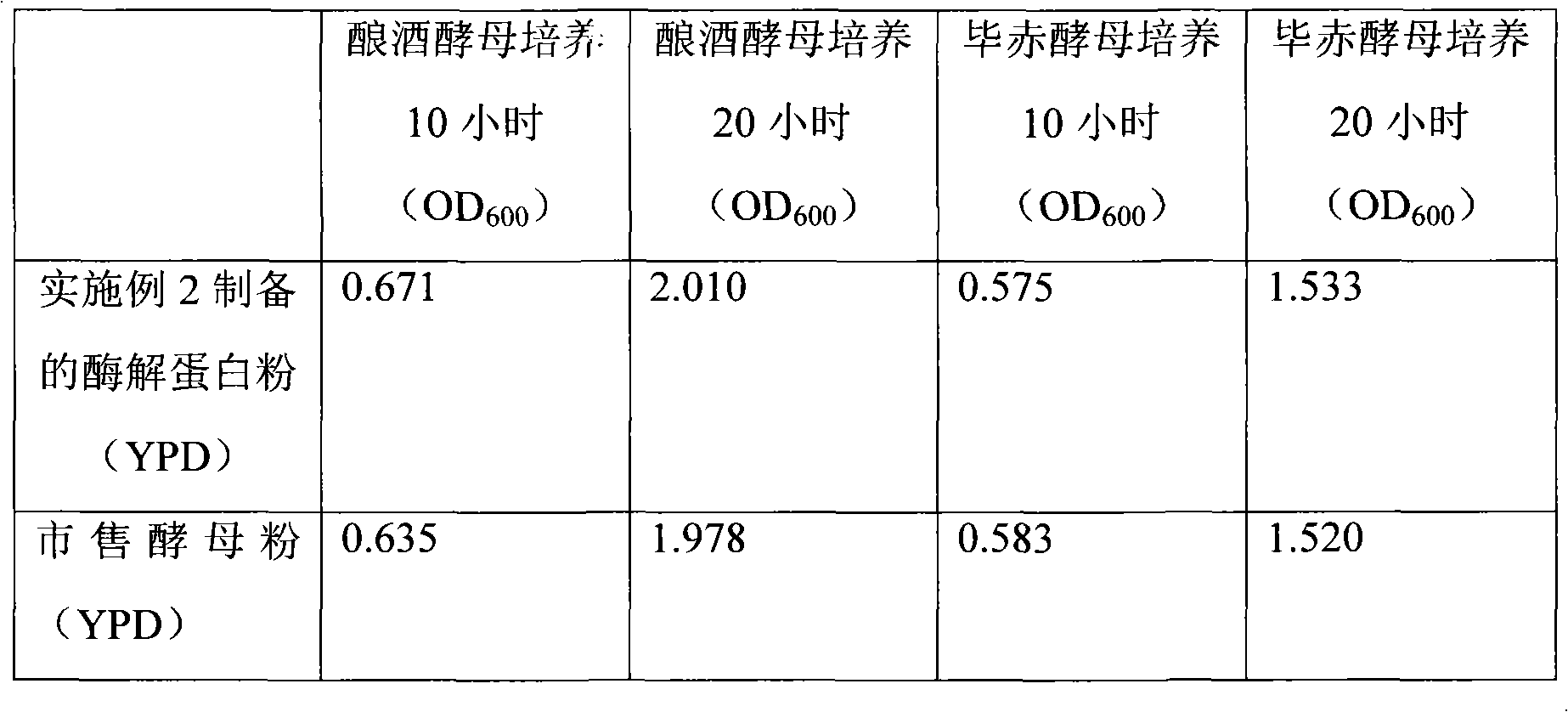

Amino acid fermentation bacteria utilization method

ActiveCN102719510AFacilitate efficient separationEasy to operateAnimal feeding stuffFermentationBiotechnologyMycoprotein

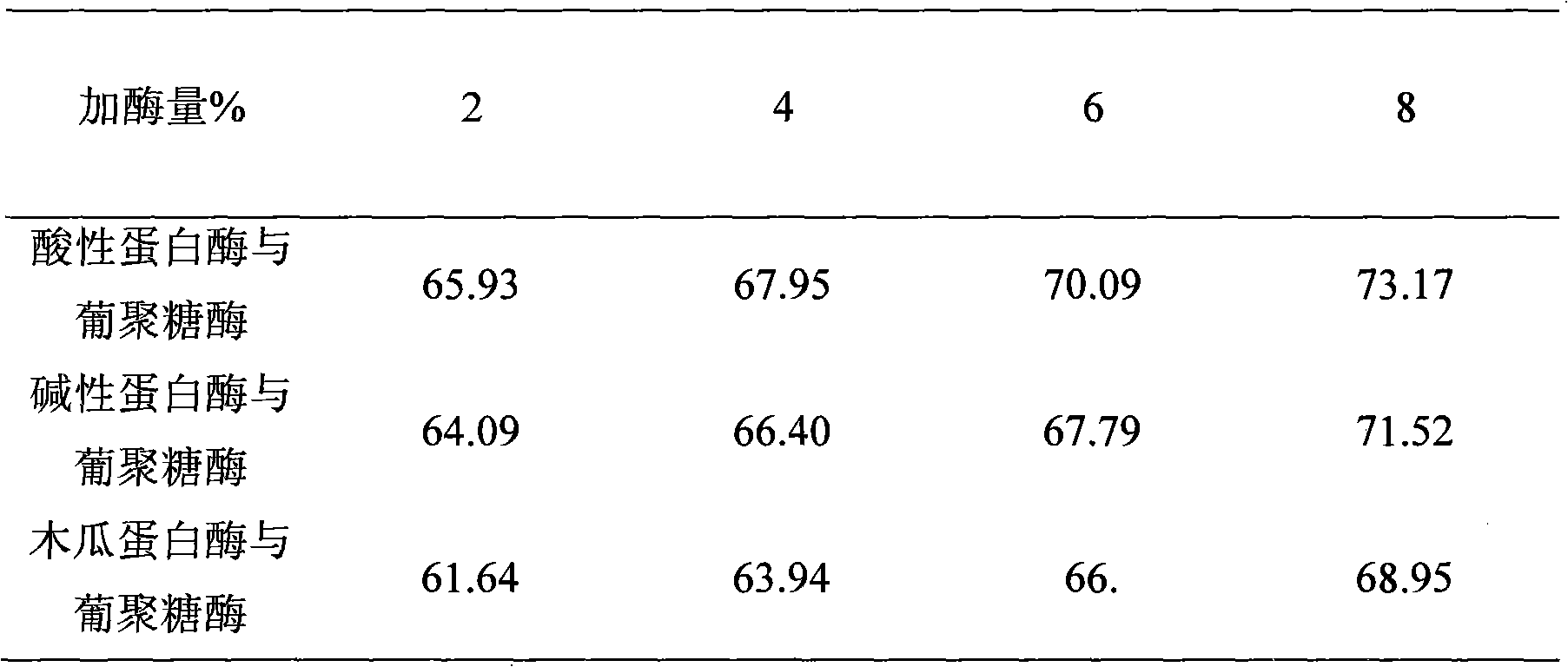

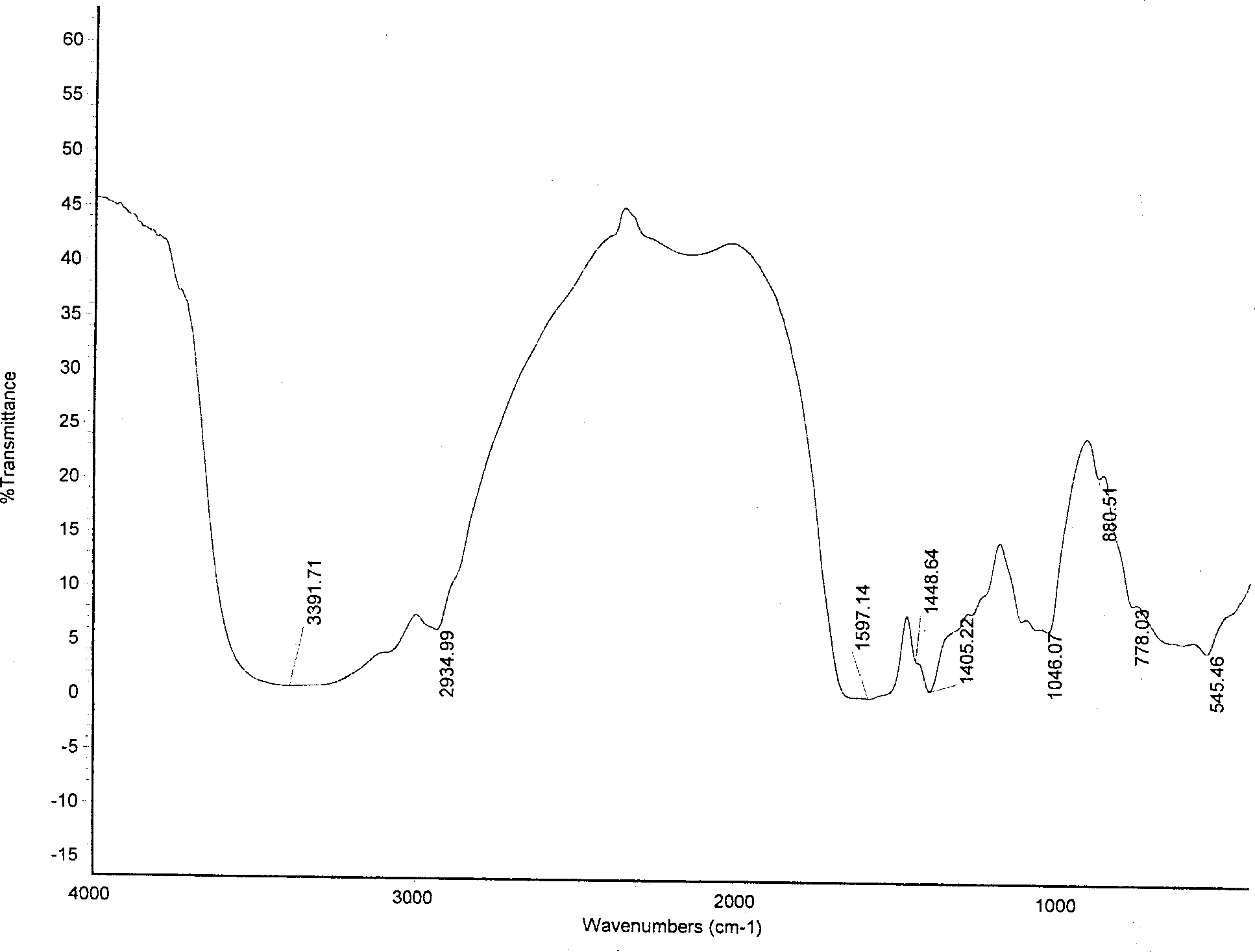

The invention discloses an amino acid fermentation bacteria utilization method, which belongs to the technical field of amino acid production. The method comprises the steps that by taking glutamic acid fermentation as an example and adopting the isoelectric point of fermentation broth, a disc separator is utilized to separate mycoprotein in the fermentation broth, and a moderate amount of compound enzyme is added into the mycoprotein serum, so that the walls of bacteria are broken and the bacteria are enzymetically hydrolyzed. The enzymatic hydrolysate is separated by the high-speed disc separator, and the cell walls are removed, the obtained clarified enzymatic hydrolysate is concentrated under low temperature to produce the enzymetically hydrolyzed mycoprotein extract, or the clarified enzymatic hydrolysate is dried by a gunite granulation fluidized bed drier, a spray granulation drier and the like to produce the enzymetically hydrolyzed mycoprotein powder. In the method, the utilization value of the mycoprotein is greatly increased, so that the mycoprotein is changed from cheap feed into high value-added yeast extract and yeast powder substitute, the product can be used as fermentation ingredient and in other fields, the resources can be sufficiently utilized in the whole process, the purposes of energy saving and consumption reduction are achieved, and the invention has a broad application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

