Method for preparing glutamic acid fermentation organic nitrogen additive from glutamic acid fermentation waste thalli

A technology for glutamic acid and organic nitrogen, which is applied in the field of preparing glutamic acid fermentation organic nitrogen additives, can solve problems such as environmental pollution and low economic value, and achieve the effects of solving environmental pollution problems, good income and high value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 enzymatic hydrolysis method

[0017] (1) The effect of compound enzyme ratio on the hydrolysis of glutamic acid fermentation waste cells

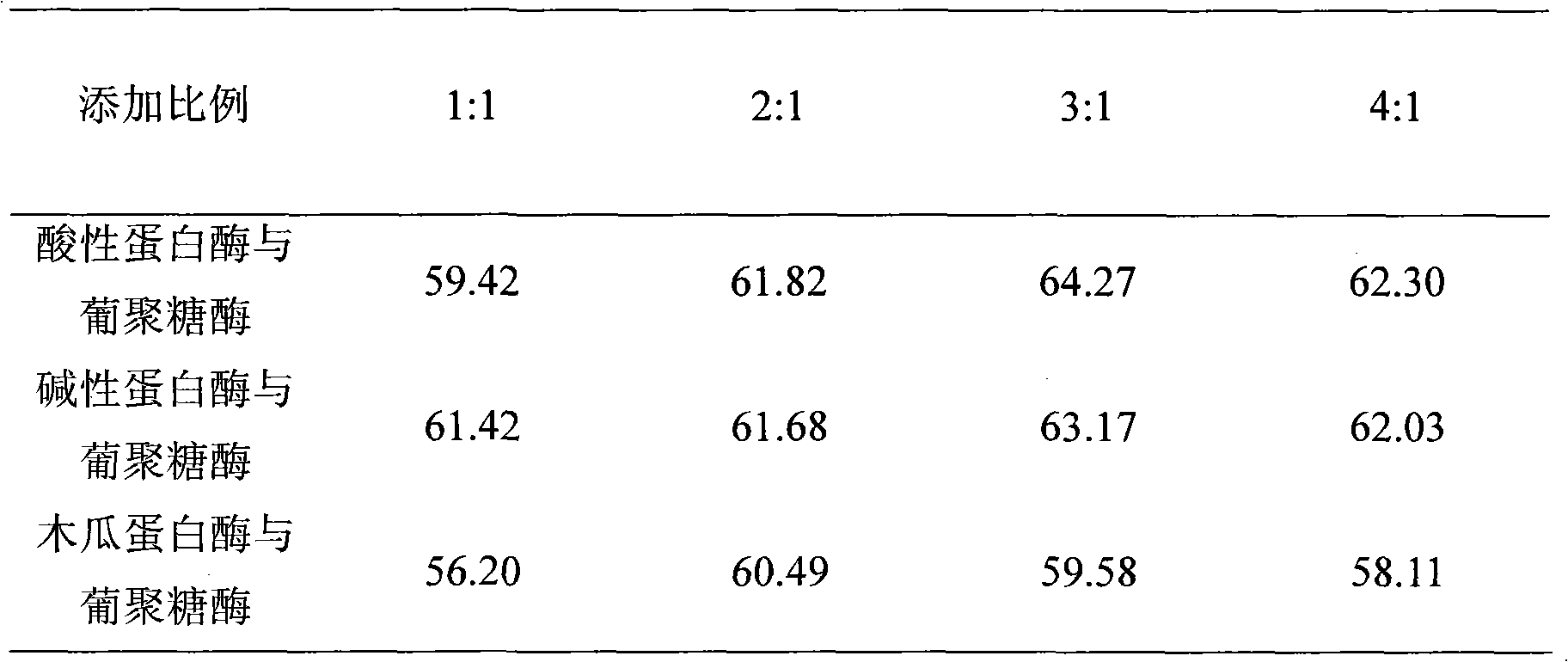

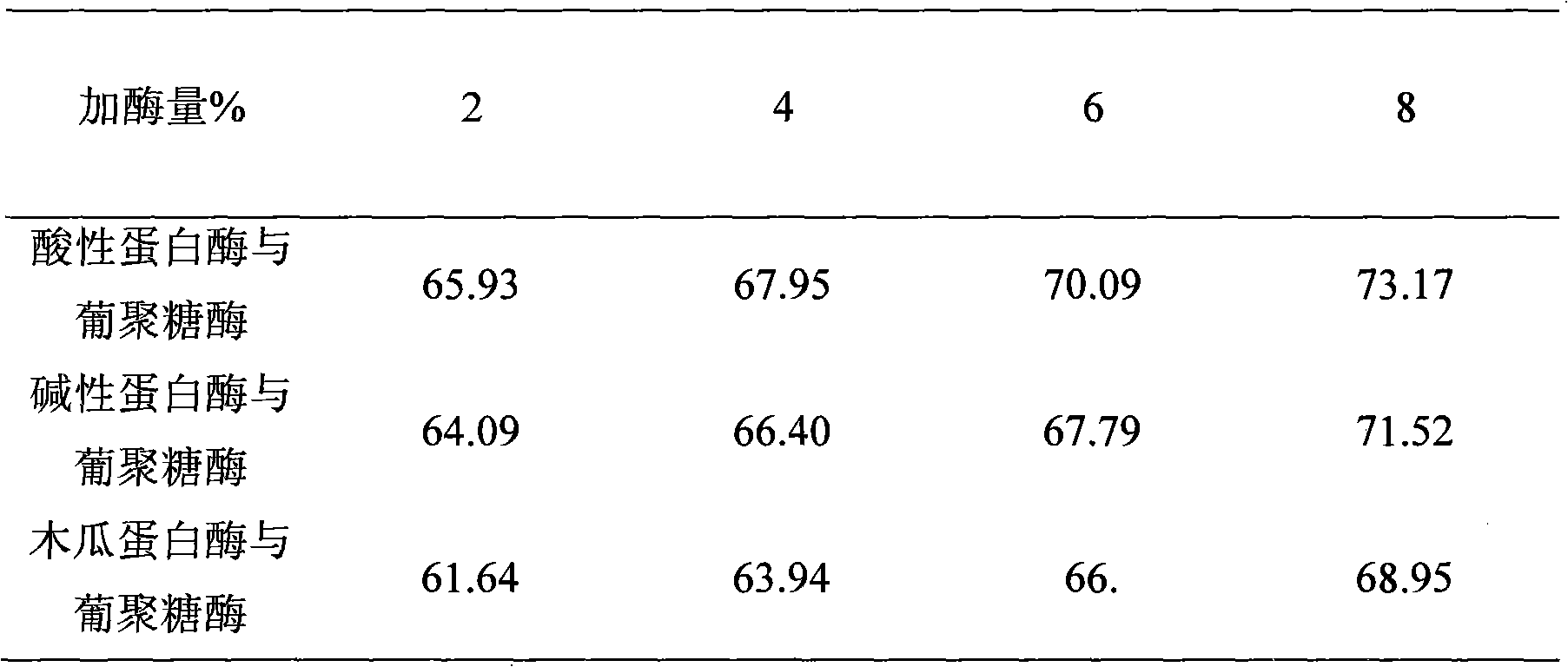

[0018] Corynebacterium glutamicum was formulated into 20g / 100mL bacterial liquid, pretreated by high-pressure homogenization, homogenization conditions: homogenization 6 times under 70MPa. Add different proportions of protease and dextranase, the amount of enzyme added is 1%, the temperature is 50°C, and the recovery rate of bacterial protein is measured after hydrolysis for 10 hours. The results are shown in Table 1. It can be seen from Table 1 that when the compound ratio of protease and dextranase is 3:1, the protein recovery rate of glutamic acid fermentation waste cells is higher, and the recovery rate of acid protease and dextranase compound cell protein is the highest. : 64.27%.

[0019] Table 1 Recovery rate (%) of glutamic acid fermentation waste thalline protein under different addition ratios of compound enz...

Embodiment 2

[0026] Embodiment 2: acid hydrolysis method

[0027] (1) Effect of pH on the recovery rate of bacterial protein

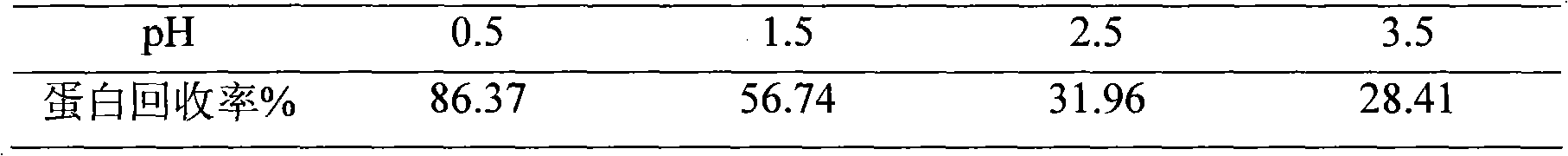

