Process for producing biological fermented (organic-inorganic compound mixed) fertilizer from glutaminic acid fermenting waste liquid

A fermentation waste liquid and bio-fermentation technology, applied in the field of amino acid fermentation, can solve the problems of difficult diffusion of flue gas, large investment in equipment, large energy consumption, etc., and achieve obvious social benefits, obvious environmental benefits, and many types of fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

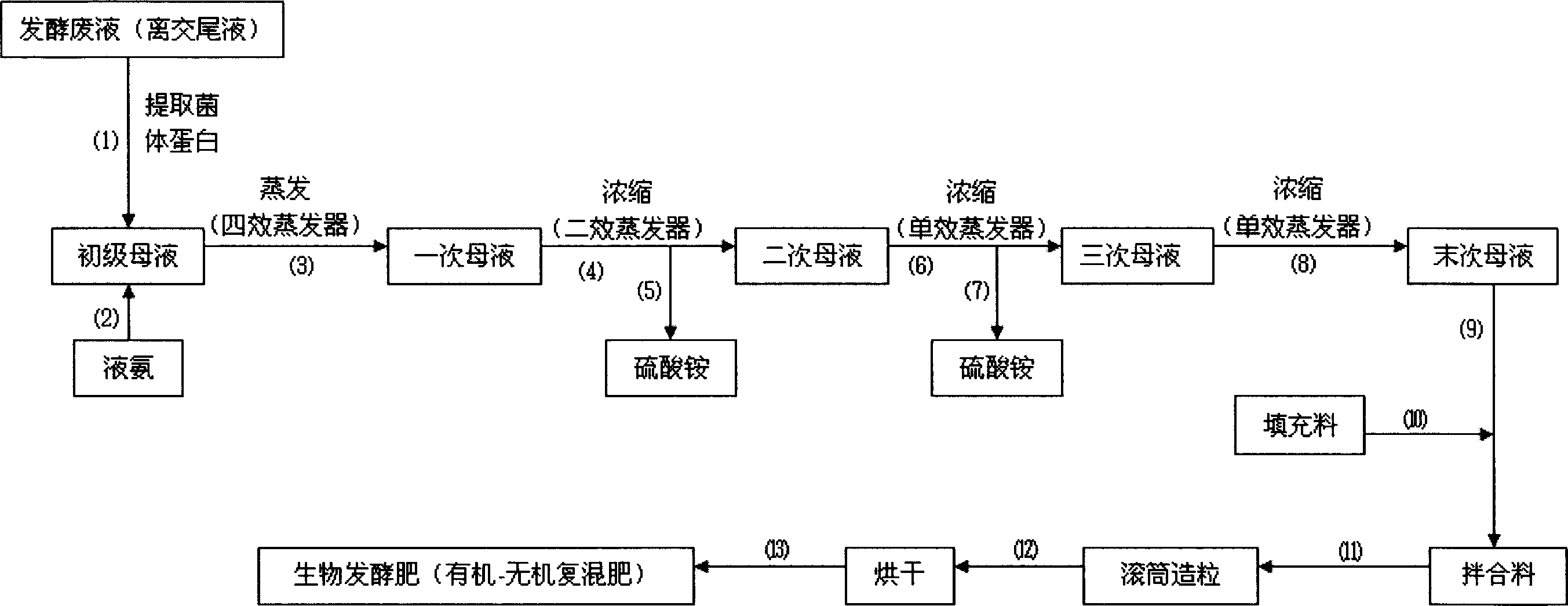

[0046] The process flow is as shown in the accompanying drawings figure 2 shown.

[0047] Fermentation waste liquid formed after extracting glutamic acid from the glutamic acid fermentation liquid (separated mating liquid) (1) extract bacterial protein to form the primary mother liquid, pass through liquid ammonia (2) adjust the pH to 4-5, pass through the four-effect evaporator (3) evaporating and concentrating 3-6 times into a primary mother liquor, after continuing to evaporate and concentrate 1-3 times through the second-effect evaporator (4), solid-liquid separation and extraction (NH 4 ) 2 SO 4 (5), while forming a secondary mother liquor, and then through a single-effect evaporator (crystallization pot) (6) after evaporating and concentrating 1-3 times, solid-liquid separation and extraction (NH 4 ) 2 SO 4 (7), three mother liquors are formed at the same time, and then evaporated and concentrated by 1-3 times through a single-effect evaporator (crystallization pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com