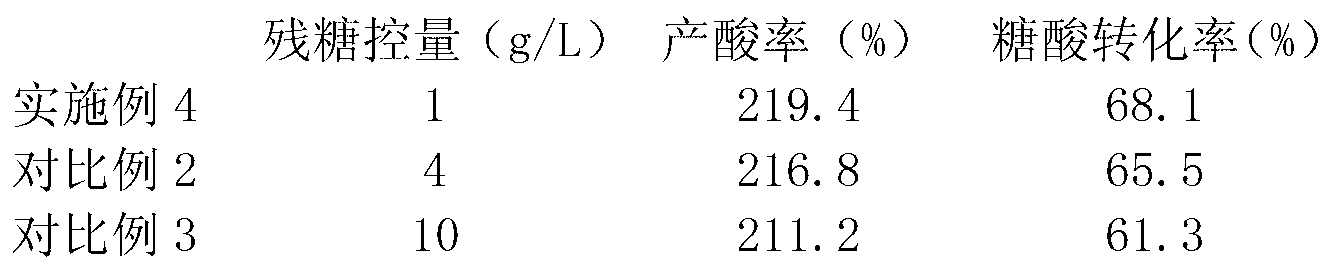

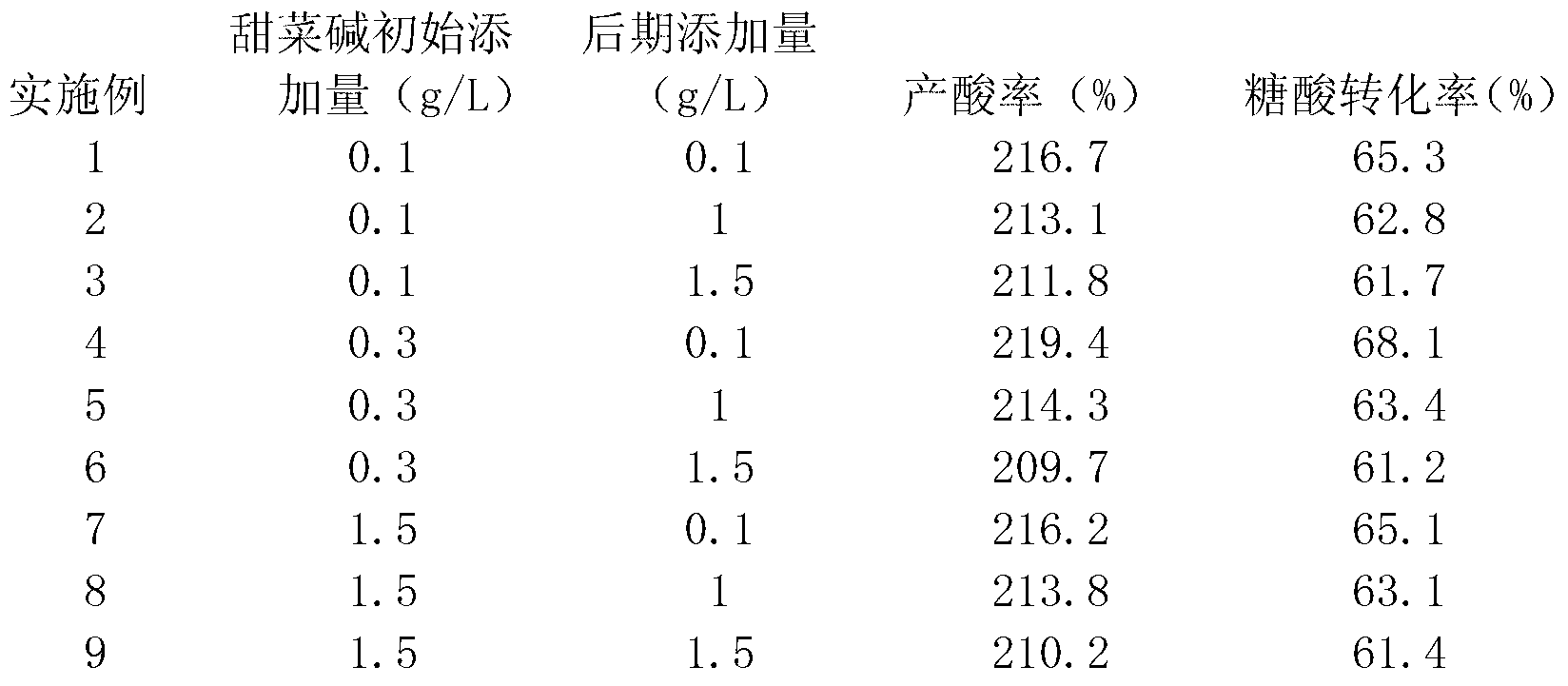

Method for increasing acid production rate and extracting rate of glutamic acid

ActiveCN109504719AReduce generationHigh transparencyBacteriaOrganic compound preparationProduction rateCeramic membrane

The invention belongs to the technical field of amino acids and discloses a method for increasing an acid production rate and an extracting rate of glutamic acid. The method for increasing the acid production rate and the extracting rate of the glutamic acid comprises the following steps: putting a brevibacterium flavum seed solution for producing the glutamic acid into a fermentation tank filledwith fermentation medium to carry out fermentation cultivation; when the brevibacterium flavum seed solution is fermented for 24 hours, separating out a fermentation solution in the fermentation tankvia a ceramic membrane; draining a filter liquor; putting concentrated thalli back into the fermentation tank; and meanwhile, supplementing a fermentation medium B to the fermentation tank; and continuing to carry out fermentation for 16 h to finish fermentation. The method for increasing the acid production rate and the extracting rate of the glutamic acid, disclosed by the invention, has the advantages that the glutamic acid fermentation process is more stable and easy to control by optimizing a culture medium; and moreover, the yield and glucose conversion rate of the glutamic acid are increased, the quality of the fermentation solution is improved, the glutamic acid extracting cost is reduced, and the comprehensive benefits are increased.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD +2

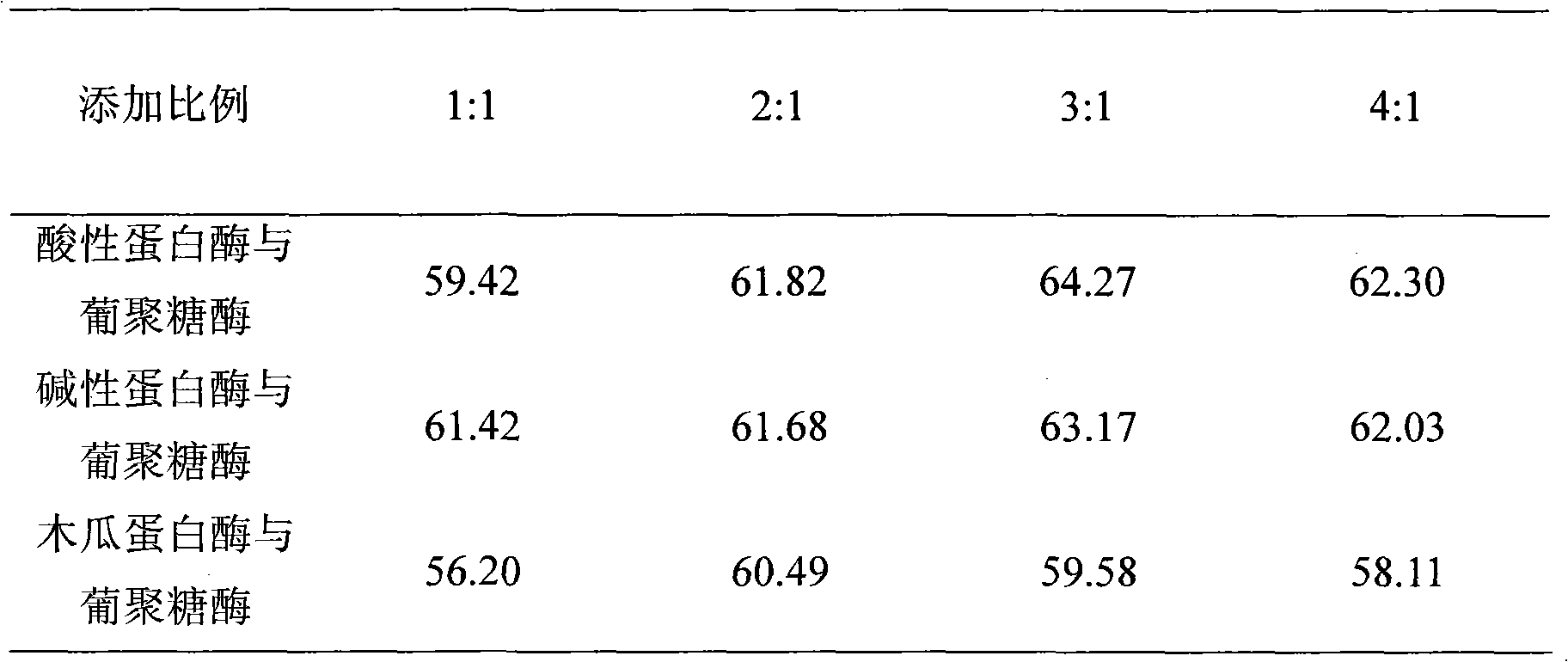

Method for preparing glutamic acid fermentation organic nitrogen additive from glutamic acid fermentation waste thalli

