Fermentation technology of glutamic acid

A fermentation process, glutamic acid technology, applied in the field of glutamic acid fermentation process, can solve the problem that the glutamic acid production cannot be greatly increased, so as to improve the utilization efficiency of bacteria and the conversion rate of sugar and acid, and reduce the production of bacteria. Acid inhibition, prolonging the effect of fermentation acid production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

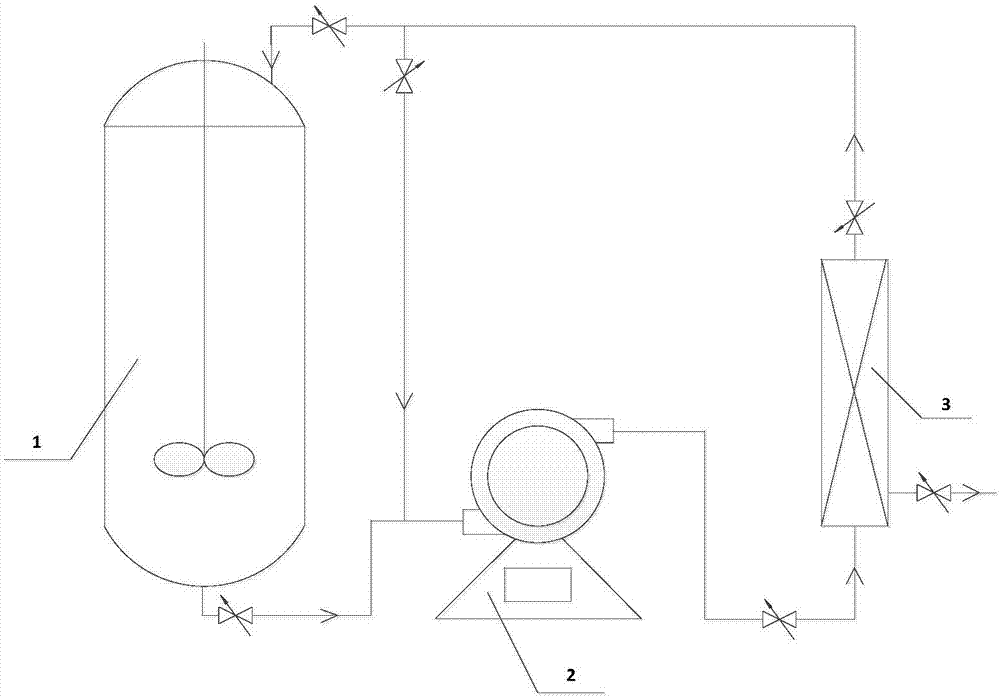

[0032] Such as figure 1 As shown, a kind of fermenting device comprises 30L fermenter 1, vertical multistage centrifugal pump 2 and ceramic membrane 3, and described fermentor outlet is connected with vertical multistage centrifugal pump inlet pipeline, and described vertical The multi-stage centrifugal pump is connected to the bottom of the high-temperature and high-pressure ceramic membrane through pipelines, and the top of the ceramic membrane is respectively connected with the feed port of the fermentation tank and the feed port of the vertical multi-stage centrifugal pump. It forms an internal circulation with the ceramic membrane, and the components are sterilized after they are connected.

Embodiment 2

[0034] A glutamic acid dialysis fermentation process, the concrete steps are as follows:

[0035] (1) if figure 1 As shown, the fermentation device was assembled, see Example 1 for the structure.

[0036] (2) The initial fermented liquid is carried out glutamic acid fermentation in fermentor after sterilization, and fermenting device keeps positive pressure state with aseptic air; Fermentation 15h measures glutamic acid output and is 106g / L, and the concentration of glutamic acid at this moment It has a strong inhibition on the continued fermentation of the bacteria to produce acid. At this time, the ceramic membrane system is turned on for dialysis of the fermentation broth, and the filtration area of the ceramic membrane is 0.2m 2 .

[0037] (3) The concentrated bacterial solution after dialysis is returned to the fermenter. The volume of the initial fermented liquid is 16.5 L, and the volume of the filtrate after filtration and dialysis is 14 L. At this time, add 5 L of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com