[0028] Corynebacterium glutamicum was formulated into a 5 g / 100 mL bacterial solution, adjusted to pH 0.5, 1.5, 2.5, and 3.5 with 6 mol / L HCl, and hydrolyzed at 115 ° C for 20 hours. The results are shown in Table 3. It can be seen from Table 3 that pH has a great influence on acid hydrolysis. When the pH is 0.5, the protein recovery rate is nearly 60% higher than that of glutamic acid fermentation waste cells when the pH is 3.5.

[0029] Table 3 Recovery rate (%) of glutamic acid fermentation waste thalline protein under different pH

[0030]

[0031] (2) Effect of cell concentration on acid hydrolysis

[0032] Make 50ml of Corynebacterium glutamicum into 5g / 100mL, 10g / 100mL, 15g / 100mL, 20g / 100mL bacterial solution respectively, put it into a 250ml Erlenmeyer flask, add 6mol / L HCl to adjust the pH to 0.5, and hydrolyze at 115°C for 18 hours , the thalline pr...

Embodiment 3

[0035] Embodiment 3: enzyme-acid binding method

[0036] (1) After the Corynebacterium glutamicum body is washed with water, a Corynebacterium glutamicum liquid with a concentration of 20g / 100mL is prepared;

[0037] (2) Adopting a high-pressure homogenizer to carry out homogenization treatment to the Corynebacterium glutamicum liquid, homogenization 6 times under the condition of 70MPa;

[0038] (3) At 50°C, use sodium hydroxide solution to adjust the pH to 4.0, add protease and dextranase compound enzyme (addition ratio 3:1, addition amount 2%), inactivate the enzyme after hydrolysis for 10 hours, centrifuge, then its protein The recovery rate is 65.31%;

[0039] (4) The residue after enzymatic hydrolysis was acid-hydrolyzed at 115°C and pH 0.5. After hydrolysis for 18 hours, it was centrifuged, and the protein recovery rate was measured to be 80.02%;

[0040] (5) The recovery rate of total bacterial protein was 93% when treated with enzyme-acid binding method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com