InactiveCN101979627ASolve pollutionIncrease valueMicroorganism based processesFermentationCombined methodFeed additive

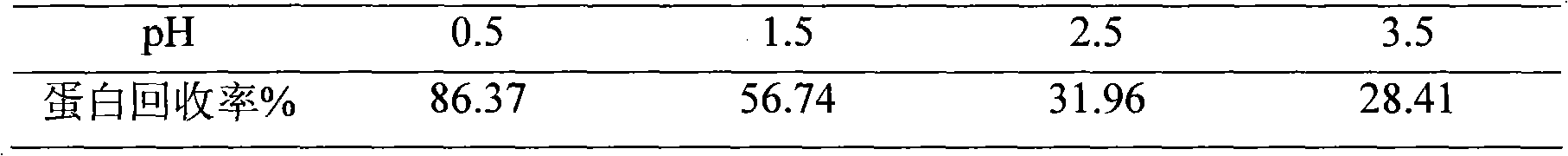

The invention relates to a method for preparing a glutamic acid fermentation organic nitrogen additive from glutamic acid fermentation waste thalli, which solves the problem that environment can be polluted by directly discharging fermented waste thalli or economic benefit is low when the fermented waste thalli are prepared into a feed additive in the conventional glutamic acid production. The glutamic acid fermentation waste thalli are taken as raw materials; protein hydrolyzate is obtained by enzymatic hydrolysis, acid hydrolysis or an enzymatic hydrolysis and acid hydrolysis combined method; and the hydrolyzate is concentrated or dried to prepare the organic nitrogen additive for fermentation. For the organic nitrogen additive prepared by the method, the protein recovery rate of the glutamic acid fermentation waste thalli reaches 93 percent; the prepared organic nitrogen additive can be recycled for glutamic acid fermentation and replaces yeast extract, peptone, corn steep liquor and other organic nitrogen additives which are used in the conventional glutamic acid production, so environmental pollution can be reduced and the added value of the organic nitrogen additive can be greatly improved; and the organic nitrogen additive has great significance for the comprehensive utilization of the glutamic acid fermentation waste thalli.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for prepering gamma-polyglutamic acid and polyglutamates

A process for preparing gamma-polyglutamic acid and polyglutamate includes such steps as culturing bacillus, such as Bacillus subtilis and lichen bacillus, in the culture medium containing carbon source, nitrogen source and Glu to obtain high-activity (1-10 U / ml) gamma-glutamyl transpeptidase, preparing high-concentration fermented liquid of gamma-polyglutamic acid, and solvent precipitation or chemical precipitation.

Owner:NANJING UNIV OF TECH

Process of preparing gamma-poly glutaminic acid

InactiveCN100999745AGood hygroscopicityGood moisturizing effectMicroorganism based processesFermentationOrganic solventNitrogen source

The present invention discloses poly-gamma-glutamic acid preparing process. The process includes the steps of culturing different kinds of poly-gamma-glutamic acid producing bacterial strains in culture medium containing carbon source, nitrogen source, NaCl and intermediate to obtain poly-gamma-glutamic acid fermenting liquor, precipitating in organic solvent, dialysis and drying to obtain poly-gamma-glutamic acid product. The process has the intermediate as the precursor for preparing poly-gamma-glutamic acid, and is simple, low in cost and high in yield.

Owner:ZHEJIANG UNIV

Biological bacterial fertilizer prepared from glutamic acid fermentation wastes

ActiveCN104262014AReduce processingLow costAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmino acid fermentationSlurry

The invention belongs to the field of treatment of fermentation waste liquid in biological fermentation industry and discloses a biological bacterial fertilizer prepared from glutamic acid fermentation wastes. The fertilizer is prepared by the following steps: S1) filtering the fermentation liquid; S2) decoloring, concentrating and crystallizing; S3) hydrolyzing; S4) preparing slurry B; and S5) preparing the biological bacterial fertilizer. The biological bacterial fertilizer disclosed by the invention effectively utilizes amino acid fermentation wastes, thereby lowering the production cost of the fertilizer and turning wastes into wealth. Moreover, the fertilizer which is durable is superior to similar products on the market.

Owner:内蒙古阜丰生物科技有限公司

Biological agent for processing glutamic acid fermentation waste water

ActiveCN104230004ASolve pollutionPromote growthMultistage water/sewage treatmentWaste water treatment from food industryMycoproteinGlutamic acid

The invention relates to biological agent for processing glutamic acid fermentation waste water. Mycoprotein is separated from glutamic acid fermentation liquid through a high-speed disc separator, bacteria removing liquid is gathered, the mycoprotein is precipitated, compound seed liquid is added to the mycoprotein for preparing probiotics, the waste water generated by extracting glutamic acid from the bacteria removing liquid is drained into a sewage processing system, compound microorganism bacterium agent is added to the waste water to perform advanced treatment, and the waste water is discharged after reaching the standard. The biological agent for processing glutamic acid fermentation waste water is economical and environmental friendly and has broad application prospect.

Owner:内蒙古阜丰生物科技有限公司

Environment-friendly process for treating glutamic acid fermentation wastewater

ActiveCN104261631ASolve pollutionPromote growthWater contaminantsAnimal feeding stuffBiotechnologyMycoprotein

The invention relates to an environment-friendly process for treating glutamic acid fermentation wastewater. Glutamic acid fermentation broth is subjected to mycoprotein separation by a high-speed disc separator, a degerming liquid is collected, mycoprotein is precipitated, a composite seed solution is added to the mycoprotein for fermentation to prepare a probiotic preparation, wastewater generated by extracting glutamic acid by the degerming liquid enters a sewage treatment system, a compound microbial agent is added for deep treatment, and then the wastewater is drained up to the standard. The environment-friendly process for treating glutamic acid fermentation wastewater is economical and environment-friendly, and has broad application prospect.

