Glutamic acid extraction technology in production of glutamic acid by fermentation method

An extraction process, a technology for glutamic acid, applied in fermentation, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of affecting yield, cumbersome steps, difficult separation, etc., to achieve good product quality, reduce consumption, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

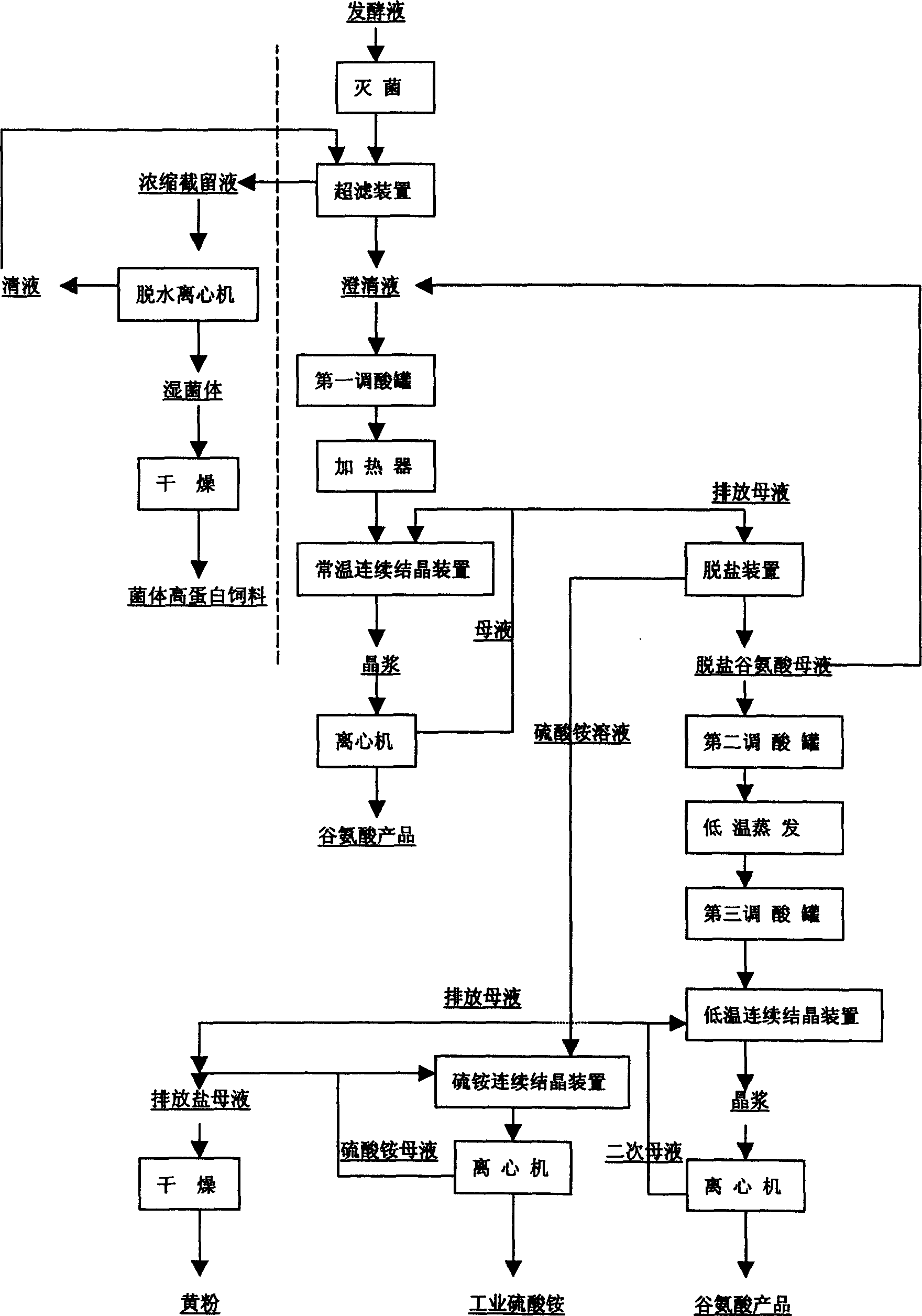

Method used

Image

Examples

example

[0036] 1. After the fermentation, the glutamic acid fermentation broth is sterilized above 100°C, and then the solids (mainly bacteria) in the fermentation broth are separated by ultrafiltration membrane. The process parameters are as follows:

[0037] Feed liquid composition: ammonium glutamate 13-14%, bacterial cells about 1.5%, soluble impurities about 2%;

[0038] Operating temperature: 80°C;

[0039] Operating pressure: 0.5Mpa;

[0040] PH value: 6~7;

[0041] Flux: 100L / m 2 .h.

[0042] 2. Centrifuge and dehydrate the concentrated retentate of ultrafiltration to obtain wet bacteria, and make protein feed after drying;

[0043] 3. In the glutamic acid filtrate obtained by ultrafiltration, the ammonium glutamate content is about 11%, and the impurity content is about 1%. Water (or crystallization mother liquor, desalination mother liquor) and sulfuric acid are added to reduce the glutamic acid concentration to 6.5-7.5%, PH=3.20-3.25, the temperature is raised to 75°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com