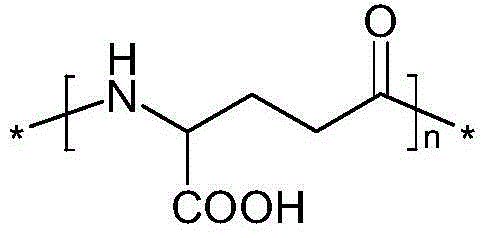

Method for preparing gamma-polyglutamic acid through soild fermentation by utilizing edible fungi residues

A technology of solid fermentation and polyglutamic acid, which is applied in the field of microbial fermentation, can solve the problems of water resource consumption, increased viscosity of fermentation liquid, and long production cycle, so as to reduce environmental pollution, prevent water loss, and delay water evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: γ-PGA was produced by solid fermentation of Flammulina velutipes mushroom residue in a 500 mL conical flask.

[0035] (1), the preparation of B.subtilis PG-8 solid microbial inoculum: after fermenting and producing γ-PGA on 10 tons of fermenters, collect the microbial cells in the fermented liquid, and add a carrier according to mass ratio 1.5:2.4, After mixing evenly, put it in a rotary vacuum double-cone dryer and dry it at 50°C until the water content is about 8%, and finally pack it in an aluminum foil bag to prevent moisture absorption to obtain B.subtilis PG-8 solid bacterial agent, which contains The number of viable bacteria is 5.0×10 10 cfu / g.

[0036] (2), solid fermentation: solid fermentation medium components (solid substrate 20g) are enoki mushroom slag 10g, monosodium glutamate meal 10g, inulin 5g, corncob powder 2.4g, MnSO 4 ·H 2 O 0.002g, MgSO 4 ·7H 2 O 0.05g; the initial moisture of the medium is 60%, pH is 7.0; sterilization at 121°C f...

Embodiment 2

[0039] Example 2: γ-PGA was produced by solid fermentation of oyster mushroom residue in a 500 mL conical flask.

[0040] (1) In this example, the preparation of B.subtilis PG-8 solid bacterial agent and the extraction method of γ-PGA are the same as the operation method in Example 1.

[0041] (2), solid fermentation: fermentation medium component (solid substrate 20g) is oyster mushroom residue 13g, monosodium glutamate meal 7g, inulin 7.5g, corncob powder 1.6g, MnSO 4 ·H 2 O 0.004g, MgSO 4 ·7H 2 O 0.05g; the initial moisture of the medium was 65%, pH was 7.0; sterilized at 121°C for 15min. Weigh the B.subtilis PG-8 solid inoculum 0.8g prepared in step (1) and inoculate it into the sterilized fermentation medium, after mixing, it is placed in a shaker for resting culture 48h, and the fermentation temperature is set to 32 ℃, during the fermentation process, stir several times with a sterile glass rod in an ultra-clean bench every 8h.

[0042] (3) Extraction and detection ...

Embodiment 3

[0044] Example 3: γ-PGA was produced by solid fermentation of mushroom residues in a 500 mL conical flask.

[0045] (1) In this example, the preparation of B.subtilis PG-8 solid bacterial agent and the extraction method of γ-PGA are the same as the operation method in Example 1.

[0046] (2), solid fermentation: fermentation medium component (solid substrate 20g) is Lentinus edodes 15g, monosodium glutamate meal 5g, inulin 3g, corncob powder 2g, MnSO 4 ·H 2 O 0.001g, MgSO 4 ·7H 2 O 0.03g medium with initial moisture of 70% and pH of 7.0; sterilized at 121°C for 15min. Weigh 1 g of the B.subtilis PG-8 solid inoculum prepared in step (1) and inoculate it into the sterilized fermentation medium, after mixing evenly, place it in a shaker for resting culture for 56h, and the fermentation temperature is set to 35°C , Stir several times with a sterile glass rod in an ultra-clean bench every 8h during the fermentation process.

[0047] (3) Extraction and detection of γ-PGA: The γ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com