Owner:内蒙古阜丰生物科技有限公司

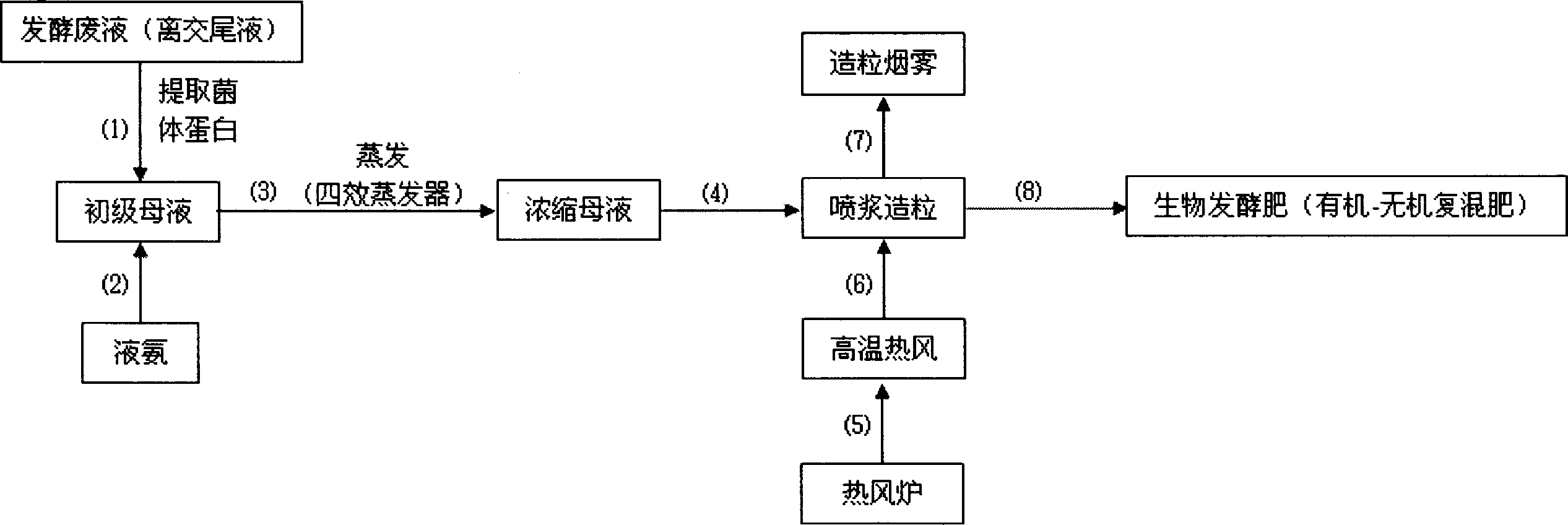

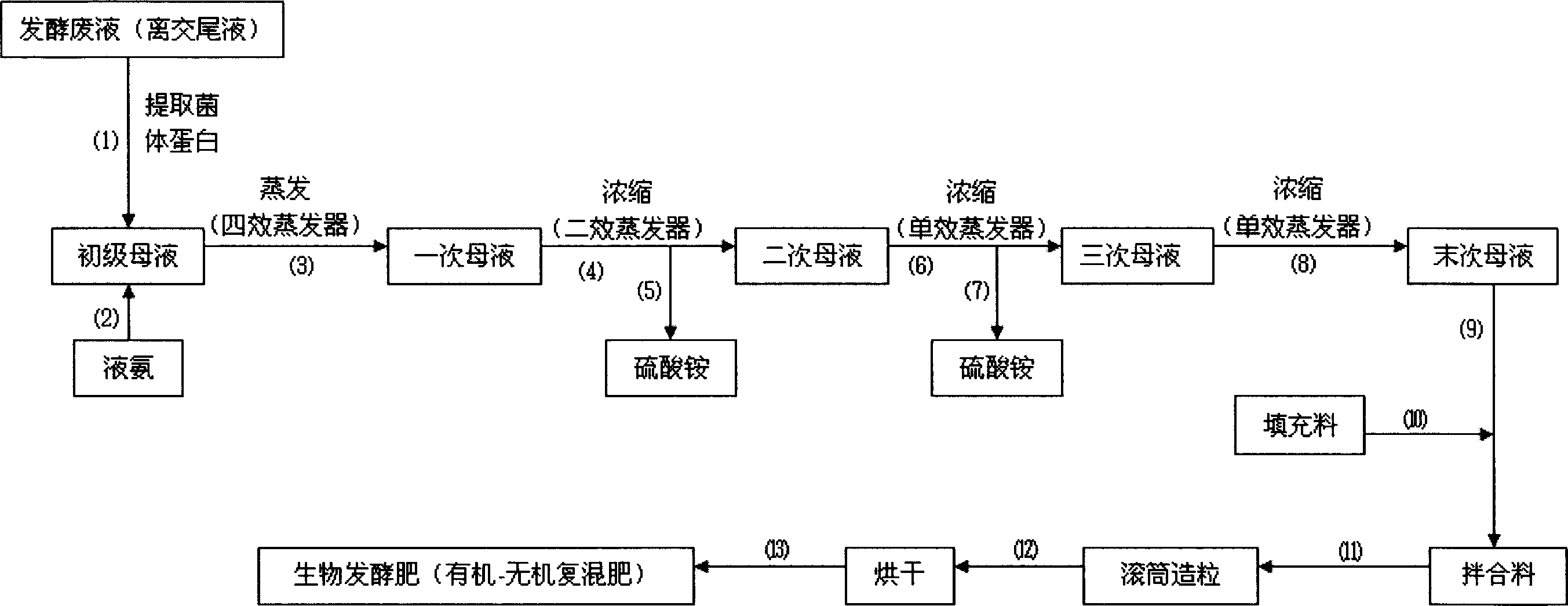

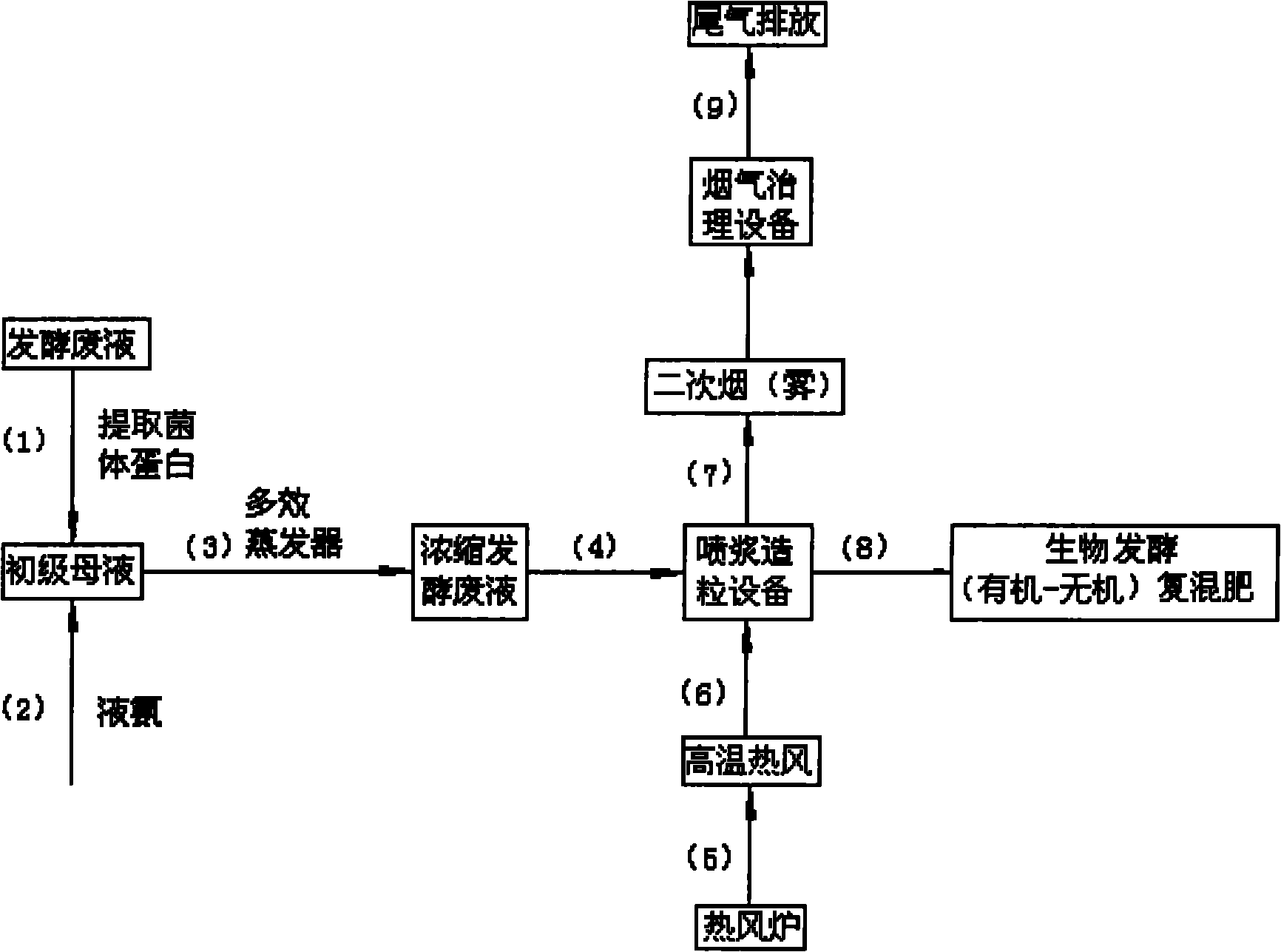

Process for producing biological fermented (organic-inorganic compound mixed) fertilizer from glutaminic acid fermenting waste liquid

InactiveCN1900022ANo secondary pollutionRich varietyClimate change adaptationSewage/sludge fertilisersLiquid wasteInorganic compound

The waste fermented liquid from glutamic acid production contains great amount of thallus, intermediate fermenting products and trace elements. The present invention provides the technological process of producing fermented fertilizer as one kind of organic-inorganic composite fertilizer with the waste fermented liquid from glutamic acid production. The technological process includes the steps of evaporating concentration, extracting ammonium sulfate, stirring mixing, drum pelletizing and stoving. The present invention has high economic benefit and environment benefit.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

Method for producing high-yield gamma-propalanine and application thereof

InactiveCN102174449ALow costImprove brain functionBacteriaChemical industryFood engineeringBioconversion

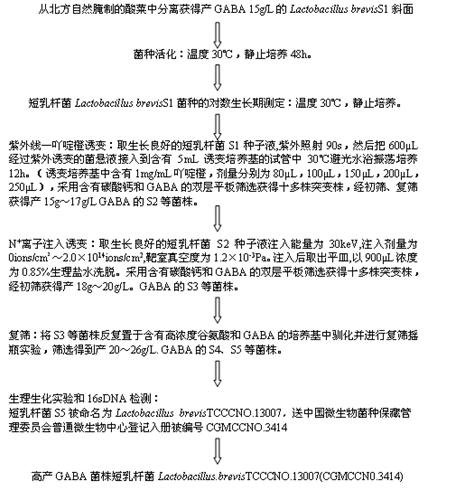

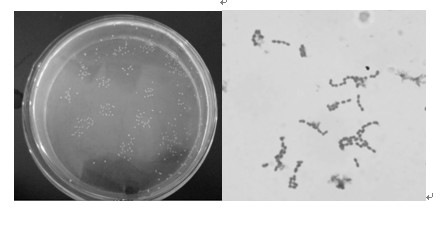

The invention relates to a method for producing high-yield gamma-propalanine and an application thereof, belonging to the technical field of biotechnology medicine and food engineering. The method comprises the following steps: carrying out strain separated screening, acridine orange-ultraviolet ray mutagenesis and N<+> injection mutagenesis to obtain a high-yield gamma-propalanine LactobacillusbrevisTCCC (CGMCC No.3414) strain; optimizing a fermentation medium and fermentation conditions; coupling fermentation of the gonotokont of the strain with resting cell biotransformation of the strain to produce the gamma-propalanine; employing the membrane filtration technology, the adsorbent resin decoloration technology, the strong acid resin cation exchange technology, the ethanol recrystallization technology, the preparative chromatography technology and the energy-saving and cost-reducing technology to separate the gamma-propalanine from the fermentation fluid and the biotransformation fluid; and then carrying out purification to obtain the crystallized gamma-propalanine with the purity of 99%. The method has the advantages of cheap raw materials, low energy consumption for production, low production cost, good product security and easy realization of industrialized production. Applied to glutamic acid fermentation waste liquor for producing the gamma-propalanine, the strain has good potential for generating social and economic benefits.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Feed additive for monogastric animals

InactiveUS6514521B1Maximize reproductive efficiencyReduce morbidityAnimal feeding stuffAccessory food factorsOrganonitrogen compoundsFeed additive

A feed additive for monogastric animals, comprising dried glutamic acid fermentation solubles, dried corn fermentation solubles, or a mixture of dried glutamic acid fermentation solubles, wherein said dried solubles have been dried to a total moisture content of less than 30% by weight at a temperature that does not denature any organic nitrogen compounds present in the solubles and wherein the feed additive increases reproductive efficiency in monogastric animals.

Owner:CATALYST INT INC

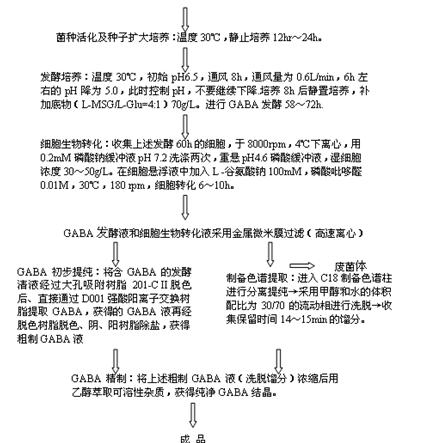

Production method and application of high-yield gamma-aminobutyric acid

ActiveCN102559552ALow costImprove brain functionBacteriaMicroorganism based processesBiotechnologyEngineering

The invention discloses a production method and an application of high-yield gamma-aminobutyric acid. The conservation number of high-yield gamma-aminobutyric acid (GABA) raffinose enterococcus M1 is CGMCC (China General Microbiological Culture Collection Center) No.5584. The production method comprises the following steps of: separating and selecting strains to obtain an Entercoccusraffinosus TCCC11660 (CGMCCNo. 5584) strain of high-yield gamma-aminobutyric acid; optimizing a fermentation culture medium and fermentation conditions; and carrying out a 10L fermentation tank experiment. The production method has the advantages of cheap raw materials, low production energy consumption, low production cost, good product safety and the like, and industrial production is easy to realize. The strain is applied to production of gamma-aminobutyric acid through glutamic acid fermentation and has good social and economic benefits.

Owner:TIANJIN UNIV OF SCI & TECH

New production technique of sodium glutamate

InactiveCN101491323AAvoid isoelectric ionization processShort processFood preparationMycoproteinFiltration

The invention discloses a novel process for producing monosodium glutamate, which comprises the following key points: performing two stages of membrane filtrations on a glutamic acid fermentation broth obtained through fermentation so as to eliminate mycoproteins and other macromolecular substances; performing decolorization through active carbons, sheet frame filtration, alkali neutralization and concentration on the fermentation broth; performing ammonia blowoff recycling in the process of the concentration; performing further decolorization through a particle carbon column; and performing concentration and crystallization to prepare the final product of the monosodium glutamate. The process achieves the procedure of converting the glutamic acid fermentation broth into sodium glutamate directly without extracting the glutamic acid, has the advantages of simple operation, short production period, low cost, less pollution, high added value of by-products, and the like, and solves the problems that the production of the monosodium glutamate by the prior art has over-dependence on sulphuric acid, high yield of wastewater and lower quality of the by-products.

