Process for prepering gamma-polyglutamic acid and polyglutamates

A technology of polyglutamic acid and glutamic acid is applied in the field of preparation of γ-polyglutamic acid and its salts, which can solve the problems of low accumulation and achieve the effects of low dosage, light color and good moisture absorption and moisture retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

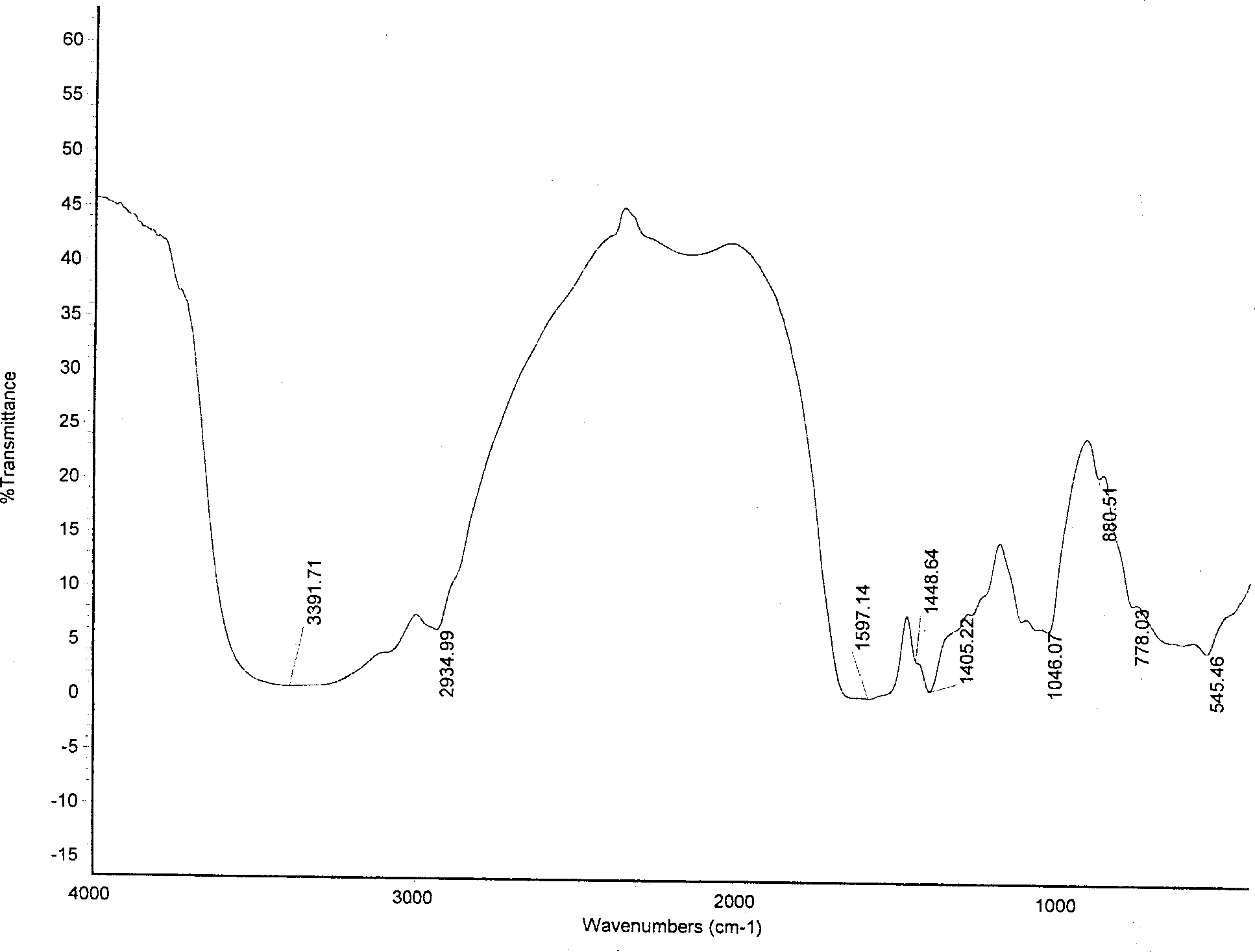

Image

Examples

Embodiment 1

[0026] Incline medium: 1-2% peptone, 0.5-1% beef extract, 0.5-1% NaCl, 2% agar, pH7.0

[0027] Shake flask medium: glucose 1.5%, yeast extract 1%, glutamic acid 2%, KH 2 PO 4 0.5%, MgSO 4 .7H 2 O0.05%, pH7.0. Fill 50ml of liquid in a 500ml Erlenmeyer flask, and sterilize at 121°C for 20 minutes.

[0028] Cultivate the purified Bacillus subtilis NX-2 on the slant medium at 25-37°C for 24-48h, then put a ring of the lawn in the shake flask medium, culture at 37°C for 48h, and shake the flask at a rotational speed of 180r / ml. Finally, the content of gamma-polyglutamic acid in the fermented liquid was 15 g / L.

Embodiment 2

[0030] The same culture conditions as in Example 1, using Bacillus licheniformis B-2 to obtain a γ-polyglutamic acid content of 10 g / L in the fermentation broth.

Embodiment 3

[0032] As in Example 1, the glucose in the shake flask culture medium was replaced with maltose, and the result was that the γ-polyglutamic acid content in the fermentation broth was 20 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com