Owner:山东阜丰生物科技开发有限公司

Environmental-protecting process for fermenting glutamic acid

Fermentation of glutamic acid is characterized by producing secondary steam condensate water during of recovery fermentative-liquid concentration process. It's cheap, saves water and has environmental pollution.

Owner:LINGHUA GROUP INCORPORATED COMPANY

Monosodium glutamate production technology

The invention discloses a monosodium glutamate production technology which comprises the following steps: fermenting glutamic acid; extracting glutamic acid: a glutamic acid fermentation broth is subjected to pasteurization and two-stage ultrafiltration to obtain bacteria paste and a glutamic acid clear solution, the glutamic acid clear solution is subjected to evaporation and concentration, and is separated after continuously isoelectric cooling to obtain crystallized alpha-glutamic acid and a separated mother solution; mixing, heating and keeping warm and separating alpha-glutamic acid and a crystal transformation mother solution to obtain the glutamic acid, preparing a suspension liquid through mixing the glutamic acid and water, controlling the crystal transformation pH value to be 4.0-5.0, rising the temperature, carrying out the crystal transformation to obtain beta-glutamic acid, neutralizing with a sodium carbonate water solution, then performing activated carbon decolorizing, filtering, carrying out decoloration and iron removal on the filtrate through a granular activated carbon column, performing evaporative crystallization and centrifugal separation on the decoloring solution, drying and screening to obtain the finished product. The monosodium glutamate production technology has the advantages that the discharge of waste liquid during the monosodium glutamate production process is reduced, the consumption of chemicals is reduced, the production cost is reduced, the economic benefit is improved, and the resource recycling is facilitated.

Owner:广州奥桑味精食品有限公司

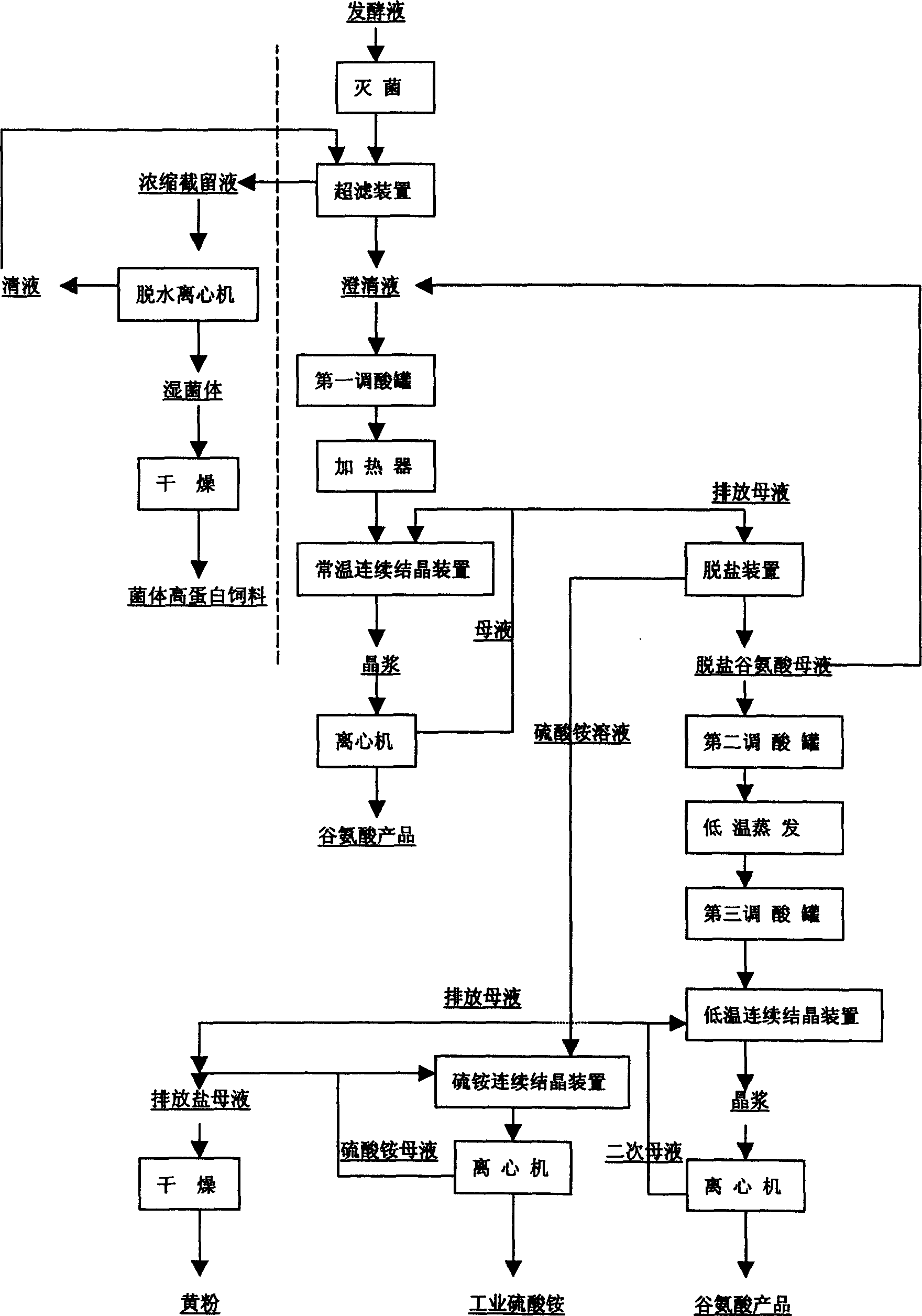

Glutamic acid extraction technology in production of glutamic acid by fermentation method

InactiveCN1597661AReduce dosageContinuous processOrganic compound preparationAmino-carboxyl compound preparationUltrafiltrationEvaporation

A process for extracting glutaminic acid in the procedure of preparing glutaminic acid by fermenting method includes such steps as sterilizing the fermented liquid, ultrafiltration, regulating pH=3.2-3.25, crystallizing, separation, washing to obtain the crystal of glutaminic acid and mother liquid, desalting part of mother liquid, merging part of desalted mother liquid with said fermented liquid regulating pH value of the rest, evaporation concentrating, regulating pH value, crystallizing, separation and washing.

Owner:徐昌洪

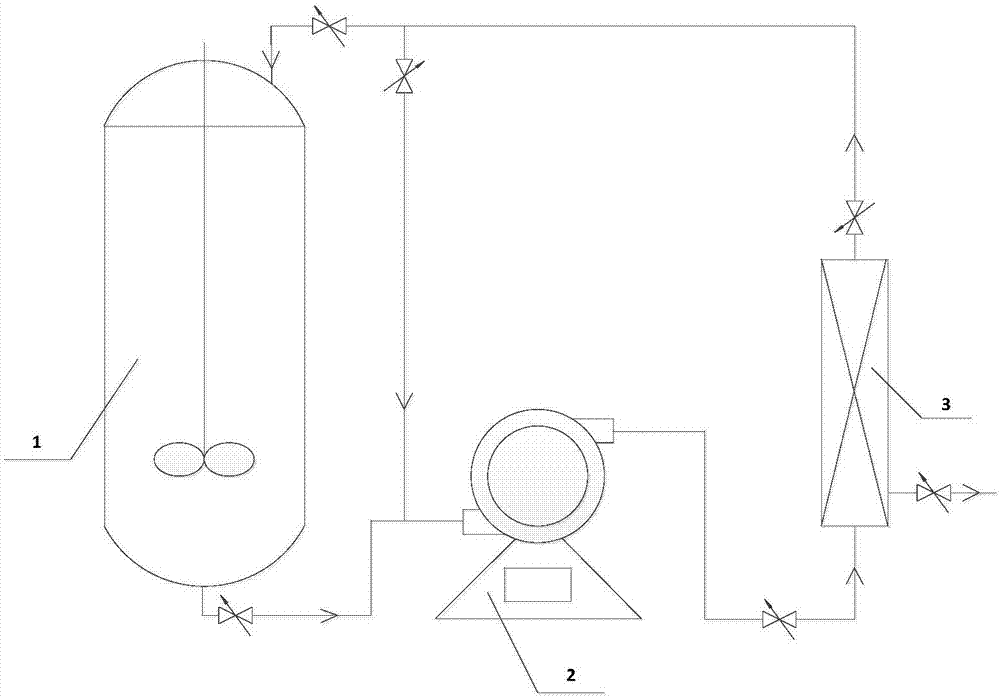

Fermentation technology of glutamic acid

InactiveCN107227324AImprove utilization efficiencyImprove conversion rateOrganic compound preparationAmino-carboxyl compound preparationHigh concentrationFiltration

The invention provides a submoderate fermentation technology of glutamic acid biotin. By using a fermentation tank and a membrane coupling technology, filtration dialysis is performed in the fermentation process to separate glutamic acid from a fermentation solution in time, so that feedback regulation caused by high-concentration glutamic acid in the fermentation solution is avoided; through adoption of a specific dialysis fermentation culture medium formula, refermentation is performed, so that the bacterium utilization efficiency and the sugar-acid conversion rate are improved; in addition, through the filtration dialysis after a certain period of fermentation, toxic byproducts in the fermentation solution can be separated in time, so that bacterial acid production inhibition is reduced; therefore, in the fermentation technology provided by the invention, through dialysis fermentation, a refermentation technology of the bacteria is achieved, the acid production cycle of glutamic acid fermentation is prolonged, and the bacterium utilization efficiency and the sugar-acid conversion rate are improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing nutritious sauce from glutamic acid tropina

A process for preparing the nutritive flavouring juice from the somatic protein recovered after the fermentation of glutamic acid includes washing the thallus of glutamic acid in water, acid hydrolyzing, adding red koji and yeast, chemical and biological fermenting, and further processing to fermented liquid. Its advantages are rich nutrients, delicious taste and strong fragrance.

Owner:YANTAI TAIHUA MARINE FOOD

Feed additive for ruminant animals

InactiveUS6312710B1Maximize efficiencyMaximize growthFood processingCoupling device detailsRuminant animalFeed additive

A feed additive for ruminants, comprising dried glutamic acid fermentation solubles, dried corn fermentation solubles, or a mixture of dried glutamic acid fermentation solubles and dried corn fermentation solubles, wherein said dried solubles have been dried to a total moisture content of less than 30% by weight at a temperature not less than about 80° F. and not more than about 900° F.

Owner:CHURCH & DWIGHT CO INC

Method for treating high-concentration wastewater of glutamic acid

ActiveCN102701507AImprove qualityLow costWater/sewage treatment by centrifugal separationDispersed particle separationWastewaterEnergy conservation

The invention provides a method for treating high-concentration wastewater of glutamic acid, in particular a method for fermenting discarded thalli by utilizing the enzymolysis of a compound enzyme and treating other waste liquid by utilizing the electroosmosis of a bipolar membrane. By the method, the problem that active ingredients cannot be separated from the high-concentration wastewater of the glutamic acid is solved, glutamic acid fermentation residual sugar can be utilized fully, energy efficiency is high, the discharge of the wastewater is a few, and the pollution is low; and an electroosmosis technology has the advantages of simplicity of operation, no pollution, long service life and the like, the investment cost of enterprises is reduced, and the effects of energy conservation,emission reduction and multiple purposes are achieved.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Method for preparing gamma-polyglutamic acid through soild fermentation by utilizing edible fungi residues

ActiveCN104673851AReduce pollutionSave resourcesMicroorganism based processesFermentationFungicideThallus

The invention discloses a method for preparing gamma-polyglutamic acid through solid fermentation by utilizing edible fungi residues. The method comprises the following steps: (1) preparation of solid fungicide: collecting thallus in gamma- polyglutamic acid fermentation liquor to be mixed with a carrier, and drying to obtain the solid fungicide; (2) solid fermentation: inoculating the solid fungicide obtained from the step (1) into a fermentation medium to be mixed uniformly, and fermenting to prepare the gamma-polyglutamic acid, wherein the fermentation medium consists of a solid matrix and an exogenous additive, and the solid matrix is a mixture of the edible fungi residues and aginomoto. Compared with the prior art in which gamma-polyglutamic acid is produced through solid fermentation, the method disclosed by the invention is used for efficiently producing gamma-polyglutamic acid, the production cost is greatly reduced through the utilization of agricultural waste residues, meanwhile, a new way is found for the disposal of the residues, and the environment pollution problem caused by the residues is avoided. Therefore, the method is a high-efficient, low-cost, environment-friendly biological reaction process and has good industrial application prospect.

Owner:轩凯生物科技(山东)有限公司

Special strawberry composite biological fertilizer as well as preparation method and application thereof

InactiveCN107827627AReduce pollutionReduce cost inputCalcareous fertilisersBio-organic fraction processingAureobasidium sp.Nutrients substances

The invention relates to a special strawberry composite biological fertilizer as well as a preparation method and application thereof. The special strawberry composite biological fertilizer comprisesthe following components: EDTA-Ca (Ethylene Diamine Tetraacetic Acid), magnesium sulfate heptahydrate, EDTA-Mg, heptahydrate, EDTA-Zn, manganese sulfate monohydrate, EDTA-Mn, boric acid, EDTA-Fe, EDTA-Cu, soybean molasses, polyglutamic acid fermentation broth, chitosan oligosaccharide, algin, compound amino acid, humic acid, bacillus thuringiensis fermentation broth, bacillus megatherium fermentation broth, bacillus mucilaginosus fermentation broth and streptomyces jingyangensis fermentation broth. Through bacterium activation, seed liquid preparation, fermentation culture and compounding, thecomposite biological fertilizer is prepared, the composite biological fertilizer is applied to strawberry planting, and a diluted composite biological fertilizer liquid is sprayed at different growthstages of strawberry respectively. Due to synergetic effects of substances such as inorganic salts, organic matters and microorganisms, long lasting nutrient substances are provided to strawberry crops, absorption of nutrients in soil by plants is promoted, the fertilizer amount is reduced, and the chemical fertilizer cost is reduced.

Owner:天津北洋百川生物技术有限公司

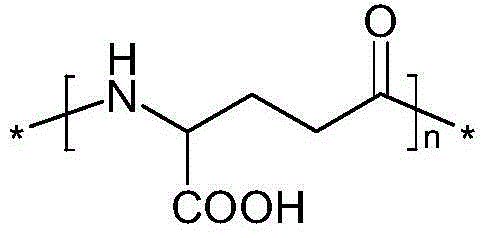

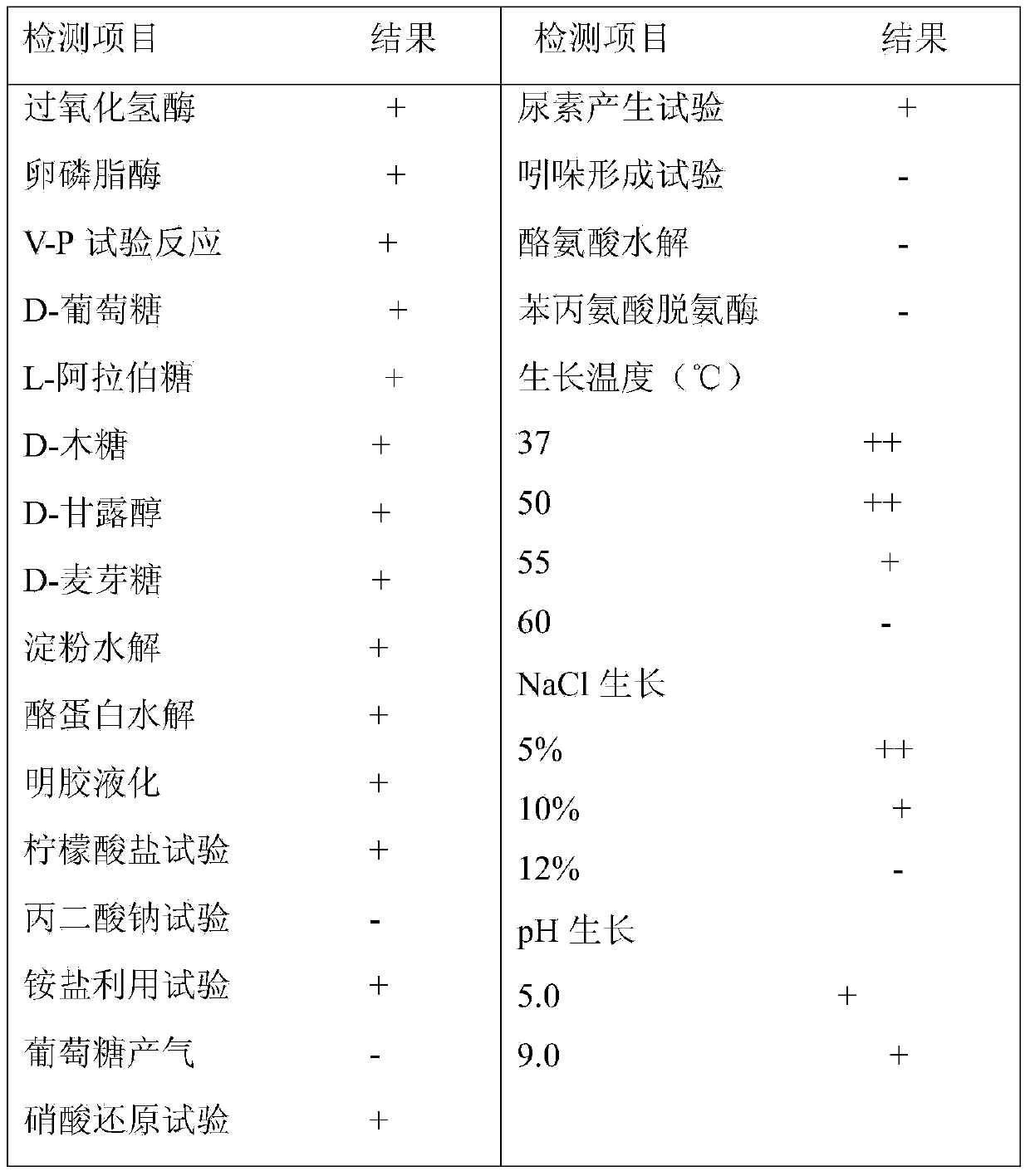

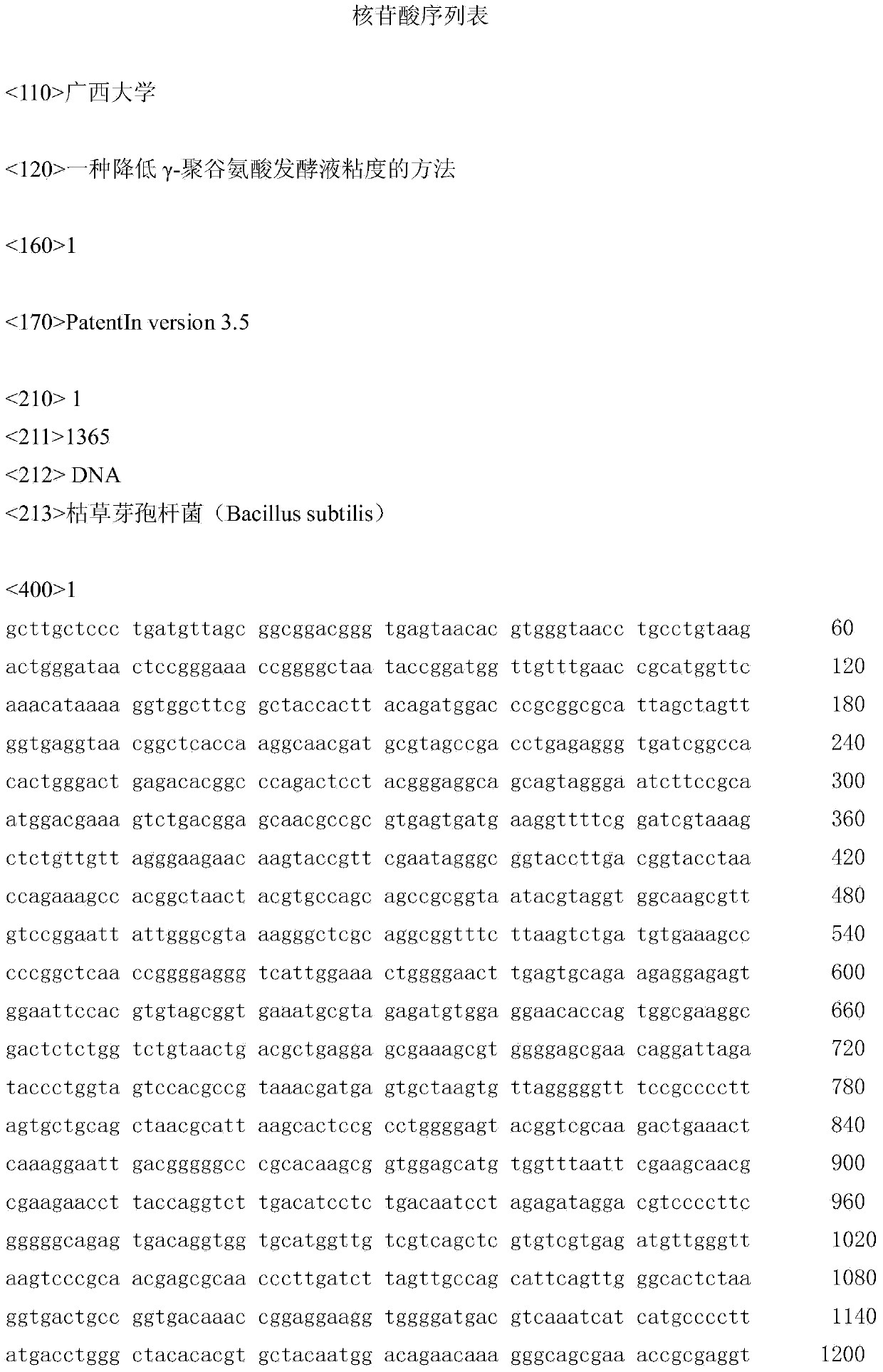

Method for reducing viscosity of gamma-polyglutamic acid fermentation liquid

InactiveCN104087628AIncrease osmotic pressureSolve the technical problem of viscosity increaseMicroorganism based processesFermentationHigh concentrationFermentation broth

The invention discloses a method for reducing the viscosity of a gamma-polyglutamic acid fermentation liquid. The method comprises the steps of bacterium activation, seed liquid preparation and liquid shaking bottle fermentation. In liquid medicine bottle fermentation, high concentration KCl is added to a liquid fermentation culturing medium, and the concentration of the high concentration KCl is 0.5-30g / L; the above bacterium is Bacillus subtilis GXA-28, has a preservation number of CCTCCNO:M2012347, and is preserved in China Center for Type Culture Collection on Sep. 14, 2012. The method enabling the KCl with the concentration of 0.5-30g / L to be added to the liquid state fermentation culturing medium in the initial stage of fermentation reduces the viscosity by 10-80% on the basis of maintaining high molecular weight and high output of gamma-polyglutamic acid, solves the bottleneck problem of the large viscosity of a gamma-PGA fermentation producing liquid, has a very good application prospect, has a low cost, and reduces the separation and purification cost of products in the industrial production.

Owner:GUANGXI UNIV

Fertilizer synergistic additive and preparation thereof

InactiveCN105585371AIncrease the effective concentrationControl formFertilizer mixturesThioureaSorbitan

The invention relates to technology of synergy for fertilizers, and more specifically relates to a fertilizer synergistic additive and a preparation thereof. The solid dosage form synergistic additive comprises the following raw materials in percentage by weight: 55-93.5% of fermentation broth of polyglutamic acid, 0.5-3% of thiourea, 0.5-9% of N-(n-butyl)thiophosphoric triamide, 5-30% of dicyandiamide, and 48-91% of diatomite. Or the liquid dosage form synergistic additive comprises the following raw materials in percentage by weight: 55-93.5% of fermentation broth of polyglutamic acid, 0.5-3% of thiourea, 0.5-9% of N-(n-butyl)thiophosphoric triamide, 5-30% of dicyandiamide, and 0.5-3% of an emulsifier. The fermentation broth contains 3-10% of polyglutamic acid, and the emulsifier is polyoxyethylene sorbitan fatty acid ester. The fertilizer synergistic additive can increase effective concentration of fertilizer nutrients, prolong effective period of the fertilizer, promote crops to absorb and transport nutrients, overcome the problem of insufficient release of the long-acting slow-release fertilizer nutrients at early stage, guarantee efficiency of fertilizer at later period, the validity period of fertilizer nutrients is longer than 120 days, so that long-acting and high-efficiency utilization of fertilizer nutrients are realized.

Owner:辽宁中科生物工程股份有限公司

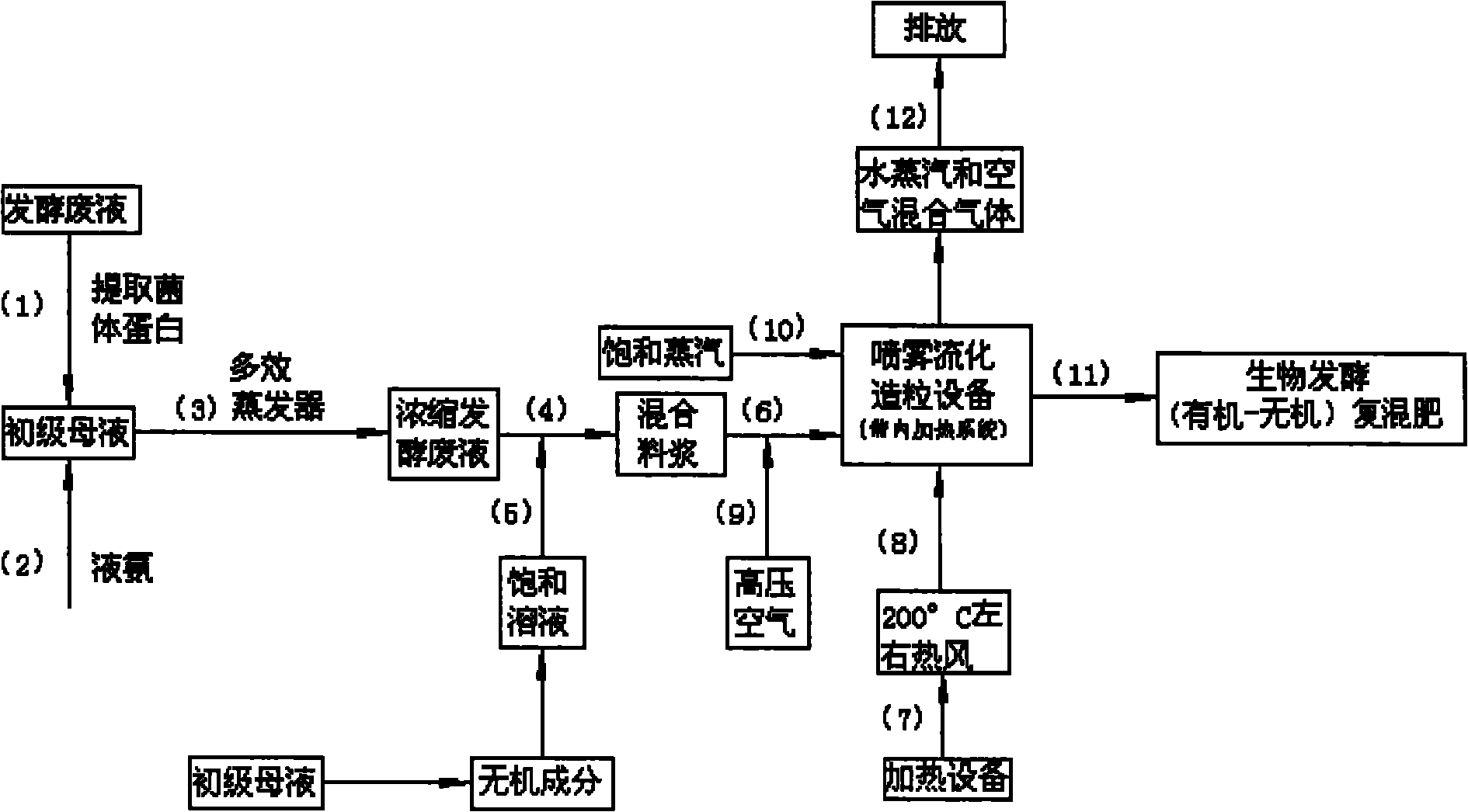

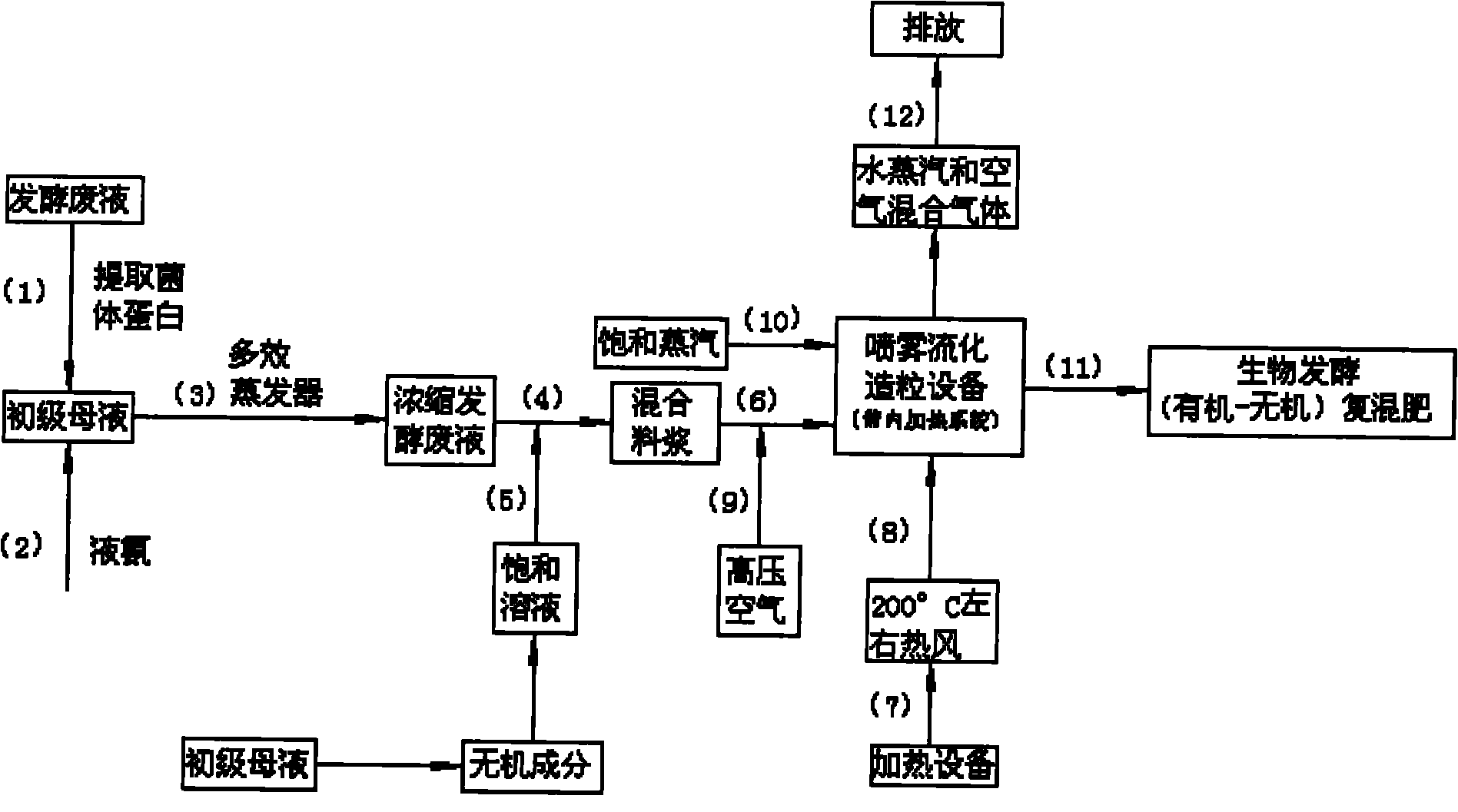

Method for producing biological fermentation compound fertilizer by fermenting organic waste water with glutamic acid

InactiveCN102093110ABiological fermentation compound fertilizer is goodNot prone to dehydration, coking and decompositionClimate change adaptationSewage/sludge fertilisersMycoproteinFungus protein

The invention discloses a method for producing a biological fermentation compound fertilizer by fermenting organic waste water with glutamic acid, which mainly comprises the following steps: carrying out multiple-effect evaporation concentration on waste liquor fermented by glutamic acid, extracting mycoprotein, carrying out multiple-effect concentration, carrying out low-temperature spraying fluidized granulation (adding inorganic constituents), screening, and cooling to obtain the finished biological fermentation compound fertilizer product. The method can overcome the defect that organic substance constituents can be coked and decomposed at high temperature, causing secondary pollution on the atmosphere and soil pollution caused by carbides in the spouting granulation technique, and develops a creative way for realizing zero discharge of organic waste water.

Owner:QEA INVESTMENT GROUP INNER MONGOLIA BIOTECH

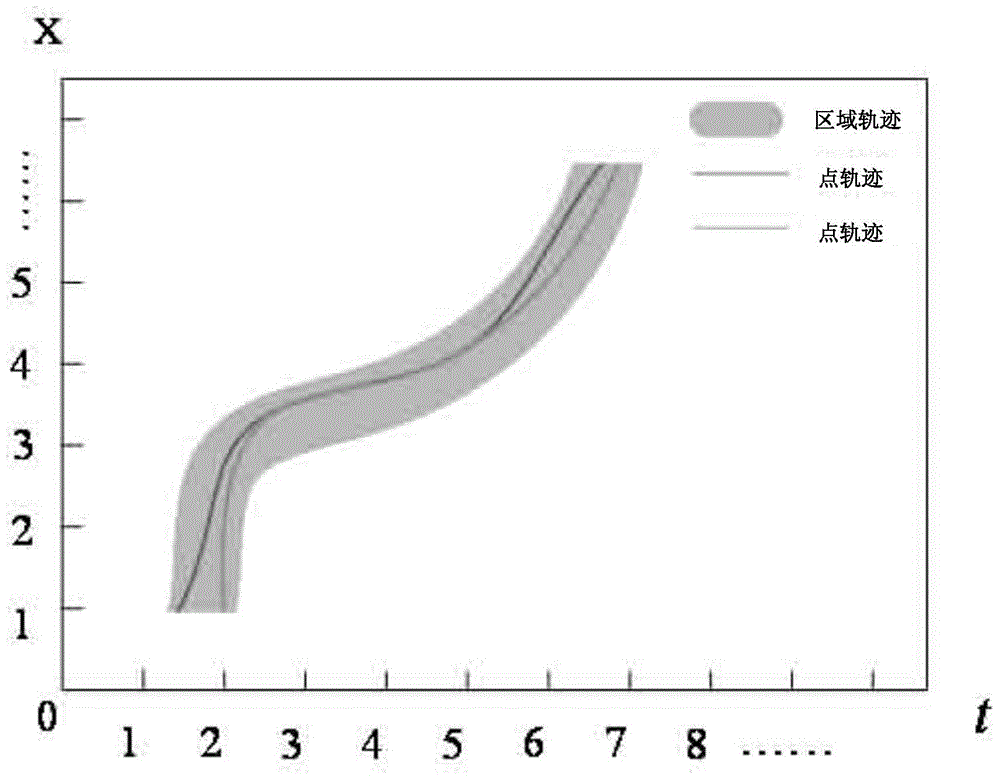

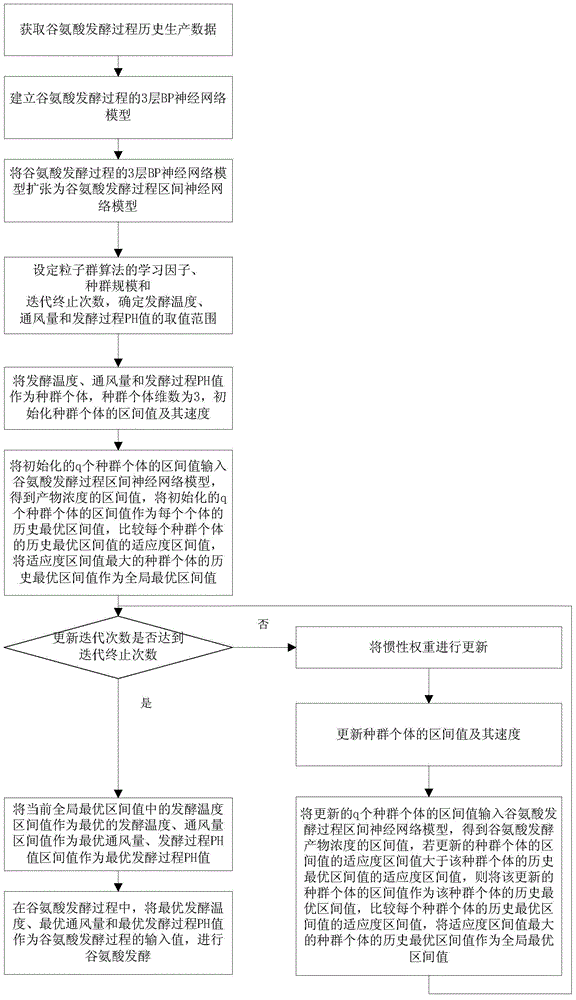

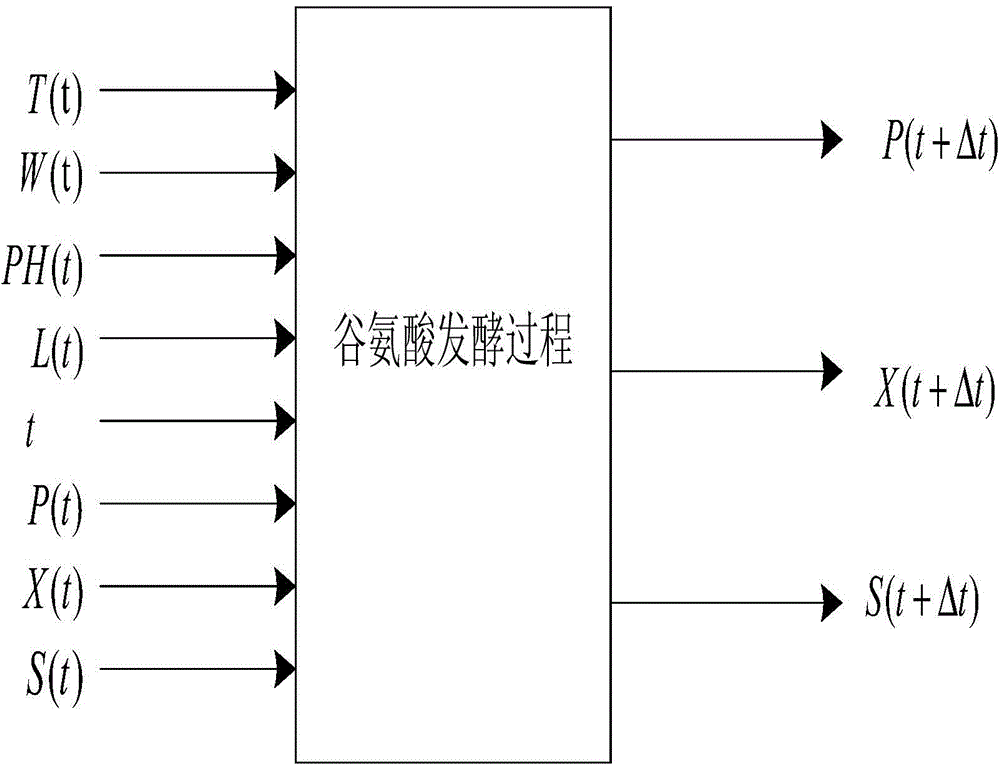

Method for improving concentration of glutamic acid fermented product based on interval optimization

The invention discloses a method for improving concentration of a glutamic acid fermented product based on interval optimization; the method comprises the steps: acquiring historical production data of glutamic acid fermentation process and establishing a three-layer BP (Back Propagation) neural network model of the glutamic acid fermentation process; expanding three-layer BP neural network model of the glutamic acid fermentation process to be an interval neural network model of the glutamic acid fermentation process; using PH value, fermentation temperature and ventilation quantity during fermentation as variables, using the concentration of the glutamic acid fermented product as an optimization target, performing interval optimization for the interval neural network model of the glutamic acid fermentation process by means of an interval particle swarm optimization algorithm and obtaining the optimal fermentation temperature, the optimal ventilation quantity and the optimal PH value of the fermentation process for the maximum concentration of the glutamic acid fermented product; and fermenting glutamic acid according to the optimal fermentation temperature, the optimal ventilation quantity and the optimal PH value of the fermentation process.

Owner:NORTHEASTERN UNIV

Method for preparing L-glutamic acid by fermentation

ActiveCN103243131AIncreased oxygen consumption rateIncrease growth rateMicroorganism based processesFermentationLactic acid bacteriumBetaine

The invention provides a method for preparing L-glutamic acid by fermentation. According to the method provided by the invention, a temperature-sensitive type glutamic acid producing strain is adopted during the fermentation process of the L-glutamic acid, and different low-concentration betaines are added into a culture medium by stages for stimulating cell respiration, so that the oxygen consumption rate of thalli is improved, the accumulation of lactic acid bacteria is inhibited, the fermentation culture temperature is simultaneously regulated and controlled, and then the acid yield and glucose-acid inversion rate of the glutamic acid are improved. The glutamic acid prepared by the method provided by the invention does not contain phosphorus components, can be directly used for industries of health care foods and medicines, and has greater application values.

Owner:山东祥维斯生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com